Method for calibrating verticality of magnetic shaft of three-shaft magnetic sensor

A calibration method, a technology of magnetic sensors, applied in the direction of the magnitude/direction of the magnetic field, the instrument, the use of electromagnetic means, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

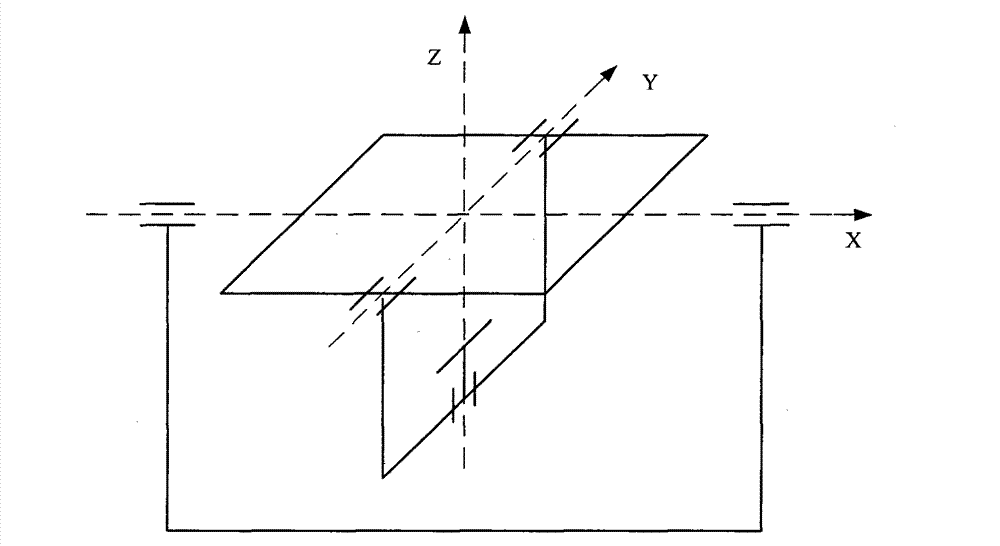

[0046] The system uses a non-magnetic turntable and a three-dimensional magnetic field generator.

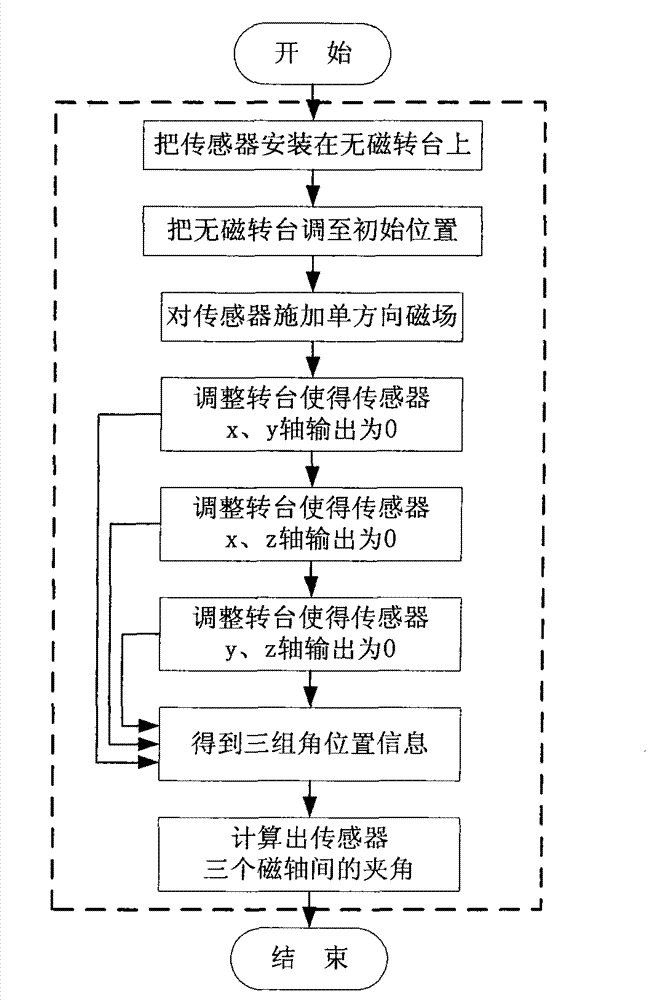

[0047] The three-dimensional magnetic field generator consists of three sets of mutually orthogonal Helmholtz coils and corresponding program-controlled constant current sources. The program-controlled constant current source is controlled by a computer, which can generate corresponding constant or expected changing currents, thereby generating expected and controllable three-dimensional magnetic fields in the local space specified by the center of the three sets of mutually orthogonal Helmholtz coils. The method for calibrating the verticality of the magnetic axis of the three-axis magnetic sensor is as follows: first, install the three-dimensional magnetic field generator and the non-magnetic turntable, and fix the magnetic sensor to be calibrated on the turntable. A large magnetic field from top to bottom is given by the magnetic field generator, so that the magnetic sensor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com