Patents

Literature

60results about How to "Reduce crawling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electromagnetic wave interference preventive material and production thereof

InactiveCN1646000AHigh specific surface areaIncrease reflectionMagnetic/electric field screeningIron powderSendust

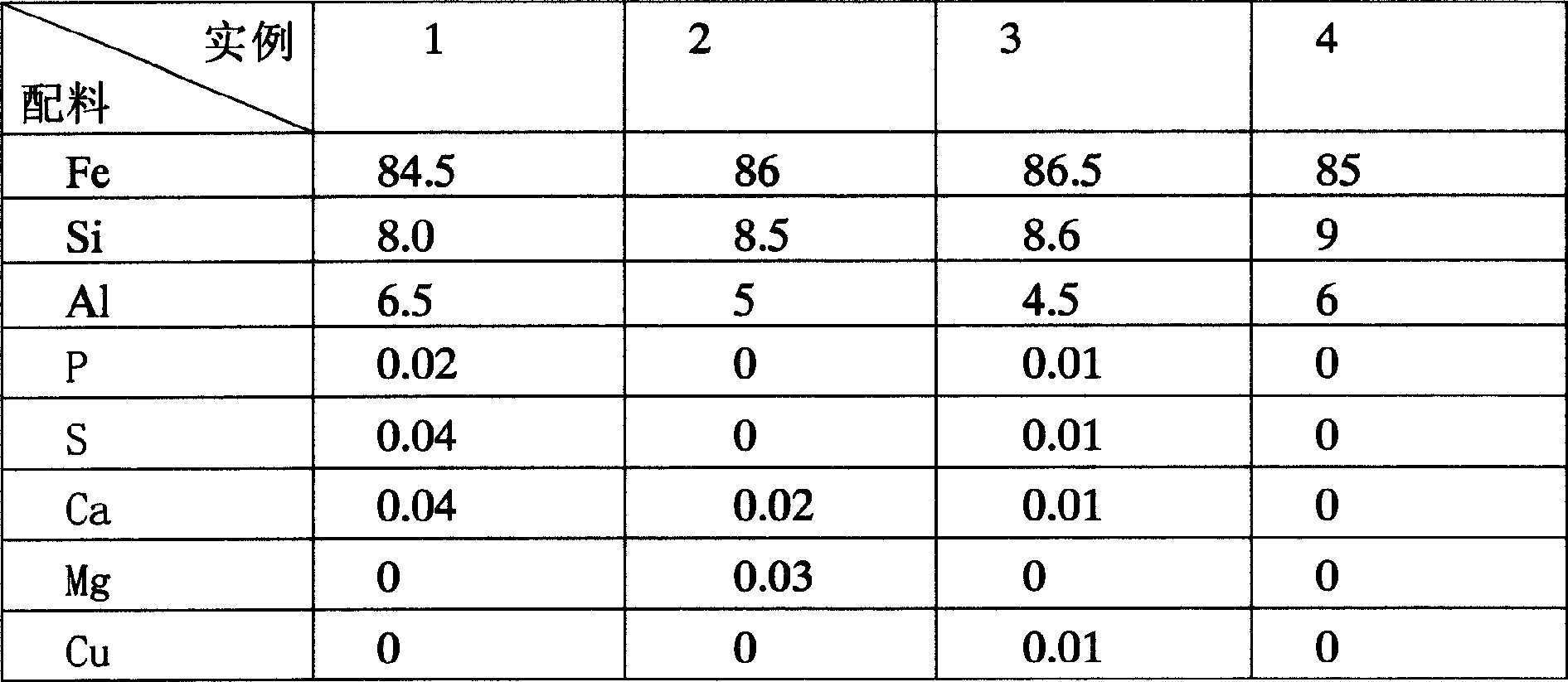

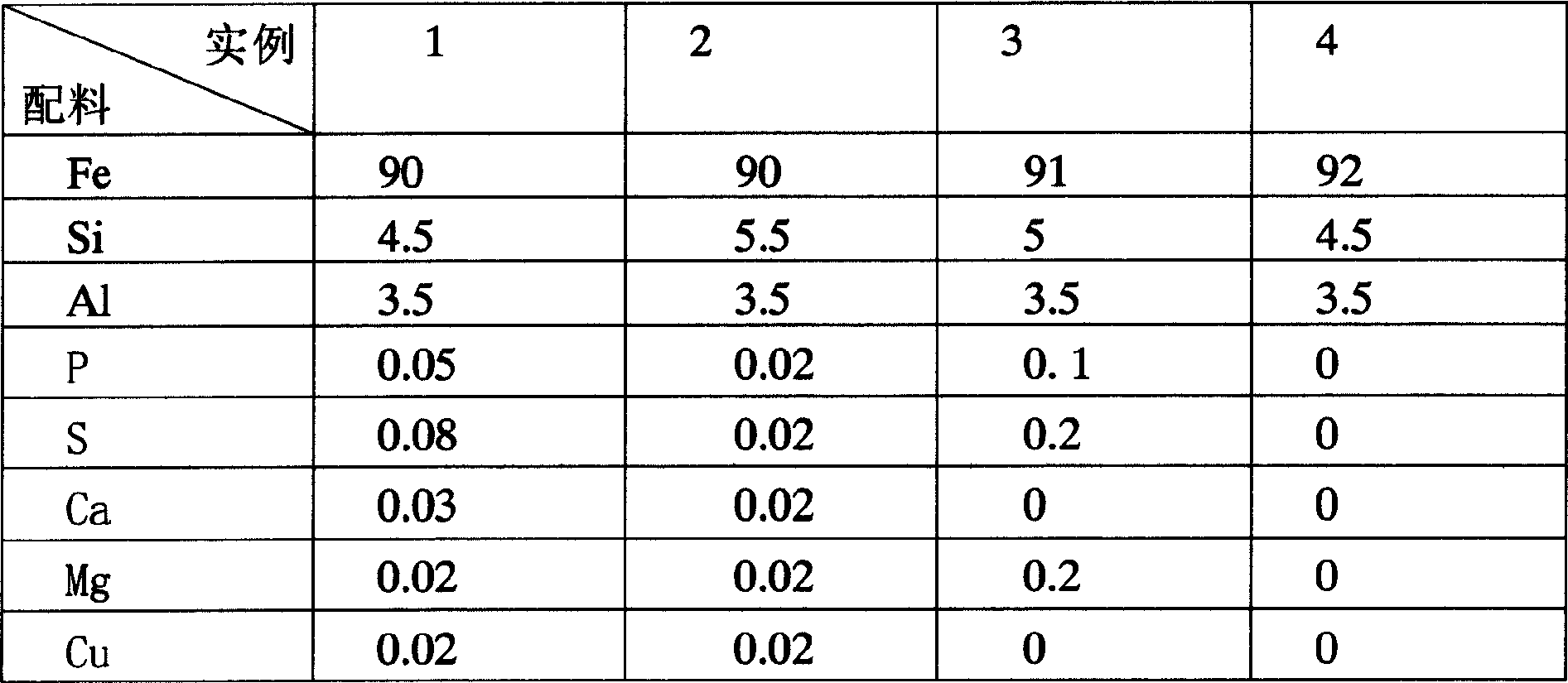

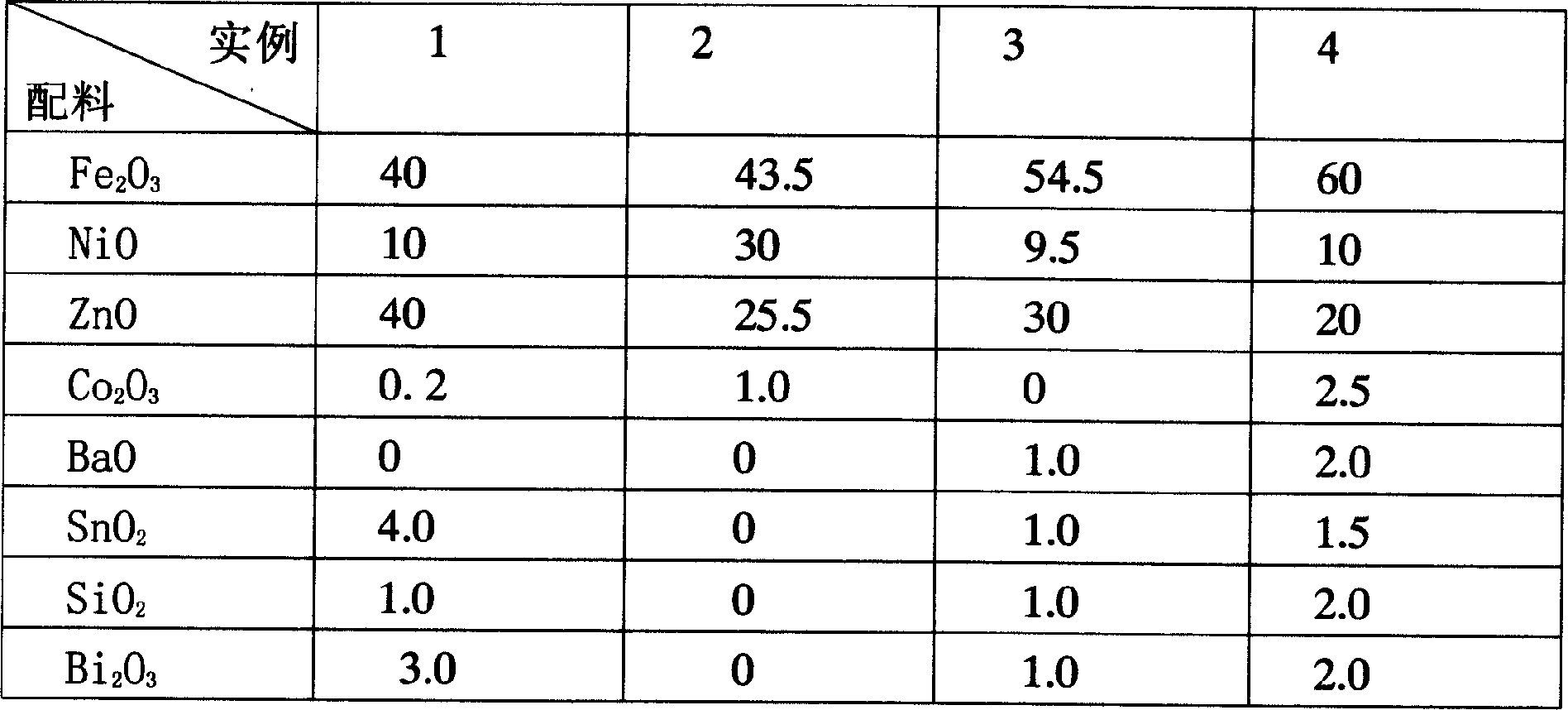

The anti electromagnetic interference material is composed of several layers: the impedance matching layer is made of absorbing type sendust powder, manganese-zinc ferrite and resin; the absorbing layer is made of absorbing type sendust powder, nickel zinc ferrite and resin; the reflecting layer is made of reflection type sendust powder, iron powder and resin.

