Spherical end face shape and position detector

A technology of spherical end and position degree, which is applied in the direction of measuring device, adopting mechanical device, mechanical measuring device, etc., to achieve the effect of simple structure, high detection efficiency and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

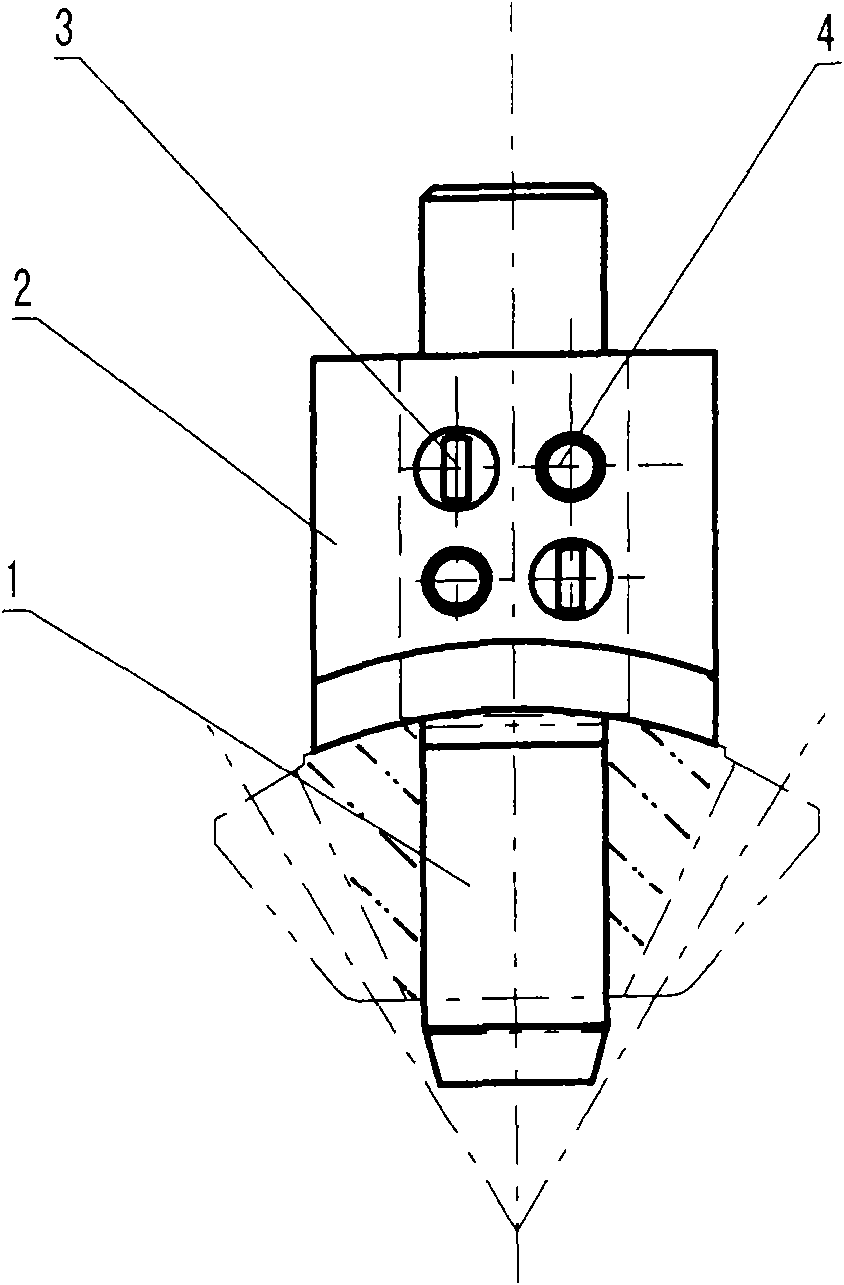

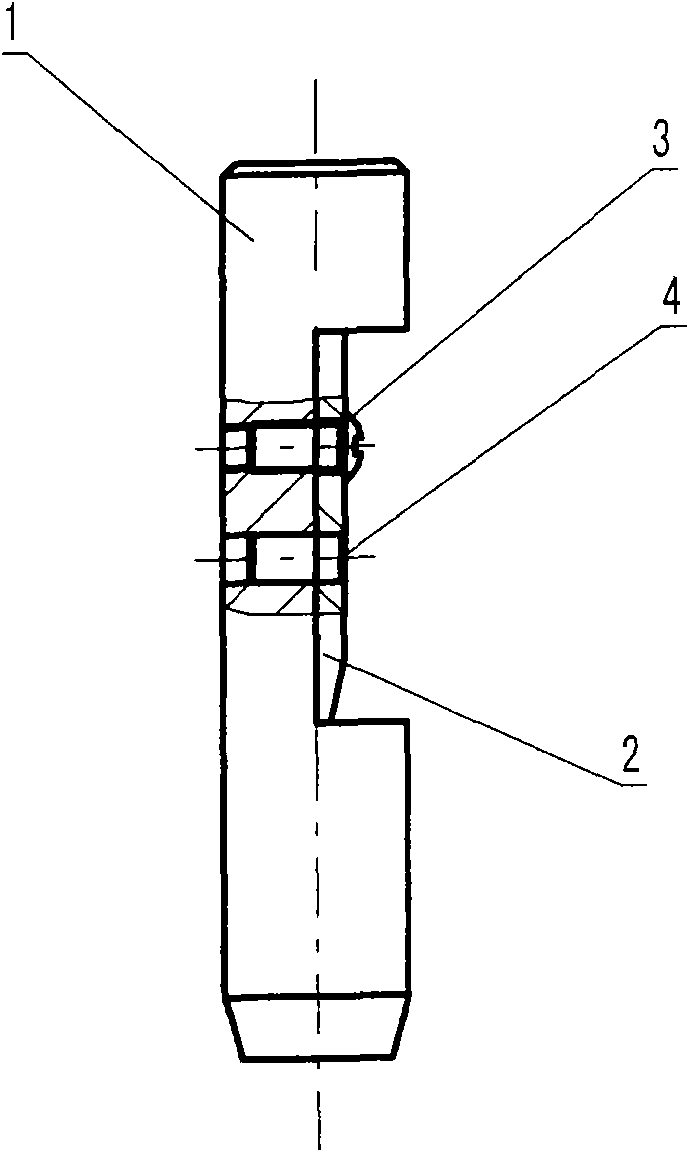

[0014] The spherical end surface shape and position inspection tool shown in the accompanying drawings is composed of a mandrel 1, a template 2, a screw 3 and a pin 4. The template 2 in the present invention is a thin plate with a downwardly curved arc detection surface, and the lateral section of the template 2 is knife-edge shaped. The middle section of the mandrel 1 is provided with a radial opening groove, and the depth of the groove is equal to the radius of the mandrel 1. The template 2 fits the bottom surface of the mandrel 1 opening groove on a plane and is fixedly connected with the screw 3 and the pin 4. The central line is coaxial with the axis of the mandrel 1, and the radius of curvature of the arc is equal to the radius of the spherical end surface to be tested. The embodiment is a test tool for detecting the shape and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com