Measuring method and tool for electrolyte level or aluminum level in aluminum electrolysis cell

An electrolyte level, aluminum electrolytic cell technology, used in measuring devices, liquid/fluid solids measurement, engine lubrication, etc. The effect of avoiding human factor interference, high measurement accuracy and high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

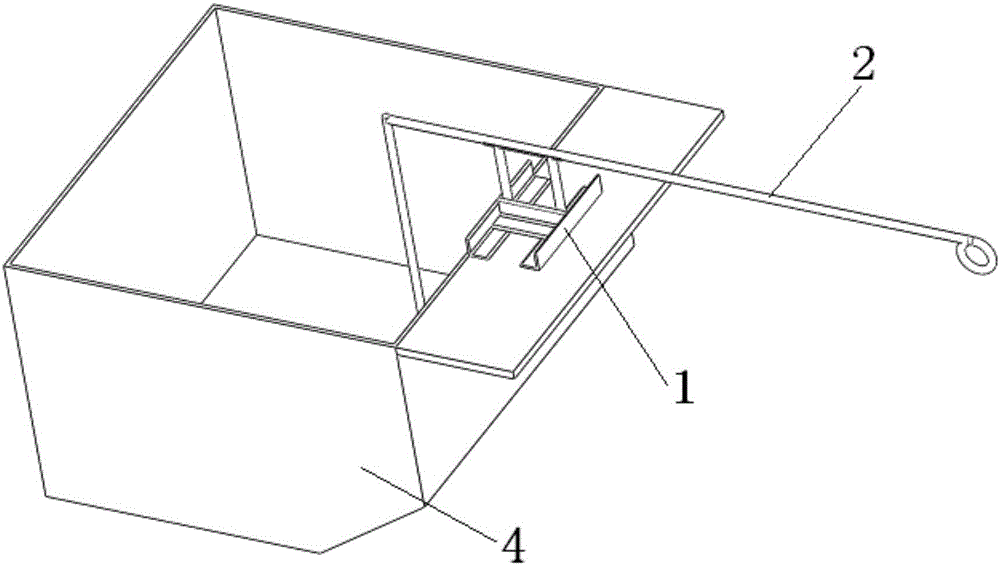

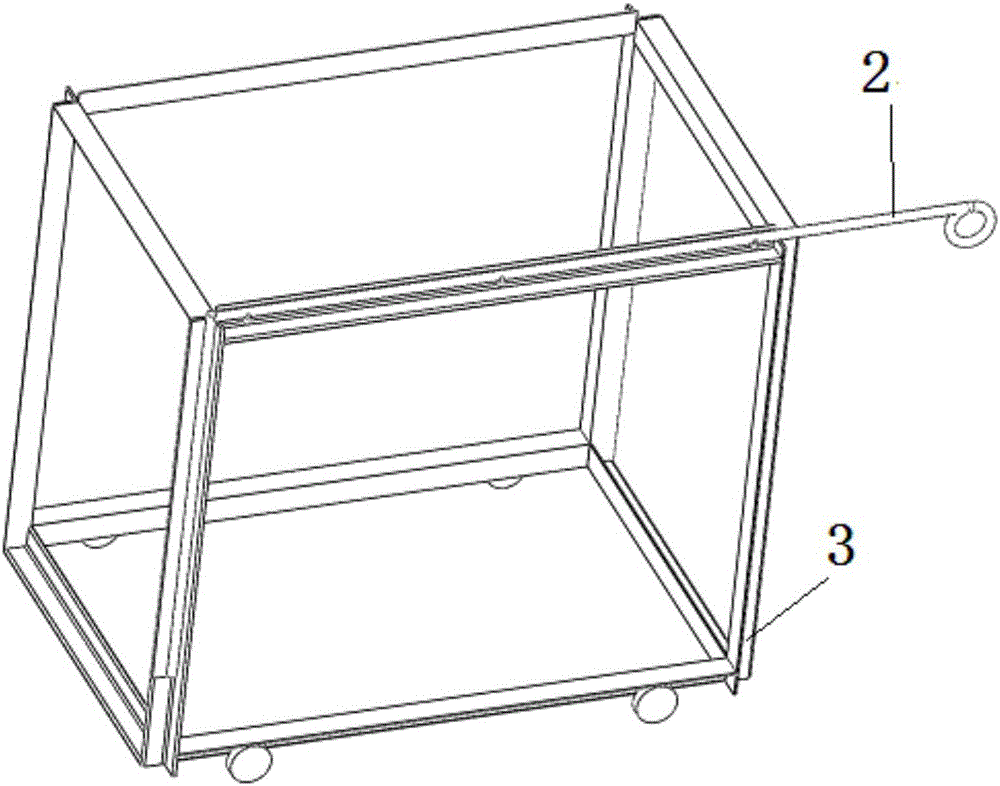

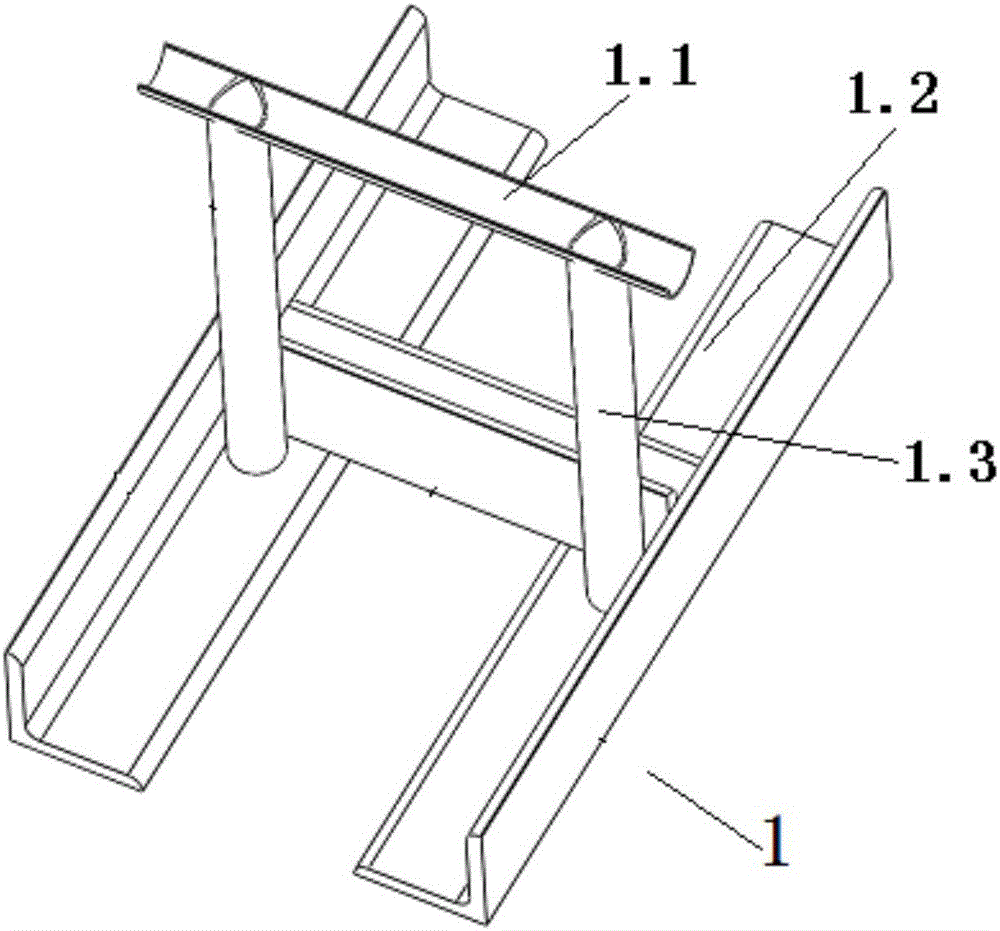

[0023] Embodiments of the present invention: a method for measuring the electrolyte level or aluminum level of an aluminum electrolytic cell of the present invention, such as Figure 1 ~ Figure 2 As shown, the method includes measuring the electrolyte level or the aluminum level of the aluminum electrolytic cell by using the measuring rod. An L-shaped measuring braze 2 composed of a rod 2.1 and a horizontal iron rod 2.2, and a horizontal support 1 is placed on the end face of the edge of the aluminum electrolytic cell 4, and then the horizontal iron rod 2.2 of the L-shaped measuring braze 2 is placed on this level On the support 1, the vertical iron rod 2.1 of the L-type measuring drill 2 is vertically inserted into the electrolyte or the aluminum liquid in the aluminum electrolytic cell 4, and at this moment the vertical iron rod 2.1 of the L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com