Owner:横店集团东磁有限公司

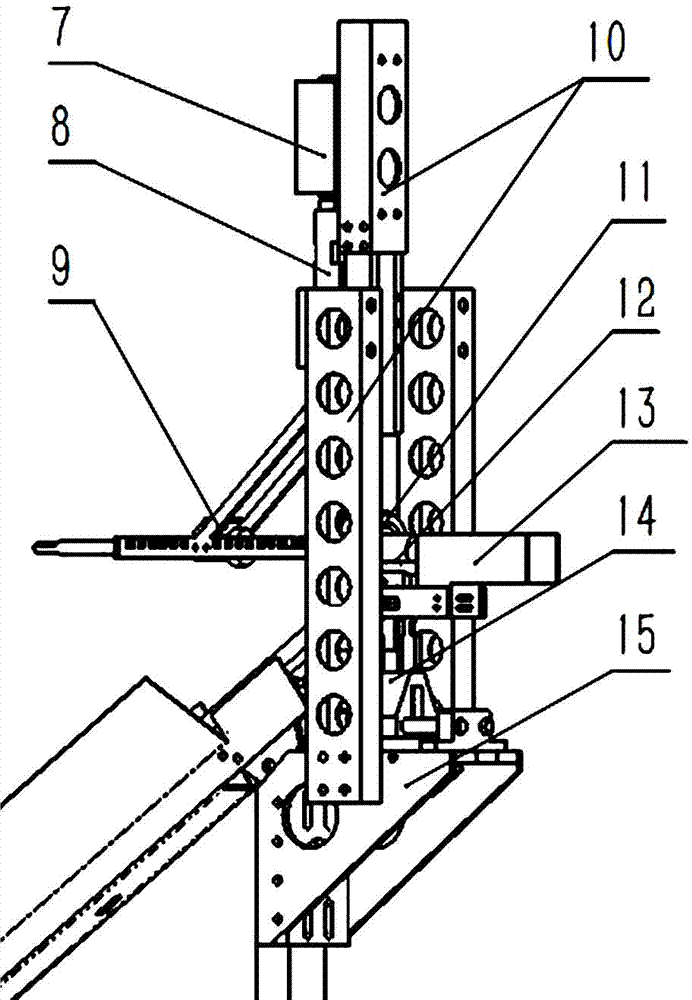

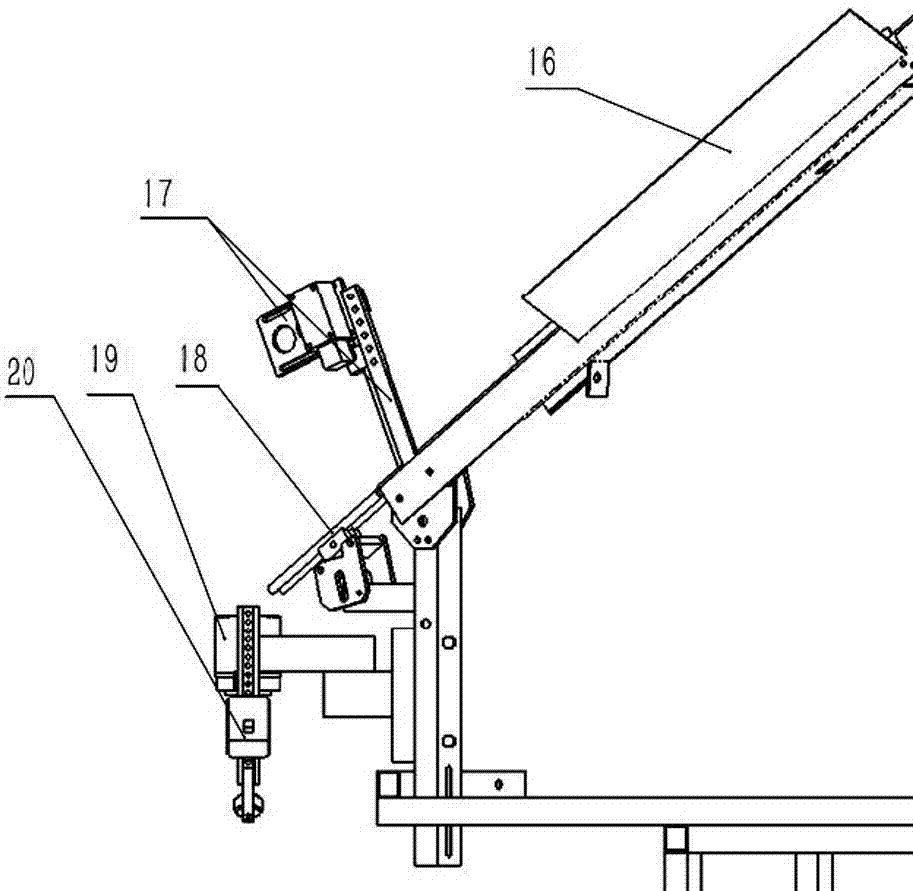

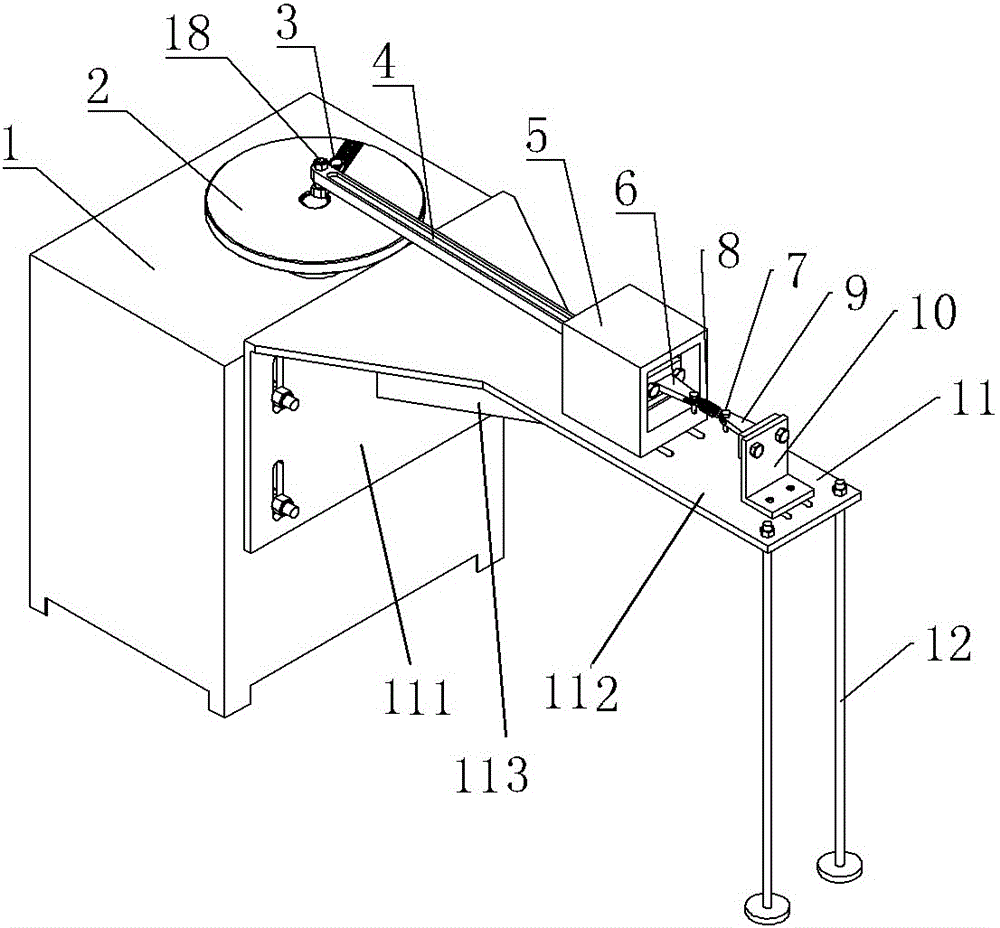

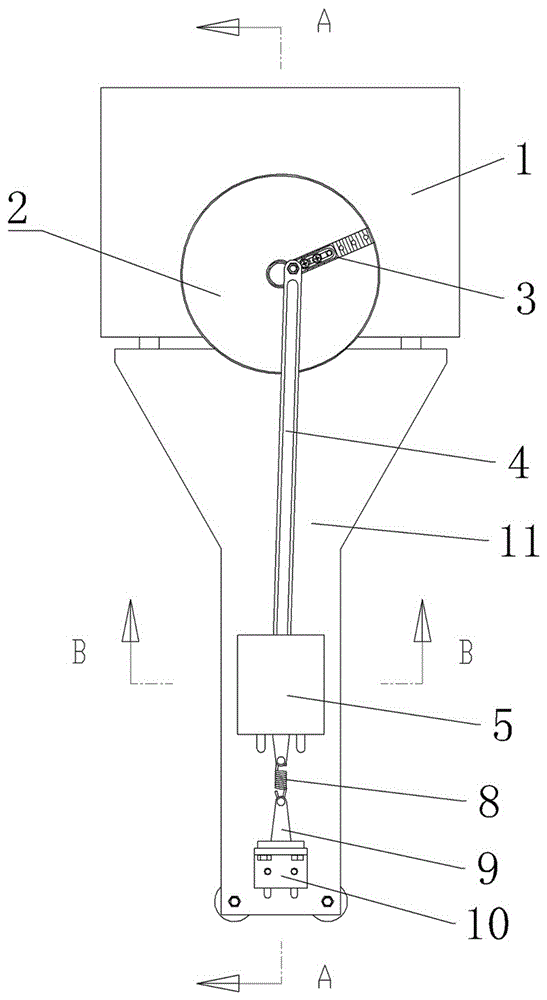

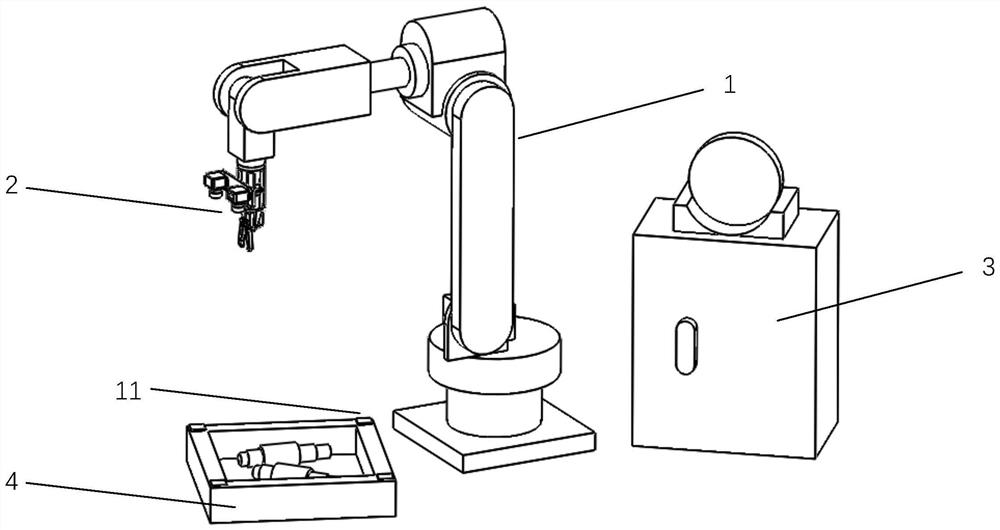

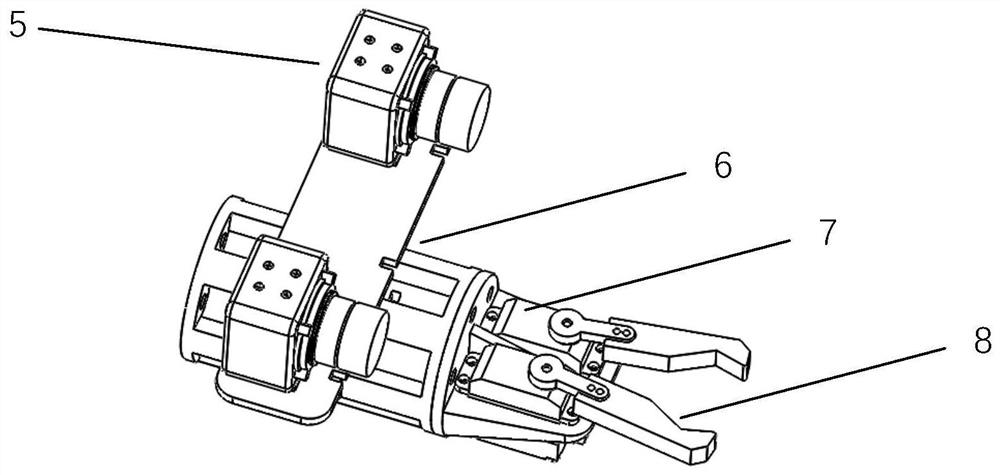

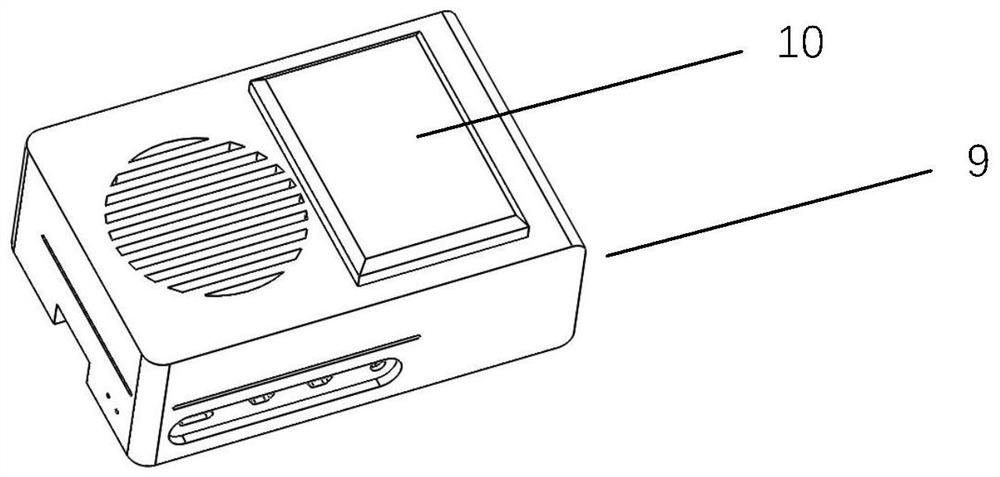

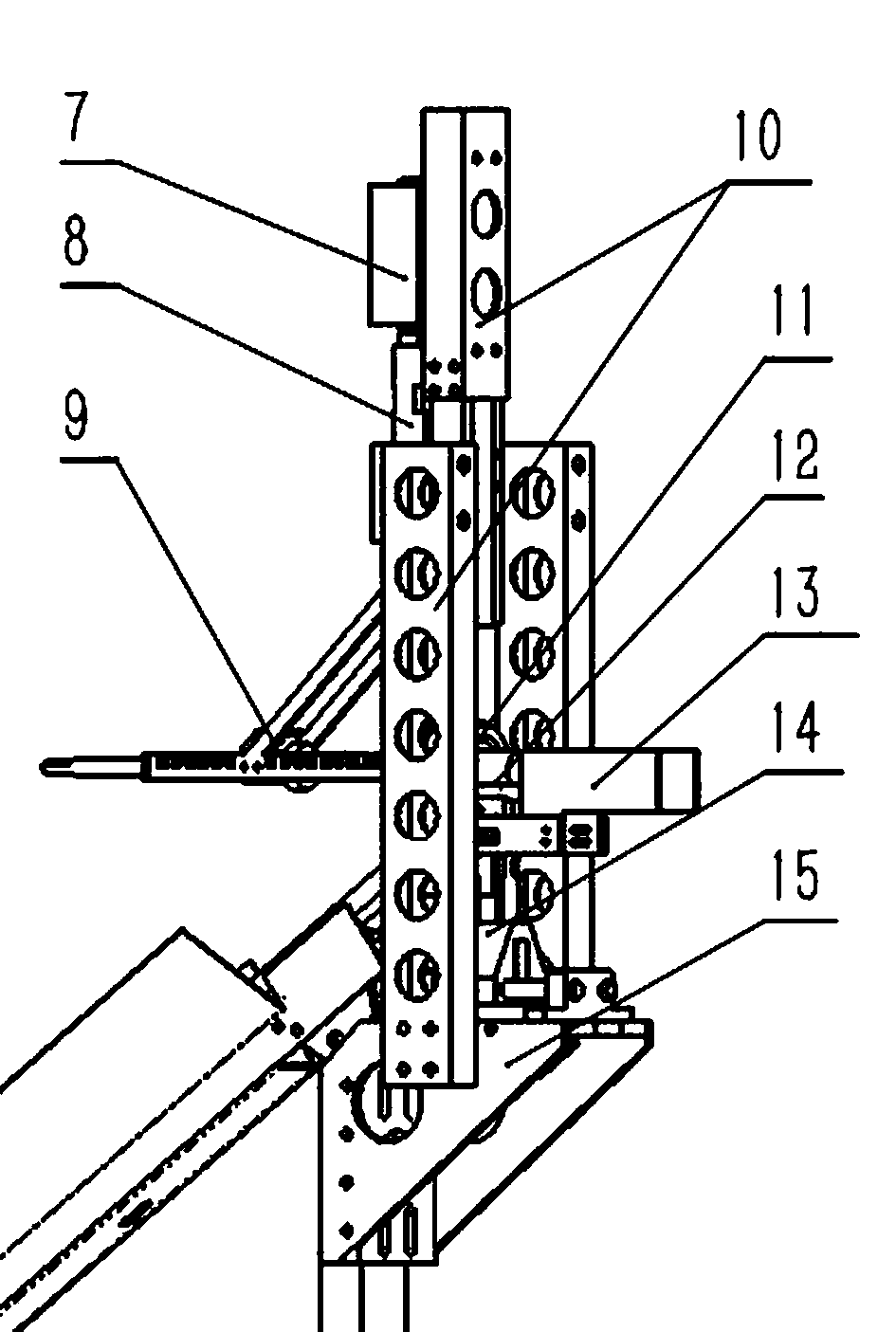

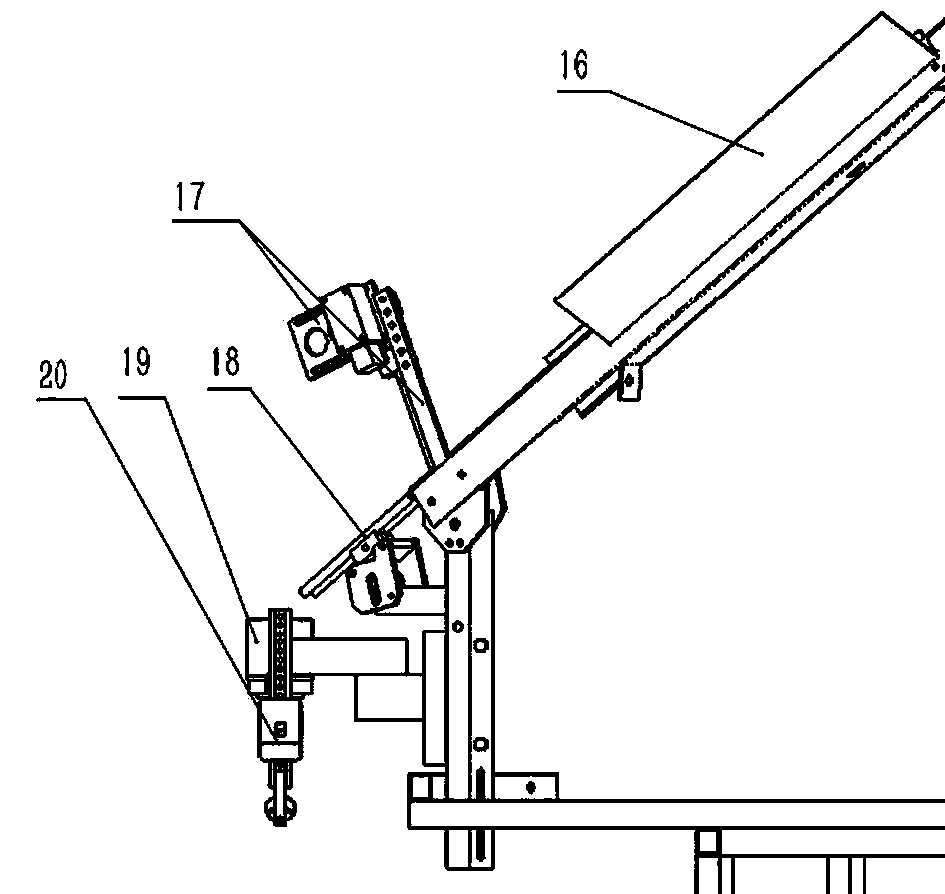

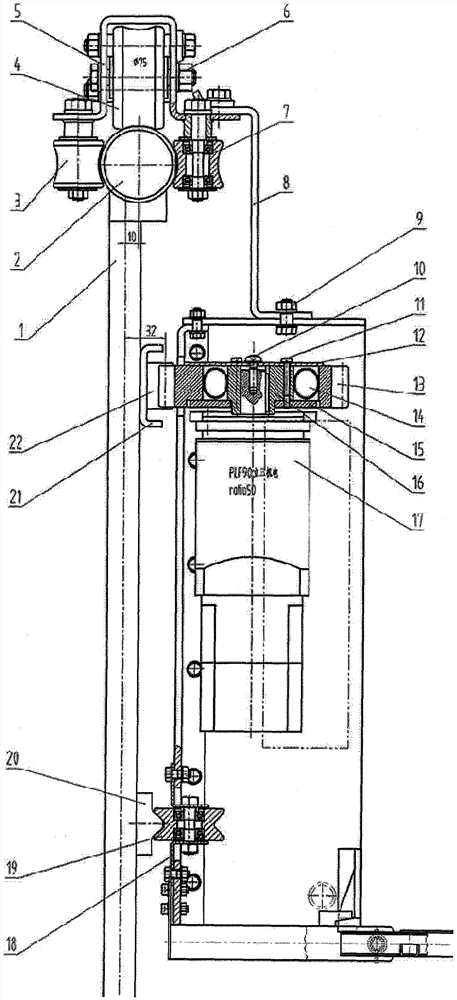

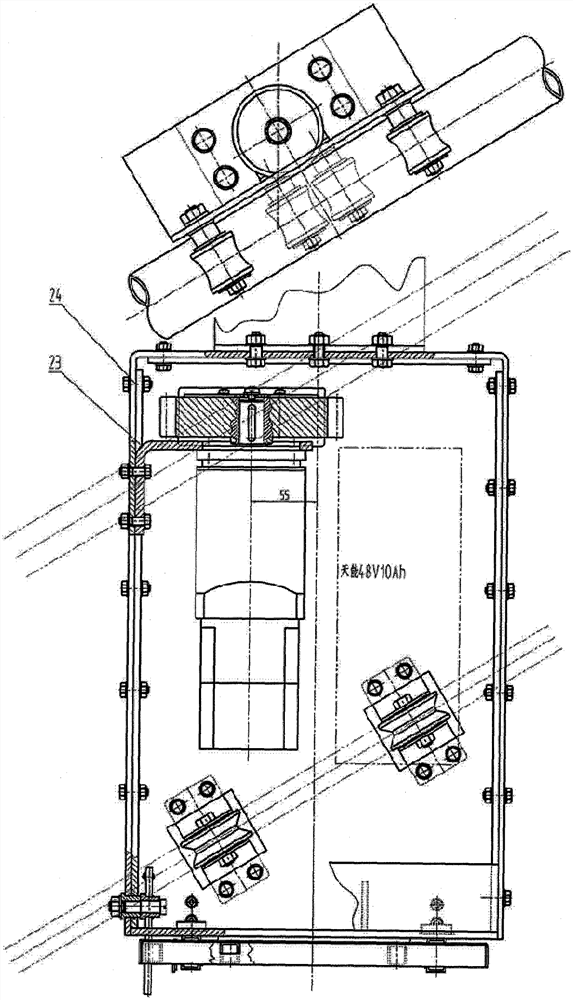

Material delivering robot with visual detecting function

ActiveCN102825605AHigh operating precisionEasy to controlJointsMetal working apparatusControl systemComputer terminal

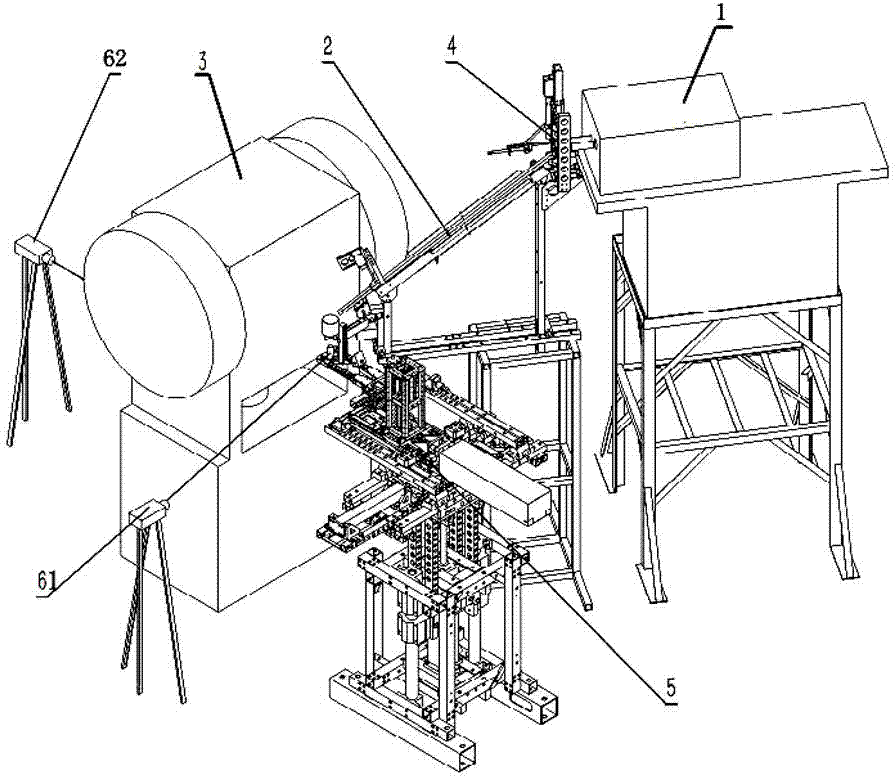

The invention discloses a material delivering robot with a visual detecting function, which comprises a control system, a visual detecting system and a material delivering system; the material delivering system comprises a material sliding mechanism and a delivering manipulator. The visual detecting system analyzes and judges the material temperature, gesture and other conditions in an analyzing module through collecting a material image at a terminal of the sliding mechanism and a material image in a forging device, and further controlling the action of the delivering manipulator through the control system according to the judgment result. The delivering manipulator of the material delivering system can effectively ensure the precision of repeatedly grabbing materials through the cooperation of a joint capable of moving and positioning on a three-dimensional direction. Furthermore, the material delivering robot is high in degree of automation; the qualified product can be automatically detected and judged in the process of delivering the material, and thus the processing efficiency of the product is effectively improved.

Owner:KUNSHAN HAIWEI AUTOMATION

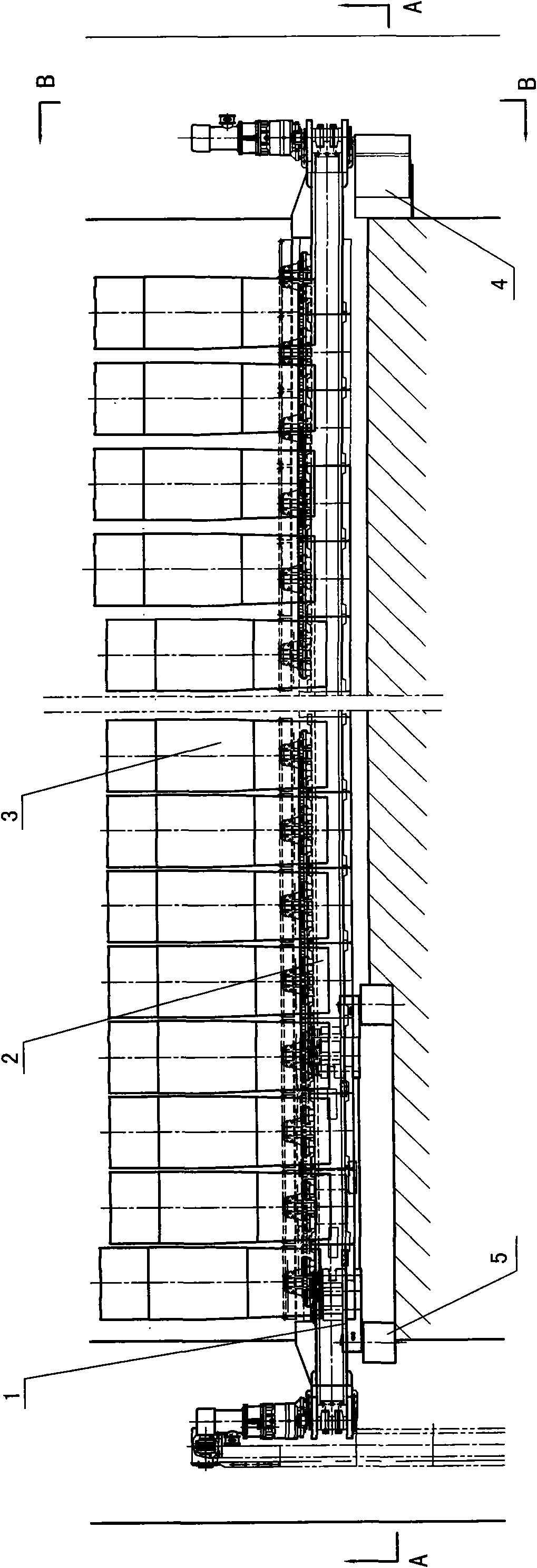

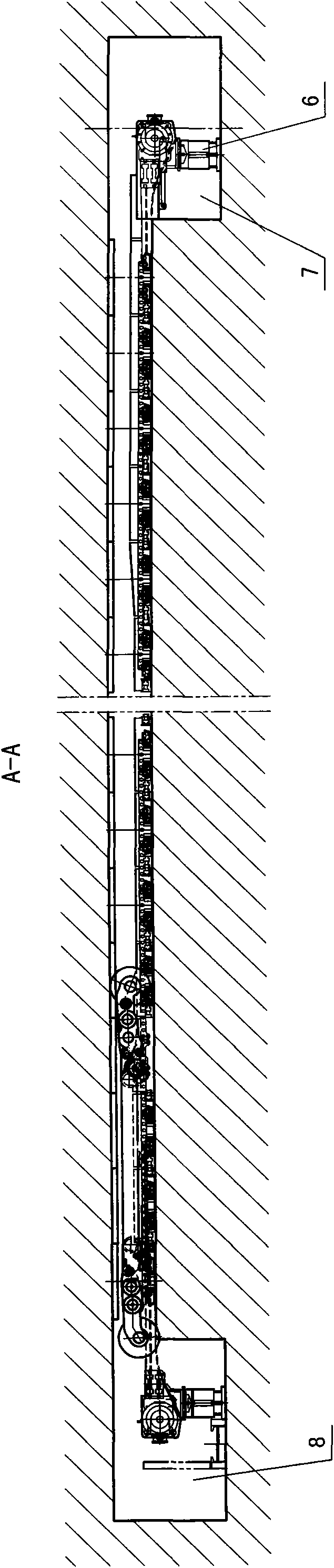

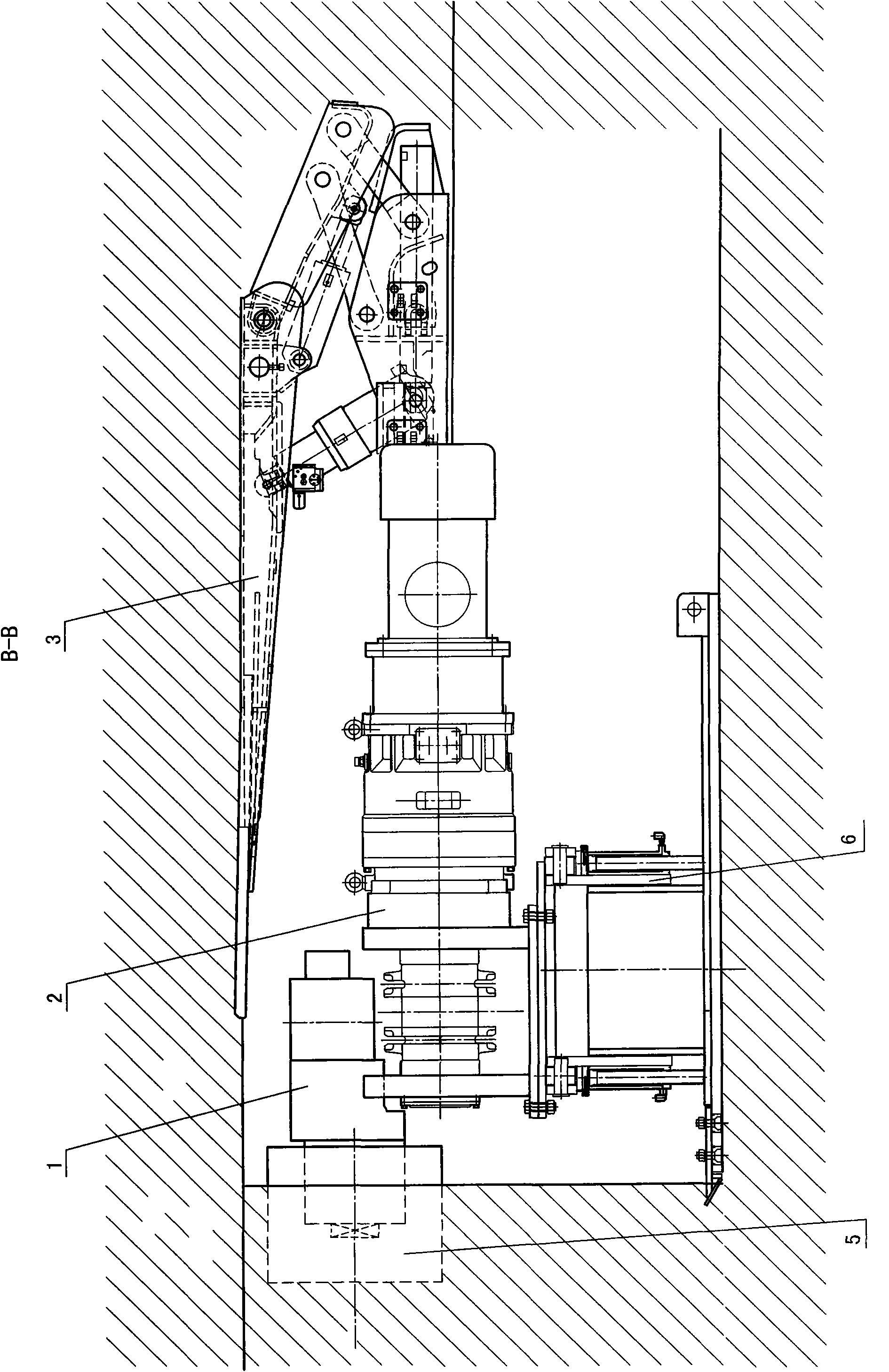

Process for stoping low coal seam containing ferric sulfide concretions and hard parting bands and hydraulic support thereof for fully mechanized mining

InactiveCN101775986ARealize comprehensive mechanized miningSolve the problems that coal mining has been unable to solveUnderground miningSurface miningRemote controlEngineering

The invention relates to a process for stoping low coal seams containing ferric sulfide concretions and hard parting bands, which adopts a fully mechanized mining process to mine coal. Working face equipment comprises a drum shearercoal-mining machine, a hydraulic support, a scraper conveyor, and the like, wherein the drum shearercoal-mining machine adopts a wide high-power high-strength drum for narrow cutting and deep cutting; the hydraulic support adopts a hydraulic shield support for advancingmoving quantitively by in different times and stretching the support in one-stepce; and water is injected into the working face for softening before stoping. The fully mechanized mining level can be enhanced by adopting the scraper conveyor with a middleedian plate straightly arranged at the head and the tail of the scraper conveyor, and a radio remote control method for the coal-mining machineshearer with the working face remote-controlled in segments automatically. The advancing jack hydraulically-controlled loop of the hydraulic support is formed into a separately push / pull and quantitively grouped advance charging loop bycomprises an adjacent support pilot control reversing valve, a differential valve, a quantitive cylinder and an alternate valve which form a separately push / pull and quantitively grouped advance charging loop. The invention can realize the fully mechanized mining forof the low coal seams containing the ferric sulfide concretions and / or the hard parting bands, and solves the difficult problem which is not solved at home and abroad for a long time. The invention can be used for mining low coal seams containing other concretions, ordinary low coal seams, medium-thickness coal seams and high coal seams.

Owner:兖矿能源集团股份有限公司

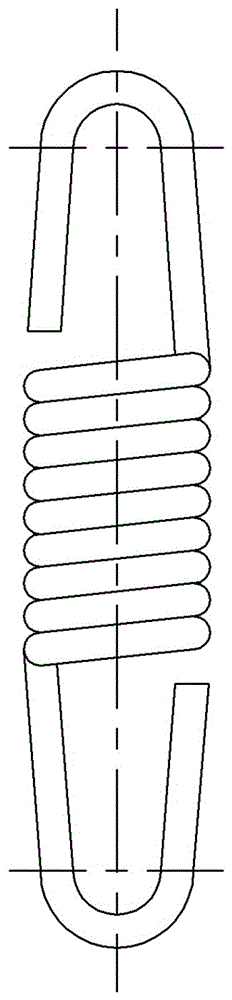

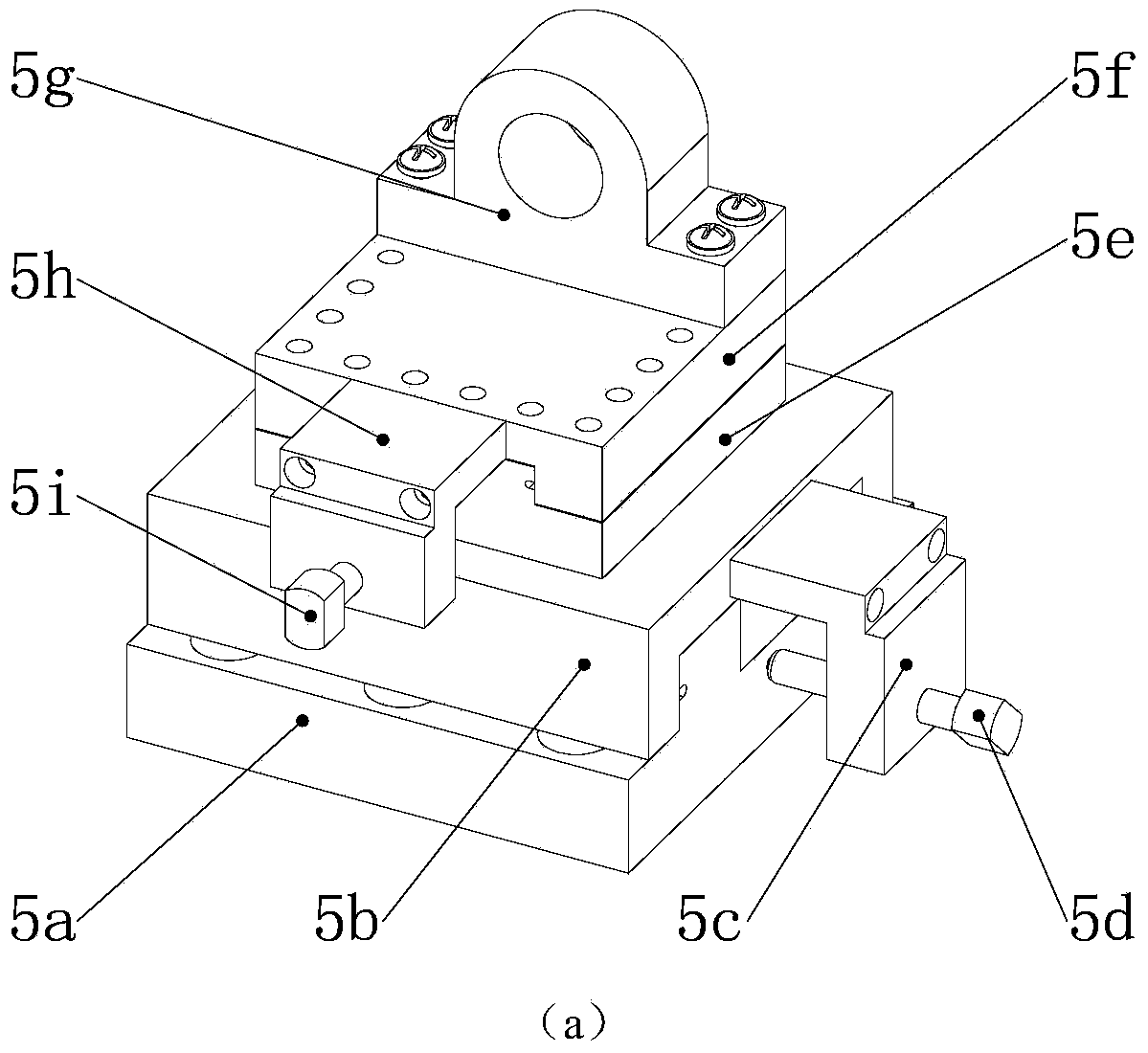

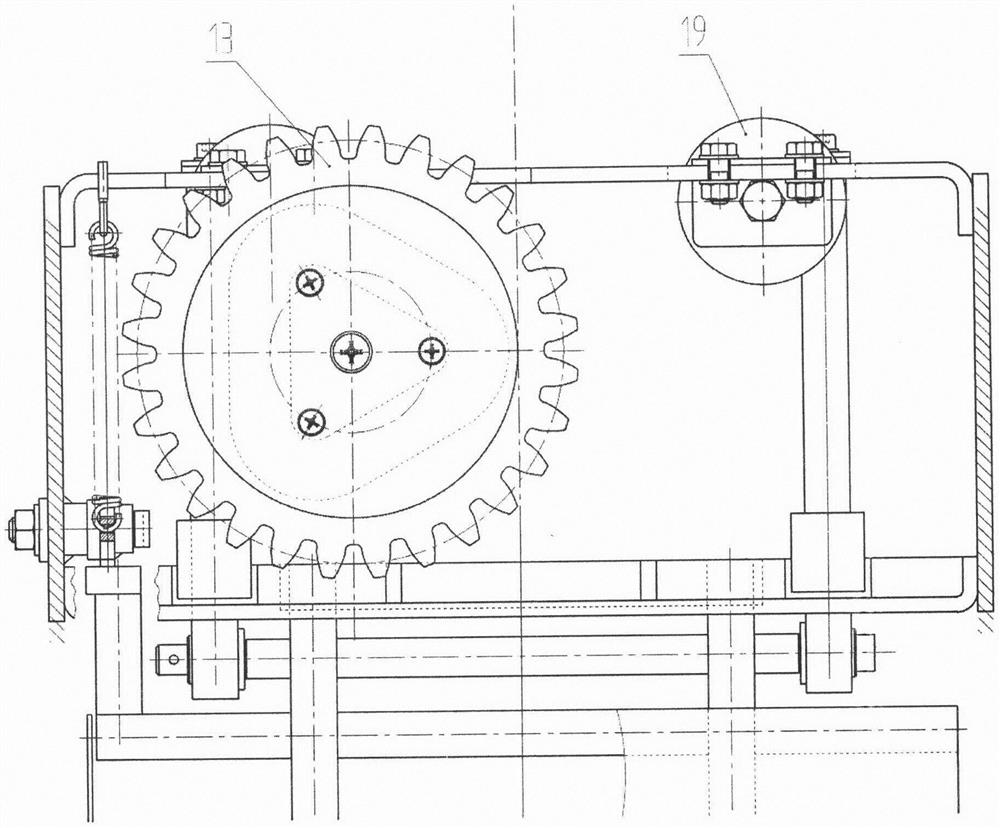

Crank-slider mechanism and spring life testing device with same

ActiveCN106840625AReduce wearReduce crawlingMachine part testingMaterial strength using repeated/pulsating forcesRolling resistanceEngineering

The invention relates to a crank-slider mechanism and a spring life testing device with the same. The spring life testing device comprises the crank-slider mechanism, the crank-slider mechanism comprises a crank, a guide rail extending in the front-and-back direction, a slider capable of moving along the guide rail and a connecting rod connected between the crank and the slider, a rolling body is arranged between the guide rail and the slider, and the guide rail and the slider achieve rolling cooperation through the rolling body. According to the crank-slider mechanism and the spring life testing device with the same, existing sliding friction cooperation between the slider and the guide rail is changed into rolling friction cooperation, the climbing phenomenon is reduced, then wear between the slider and the guide rail is reduced, the spring life testing device can conduct over ten thousands times of stretching fatigue tests on a spring, and the service life of the device is long.

