Quality measurement device and method

A quality detection method and technology of detection devices, which are applied in measurement devices, weighing, instruments, etc., can solve the problems of uneven position, influence on the accuracy of measurement, and influence on the measurement accuracy of suspended sensors, and achieve the effect of fast response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

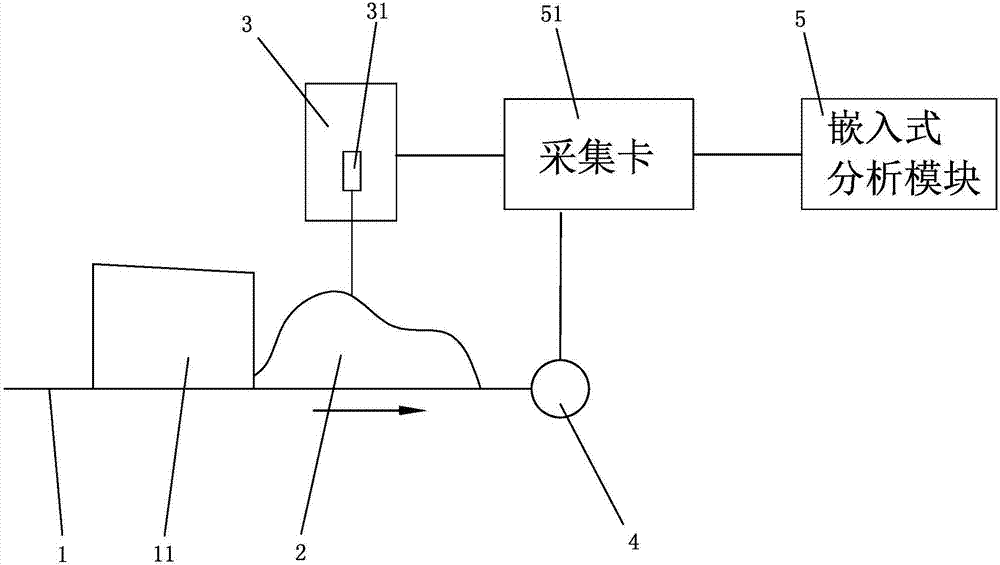

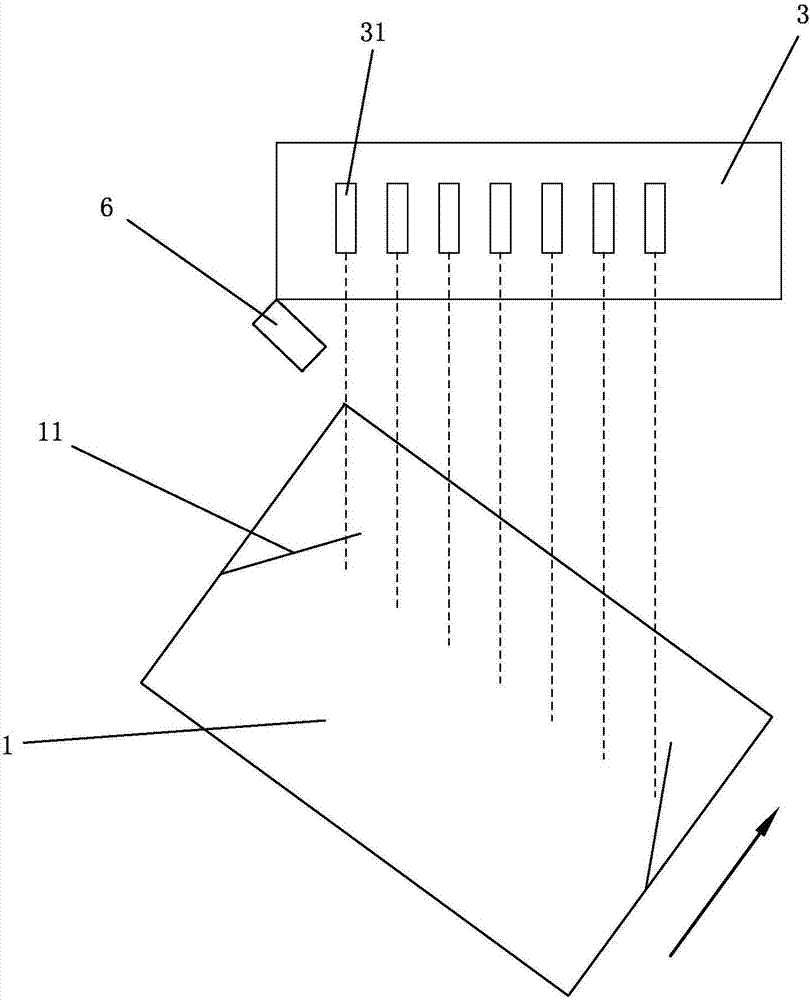

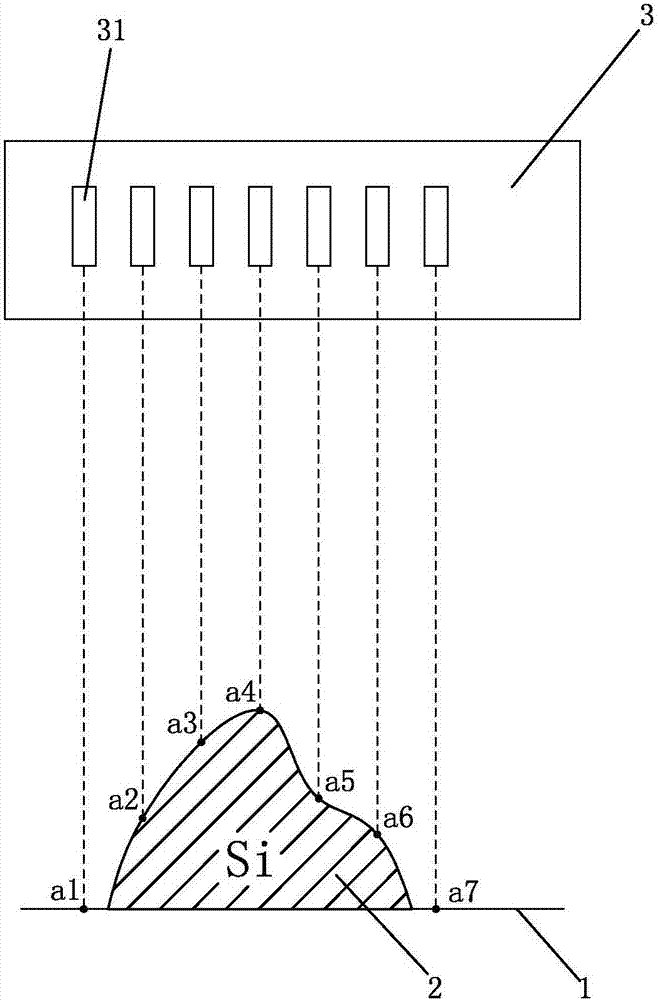

[0024] see Figure 1 to Figure 2 As shown, a material quality detection device of the present invention includes a conveyor belt 1, a laser ranging module 3, a speed measurement module 4 and an embedded analysis module 5, and the speed measurement module 4 is used to measure the speed of the conveyor belt 1; The laser distance measuring module 3 includes several laser distance measuring sensors 31 arranged linearly at equal intervals. Vertical direction distribution; the laser ranging module 3 is connected to the embedded analysis module 5 through the acquisition card 51, and the speed measurement module 4 is connected to the embedded analysis module 5.

[0025] The power of the laser ranging sensor is about 1mW, and the output signal is a continuous voltage signal of 0 to 5V.

[0026] A compensation light source 6 is also included, and the compensation light source 6 is arranged above the conveyor belt 1 . The compensation light source 6 is an LED light source, and the spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com