Engine oil consumption real-time testing method and device

An engine oil, real-time testing technology, applied to engine components, engine lubrication, lubrication indicating devices, etc., can solve problems such as high cost, error, fluctuation measurement, etc., to improve measurement accuracy, accurate response, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

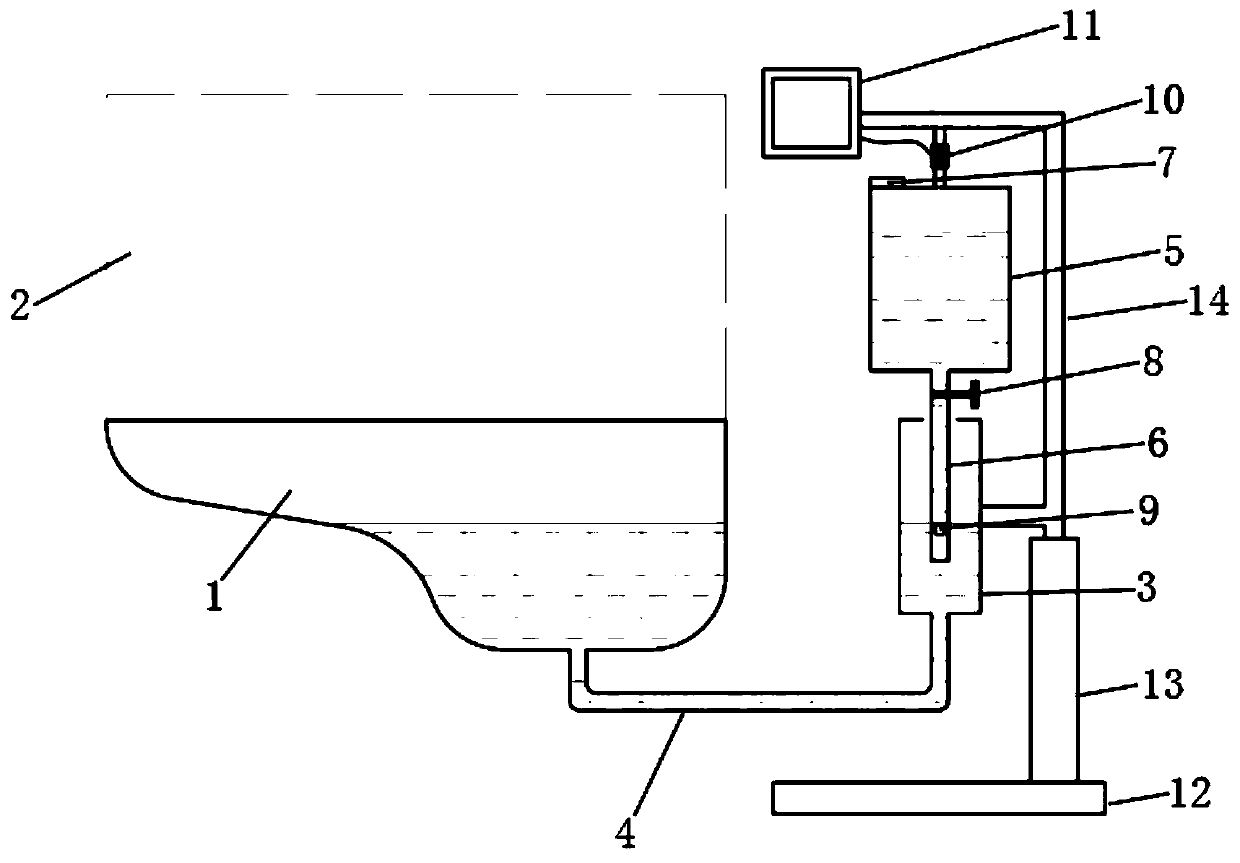

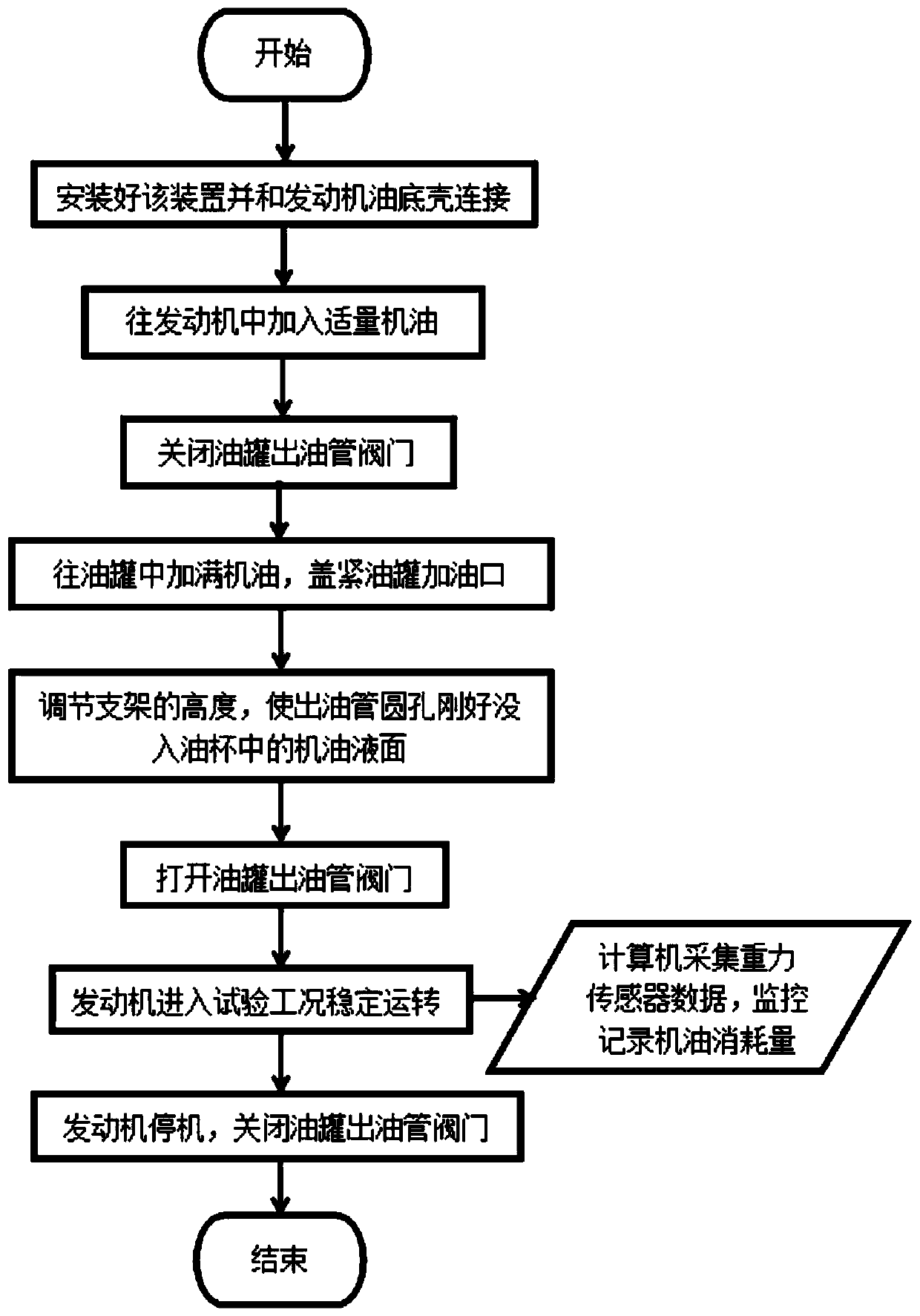

[0038] refer to figure 1 , a kind of engine oil consumption real-time testing method of the present invention, comprises the steps:

[0039] Step 1: Add engine oil to engine 2, feed back the liquid level in engine 2 in real time, and start engine 2 for testing. Specifically, in this step, the liquid level in the engine 2 is fed back in real time, including: communicating with the oil pan 1 of the engine 2 through the first oil supply assembly, so that the first oil supply assembly and the oil pan 1 Form a U-shaped tube structure. According to the liquid level balance principle of the U-shaped pipe structure, the liquid level in the first oil supply assembly is consisten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com