Owner:HENAN PINGGAO ELECTRIC +2

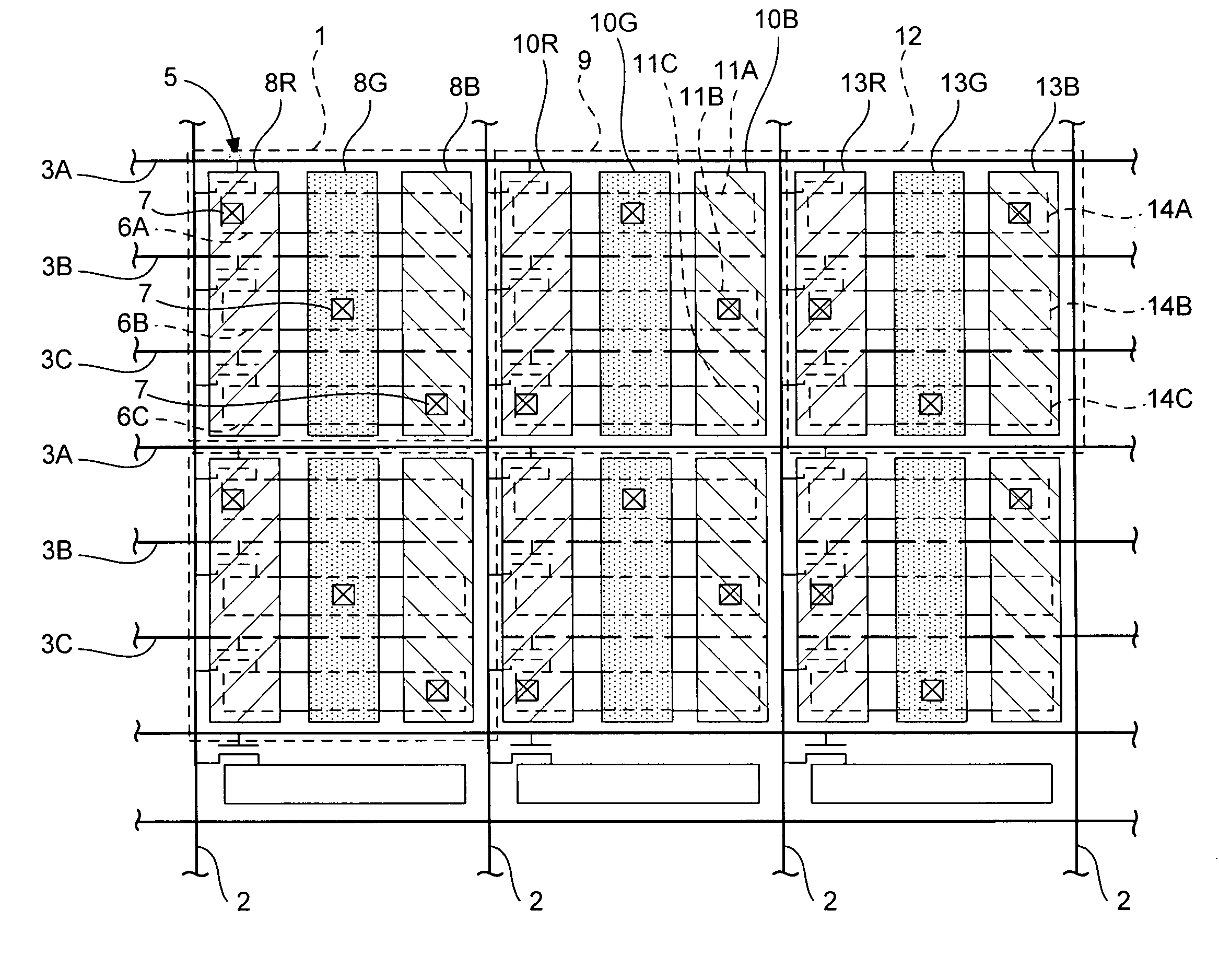

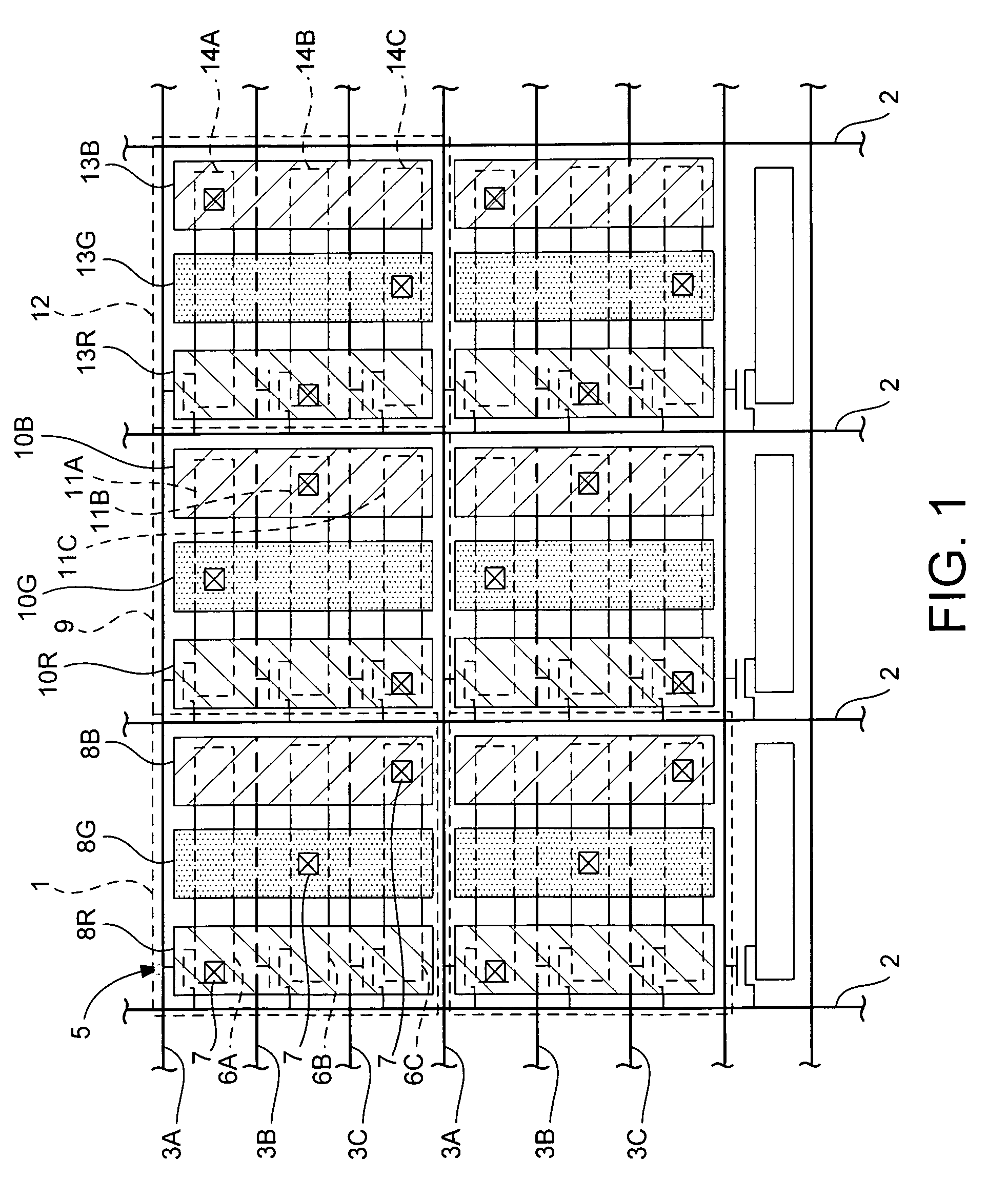

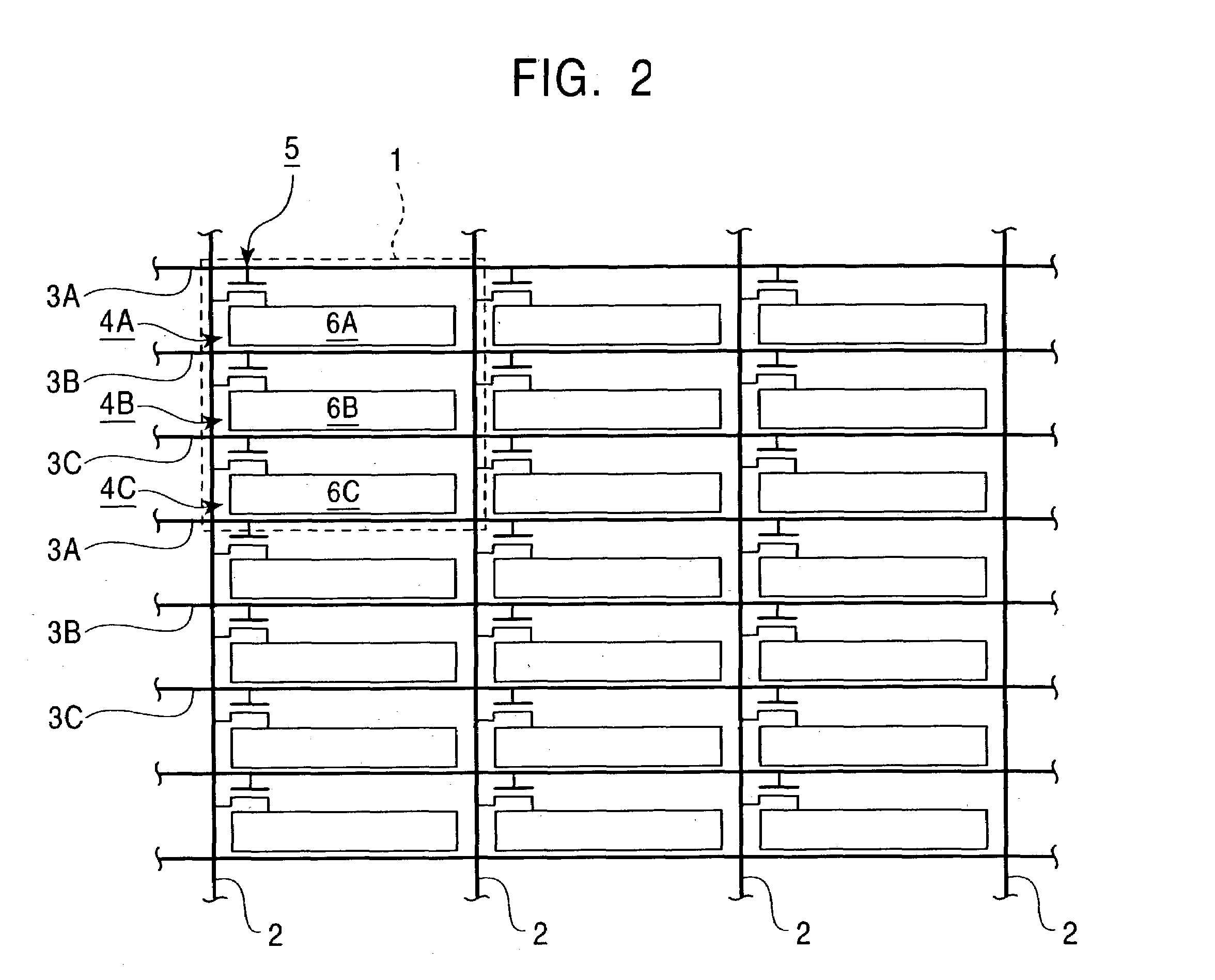

Liquid-crystal display apparatus capable of reducing line crawling

InactiveUS7301517B2Reduce power consumptionGood image qualityTransistorStatic indicating devicesLiquid-crystal displayElectricity

In a liquid-crystal display apparatus, each color pixel has three dots enclosed by adjacent signal lines and adjacent scanning lines. Each dot is provided with a switching device and a dot electrode. Each color pixel is provided with three display electrodes electrically connected to three dot electrodes through contact holes passing through an insulation layer. The display electrodes are disposed so as to overlap with the three dot electrodes. Each of the display electrodes is electrically connected to only one of the three dot electrodes. Each of the dot electrodes is electrically connected to only one of the display electrodes.

Owner:ONANOVICH GROUP

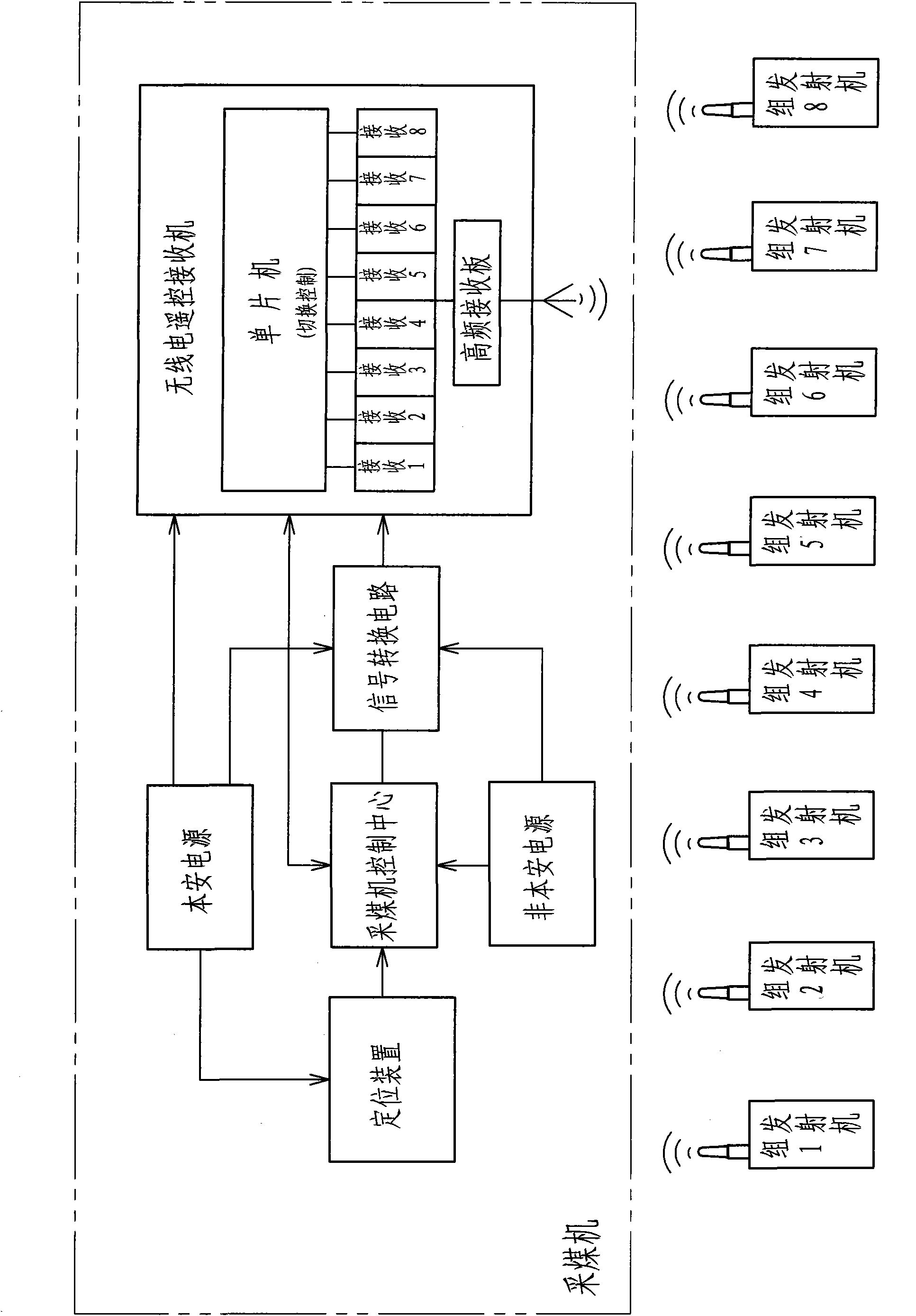

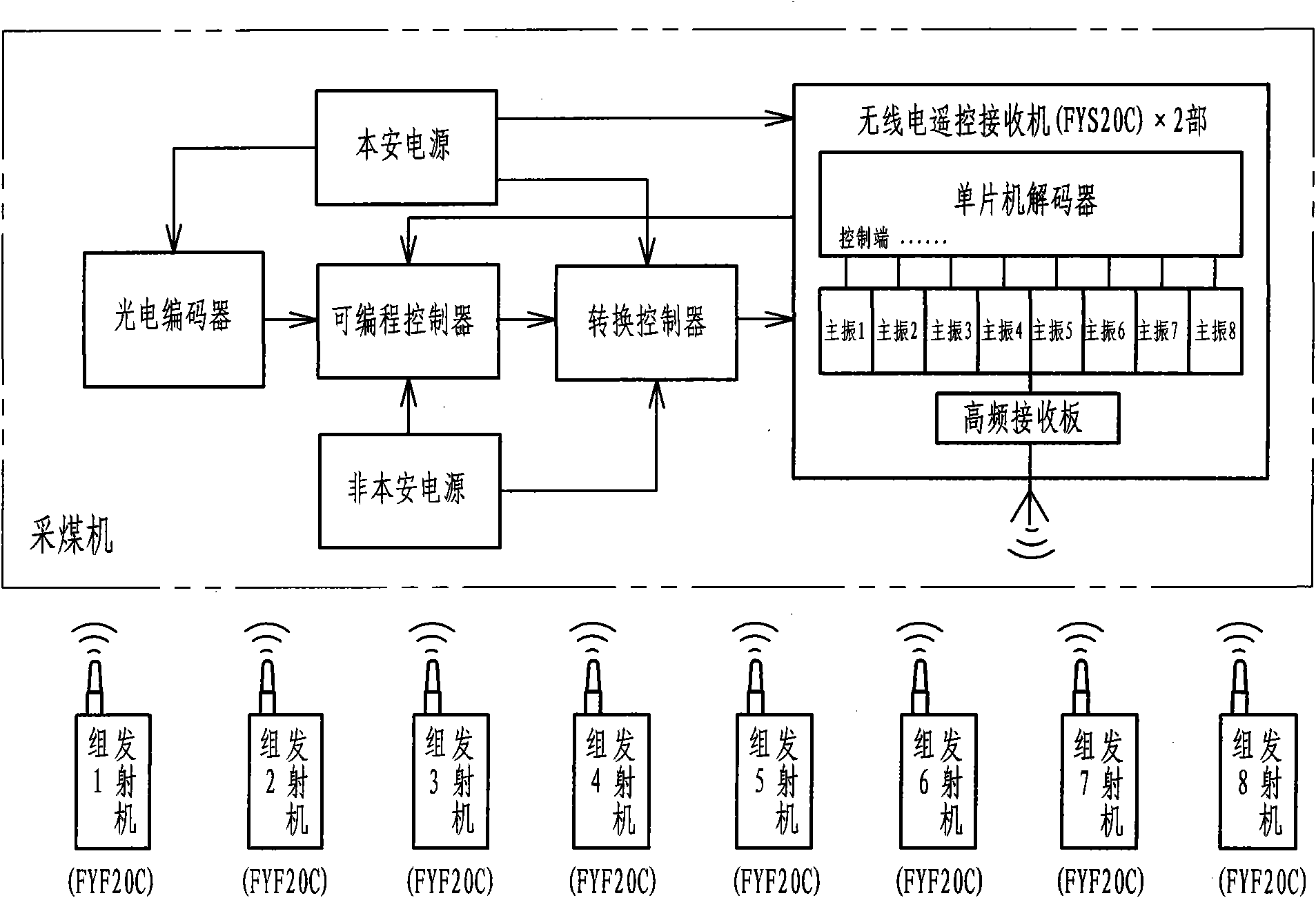

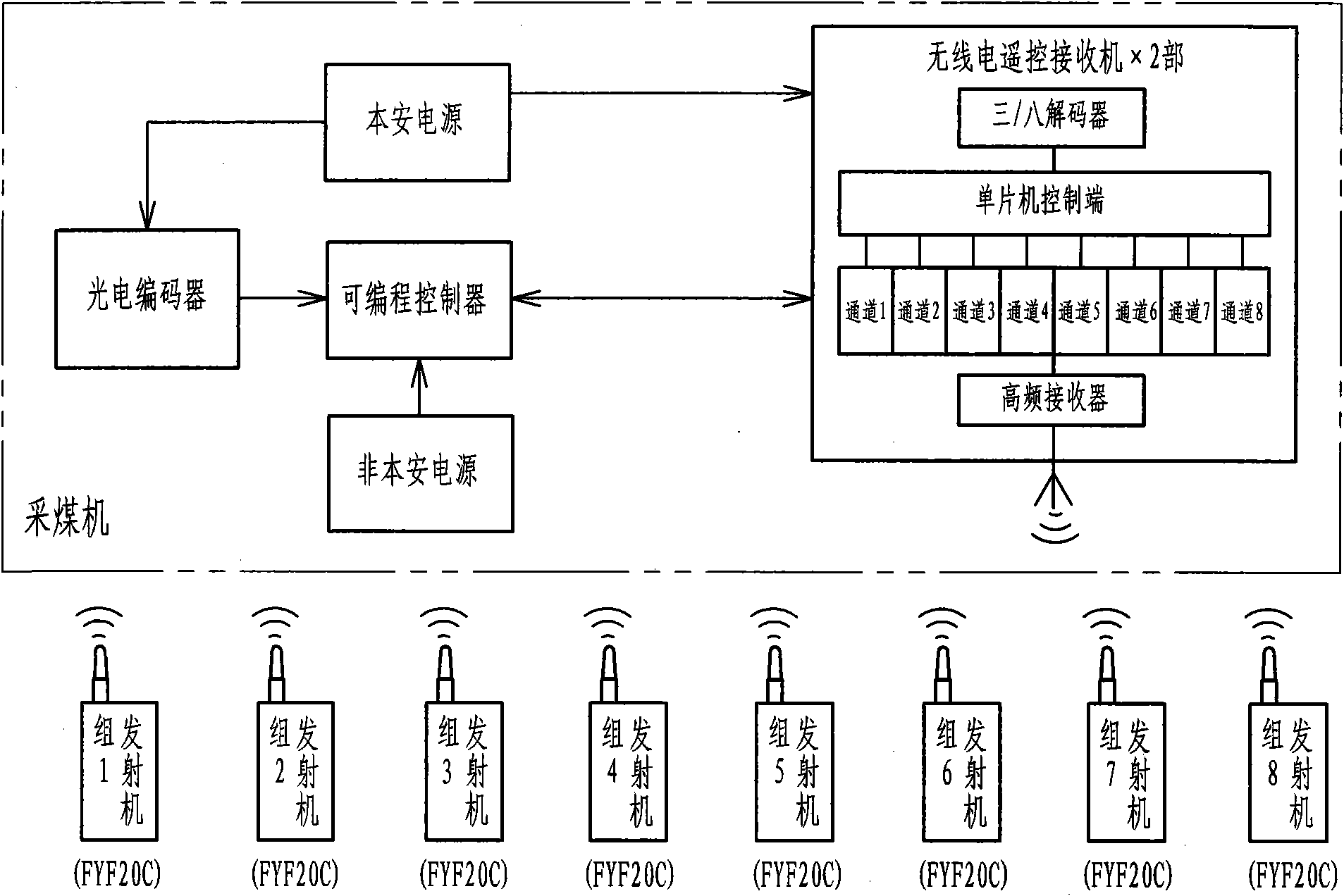

Remote control method and device of thin seam working surface coal mining machine

InactiveCN101871364ASegment positioning is accurateWork reliablyMining devicesTransmission systemsAutomatic segmentationMachine control

The invention relates to a remote control method of a thin seam working surface coal mining machine. automatic segmentation remote control is used in the remote control method and comprises the following steps of: segmenting a working surface, and inputting segment parameters into a coal mining machine control center so that the coal mining machine only receives a remote control command of a radio transmitter, which is set in the segment, and increasing a positioning device in a remote control device comprising a transmitter, a receiver and the coal mining machine control center to detect theposition of the segment where the coal mining machine is; outputting a position segment code signal through the operation processing of the coal mining machine control center, and controlling and switching carrier frequencies or passages or decoding formats, and the like of the receiver through an automatic switching control circuit newly increased in the receiver. Each transmitter adopts different transmitting carrier frequencies or coding formats, and the like to correspond to the set working surface segment and the switchable receiving of the receiver. The invention can reduce the creepingand the crawling of operators following machines and the labor intensity, realizes safety and high efficiency, has man-machine conversation interface segment setting, flexibility, convenience and accurate positioning, is especially suitable for the remote control of the thin seam coal mining machine, and is also suitable for moderate and thick seam coal mining machines.

