High-precision probe device used for linearity error measurement

A straightness error and high-precision technology, which is applied in the field of high-precision measuring head devices, can solve the problems of low measurement accuracy and high manufacturing cost, and achieve the effects of improving motion stability, improving motion stability, and reducing dynamic and static friction coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

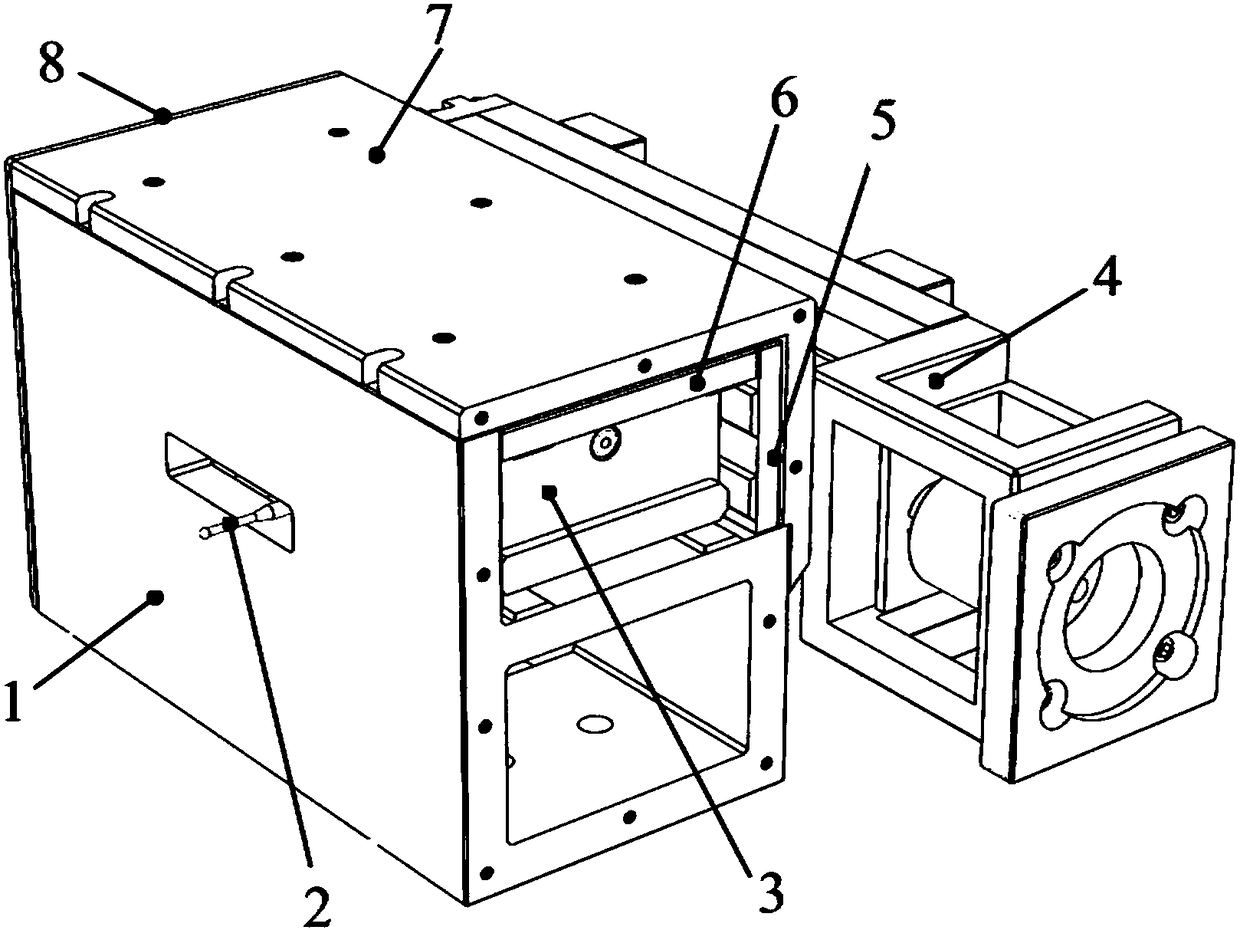

[0024] Taking the measurement of the helical deviation of a straight-toothed standard gear with grade 1 precision as an example, the specific implementation of the high-precision measuring head device proposed by the invention is described.

