Magnetic quantitative tipping bucket metering device

A technology of metering device and quantitative device, applied in the direction of fixed measuring room, etc., can solve the problems of large mechanical vibration and impact, affecting the life of the machine, complex mechanical structure, etc., and achieve the effect of no mechanical impact, long working life and accurate precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

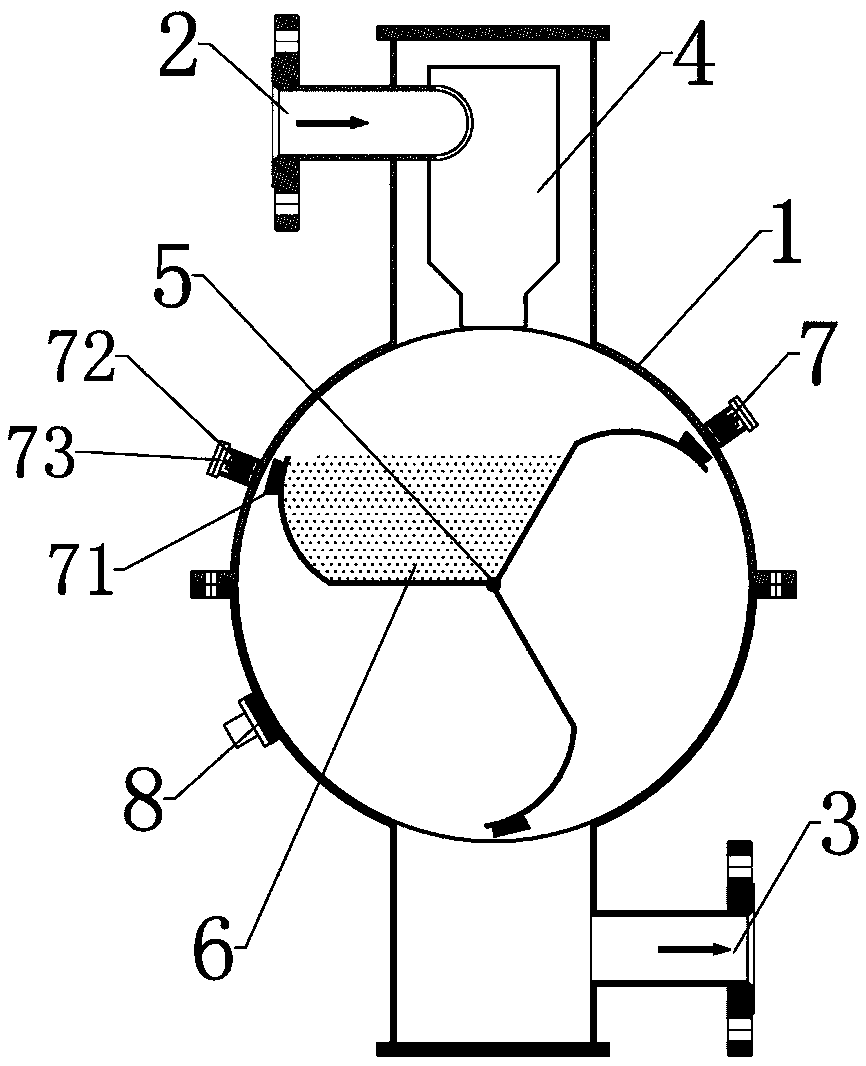

[0017] Such as figure 1 As shown, a magnetic quantitative tipping bucket metering device includes a container shell 1, a medium inlet 2 on the upper part of the container shell 1 and a medium outlet 3 on the lower part, and the medium inlet 2 communicates with the gas-liquid separation device 4 in the container shell 1 , the gas-liquid separation device 4 is a columnar swirl structure; the middle part of the container housing 1 is provided with at least three metering buckets 6 and magnetic quantitative devices 7 arranged at equal intervals that can rotate continuously around the central rotating shaft 5, and the surface of the metering bucket 6 is coated with anti- Corrosion anti-adhesive oil material, magnetic quantitative device 7 includes the magnet A71 that is located at the edge of the inner wall of the container housing 1 near the meteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com