Owner:兖矿能源集团股份有限公司

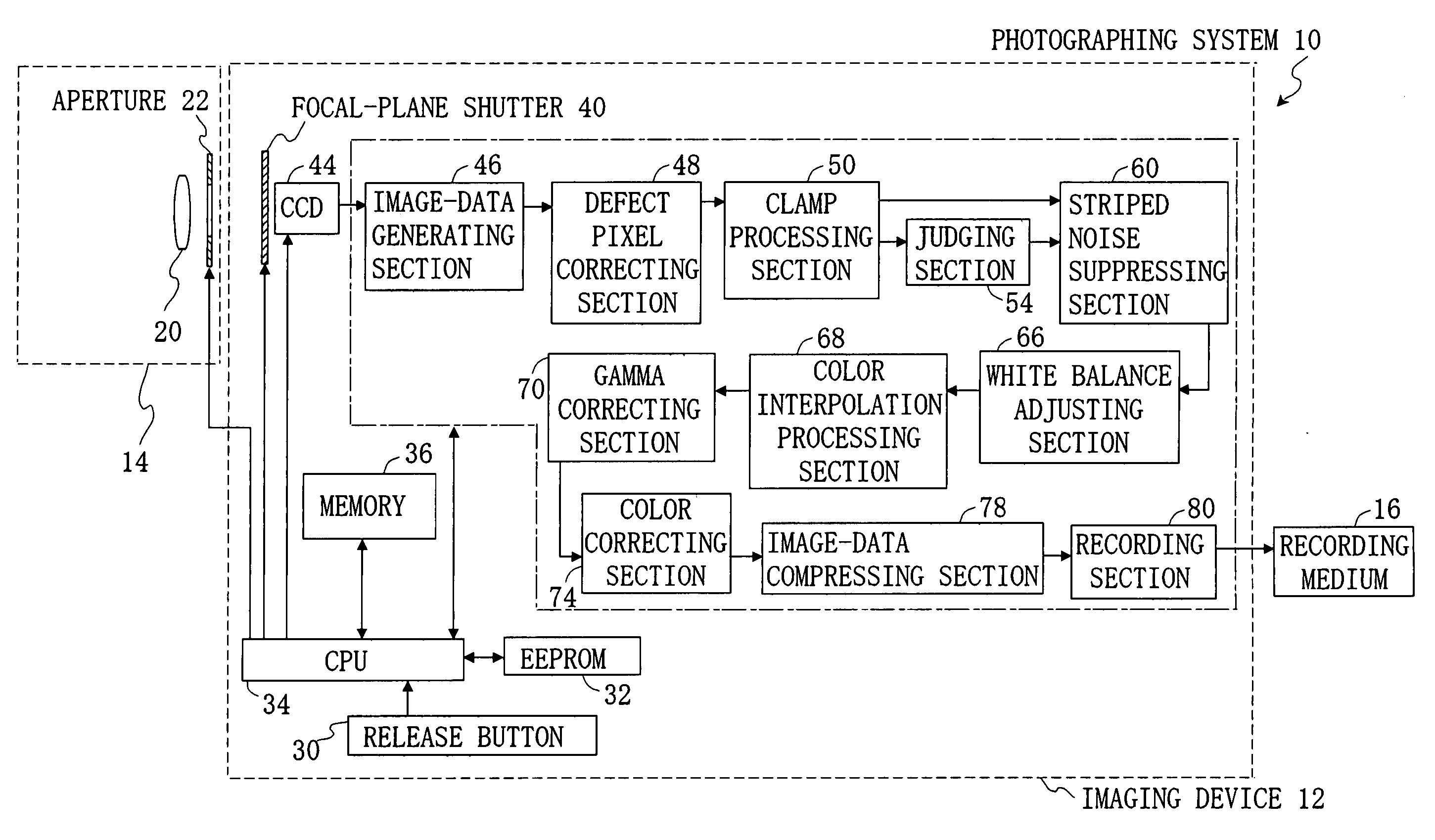

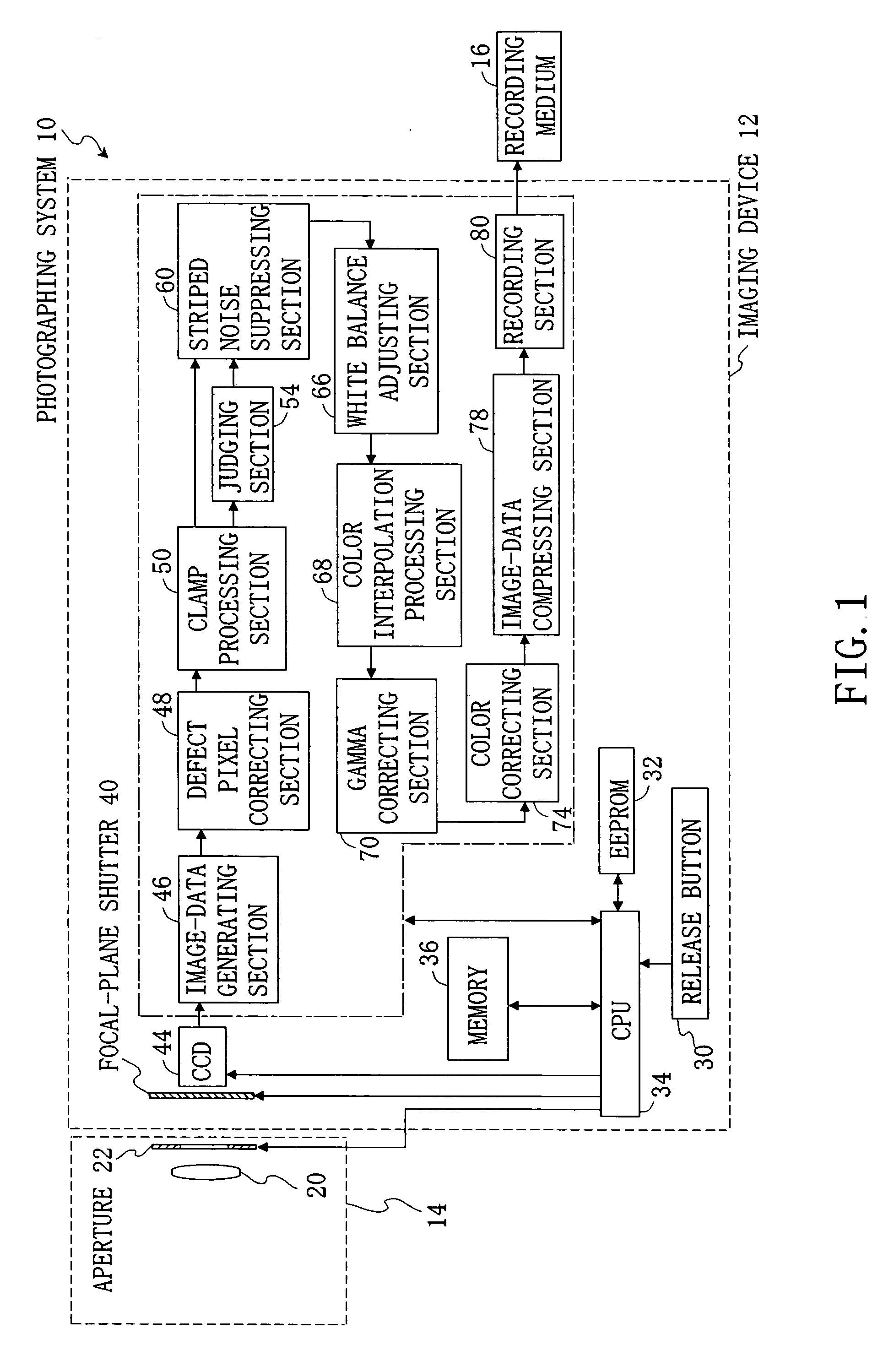

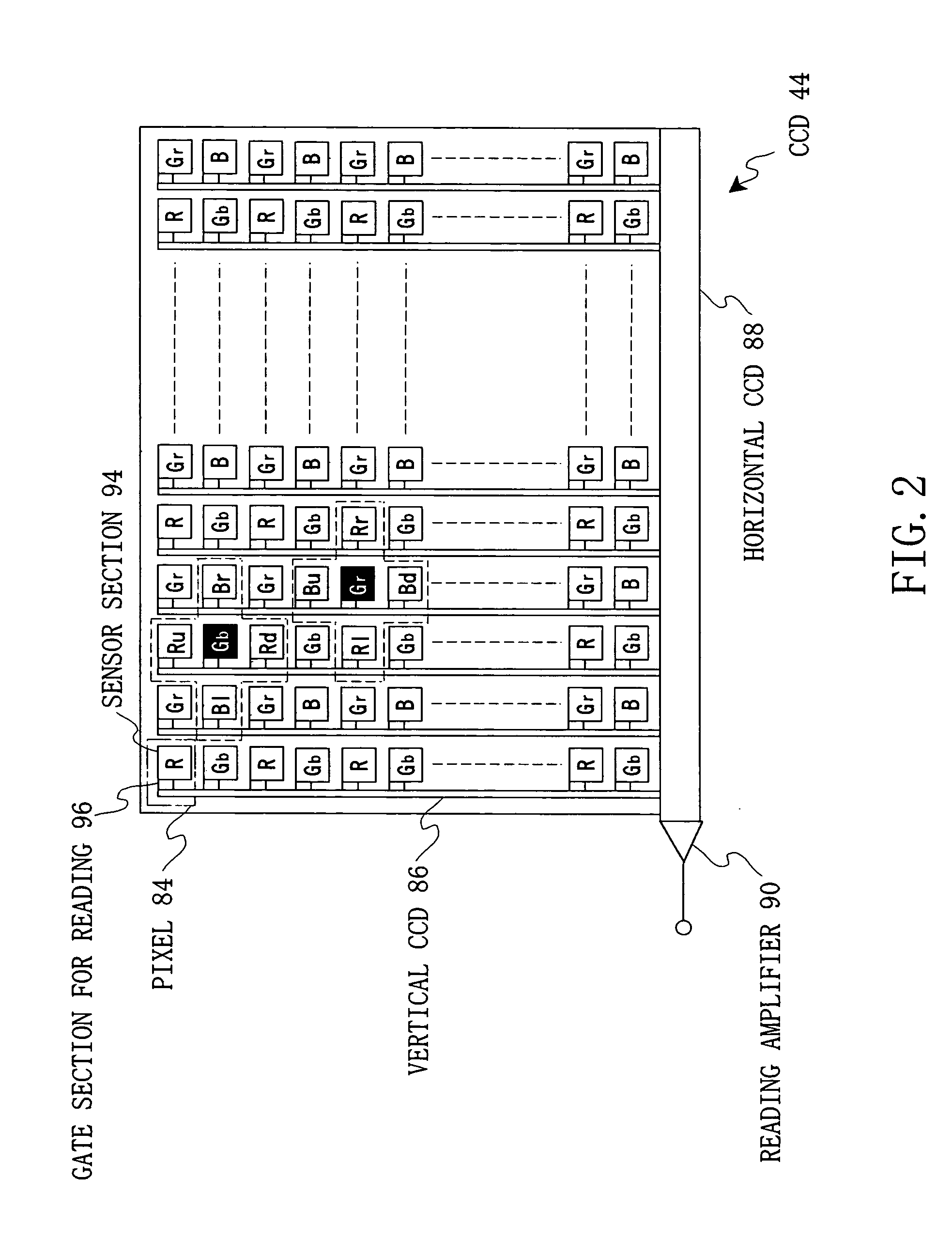

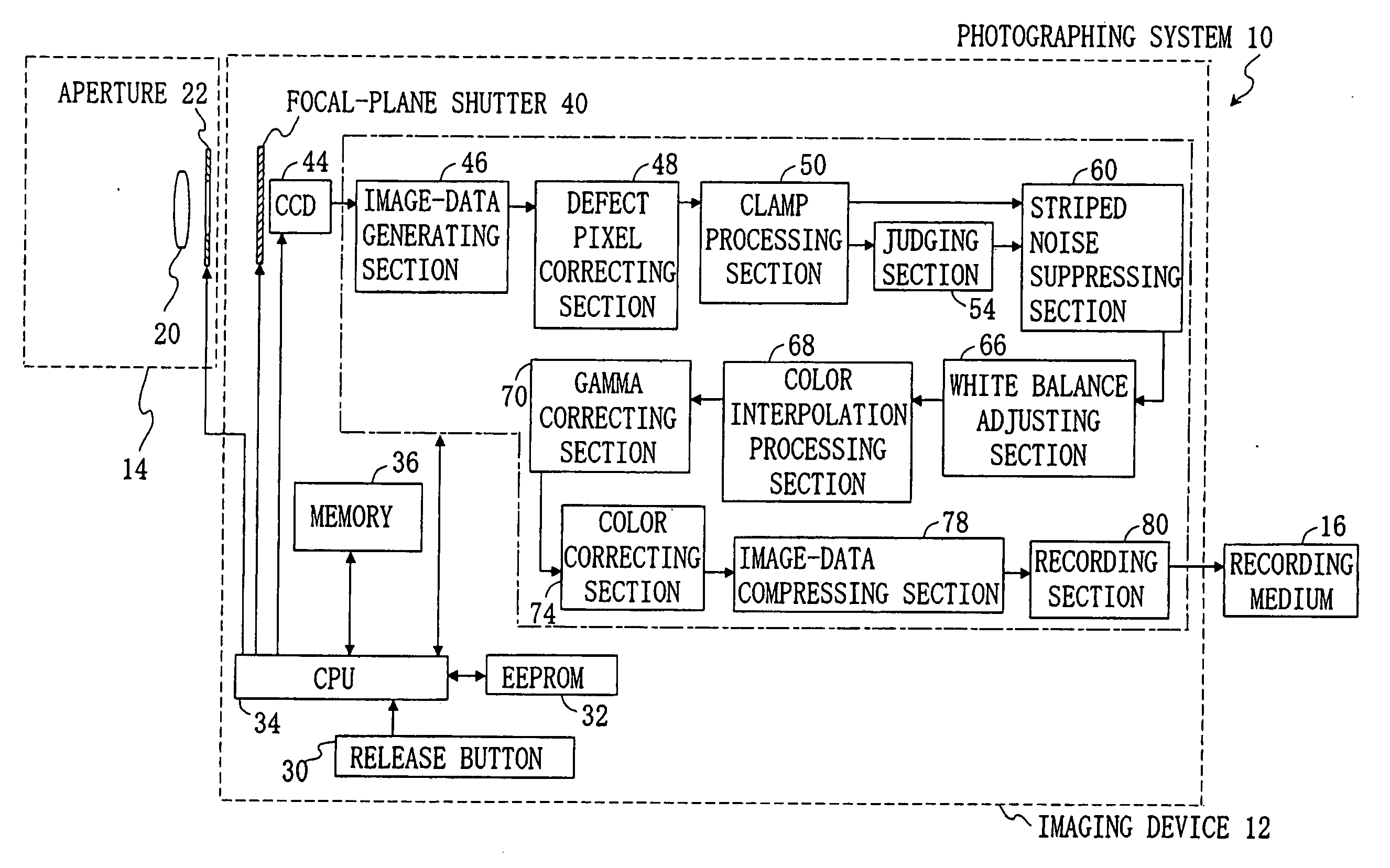

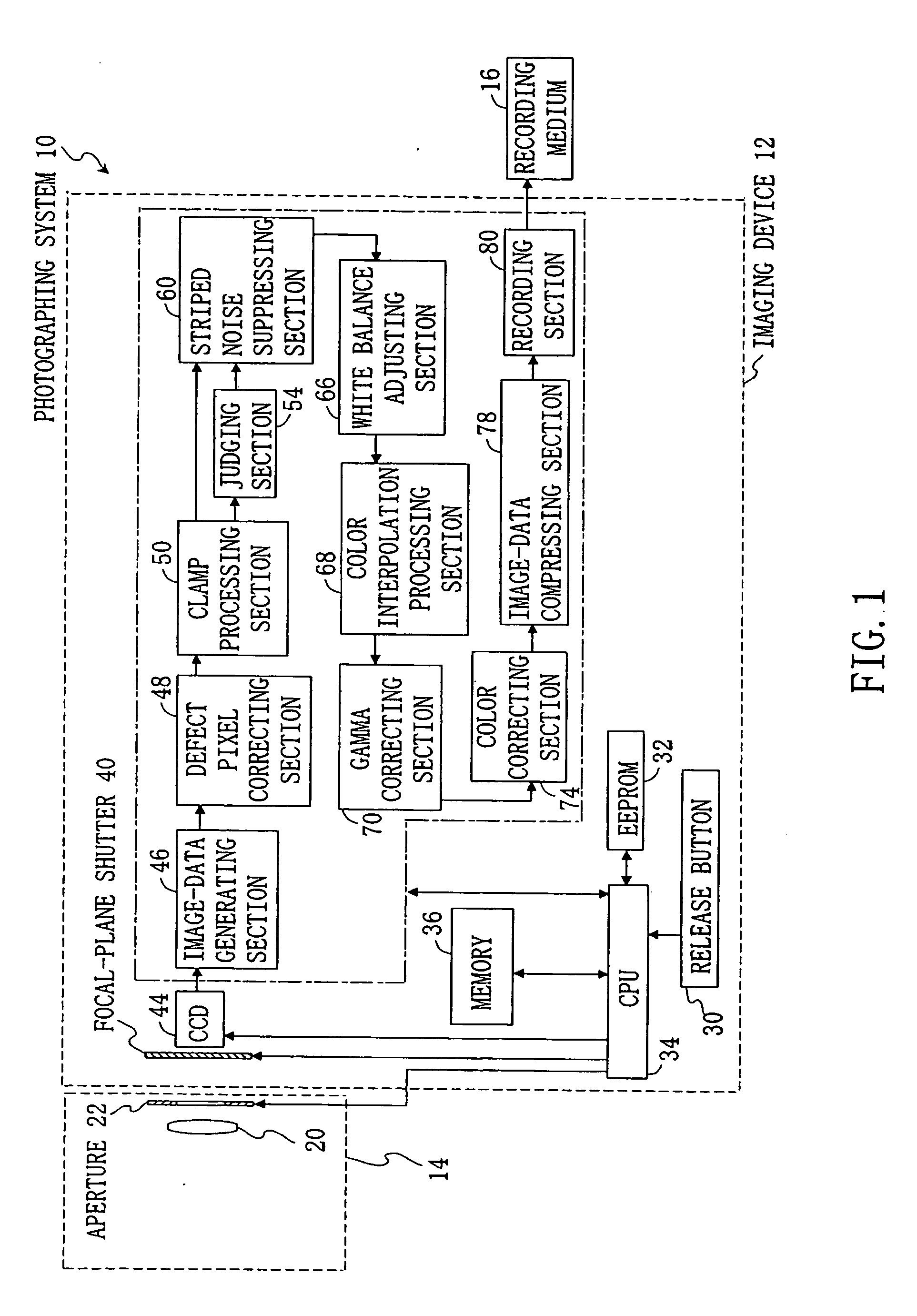

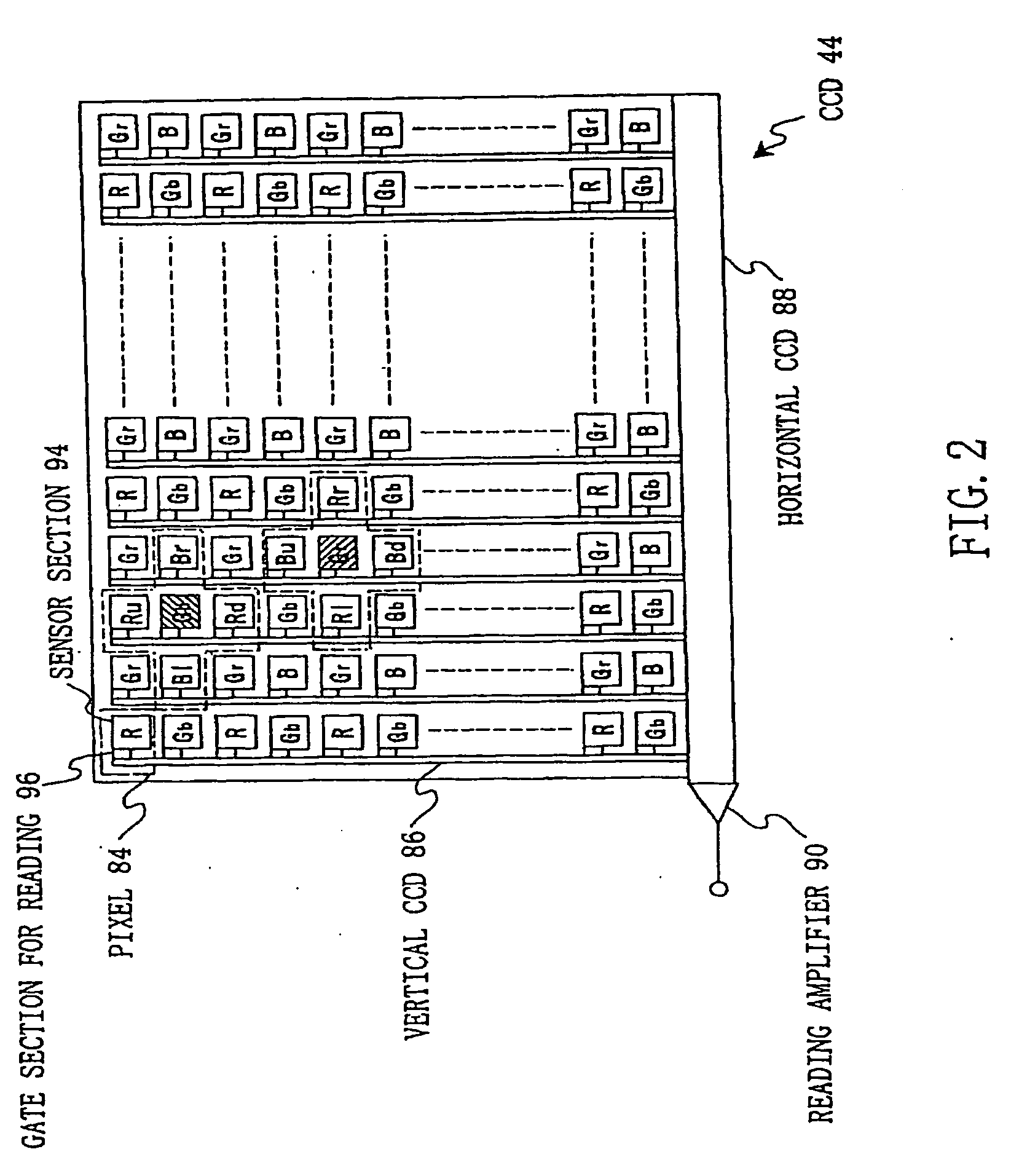

Imaging device

InactiveUS20040246352A1Reduce crawlingTelevision system detailsTelevision system scanning detailsColor imageImaging equipment

A color image sensor has a first, second, and third color component pixels. The third color component pixel includes more intensity information than the first and second color component pixels. A difference estimating section estimates difference in a signal level exerted on a pixel signal of the third color component pixel, using the pixel signal of a pixel peripheral to the third color component pixel. A correcting section corrects the pixel signal of the third color component pixel on the basis of the estimated difference. Accordingly, when the third color component is green in a Bayer array, a pixel signal of a green pixel in a row of red pixels becomes equal to the pixel signal of a green pixel in a row of blue pixels. Therefore, line crawling can be suppressed without smoothing an image.

Owner:NIKON CORP

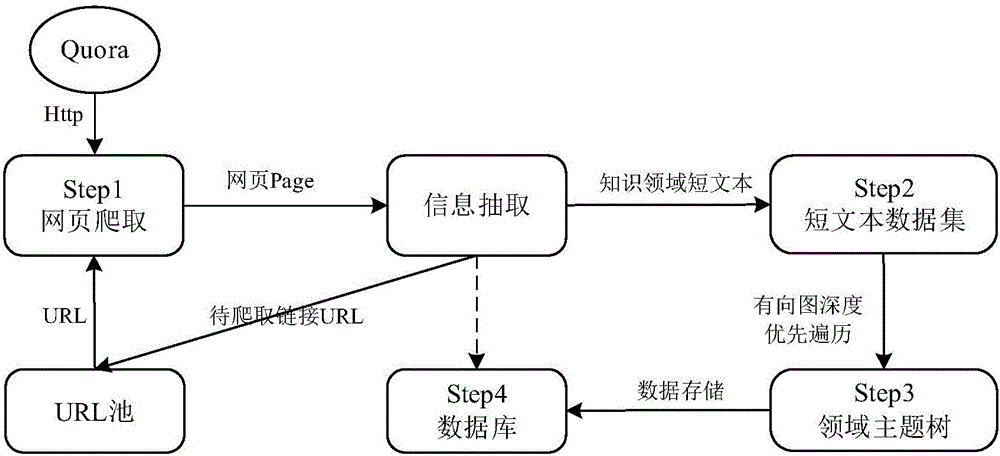

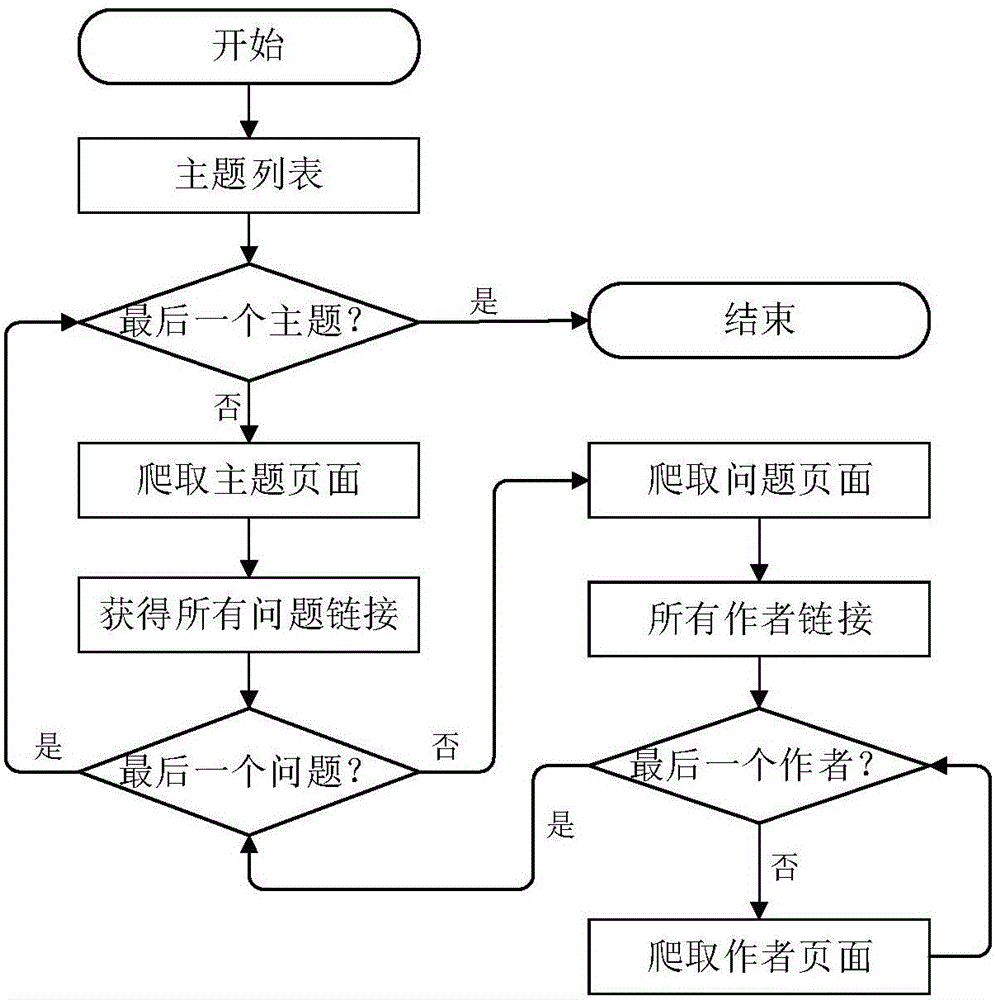

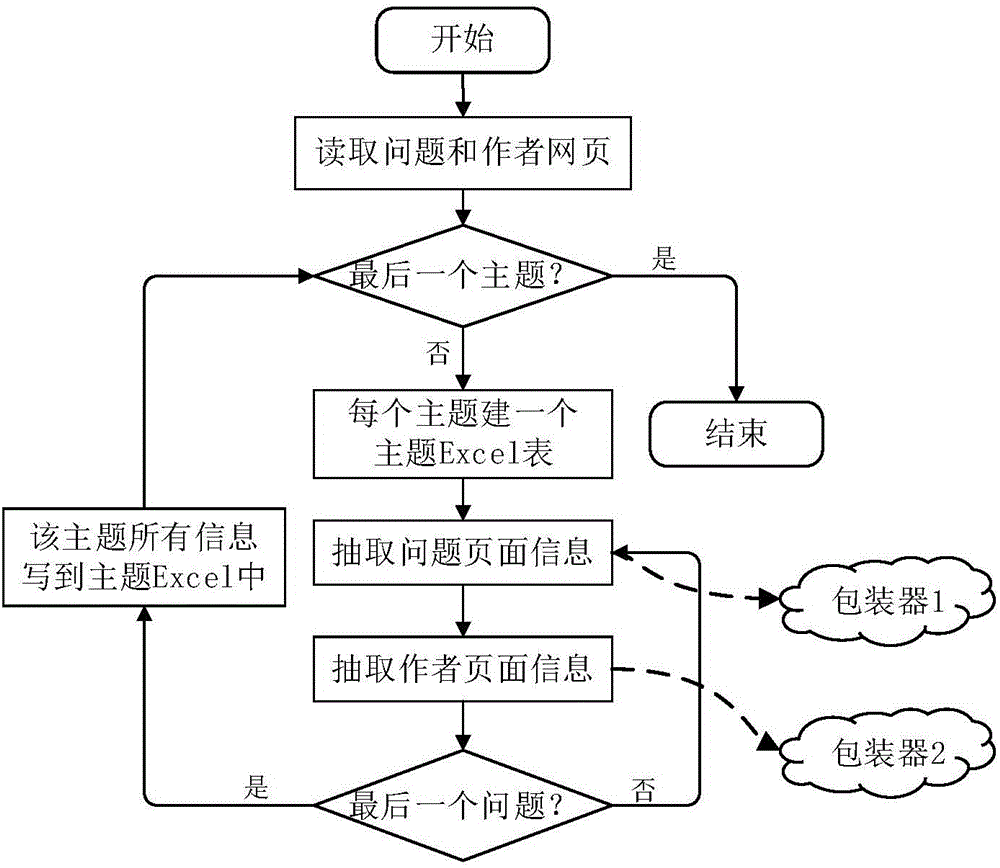

Method for automatically obtaining short text of knowledge domain from community question-and-answer website

ActiveCN105760514AImplement storageEasy to learnWeb data indexingSpecial data processing applicationsData setSemi-structured data

The invention provides a method for automatically obtaining short text of the knowledge domain from a community question-and-answer website.Question-and-answer web pages and author web pages of each subject of the domain corresponding to the knowledge domain can be crawled from the community question-and-answer website, a system with comprehensive data is obtained, and learning and using of a user are convenient.The method comprises the following steps that 1, a Web page of the knowledge domain in the community question-and-answer website is crawled; 2, short text, with concentrated web page data, of the knowledge domain is extracted; 3, a domain subject tree is constructed; 4, storing of the domain subject tree is conducted.By means of the method, the short text of the knowledge domain can be automatically extracted from semi-structured data of the community question-and-answer website, the question-and-answer web pages and the author web pages of each subject of the domain corresponding to the knowledge domain are crawled from the community question-and-answer website, a web page data set of the knowledge domain is constructed, the short text of the knowledge domain is automatically extracted from the web page data set, and parent child relationships are found, so that the domain subject tree is constructed, storing of the domain subject tree is achieved, and learning and using of the user are convenient.

Owner:XI AN JIAOTONG UNIV

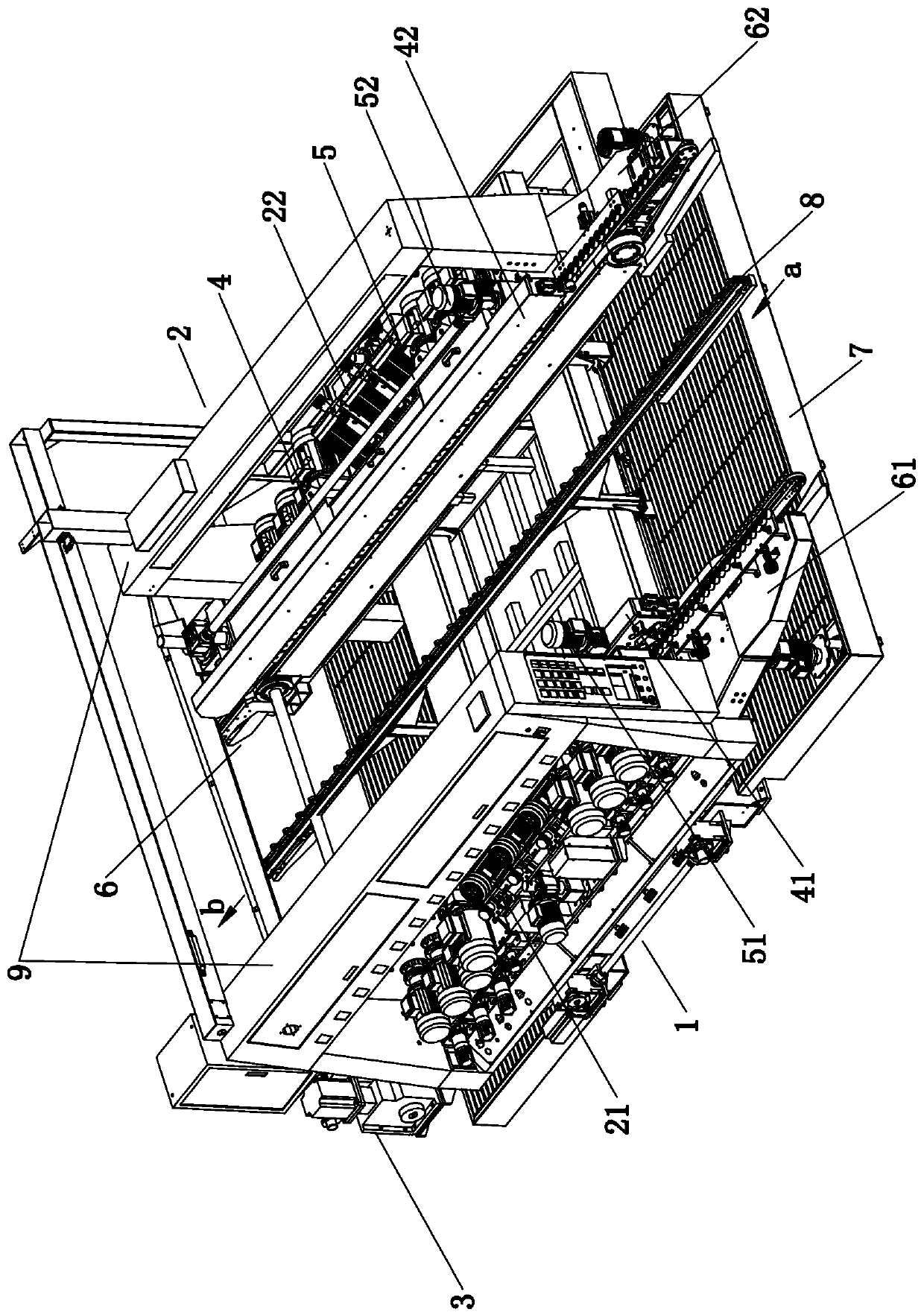

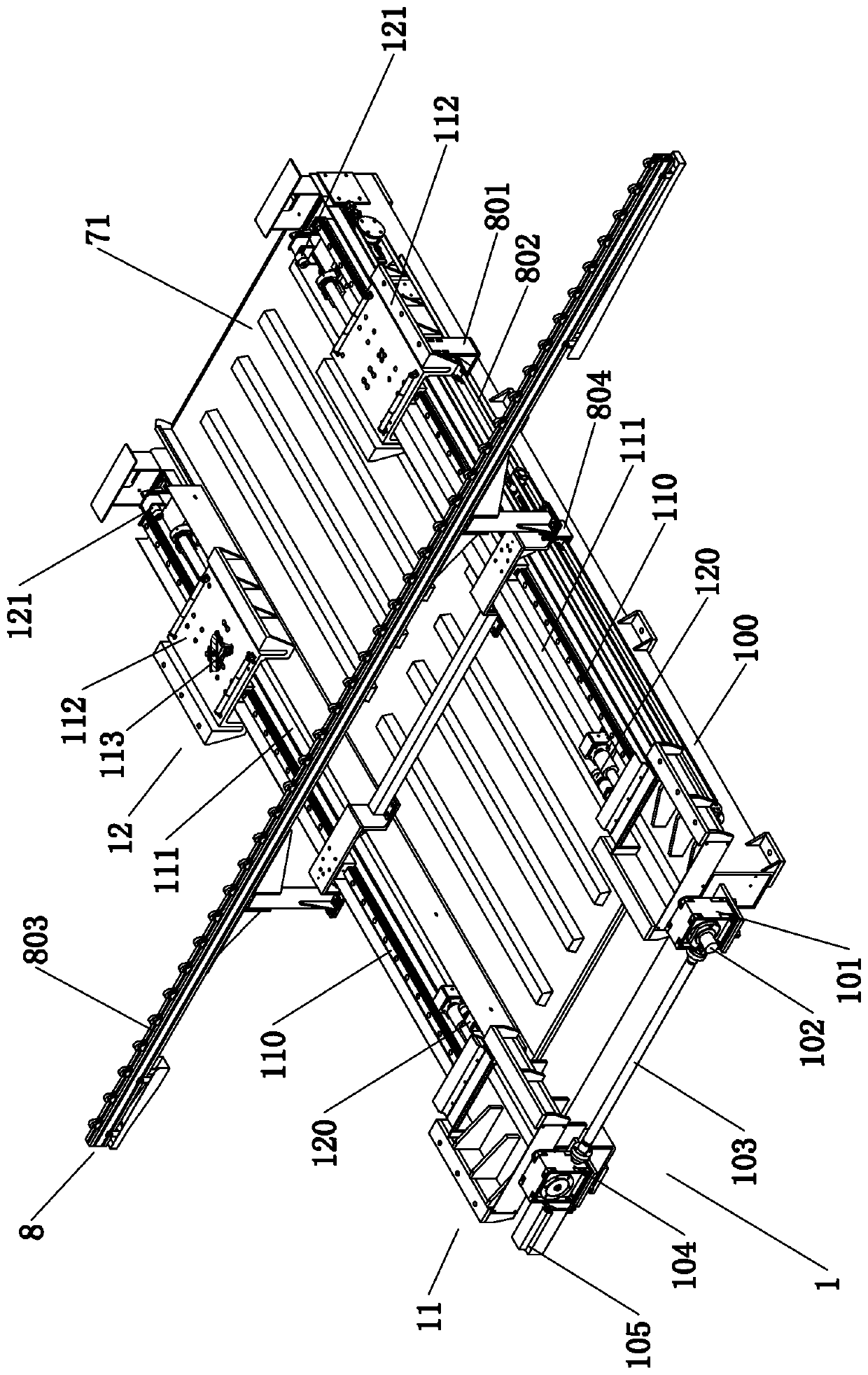

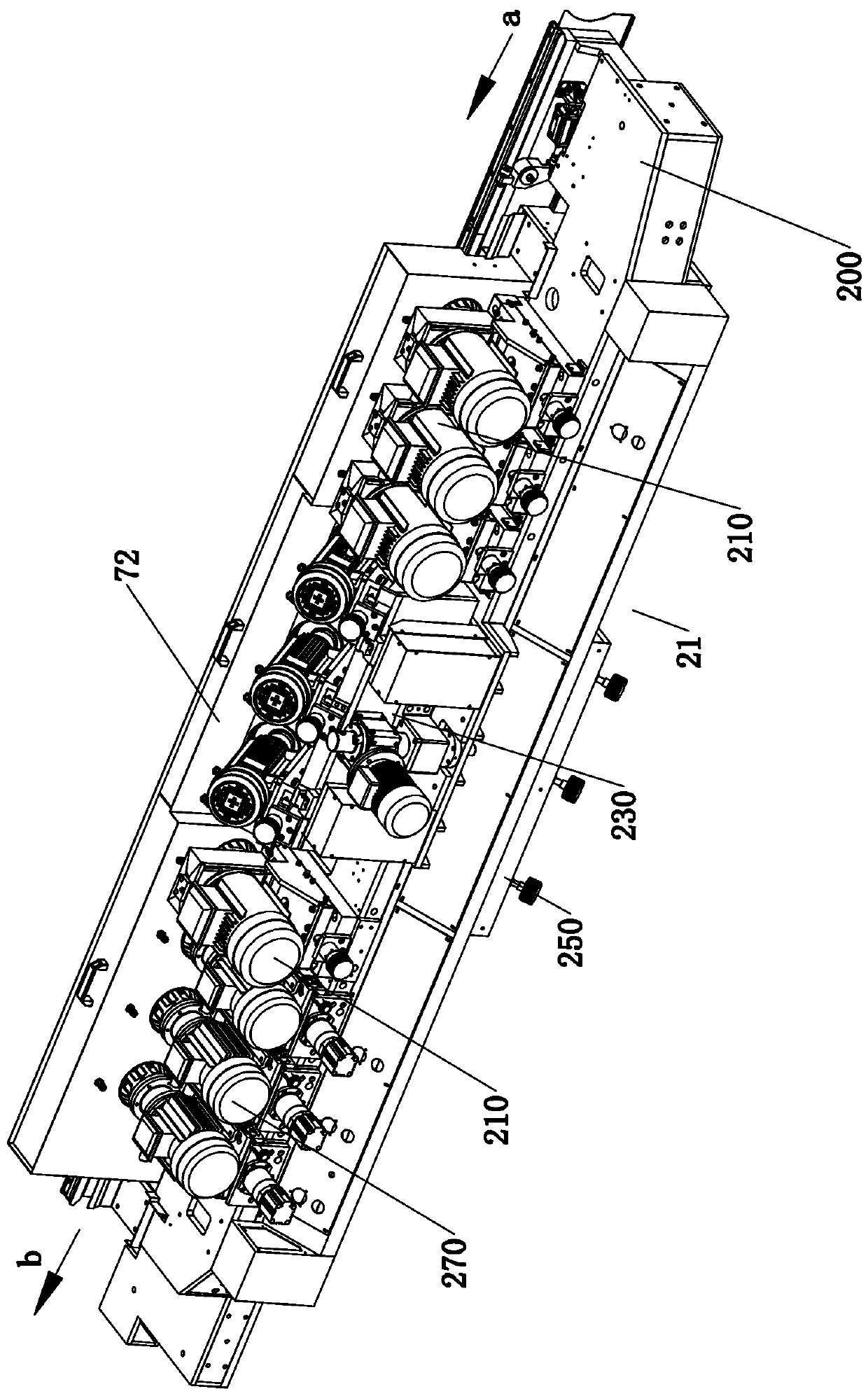

Horizontal-type high-speed fine grinding linear double-edge edge grinding machine for glass

