Freon gas detection warning device and detection method thereof

A gas detection alarm and freon technology, applied in the field of analysis and detection, can solve the problems of bulky gas chromatography instruments, not suitable for portable detection, and unsatisfactory results, and achieve the effects of ensuring reproducibility, improving instrument stability, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation of embodiment 1 freon chromatographic column

[0021] The specific implementation of the production process of the chromatographic column

[0022] (1) Material: stainless steel tube (outer diameter Wall thickness 0.5mm), DG-2 (80-100 mesh), ApiezonL (Apiezon-L), acetone

[0023] (2) Manufacture of chromatographic column body: cut off the outer diameter A stainless steel tube with a wall thickness of 0.5mm and a length of 1600mm, with a flat and neat fracture, no burrs, no closing or flaring, and the tube material is wound into a spiral chromatographic column.

[0024] (3) Cleaning: Soak the chromatographic column body in a mixture of industrial detergent and pure water, clean it with an ultrasonic cleaner for about half an hour, then clean it with an ultrasonic cleaner for 40 minutes, rinse it with pure water, and then put it into the Oven dry. Use compressed air to blow out impurities in the pipe wall.

[0025] (4) Chromatographic filler treatm...

Embodiment 2

[0032] Example 2 Separation Verification Test of Freon Chromatographic Column

[0033] Analysis conditions: ECD detector, column temperature 70°C, carrier gas is high-purity nitrogen, column front pressure is 0.2MPa;

[0034] Standard gas: F-1301 (24ppm), F-12 (52ppm), F-11 (25ppm) mixed standard;

[0035] Turn on the power of the instrument, adjust the front pressure of the high-purity nitrogen column to 0.2MPa, set the column temperature to 70°C, keep the column temperature constant for 2 hours, and then enter the standard gas for analysis.

[0036] seperate effect:

[0037] signal peak F-1301 F-12 F-11 Peak time (s) 73 95 232 Peak area 1016 351 284 2115

[0038] The column prepared in embodiment 1 and the commercially available column check the standard gas, and the results are as follows:

[0039]

[0040]