[0025] (1) Machining accuracy of key components.

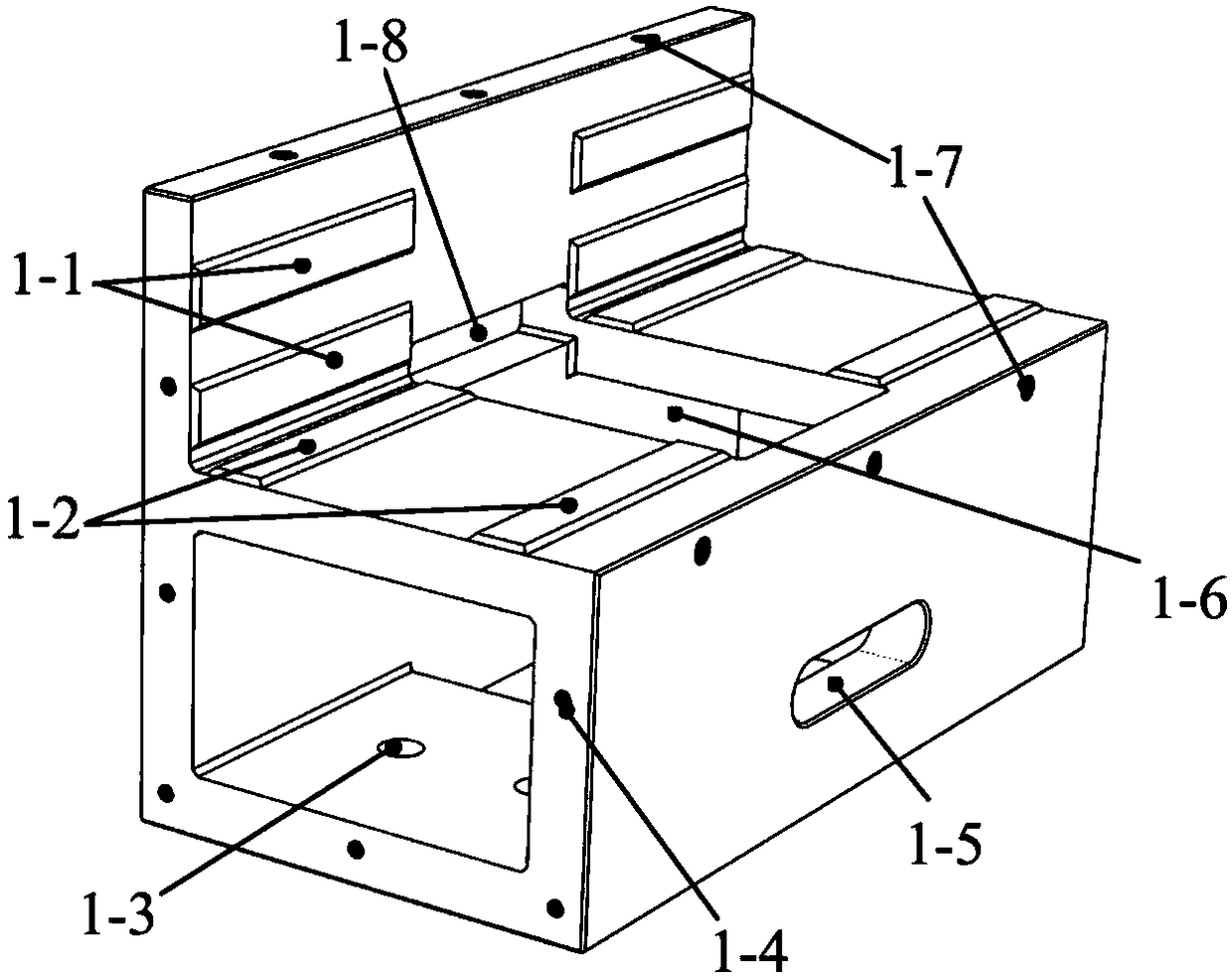

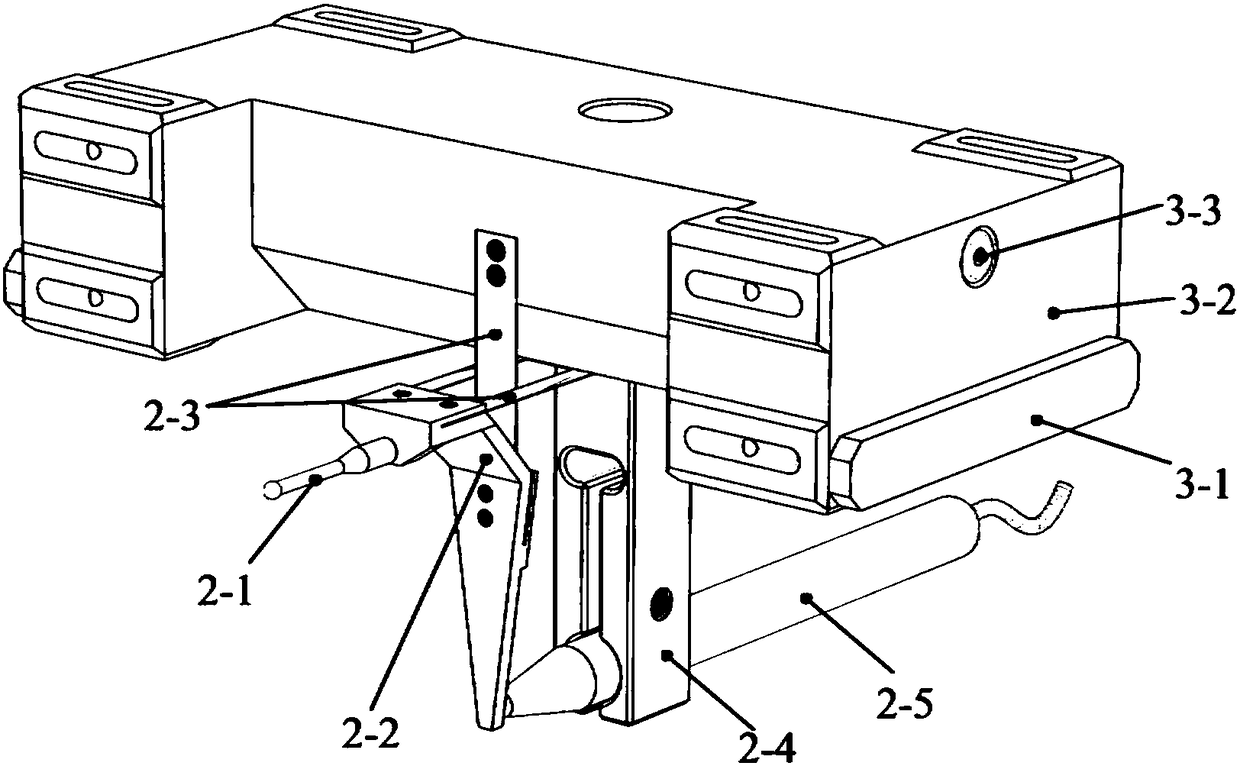

[0026] The horizontal working surface 1-2 of the guide rail seat 1, the vertical working surface 1-1, each working surface 3-2-1 of the slide block 3-23 pasted with the PTFE guide rail soft belt, the upper pressing plate 6 and the side pressing plate 5 The flatness error of the working surface is not greater than 1 μm, and the flatness error of the horizontal plane 1-2 of the guide rail seat used as the probe reference is not greater than 0.5 μm;

[0027] After the slider 3-2 is pasted with the PTFE guide rail soft belt, the distance error of the relatively parallel slider working surface is not more than 1 μm; after the slider is attached to the horizontal working surface 1-2 of the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com