PendingCN109909834AGuaranteed synchronicityGuaranteed repeat positioning accuracyEdge grinding machinesGrinding/polishing safety devicesPipe fittingMobile end

The invention relates to a horizontal-type high-speed fine grinding linear double-edge edge grinding machine for glass. A box body grinding wheel group arranging mechanism is installed on a machine tool body opening and closing mechanism, the front end and the back end of the box body grinding wheel group arranging mechanism are provided with the feeding end and the discharging end respectively, and the left end and the right end of the machine tool body opening and closing mechanism are provided with the fixed end and the moving end; a main transmission mechanism, a compressing frame mechanism, a compressing frame lifting mechanism and an electric cabinet control mechanism are arranged on the box body grinding wheel group arranging mechanism separately, a feeding and discharging guiding mechanism is arranged between the feeding end and the discharging end of the box body grinding wheel group arranging mechanism, and an automatic central bracket mechanism is arranged on the machine tool body opening and closing mechanism, located between the fixed end and the moving end and located in the middle of the box body grinding wheel group arranging mechanism; and a cooling water circulating system is provided with two ground water tanks, and the two ground water tanks are arranged at the feeding end and the discharging end separately and communicate with each other through a pipe fitting. According to the horizontal-type high-speed fine grinding linear double-edge edge grinding machine for the glass, the machining efficiency is high, the standby time is shortened, and meanwhile the grinding and polishing quality of the glass edge is improved.

Owner:广东高力威机械科技有限公司

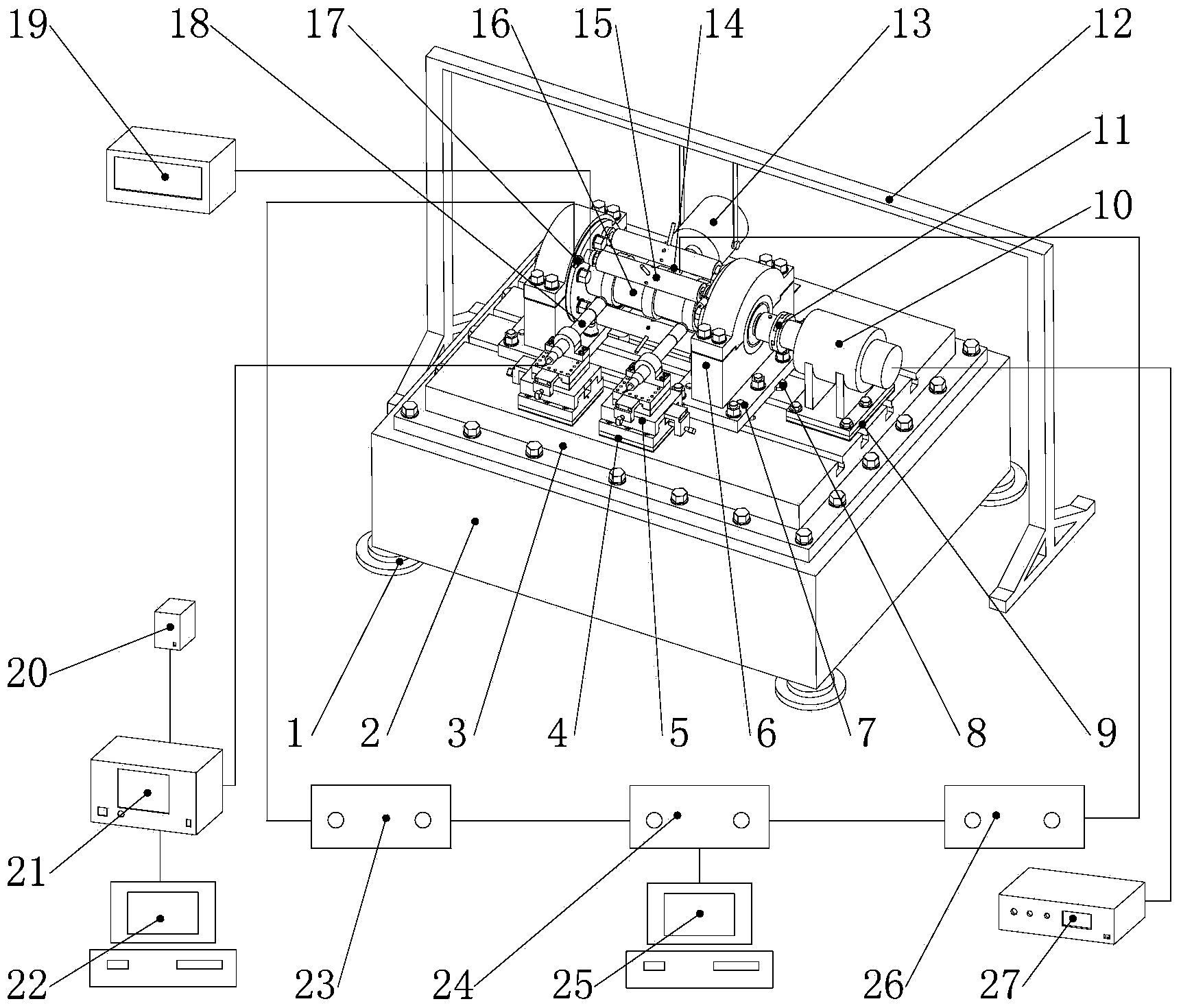

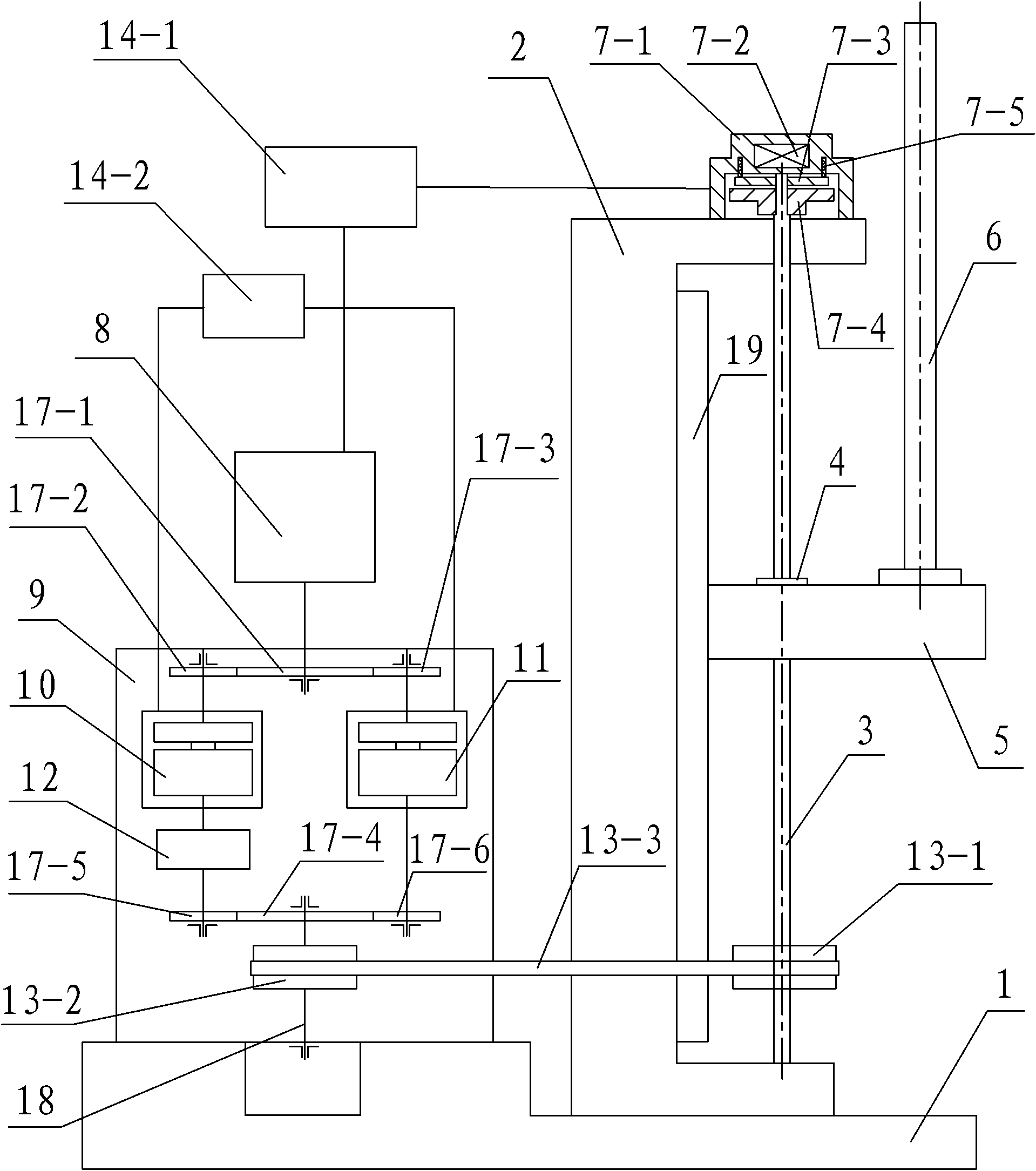

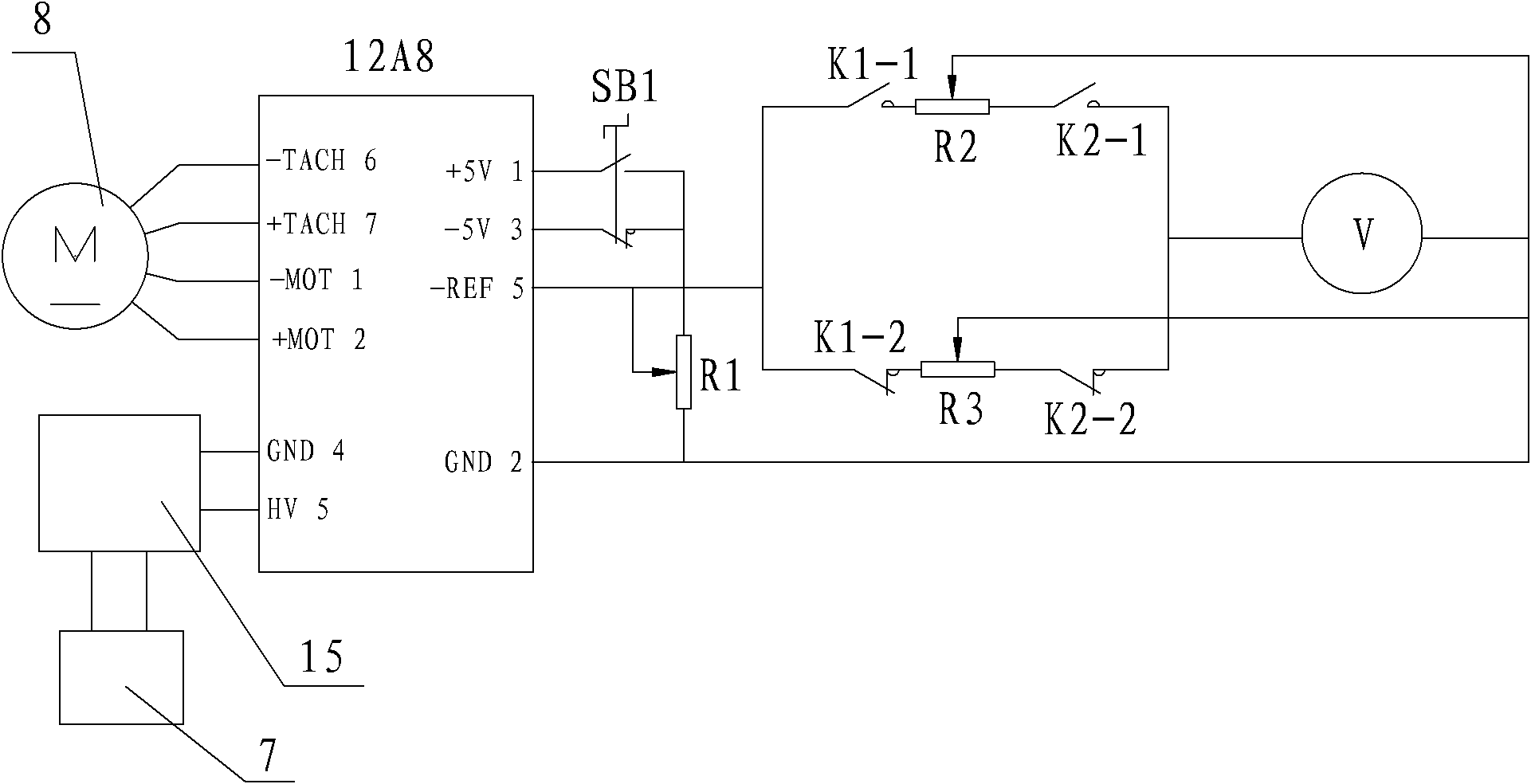

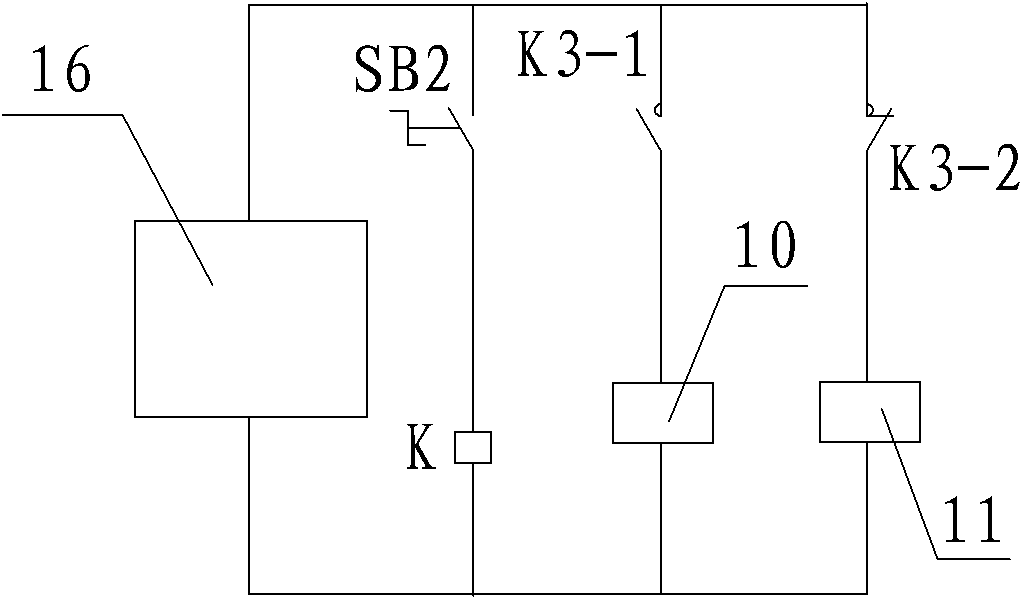

Angular contact ball bearing dynamic parameter tester

The invention relates to an angular contact ball bearing dynamic parameter tester, comprising leveling sizing blocks, an experiment platform, a T-shaped substrate, a displacement meter IPN (interpenetrating polymer network) damping plate, displacement meter supports, location cylindrical pins, guide flat keys, a motor IPN damping plate, a direct current motor, a TS-B elastic coupler, an exciter support, an exciter, an impedance head, an axial loading mechanism, a bearing assembly, accelerator sensors, optical pens, a CHB digital readout instrument, a 24-V direct current power supply, a CCS controller, a computer provided with CCSManager software, a signal conditioner, a data collector, a computer provided with CRAS software, a power amplifier and a motor speed regulator. Compared with the prior art, the angular contact ball bearing dynamic parameter tester has the obvious advantages that the device is simple in structure, higher in positioning precision and test precision, capable of testing dynamic parameters of a bearing under different rotary speeds and different axial load work conditions and strong in universality, and can be used for testing the dynamic parameters of bearings of different dimension series.

