Double-marble balanced centering type internal dial gauge

A dial indicator and inner diameter technology, applied in the field of testing instruments, can solve the problems of shortening the measurement time and inability to align

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

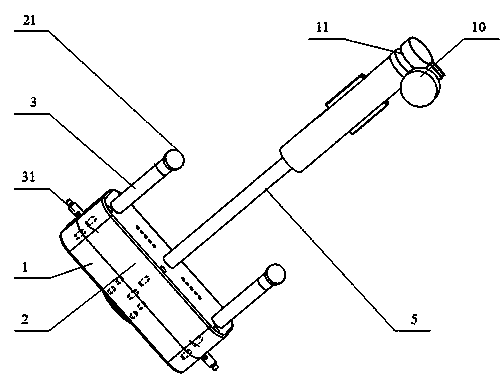

[0049] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

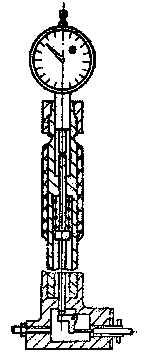

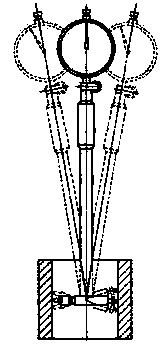

[0050] The present invention is a kind of inner diameter dial gauge with double marble balance and centering. The invention redesigns the transmission structure of the inner diameter dial gauge to solve the defect that the centering cannot be centered in a short time during the early balance centering, and the blind area in the hole can be made visible. Therefore, it is possible to judge whether the dial indicator frame is balanced and centered, whether it has reached the measurement state, through direct visual observation, shorten the measurement time as much as possible, and improve the measurement accuracy.

[0051] As a specific embodiment of the present invention, the present invention provides a dual pin balance centering inner dial gauge, the inner diameter dial gauge includes a measuring part, a push rod part and a main dial 10, and the push rod part includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com