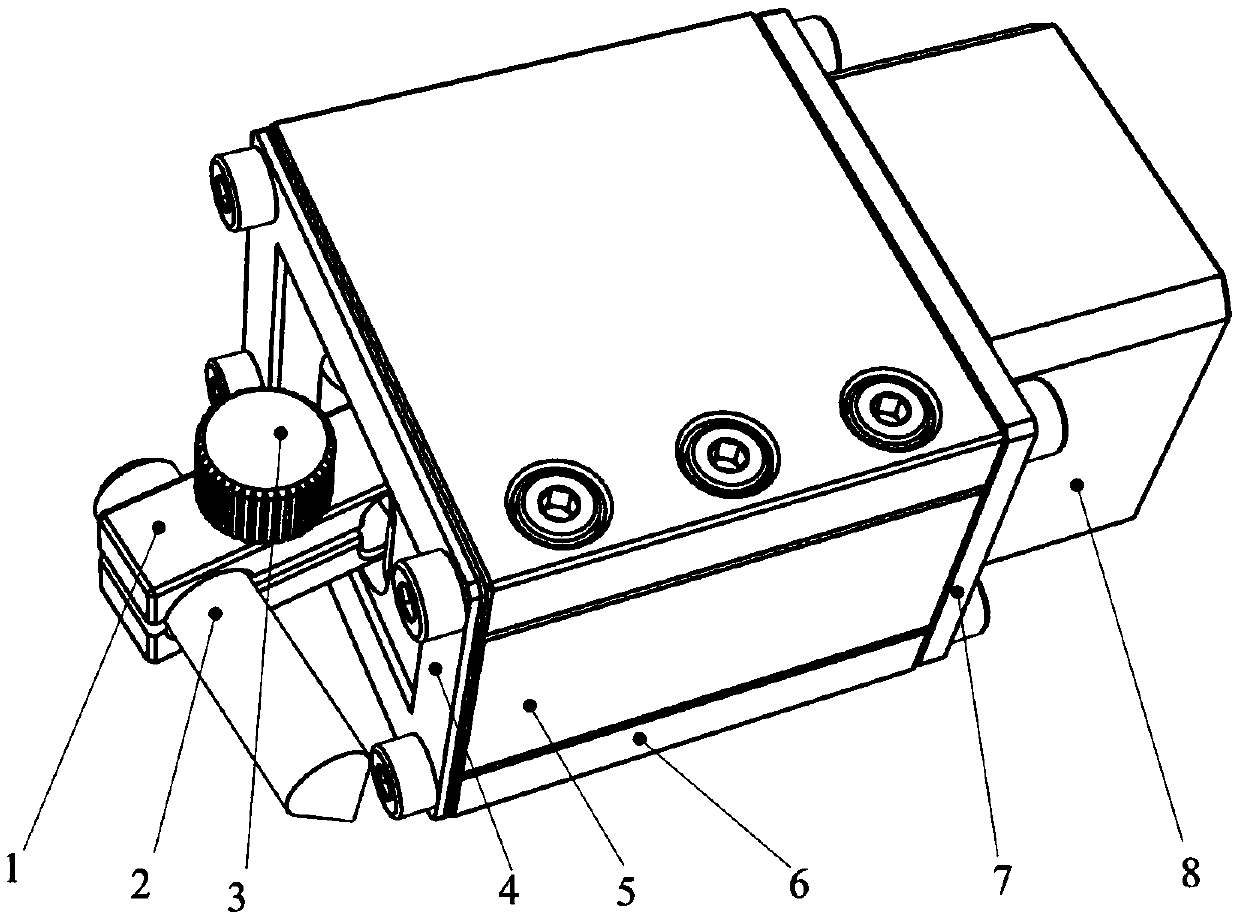

A high-precision diamond pen grinding wheel dresser and its installation method

A grinding wheel dresser and diamond pen technology, applied in metal processing equipment, abrasive surface adjustment devices, manufacturing tools, etc., can solve the problem of low dressing accuracy of diamond pen grinding wheel dressers, and achieve good market application prospects and high linear motion accuracy. , the effect of high trimming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