Owner:NANJING UNIV OF SCI & TECH

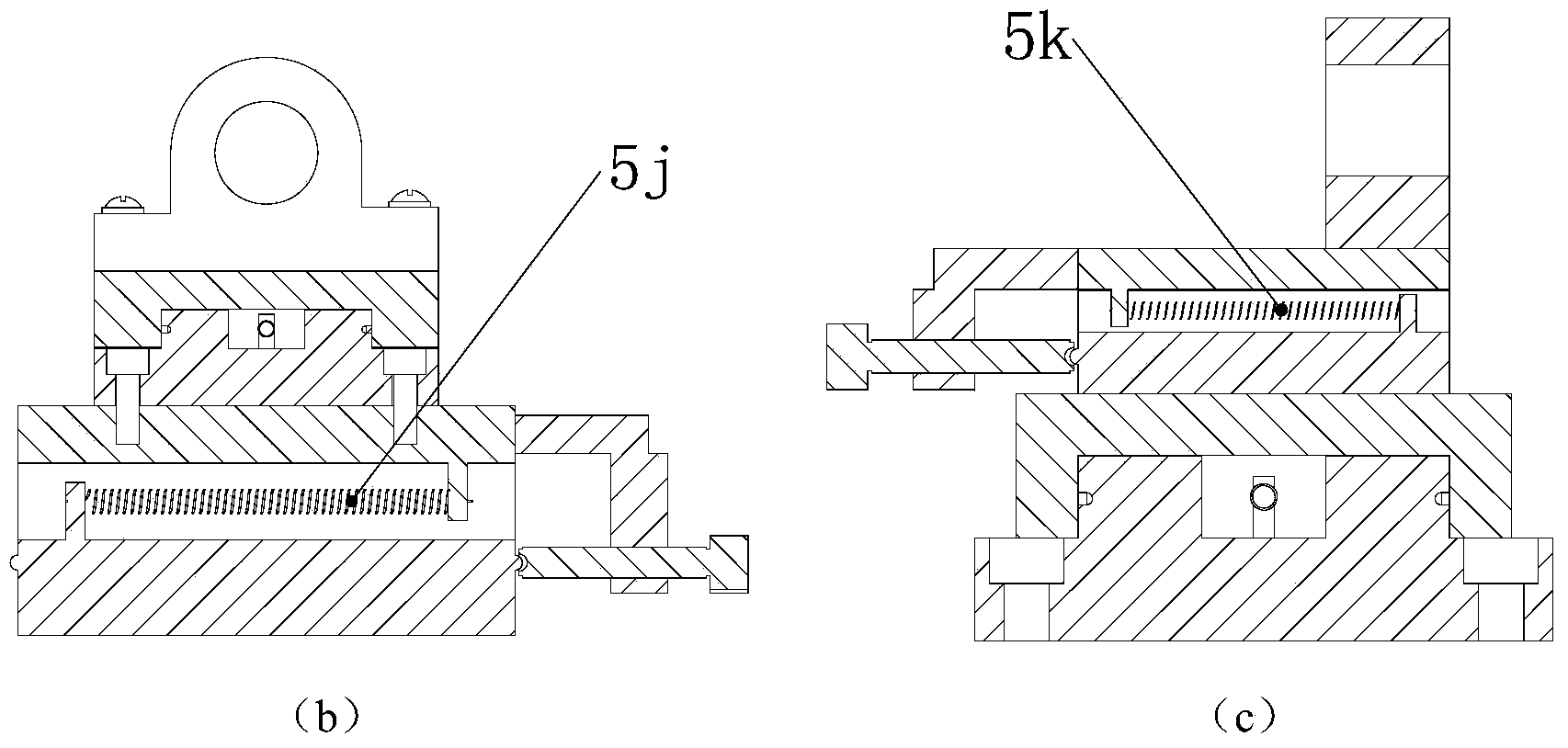

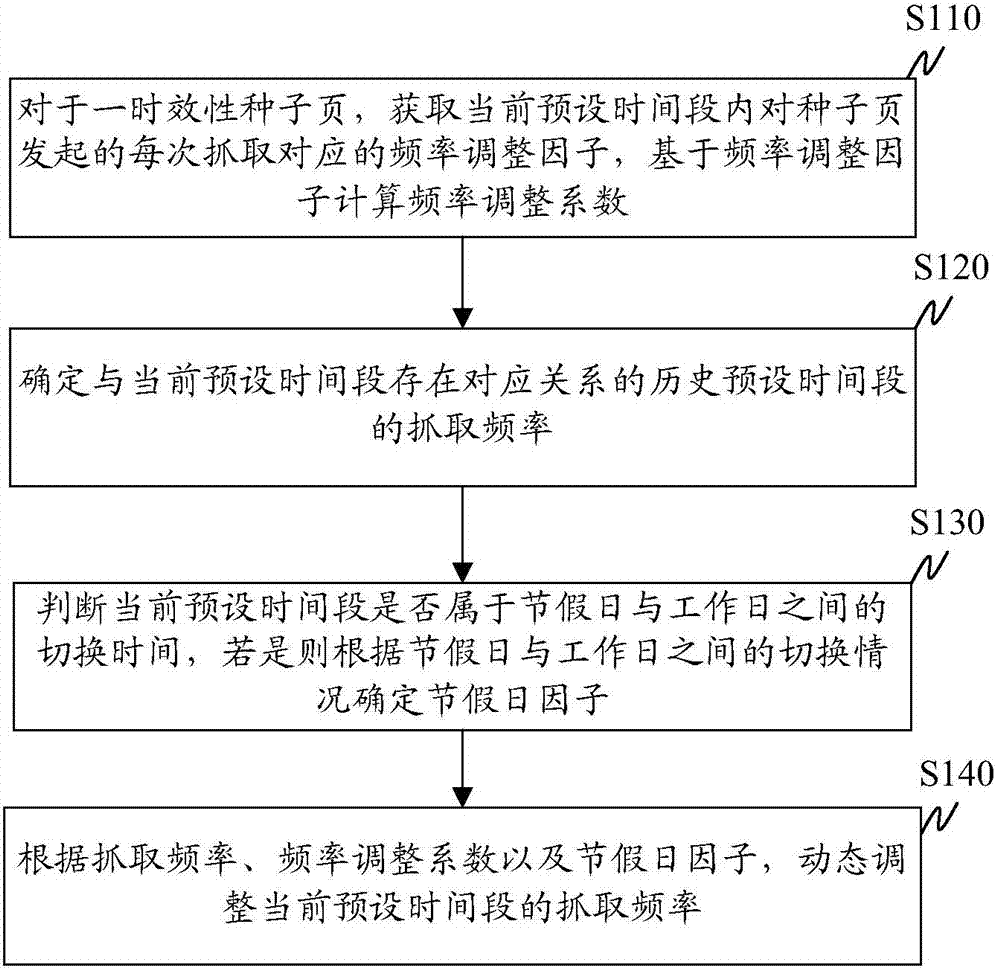

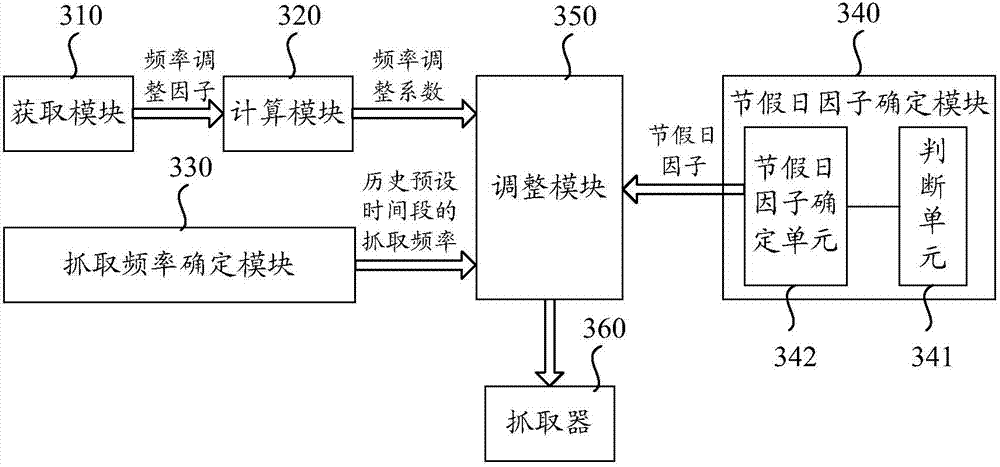

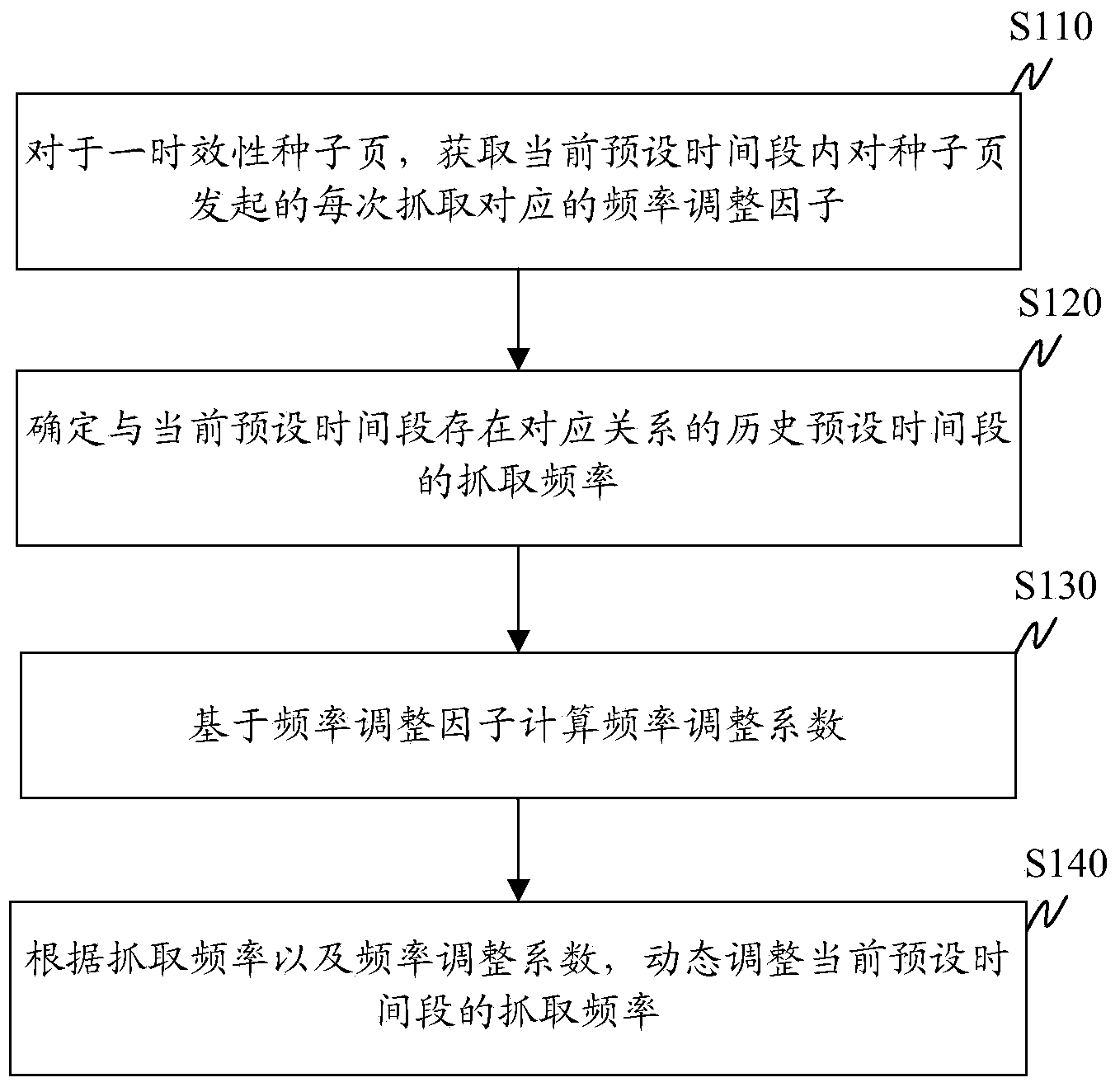

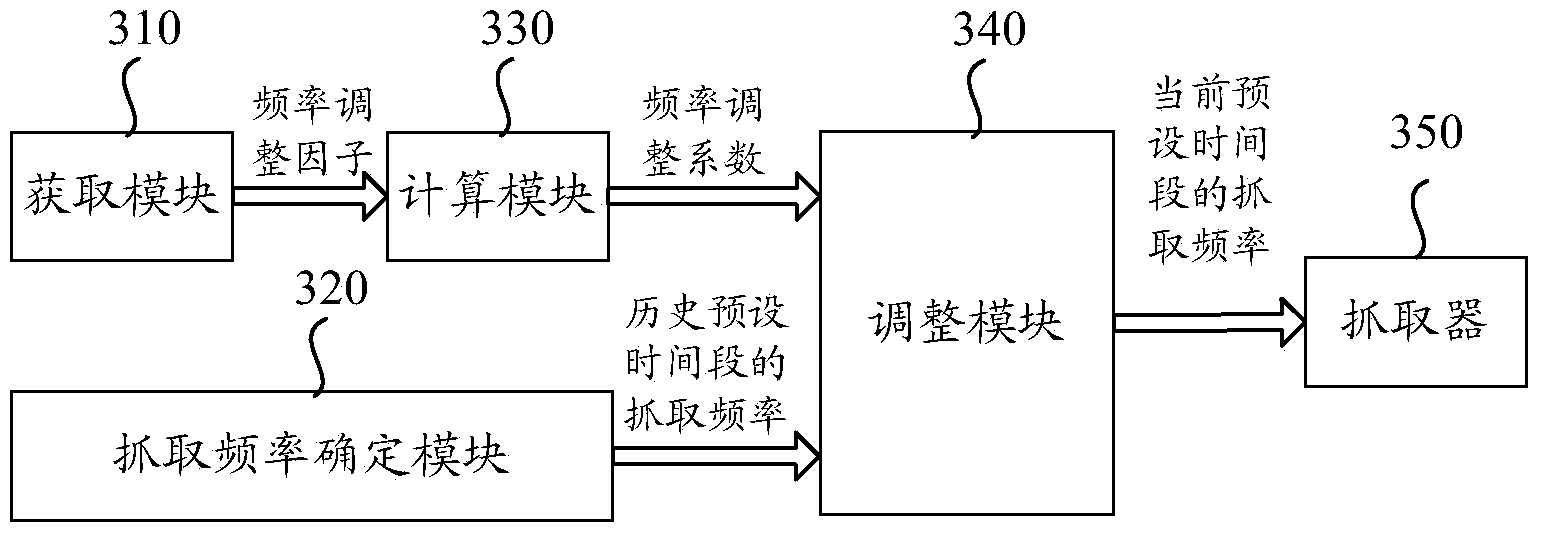

Method and device for grabbing timeliness seed page

InactiveCN103617264AReduce crawlingImprove accuracySpecial data processing applicationsSwitching timeFrequency regulation

The invention discloses a method and device for grabbing a timeliness seed page. The method comprises the steps that for the timeliness seed page, a frequency regulation factor corresponding to grabbing conducted on the seed page every time within the current preset time period is obtained; a frequency regulation coefficient is calculated based on the frequency regulation factors; the grabbing frequency of the historical preset time period corresponding to the current preset time period is determined; whether the current preset time period belongs to the switching time between holidays and working days or not is judged, and if yes, the holiday factor is determined according to the switching situation of the holidays and working days; the grabbing frequency within the current preset time period is dynamically regulated according to the grabbing frequency, the frequency regulation coefficient and the holiday factor. According to the method and device for grabbing the timeliness seed page, the holiday factor and the grabbing frequency can be dynamically regulated, unnecessary grabbing rate of the seed page is reduced, and new links can be found timely and will not be lost.

Owner:BEIJING QIHOO TECH CO LTD +1

Imaging device performing color image data processing

InactiveUS20090122166A1Reduce crawlingTelevision system detailsColor signal processing circuitsColor imageImaging equipment

A color image sensor has a first, second, and third color component pixels. The third color component pixel includes more intensity information than the first and second color component pixels. A difference estimating section estimates difference in a signal level exerted on a pixel signal of the third color component pixel, using the pixel signal of a pixel peripheral to the third color component pixel. A correcting section corrects the pixel signal of the third color component pixel on the basis of the estimated difference. Accordingly, when the third color component is green in a Bayer array, a pixel signal of a green pixel in a row of red pixels becomes equal to the pixel signal of a green pixel in a row of blue pixels. Therefore, line crawling can be suppressed without smoothing an image.

Owner:NIKON CORP

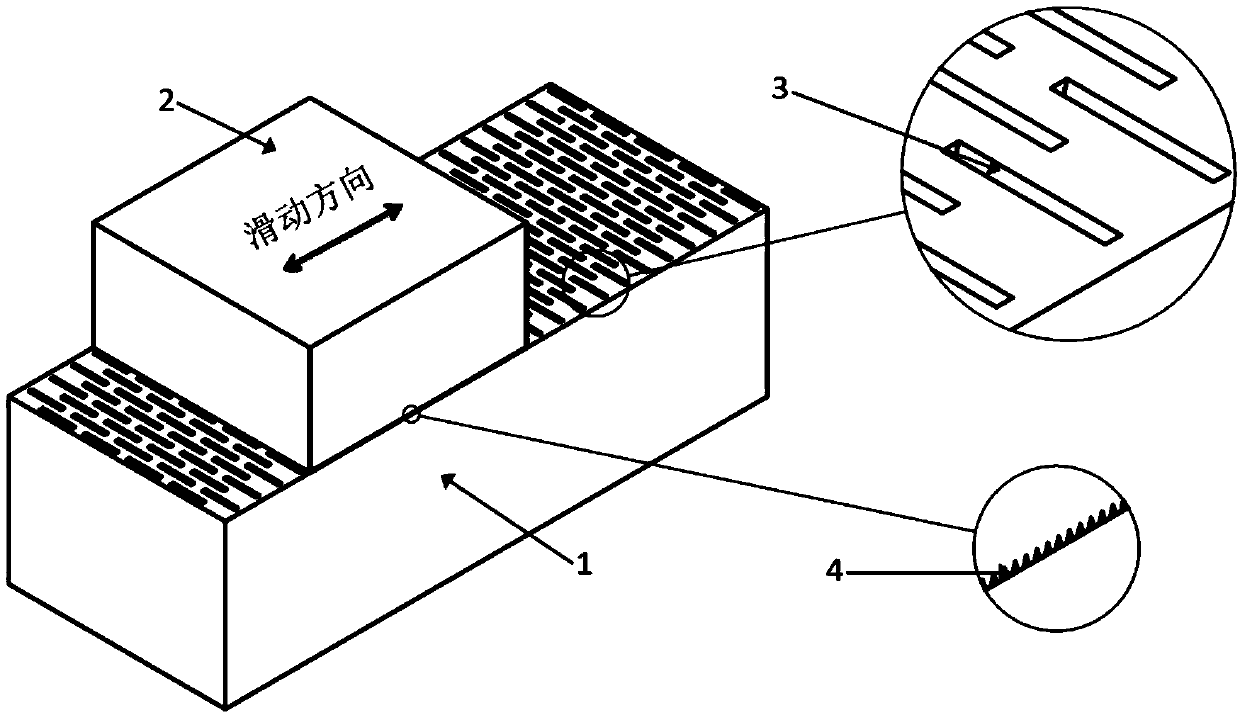

Micro-nano composite texture guide rail and preparation method thereof

ActiveCN109514277AImprove low-speed performancePrevent leakageLarge fixed membersMicro nanoReciprocating motion

The invention belongs to the surface treatment technology for machine tool guide rails, and particularly relates to a micro-nano composite texture guide rail and a preparation method thereof. The micro-nano composite texture guide rail comprises a fixed guide rail and a sliding guide rail, the fixed guide rail is located below the sliding guide rail, and the sliding guide rail can do reciprocatingmotion relative to the fixed guide rail. Multiple micro-texture grooves perpendicular to the sliding direction are formed in the surface, in contact with the sliding guide rail, of the fixed guide rail, and the micro-texture grooves are arranged evenly in a staggered manner. Correspondingly, multiple nano-texture grooves perpendicular to the sliding direction are formed in the surface, in contactwith the fixed guide rail, of the sliding guide rail, and the nano-texture grooves penetrate through the surface of the sliding guide rail. According to the micro-nano composite texture guide rail, the micro-texture grooves perpendicular to the sliding direction are formed in the fixed guide rail of the guide rail, lubricating oil can be stored, and grinding scraps can be collected; and the nano-texture grooves perpendicular to the sliding direction are formed in the sliding guide rail, forming of a lubricating oil film is facilitated, and therefore the functions of enhancing lubricating, reducing friction and improving the performance of the guide rail are achieved.

Owner:SHANDONG UNIV

Micro-injection pump

ActiveCN111420166AIncrease amplitudeReduces the impact of motion precisionMedical devicesPressure infusionUltrasonic sensorElectric machine

The invention provides a micro-injection pump. The micro-injection pump comprises: a base; a mounting structure which is used for mounting an injector; a lead screw which is rotationally assembled onthe base; a motor of which the output shaft is in transmission connection with the lead screw; a guide structure which is arranged on the base; a moving block which is matched with the guide structure, is in threaded connection with the lead screw at the same time and does reciprocating rectilinear motion under the action of a lead screw nut mechanism, wherein the moving block is used for pushinga plunger rod of the injector to perform injection operation; an ultrasonic transducer which is fixed on the moving block; and an amplitude pole, wherein one end of the amplitude pole is connected tothe ultrasonic transducer, and the other end abuts against the plunger rod of the injector. The ultrasonic transducer is used for converting input electric power into mechanical waves, and the amplitude pole is used for improving the amplitude of the mechanical waves and transmitting the mechanical waves to the plunger rod, so that a plunger at the end of the plunger rod generates reciprocating vibration. Friction force between the plunger and the injector cavity is kinetic friction force all the time and has small friction coefficient, the influence of the friction force on the movement precision of the plunger is reduced, and the feeding precision of the plunger is improved.

Owner:HENAN UNIV OF SCI & TECH

Method for gathering newly hatched silkworms from parent silkworms

The invention discloses a method for gathering newly hatched silkworms from parent silkworms. In the period from taking of an original strain out of a storehouse to gathering of the newly hatched silkworms, the temperature, the humidity and the light condition of silkworm egg embryos in different developmental stages are adjusted, so that the newly hatched silkworms are hatched by the same level; two technical links of sweeping and weighing prior to gathering of the newly hatched silkworms are eliminated, so that both labor and time are saved, the method is simple and convenient to operate, inconvenience in weighing operation caused by the fact that the silkworms are extremely small and the crawling capacity is high is avoided, the damage to newly hatched silkworm bodies due to inappropriate operation of the newly hatched silkworm gathering method or over-exertion is reduced, and potential safety hazards of low cocoon production amount are avoided; the operation steps are reduced, so that the newly hatched silkworm gathering time is greatly shortened, the newly hatched silkworms can be prevented from hunger, and the physical health of the newly hatched silkworms is improved; meanwhile, the attack probability of contagious silkworm diseases is reduced, so that the disease resistance of the parent silkworms is improved, spreading of pebrine viruses is effectively controlled or reduced, and non-toxic silkworm eggs are produced; the loss caused by the pebrine viruses of the original strain in the whole breeding batch of a silkworm raiser is reduced.

Owner:GUIZHOU SERICULTURE RES INST GUIZHOU PEPPER RES INST

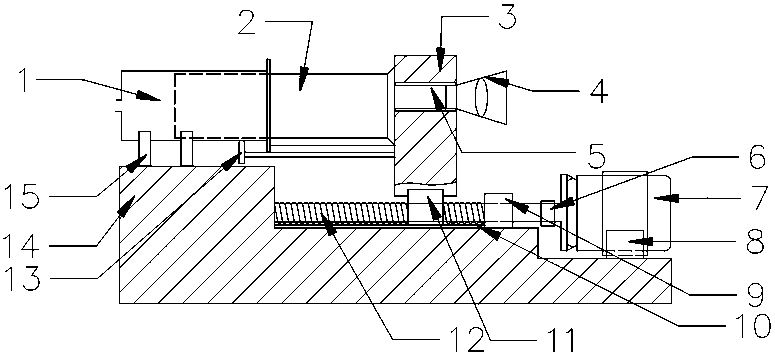

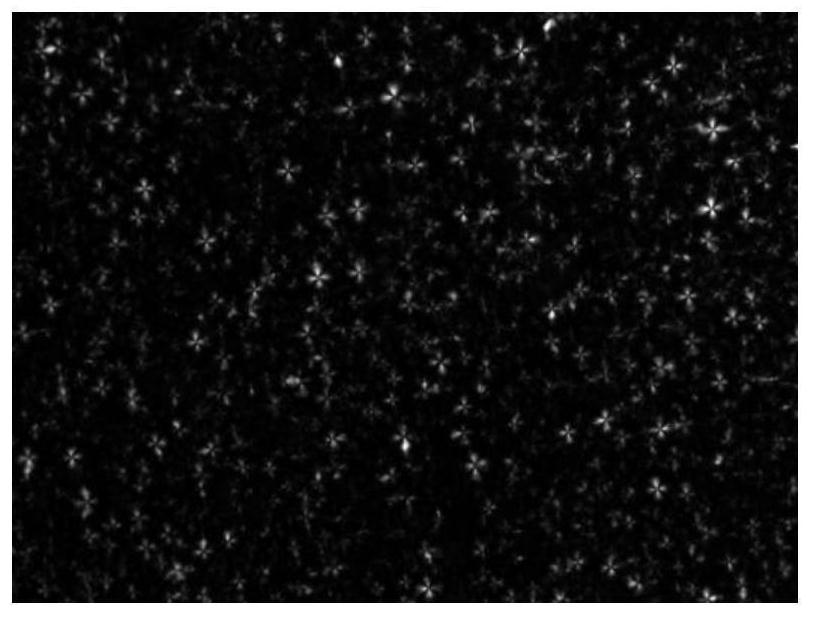

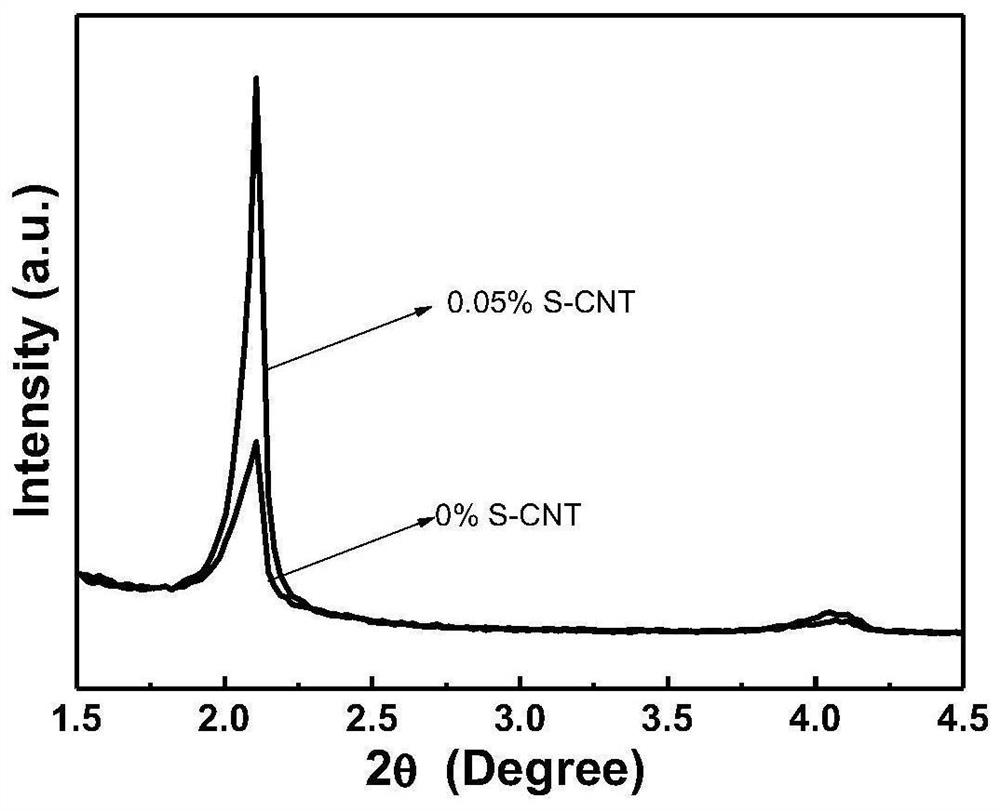

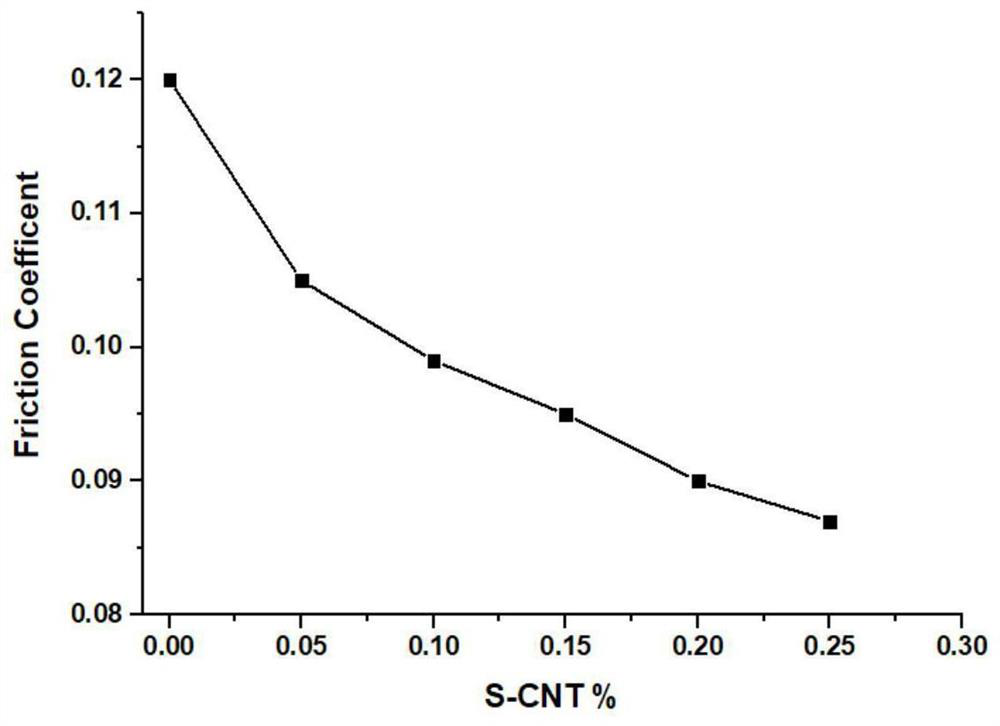

Modified carbon nanotube ionic liquid layered liquid crystal lubricant and preparation method thereof

ActiveCN111876223AGood dispersionImprove the lubrication effectLubricant compositionModified carbonIonic liquid

The invention relates to a modified carbon nanotube ionic liquid layered liquid crystal lubricant and a preparation method thereof. The lubricant with anti-creeping performance is prepared by compounding stearyl alcohol modified carbon nanotubes and ionic liquid layered liquid crystals. In the invention, the stearyl alcohol modified carbon nanotube is introduced into the ionic liquid layered liquid crystal, so that the dispersity and lubricity of the carbon nanotube are improved, and meanwhile, the problems of creeping and leakage in the use process of the lubricant are also solved to a certain extent; the modified carbon nanotube ionic liquid layered liquid crystal lubricant prepared by the invention is a semi-liquid semi-solid lubricant, achieves better balance in friction reduction, wear resistance and anti-creeping performance, and can be applied to lubrication of balls, pin rollers, bearing rings and the like.

Owner:郑州宏润科技股份有限公司

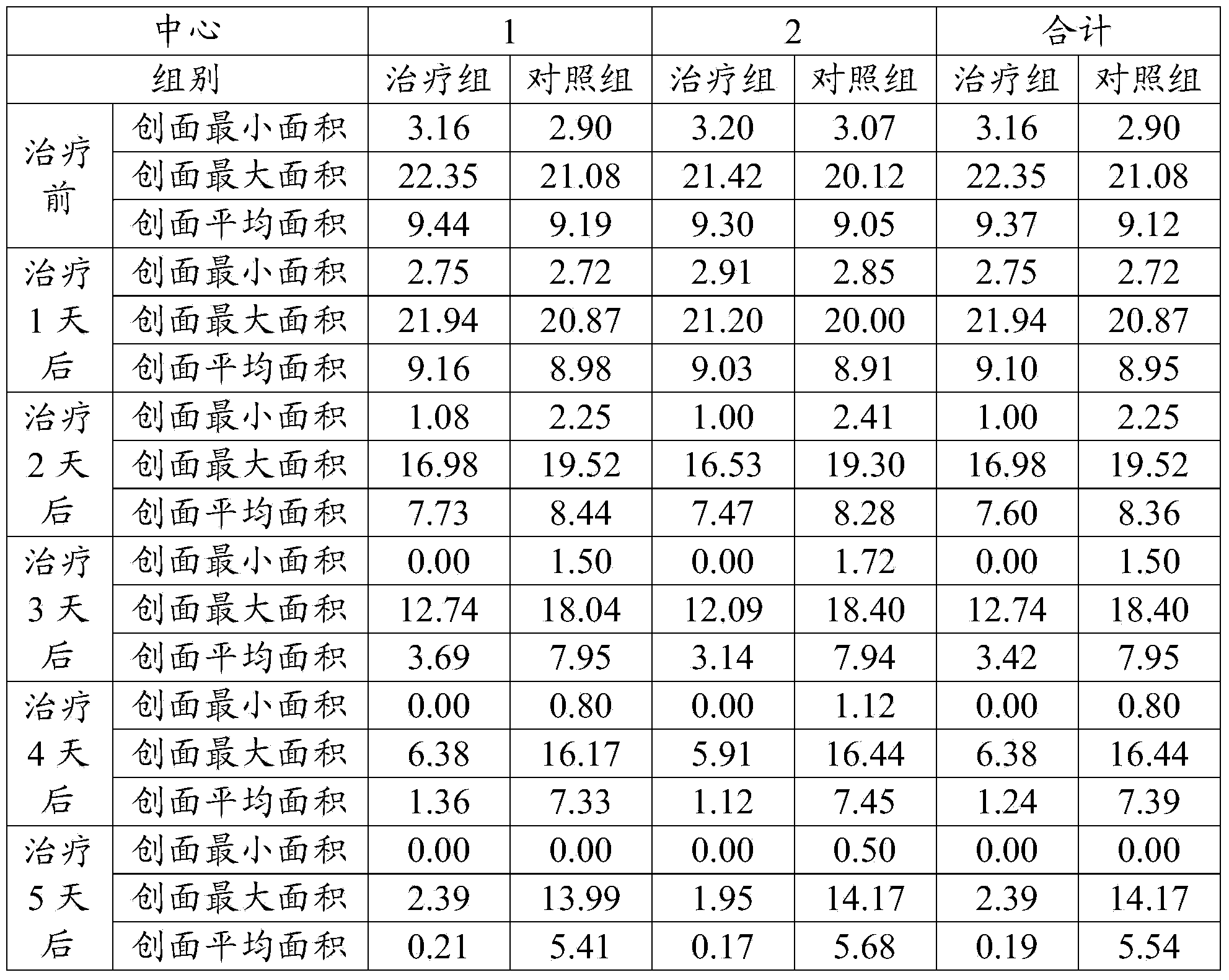

Composition capable of promoting wound healing and reducing scarring

InactiveCN103520708AEasy to reorganizeEasy to crawlPeptide/protein ingredientsPharmaceutical non-active ingredientsHypopigmentationIrritation

The invention discloses a composition capable of promoting wound healing and reducing scarring. The composition comprises the following components in percentage by weight: 5-9 percent of carbomer, 1-5 percent of tea tree oil, 0.0001-0.0009 percent of recombinant human epidermal growth factors, and 10-20 percent of glycerinum. The composition can effectively regulate the moisture content of dynamic cells in different environments, does not have irritation or sensitization response, can inhibit wound bacterial reproduction, is advantageous to growth of wound capillary vessels, can promote subcutaneous collagen growth and fibrous tissue recombination, can promote creeping of epithelial cells, can shorten the time of wound healing, has the effects of diminishing inflammation and stopping bleeding, relieving pains and protecting wound, repairing wounds and skin ulcer. The composition has repairing and healing effects on face mild-moderate acnes and injuries caused by laser treatment, can reduce the scarring, prevents hyperpigmentation, and improves healing quality.

