Traceability Calibration Device and Traceability Method for Elastic Constant of Microcantilever Beam

A micro-cantilever and calibration device technology, applied in the intersection of nanotechnology and metrology, can solve problems such as inability to trace the elastic constant, and achieve the effect of ensuring uniformity, avoiding Abbe errors, and ensuring measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

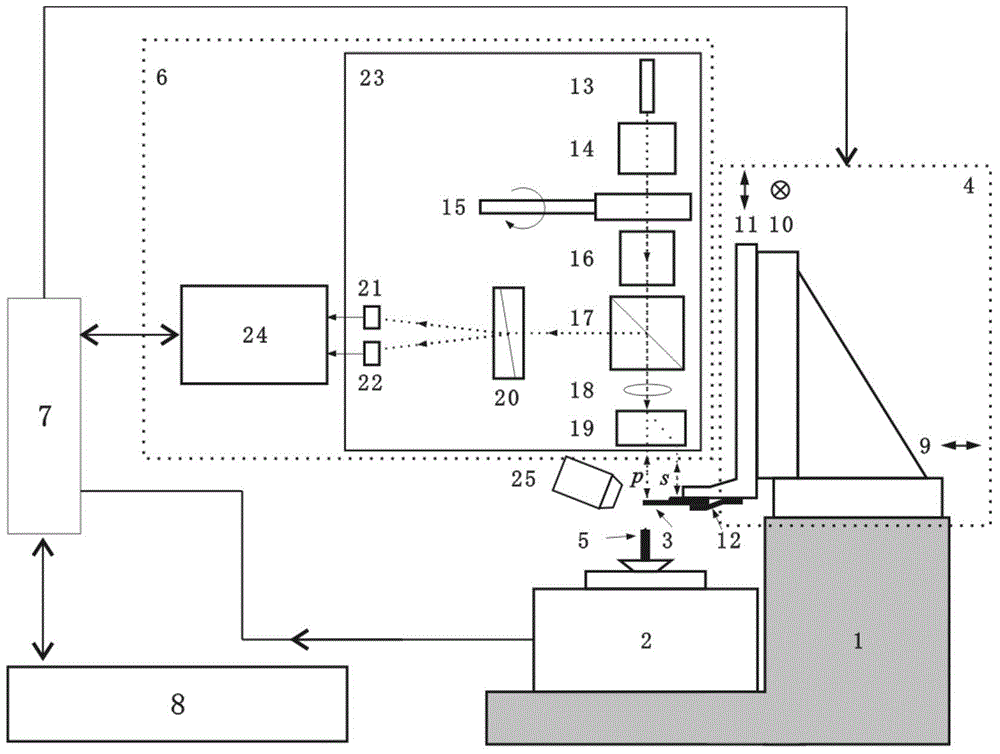

[0013] The micro-cantilever beam elastic constant traceability calibration device and traceability method of the present invention are described with reference to the accompanying drawings.

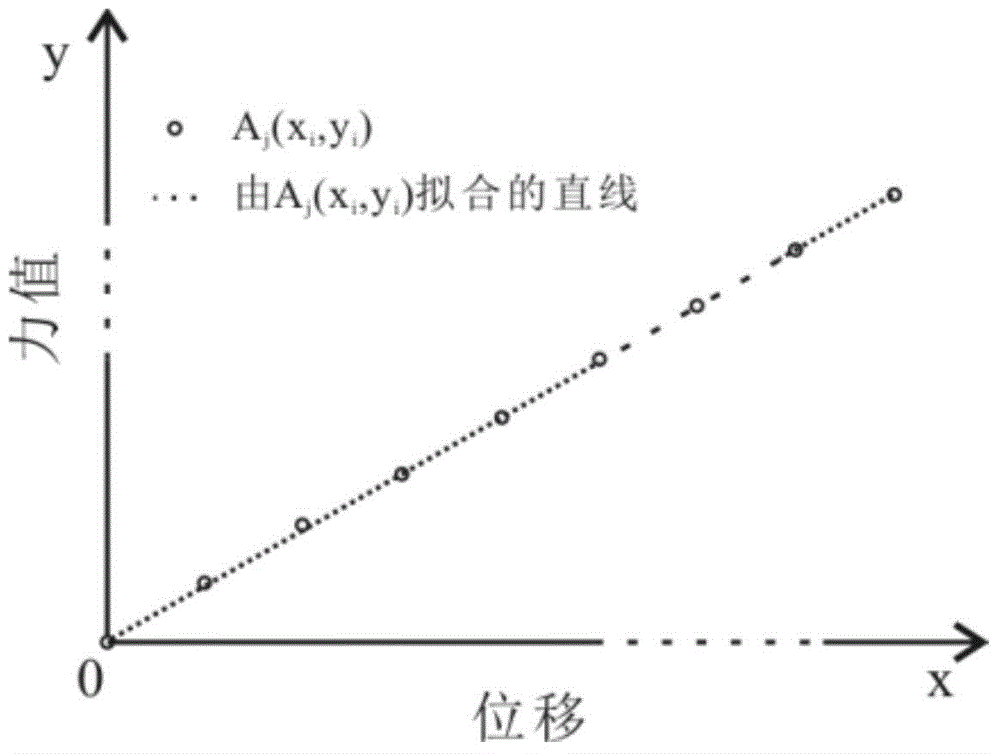

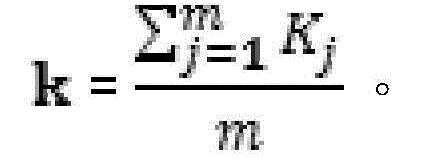

[0014] The micro-cantilever beam elastic constant traceability calibration device of the present invention is designed based on the use of a polarization differential interferometer as the displacement measurement method of the free end of the micro-beam to achieve traceability with the length unit meter (m) in the International System of Units; As a force measurement method, the nanobalance realizes the traceability of the force unit Newton (N) in the International System of Units. The feature of the traceability method based on the traceability calibration device is that the force-displacement curve of the micro-cantilever beam is obtained through experiments, and then the traceability value of the elastic constant of the micro-cantilever beam is obtained by a method of straight line fit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com