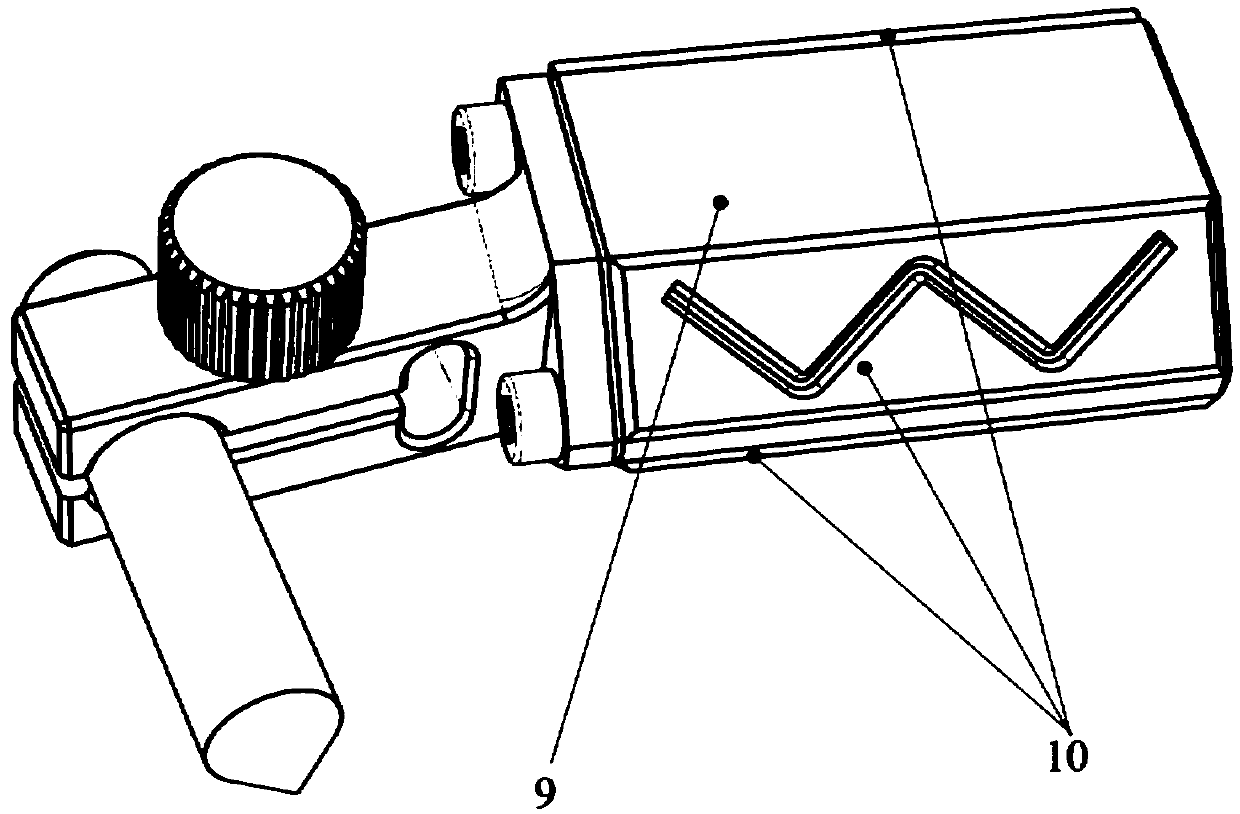

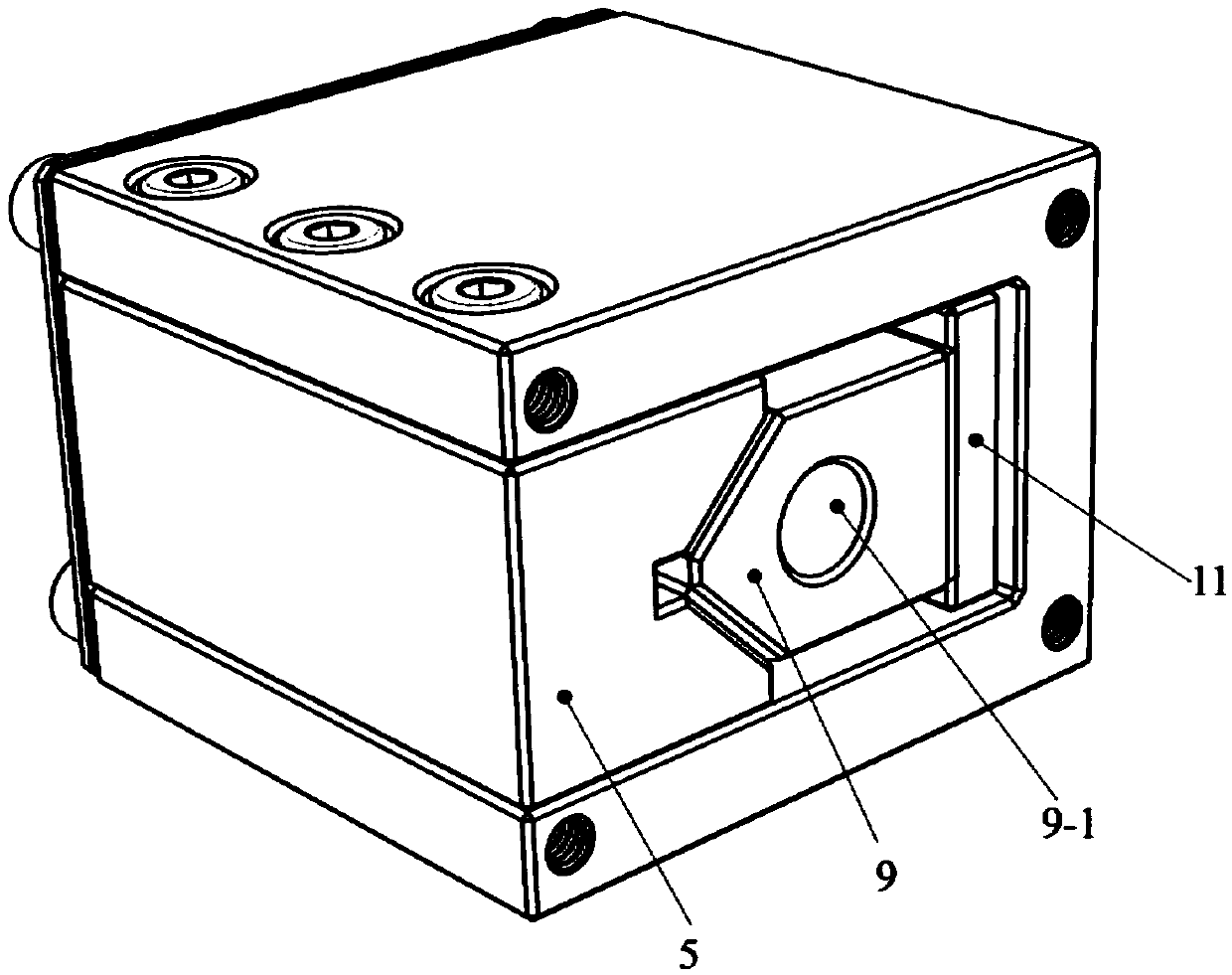

[0025] (1) Matching research of slider 9 and guide rail 5

[0026] First grind the two concave V-shaped surfaces of the guide rail 5 and the two convex V-shaped surfaces of the slide block 9 . Through mutual matching research, it is ensured that the flatness error of the four planes is less than 1 μm and more than 80% of the areas are in contact with each other.

[0027] Then grind the installation reference surface of the guide rail 5 to ensure that the parallelism error between the intersection line of the two concave V-shaped surfaces of the guide rail 5 and the installation reference surface is less than 1 μm. The standard mandrel can be used for detection during measurement; put the standard measuring mandrel into the V-groove of the guide rail 5, measure the height difference between the highest points at both ends of the mandrel relative to the installation datum plane of the guide rail 5, and grind the installation datum of the guide rail 5 Surface to reduce this diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com