Owner:易金阳

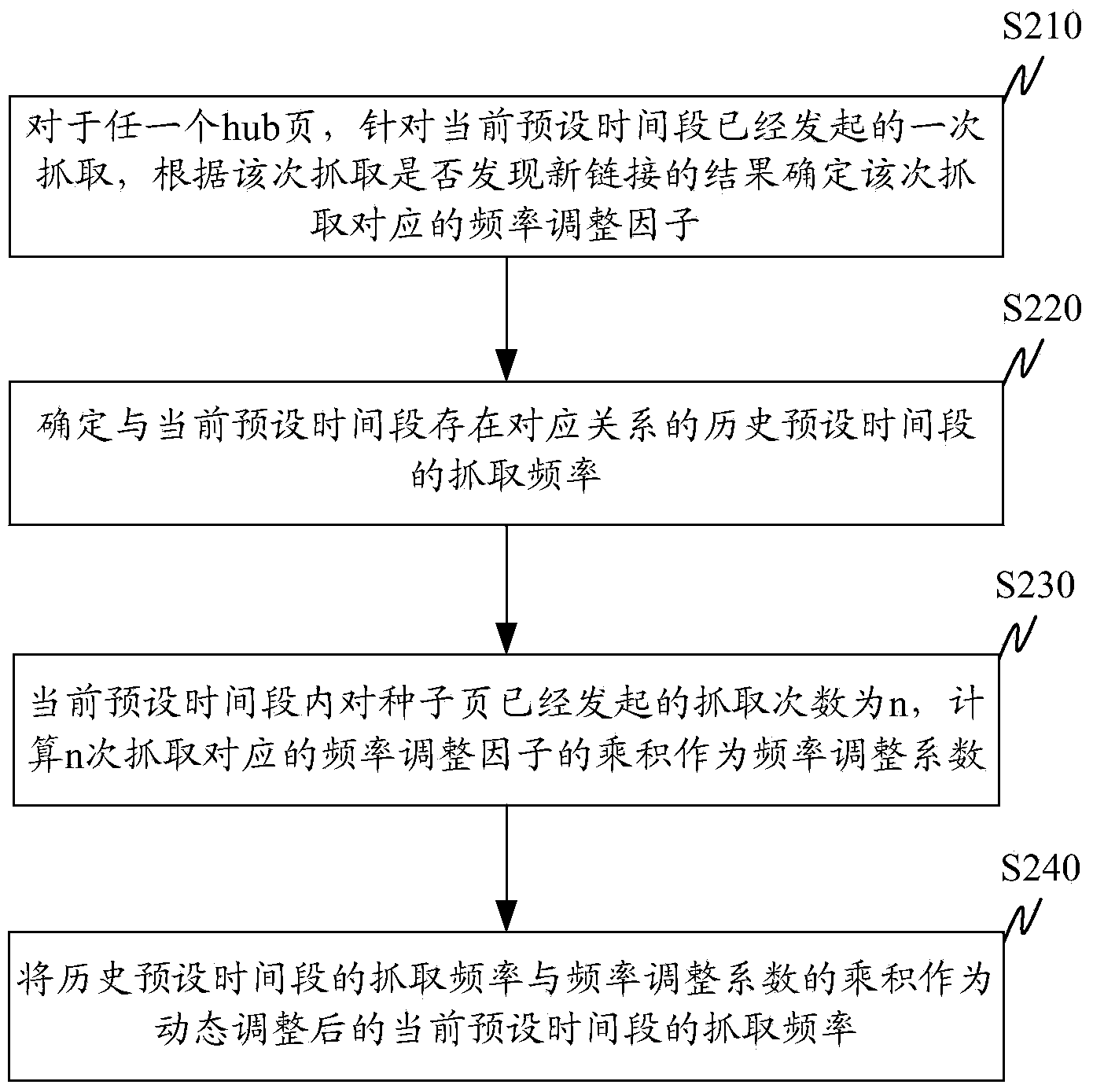

Capturing method and capturing device for timeliness seed page

InactiveCN103631919AReduce crawlingImprove accuracyWeb data retrievalSpecial data processing applicationsComputer science

Owner:BEIJING QIHOO TECH CO LTD +1

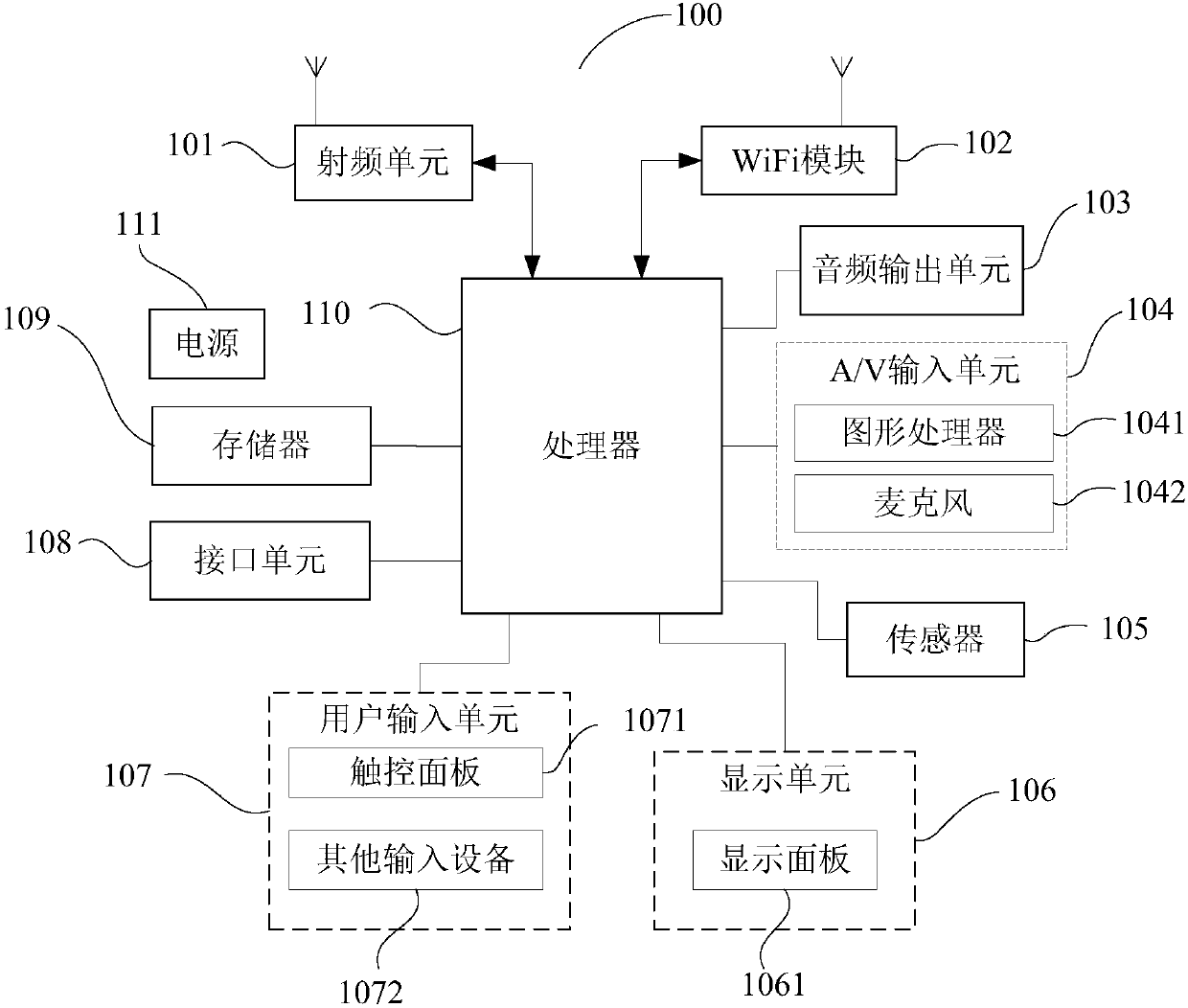

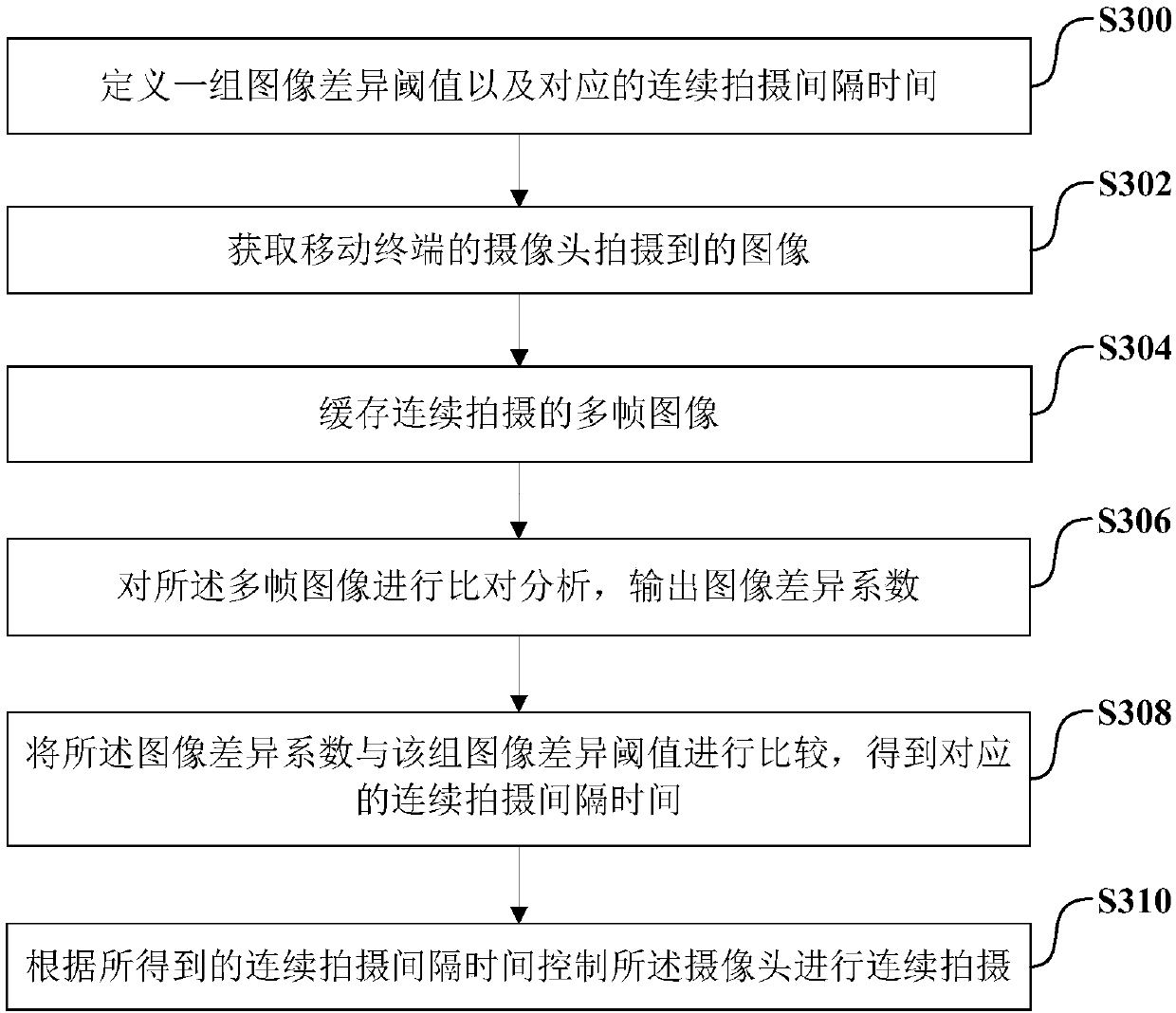

Continuous photographing method, mobile terminal and computer readable memory medium

InactiveCN107734259AAdd funReduce complexityTelevision system detailsColor television detailsComputer visionComputer graphics (images)

Owner:NUBIA TECHNOLOGY CO LTD

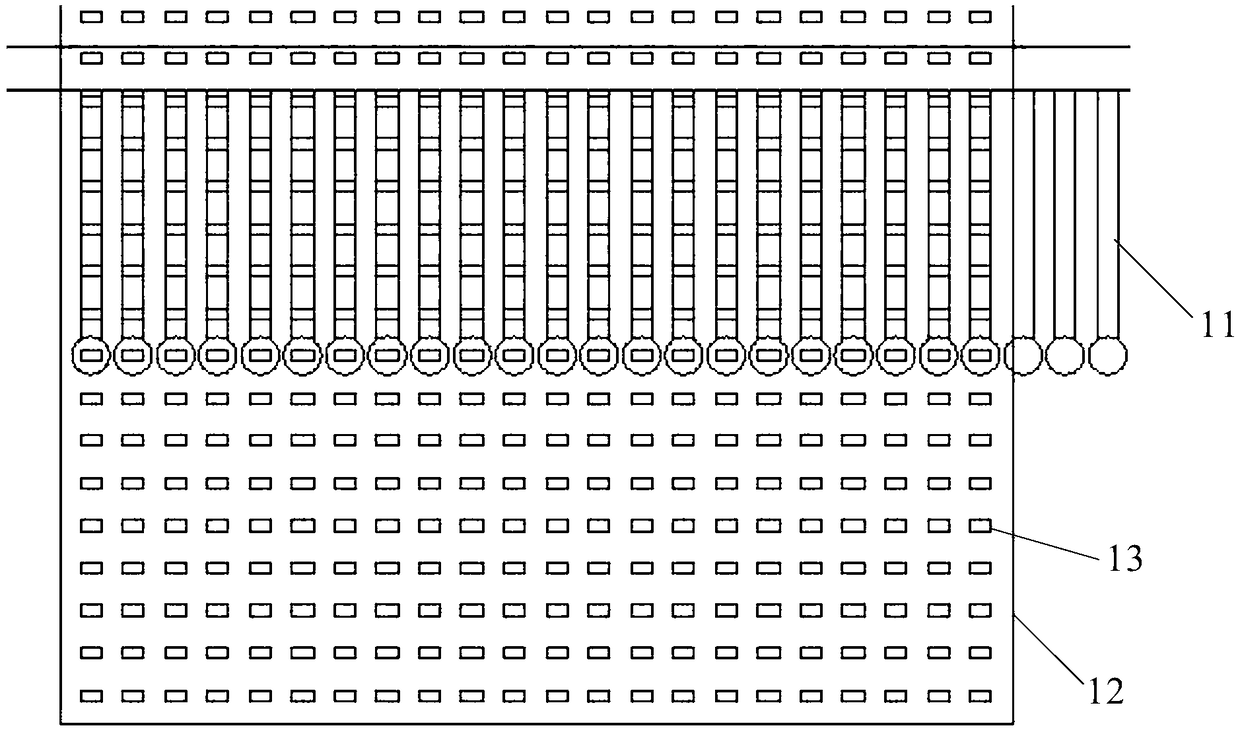

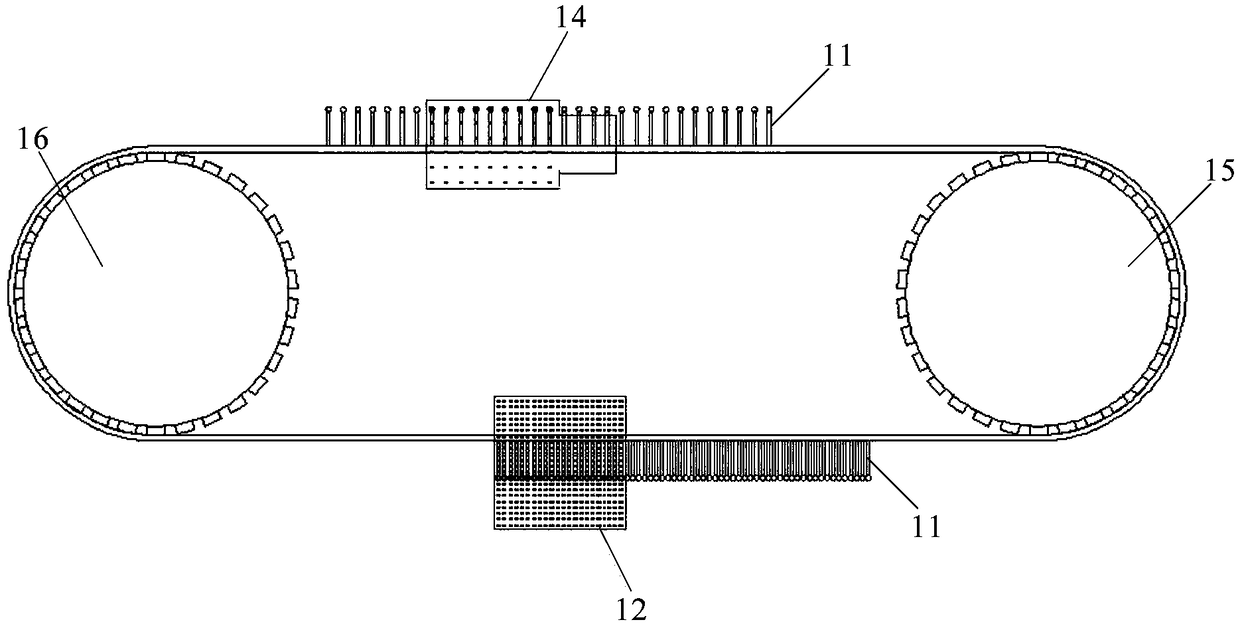

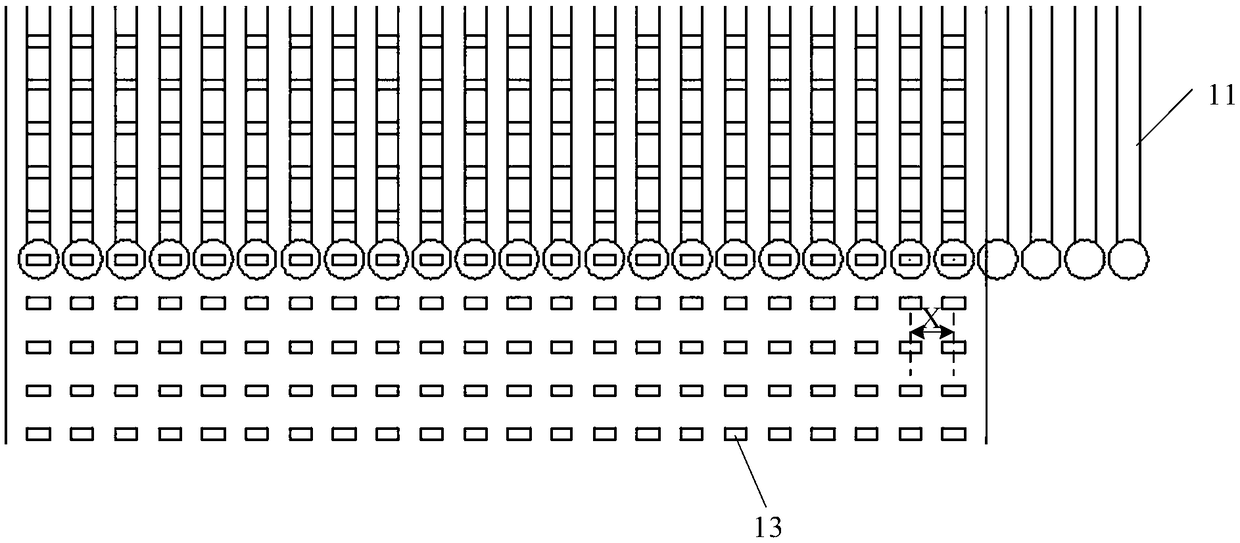

Beating device for surface light source and beating method thereof

The embodiment of the invention provides a beating device for a surface light source and a beating method thereof, and relates to the technical field of a backlight source. The problem that the surface light source has high cost and low mass production efficiency due to excessive transfer time is solved. The beating device comprises a gripping mechanism, the gripping mechanism comprises at least one gripping group, each gripping group comprises a plurality of gripping arms, and a plurality of the gripping arms in the same gripping group are used for simultaneously grasping a plurality of LED wafers from a crystal expansion plate and transferring a plurality of the LED wafers to a flexible circuit board; a stroke amplifying mechanism is used for amplifying spacing between the plurality of gripping arms of the LED wafers to make spacing between the adjacent two gripping arms match the spacing between positions to place the adjacent LED wafers on the flexible circuit board; a stroke reduction mechanism is used for reducing the spacing between the plurality of gripping arms which release the LED wafers, so that the spacing between the adjacent two gripping arms matches the spacing between the adjacent LED wafers in the plurality of LED wafers to be captured on the crystal expansion plate. The device is used for making the surface light source.

Owner:BOE TECH GRP CO LTD +1

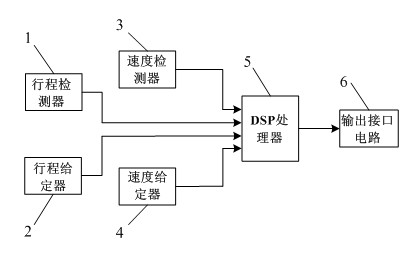

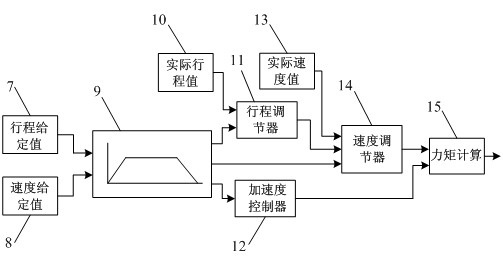

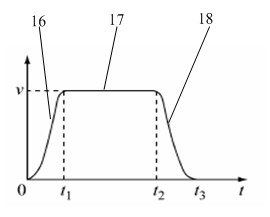

Three-stage speed setting mine hoist control method and device

A three-stage speed given mine hoist control method and device, the stroke detector, stroke giver, speed detector, and speed giver of the control device are all connected to the input end of a DSP processor; the DSP processor The output terminal of the hoist is connected with the hoist power control system through the output interface circuit. The control method uses the position detector to detect the stroke of the coal mine hoist winch, so that the controller can control the position of the hoist; the stroke detector is used to detect the stroke, and the speed detector is used to detect physical quantities such as lifting or lowering speed, and then the detected physical quantity Data sampling is carried out at the signal level loop summary, and the voltage data obtained after sampling is sent to the controller as the control basis. Advantages: This device adopts the three-stage speed given hoist control method with feedback within the stroke, which has fast lifting speed, high control precision, simple structure and convenient operation.

Owner:CHINA UNIV OF MINING & TECH +1

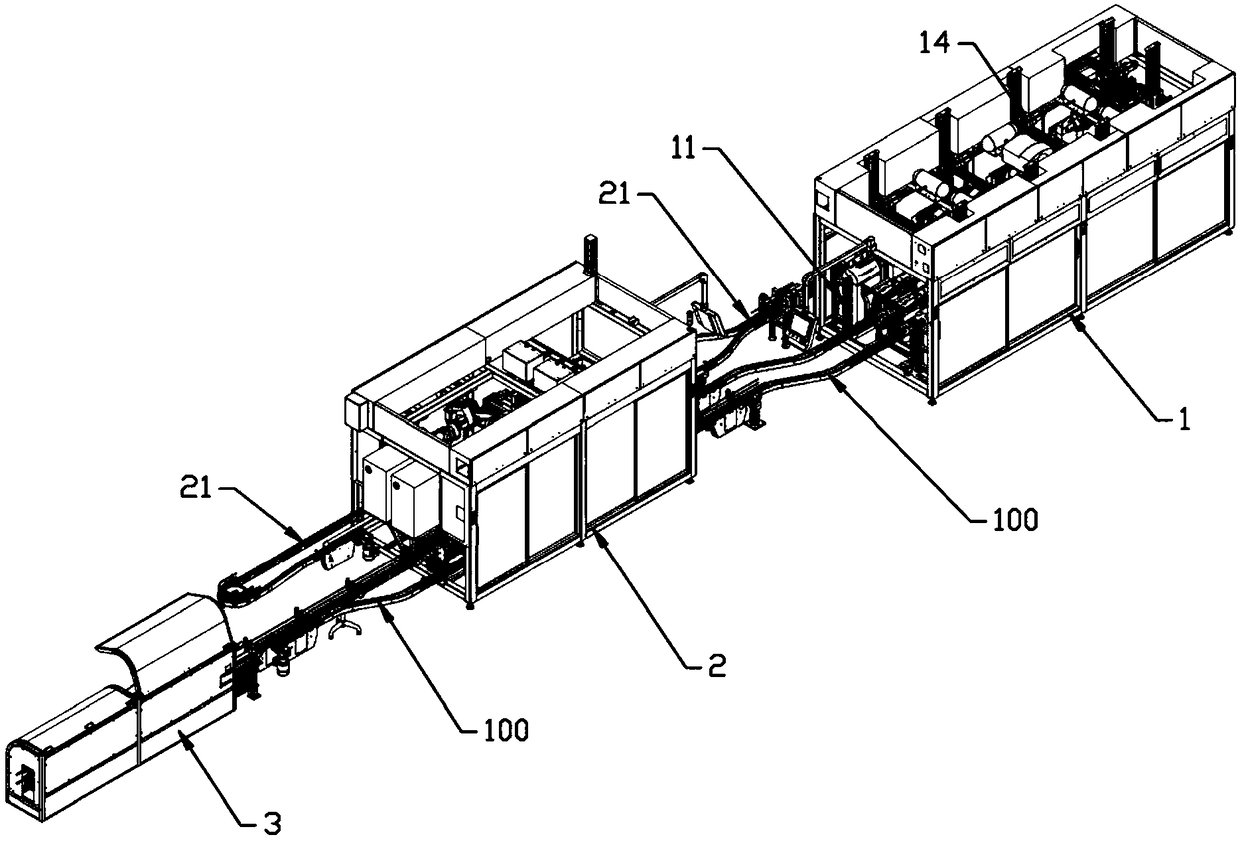

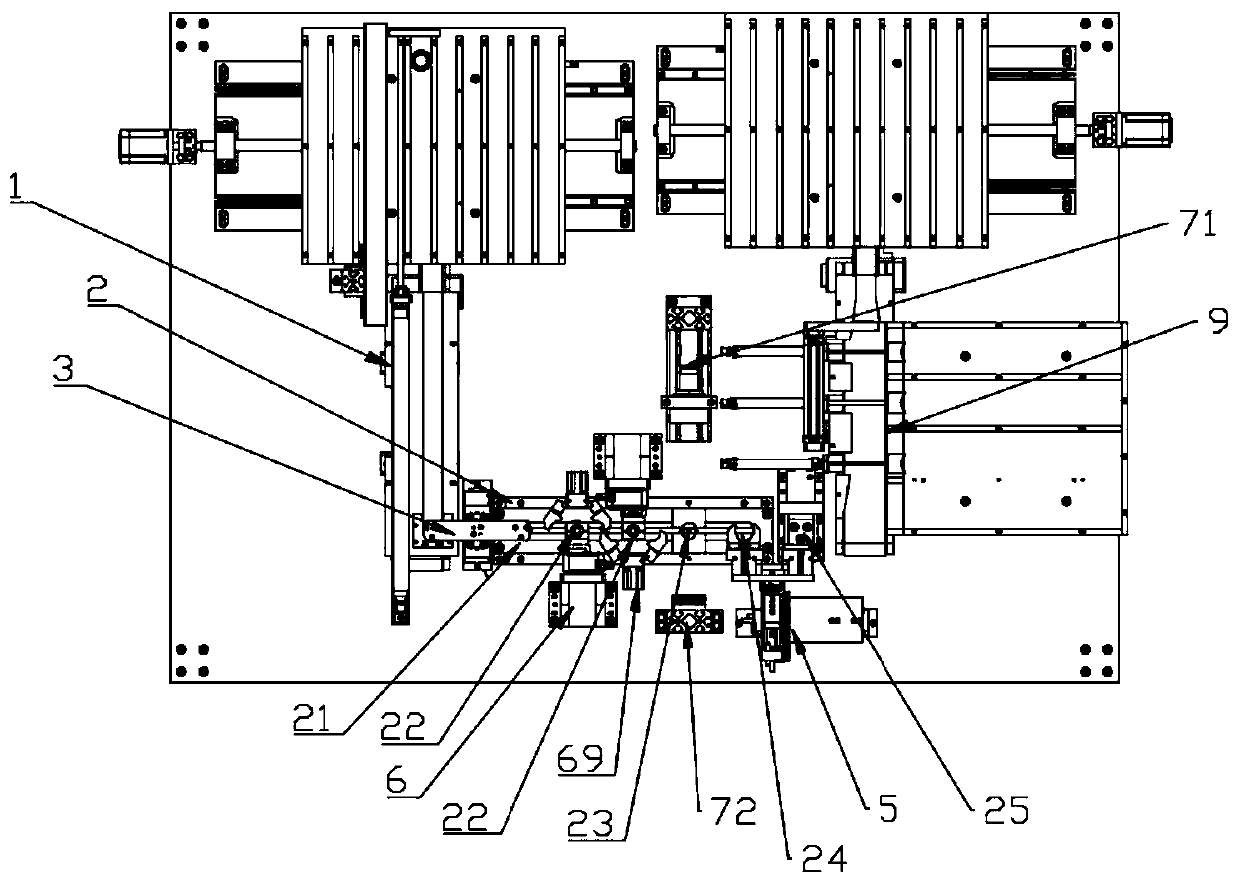

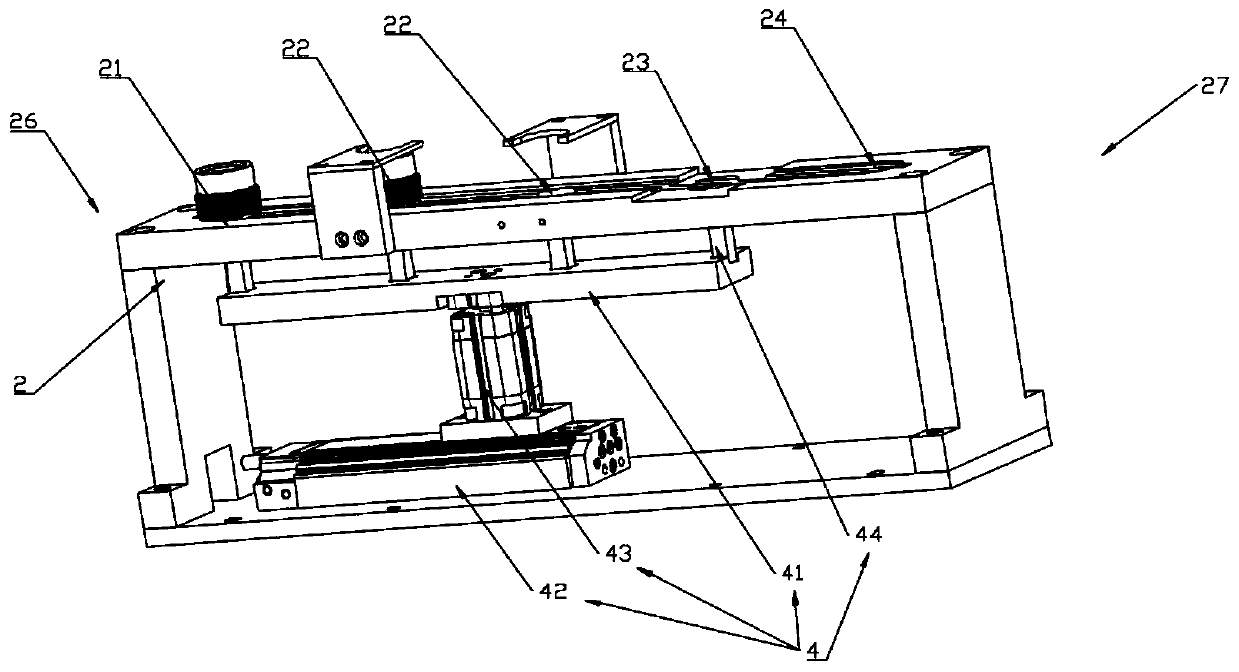

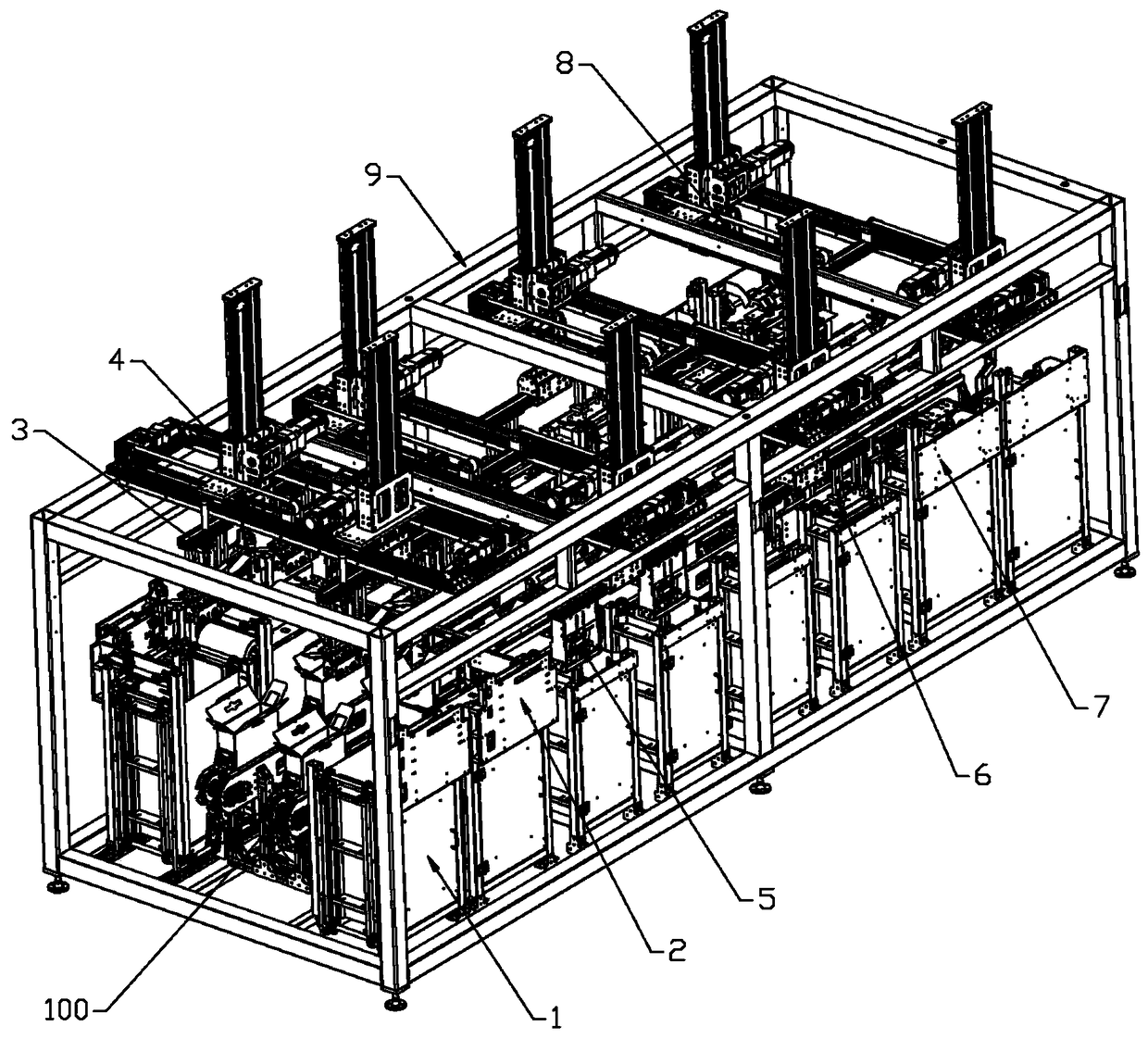

Robot automatic packaging system used for smiling face packets

The invention discloses a robot automatic packaging system used for smiling face packets. The robot automatic packaging system comprises a packaging box conveyor line (100). A box opening and partitioning machine (1), a boxing machine (2) and a cover buckling machine (3) are sequentially arranged in the conveying direction of the packaging box conveyor line (100). Three stations including a box opening station, a lower partition plate station and a side partition plate station or four stations including a box opening station, a lower partition plate station, a gasket station and a side partition plate station are sequentially arranged in the box opening and partitioning machine (1). After single-side milk packets on pre-integration conveyor lines (23) are grabbed to a milk packet integration line (25) through single-side bag grabbing and conveying devices (24) in the boxing machine (2) to be integrated into milk packet units, a robot drives flexible clamping apparatuses (29) to conductgrabbing and boxing; and packaging boxes obtained after boxing are conveyed to the cover buckling machine (3) to be subjected to cover buckling. The system is specially designed for automatic packaging of the milk packets of the smiling face packets, the structure is clear, actions are accurate, rapidness and high efficiency are achieved, and the system is rich in elasticity.

