Measurement method and measurement device for waste percentage of combing machine

A testing device and testing method technology, applied in the textile field, can solve the problems of inaccurate testing, not considering wind consumption, testing work affecting normal spinning, etc., and achieve the effects of improving production efficiency and accurate noil rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

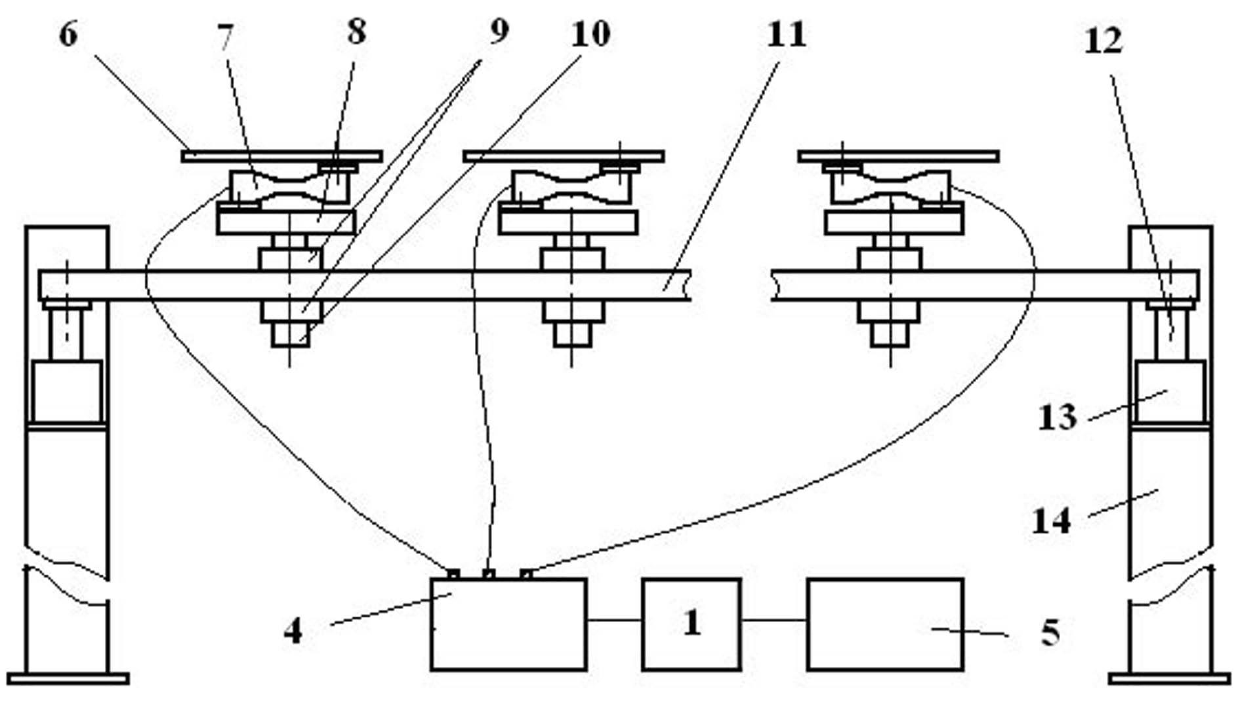

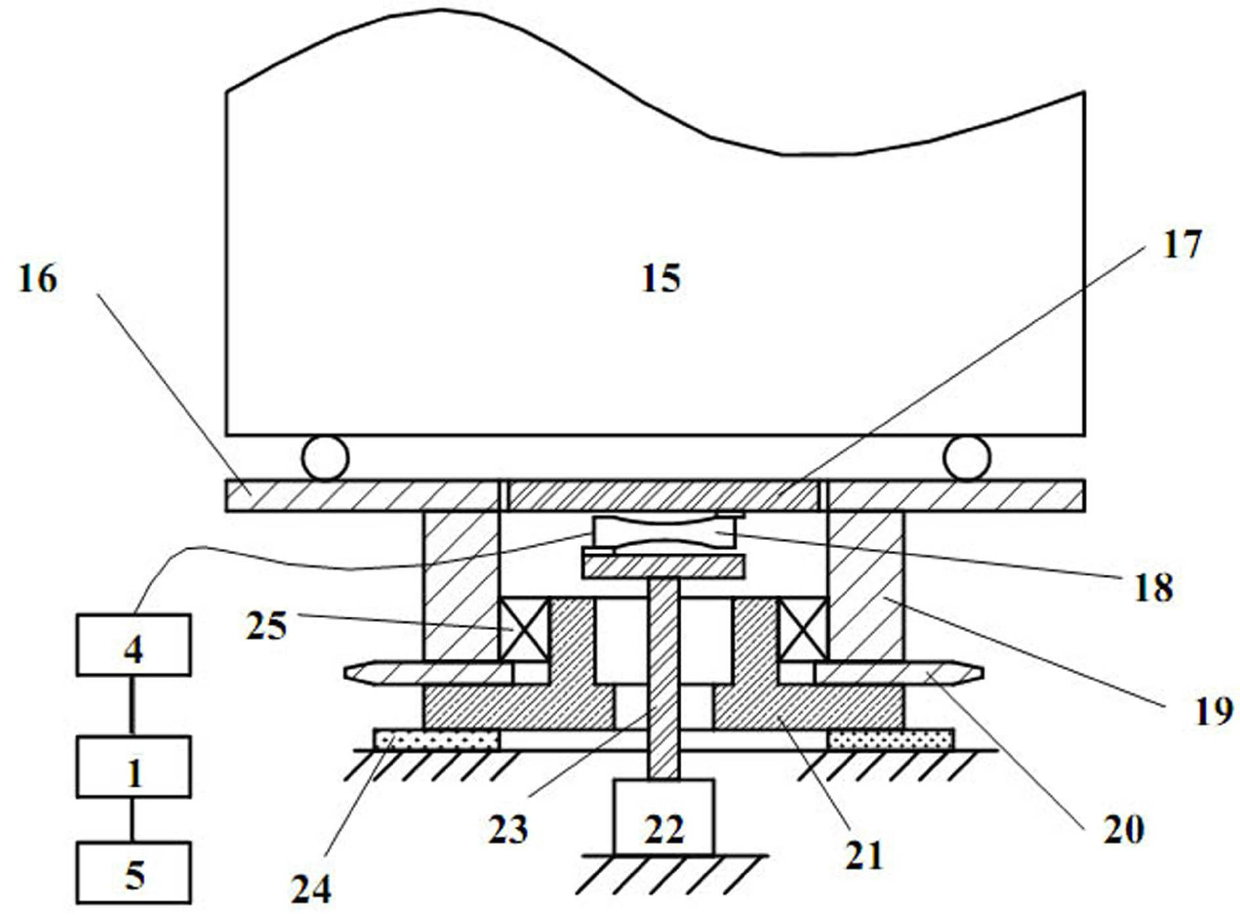

[0023] The present invention will be described in further detail below through embodiments in conjunction with the accompanying drawings.

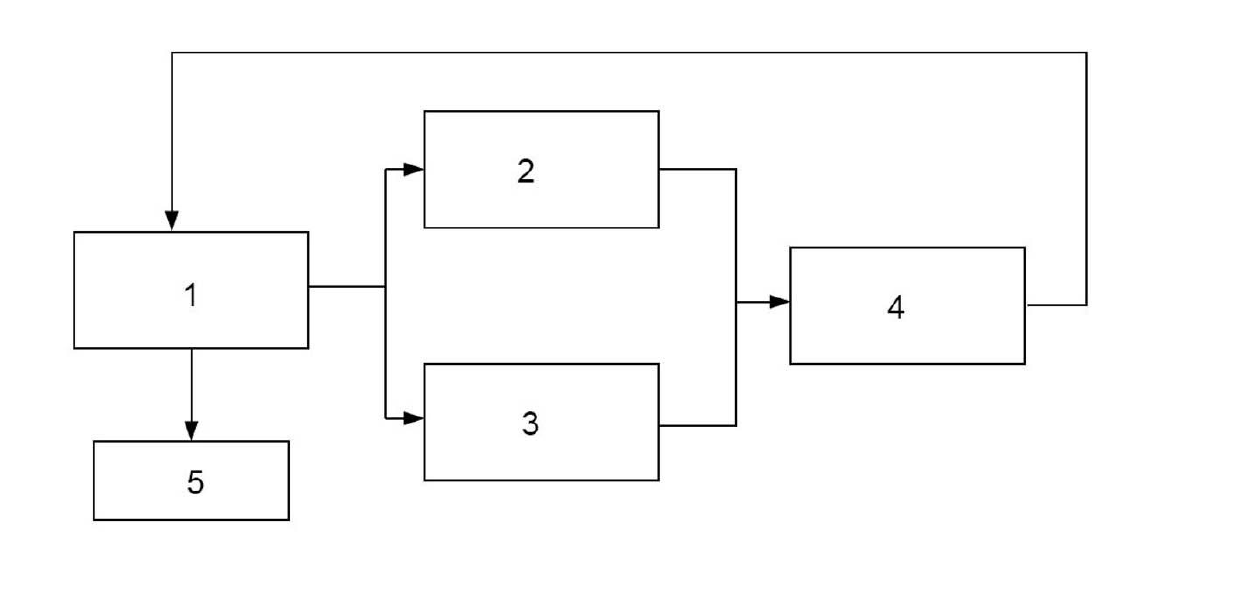

[0024] Such as figure 1 , figure 2 and image 3 Shown, the comber noil rate test method provided by the present invention is to measure the lap weight G of the comber and the combed sliver weight g of the comber output in the measurement unit time, and calculate the combed according to the following formula Machine noil rate η (%):

[0025]

[0026] In this embodiment, since the combing machine is provided with 8 lap rollers, and there is 1 lap above each lap roller, each lap is weighed twice, and the time interval between the two weighings is 3 minutes; let G 1i , G 2i Respectively, the weight of the i-th cotton lap (i=1,2,3...8) when the cotton lap is weighed for the first time and the second time, g 1 、g 2 are the weights of the sliver cans when they are weighed for the first time and the second time respectively, then the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com