Embodiment 3

[0041] Embodiment 3 Freon gas detection alarm device

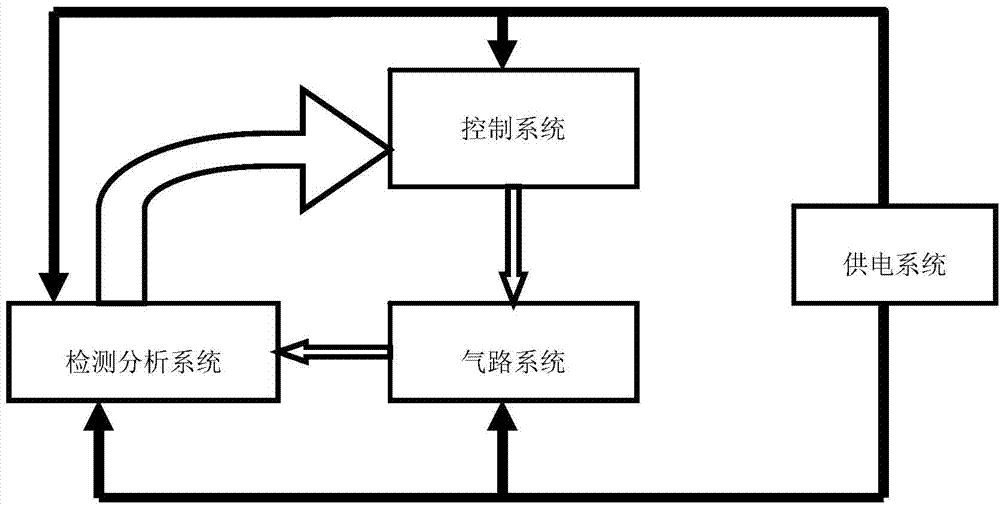

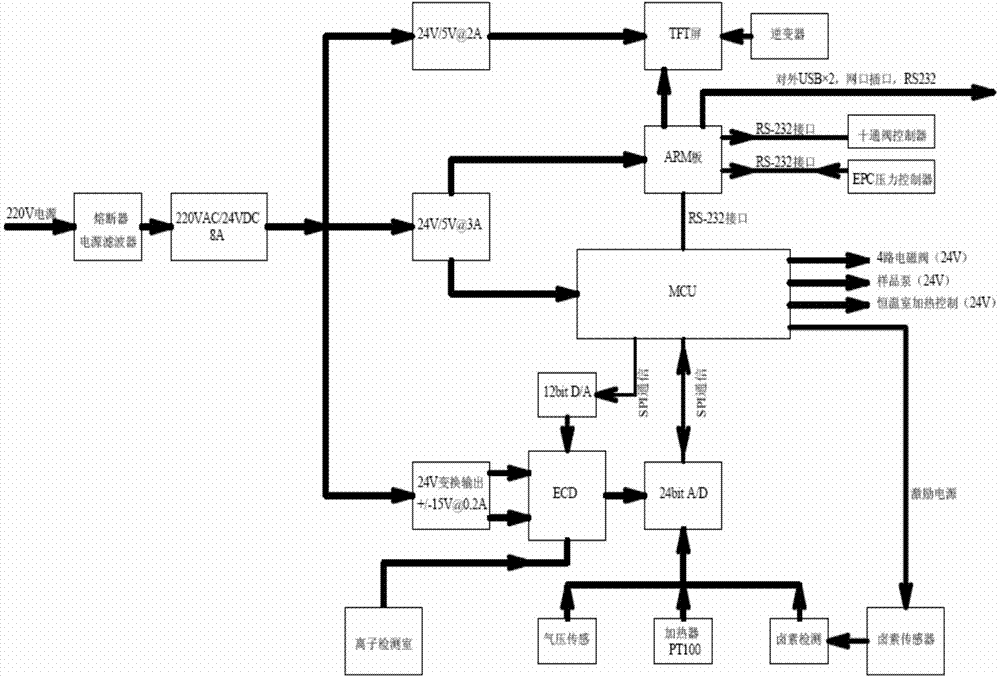

[0042]A Freon gas detection and alarm device, 320mm×410mm×220 (L×H×W), which includes a detection and analysis system, a gas circuit system, a control system and a power supply system, the detection and analysis system, the gas circuit system, and the control system are connected to each other, and the power supply The system supplies power to all three; ( figure 1 )

[0043] 3.1 Gas system design

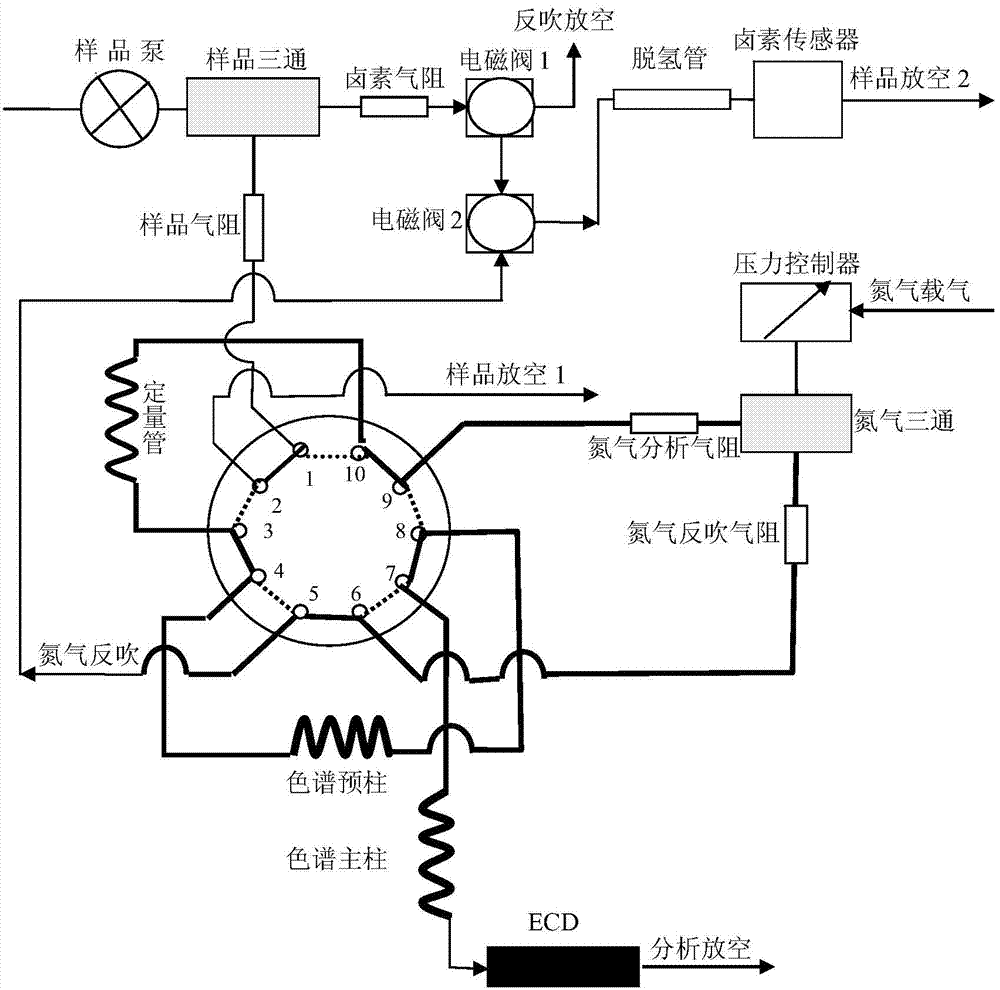

[0044] The gas circuit system is divided into two routes, one is sample gas, and the other is carrier gas (high-purity nitrogen), mainly composed of sampling pump, tee, sample air resistance, nitrogen air resistance, pressure controller, ten-way valve, etc. composition. For the flow chart of the air system, see figure 2 .

[0045] A. The sample gas enters the three-way block from the air pump, and enters the halogen sensor through the air resistance, solenoid valve and dehydrogenation tube all the way. The response of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com