Owner:苏州澳昆智能机器人技术有限公司

Automobile steering device gear sleeve detection device

PendingCN110385278ARealize fully automatic full-scale inspectionReduce crawlingUsing optical meansUsing fluid meansConveyor beltGear wheel

The invention discloses an automobile steering device gear sleeve detection device which comprises an inlet conveying mechanism, a detection table, a first moving mechanism, a second moving mechanism,a third moving mechanism, an inner diameter detection structure, an outer diameter detection mechanism, a height detection mechanism and a separation mechanism. According to the automobile steering device gear sleeve detection device provided by the invention, through the cooperation of the inlet conveying mechanism, the separation mechanism and various detection equipment, the full-automatic full-size detection on a sleeve is realized, and no human intervention is needed, so that the detection efficiency is greatly improved, and the labor cost on detection is reduced; through the cooperationof a U-shaped block and a first conveyor belt conveying machine, a conveying path of a workpiece is ensured, and workpieces at the output end are located on the same position, so that the moving mechanisms can grab the workpieces; through the arrangement of a second ejecting mechanism, the sleeve can be helped to smoothly enter a storage mechanism; and in addition, the second ejecting mechanism adopts the cooperation of a rotary block and a limited block, one-way opening is realized, the use of an air cylinder is reduced, and the equipment cost is reduced.

Owner:HAERING PRECISION TAICANG CO LTD

Single-motor and wide-speed-regulation range crucible rod operation speed regulating system and speed regulation method

InactiveCN102220627AReduce manufacturing costSimple structureFrom frozen solutionsSpeed control systemNormal growth

The invention discloses a single-motor and wide-speed-regulation range crucible rod operation speed regulating system and a speed regulation method. The system comprises a base, a crucible rod operation device arranged on the top end of the base, a power and speed regulating system connected with the crucible rod operation device, and an operation and speed control system connected with the crucible rod operation device and the power and speed regulating system, wherein the power and speed regulating system comprises a direct-current speed measuring torque machine set and a speed regulating device which consists of two electromagnetic clutches, a harmonic wave reducer and a timing belt pulley 2. The method comprises the following step: calibrating a speedometer V before use; in a chargingstage, allowing the crucible rod to operate upward in an actually required quick operation speed direction; in a crystal normal growth section, allowing the crucible rod to operate downward in an actually required slow operation speed direction; and in a discharge stage, allowing the crucible rod to operate upward in the actually required quick operation speed direction. In the invention, the structure is simple, the design is reasonable, the speed regulation range is wide, the manufacturing cost is low, the use and operation are convenient and quick, and the promotion and use are convenient.

Owner:XIAN XIGUANG MACHINERY MFG

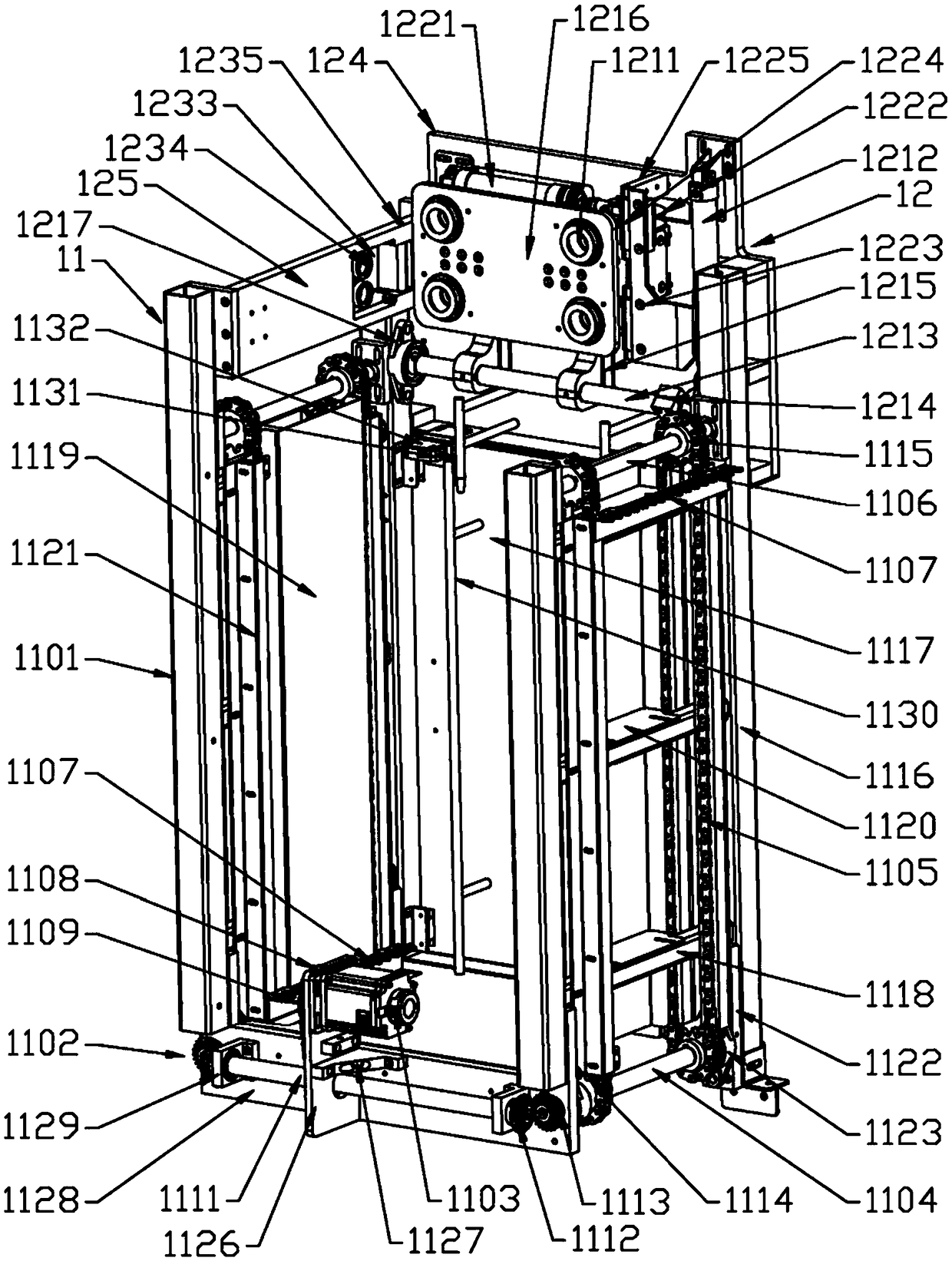

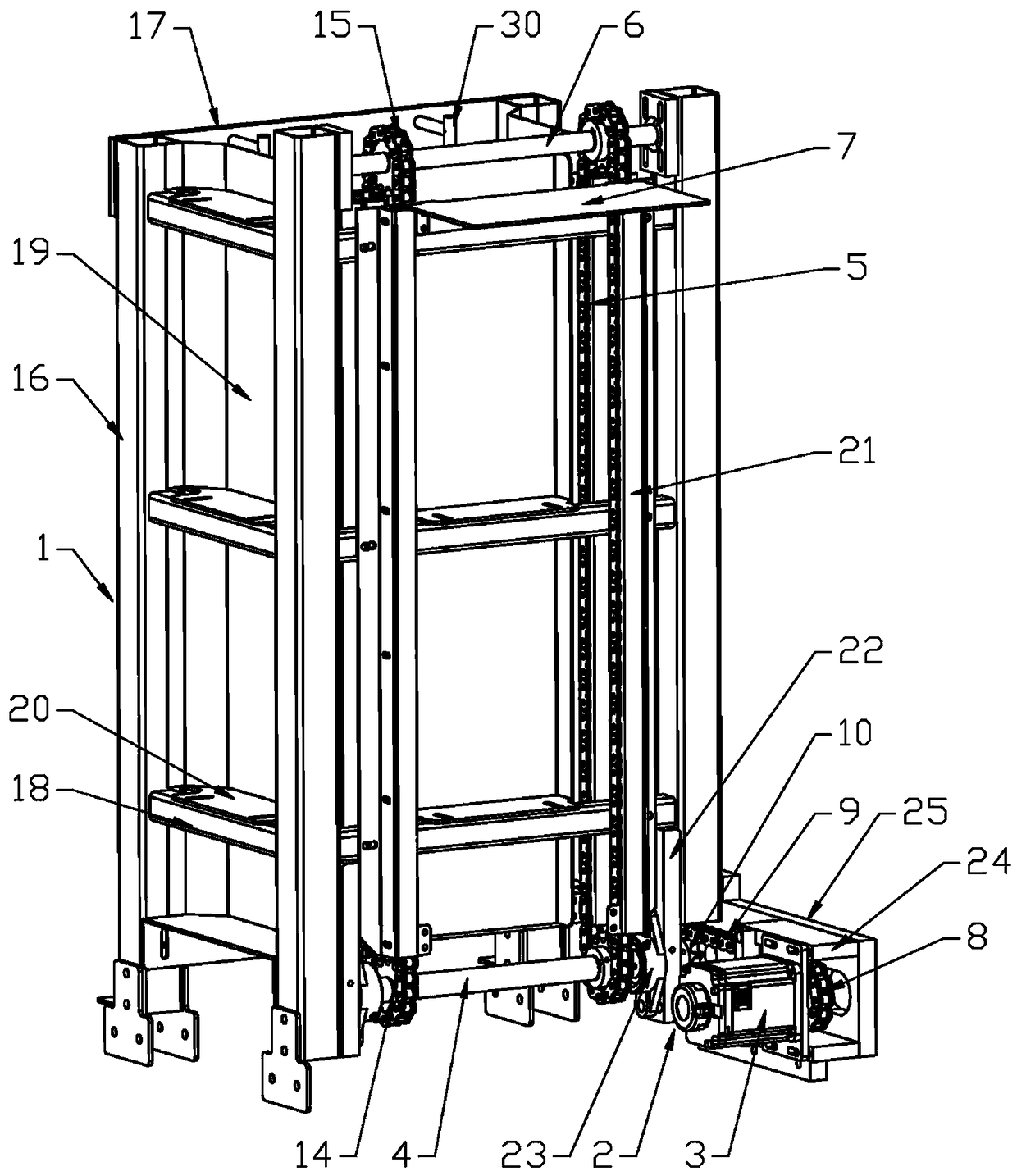

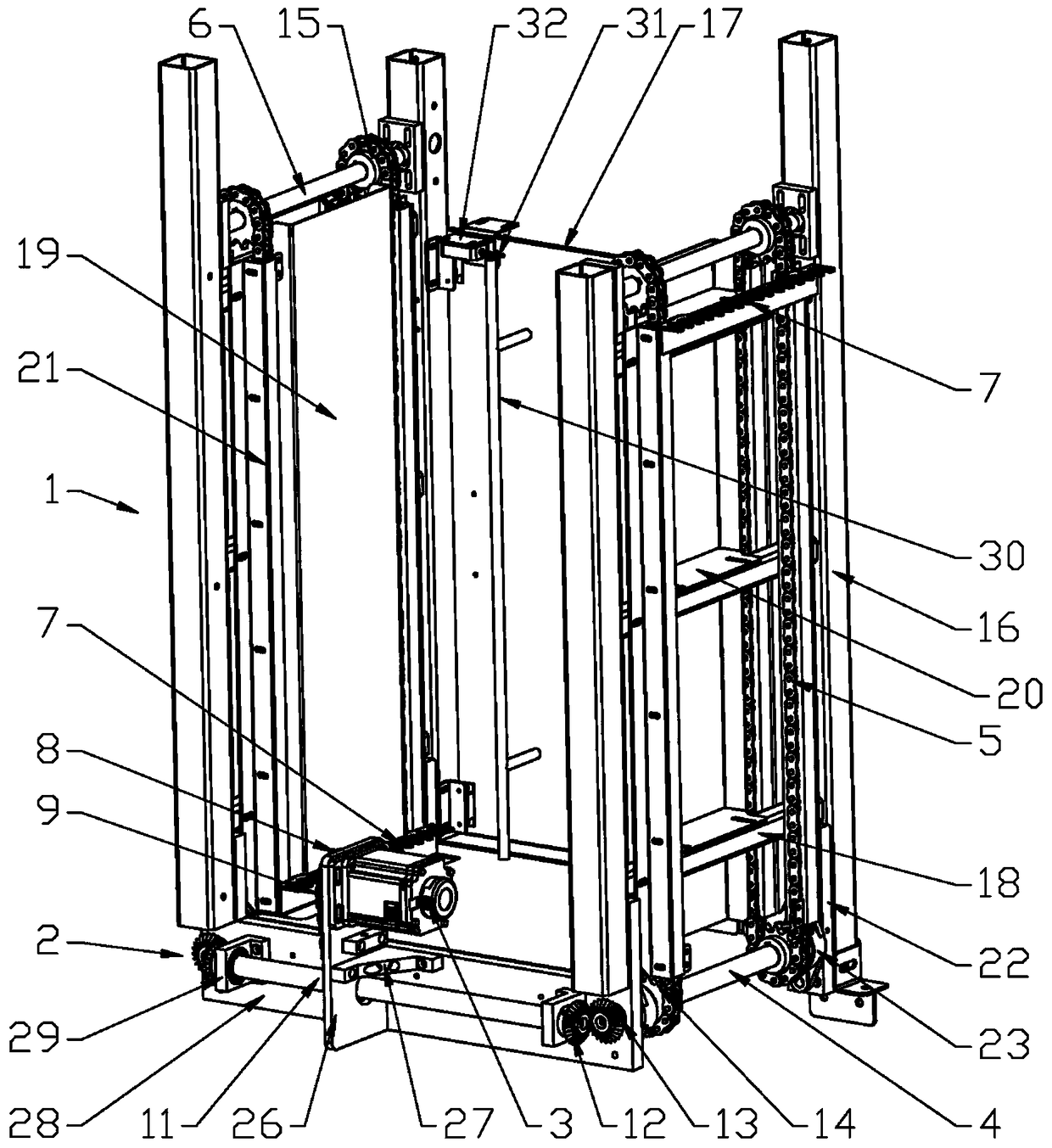

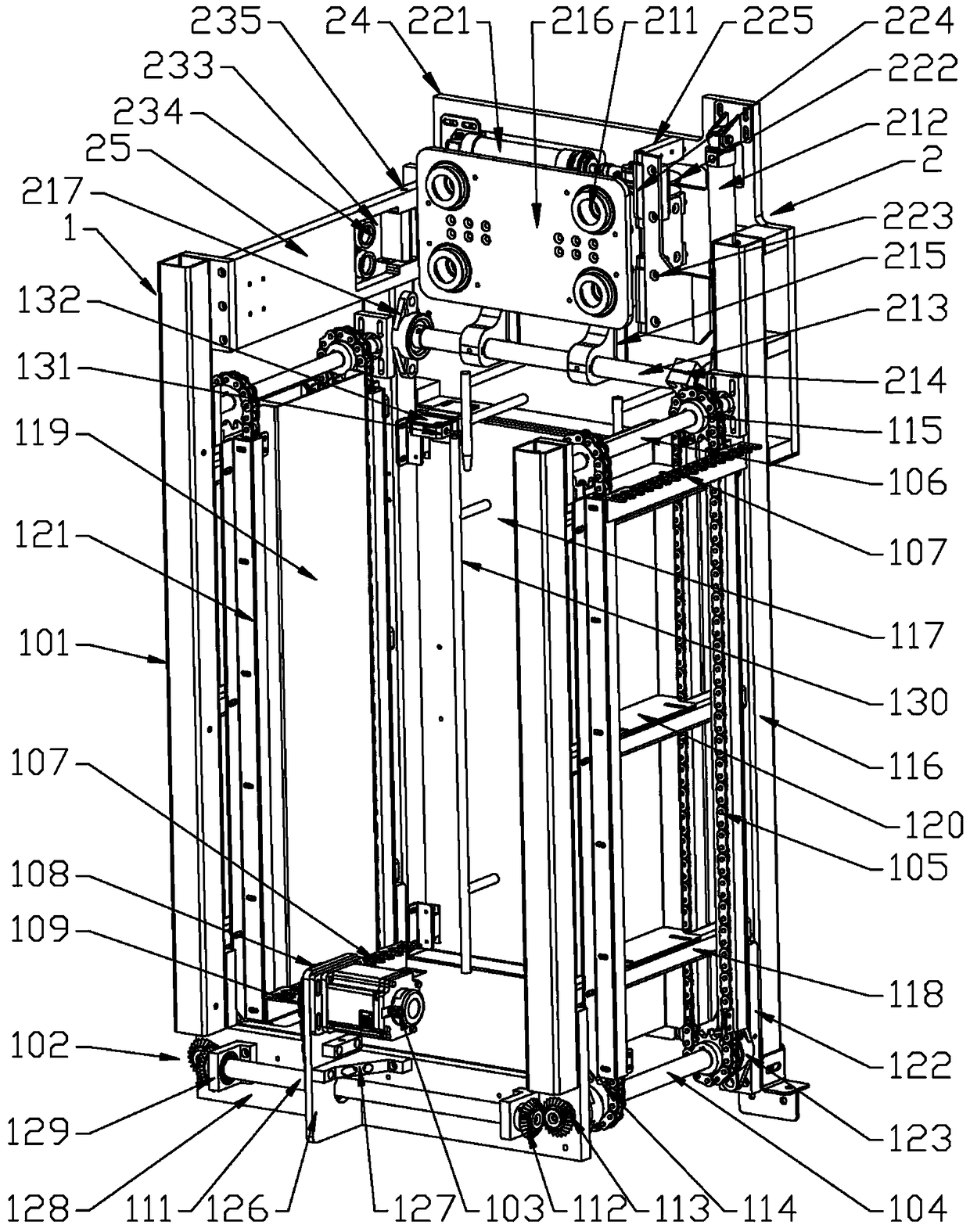

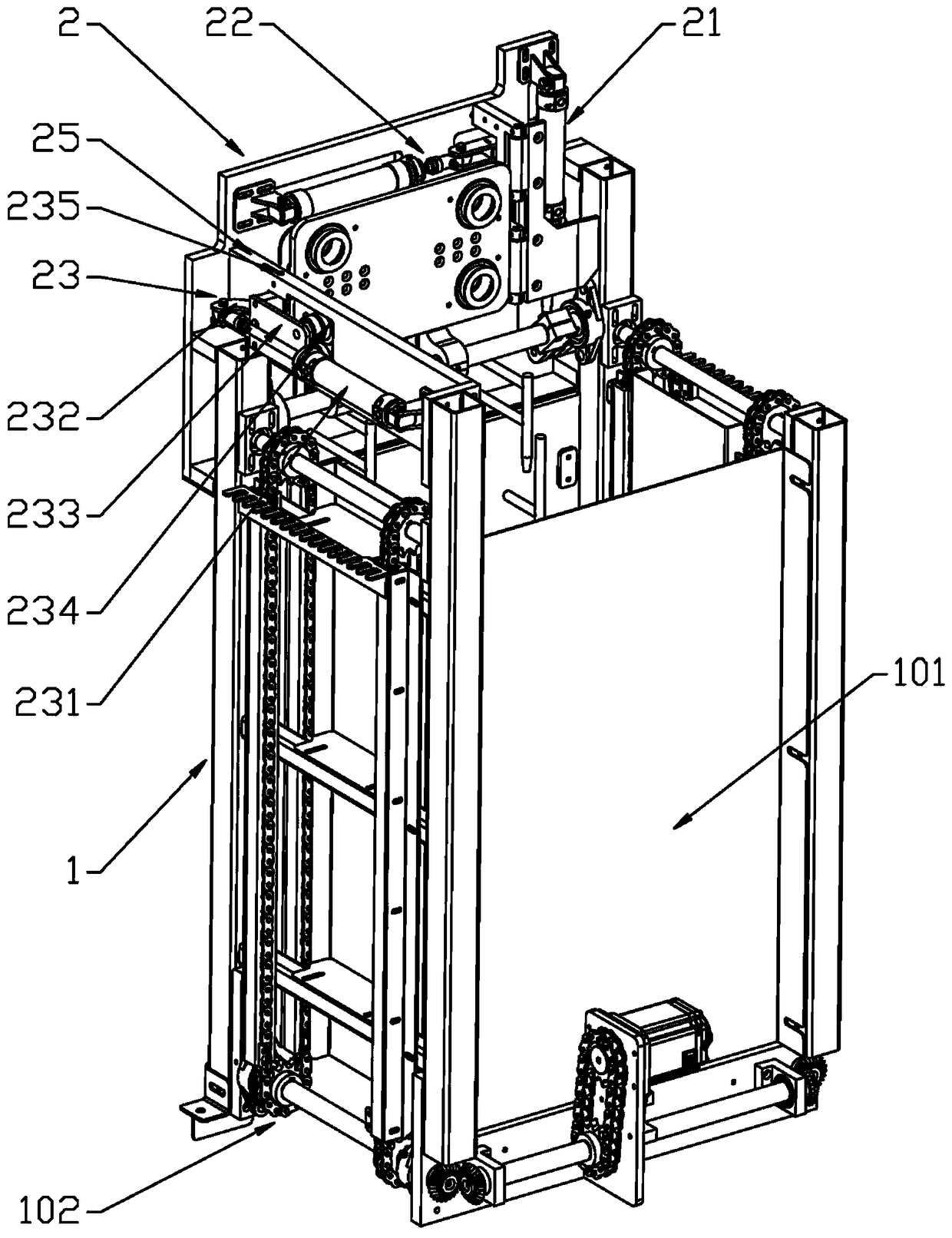

Vertical storing feeder

PendingCN109110389AConsistent stateReduces the difficulty of grasping or grippingConveyorsEngineeringDrive shaft

The invention discloses a vertical storing feeder. The feeder comprises a storing groove (1), the storing groove (1) is vertically arranged relative to the horizontal plane, a material in the storinggroove (1) is horizontally placed, a vertical loading mechanism (2) is arranged on the storing groove (1) and comprises a motor (3) capable of driving a driving shaft (4) to rotate, the driving shaft(4) drives a driven shaft (6) to rotate through a transmission part, a supporting plate (7) fixed to the transmission part (5) and used for placing the material is arranged on the outer side of the transmission part (5), the motor (3) drives the driving shaft (4) to rotate so as to drive the supporting plate (7) on the transmission part (5) to ascend, and the material is fed to the top end of thestoring groove (1). The material is horizontally placed in the storing groove, and is vertically and upwards fed, material state consistency is ensured, clamping apparatus grabbing or clamping difficulty is reduced, space in the horizontal direction can be effectively saved, and space in the vertical direction is positively used.

Owner:苏州澳昆智能机器人技术有限公司

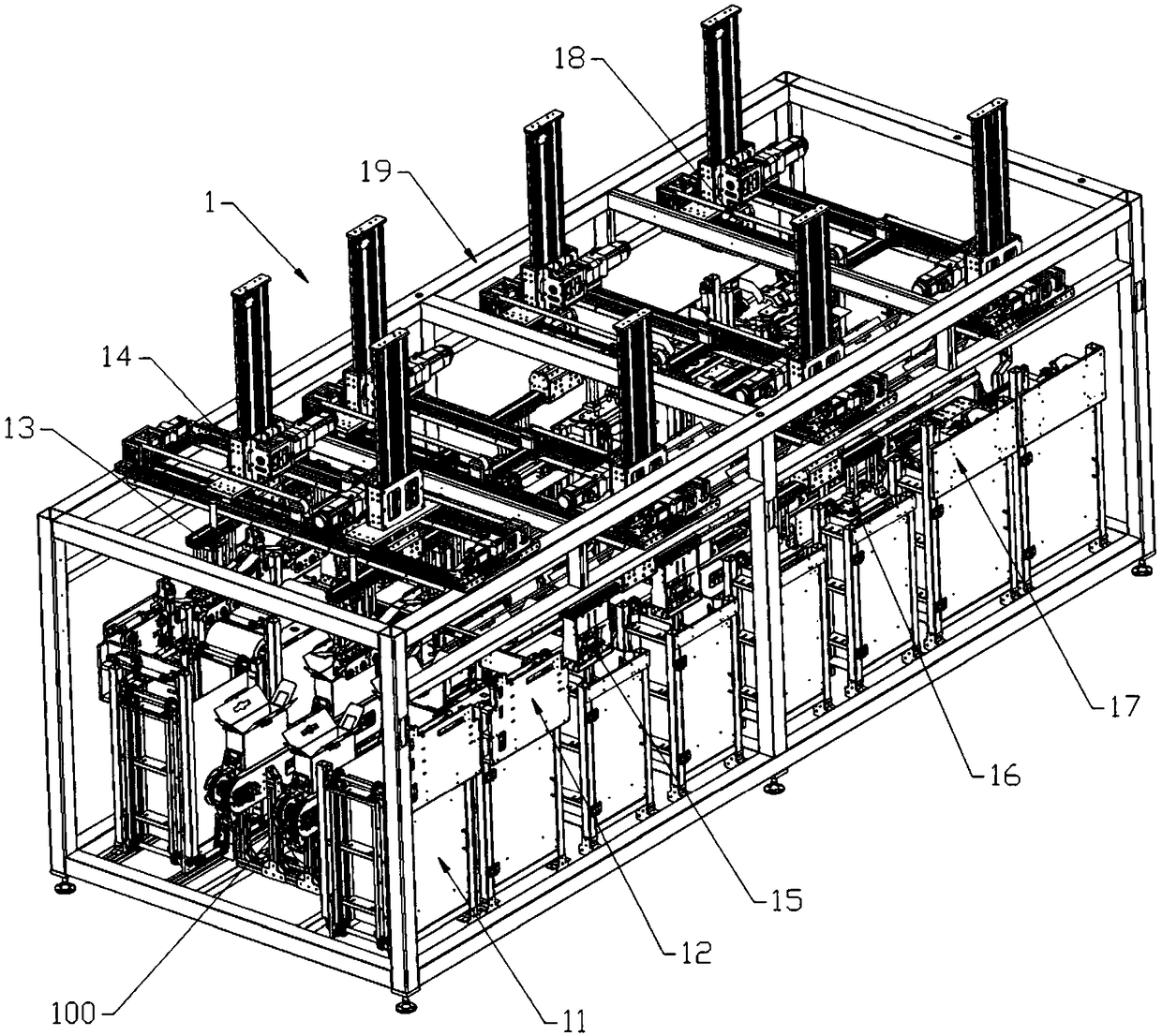

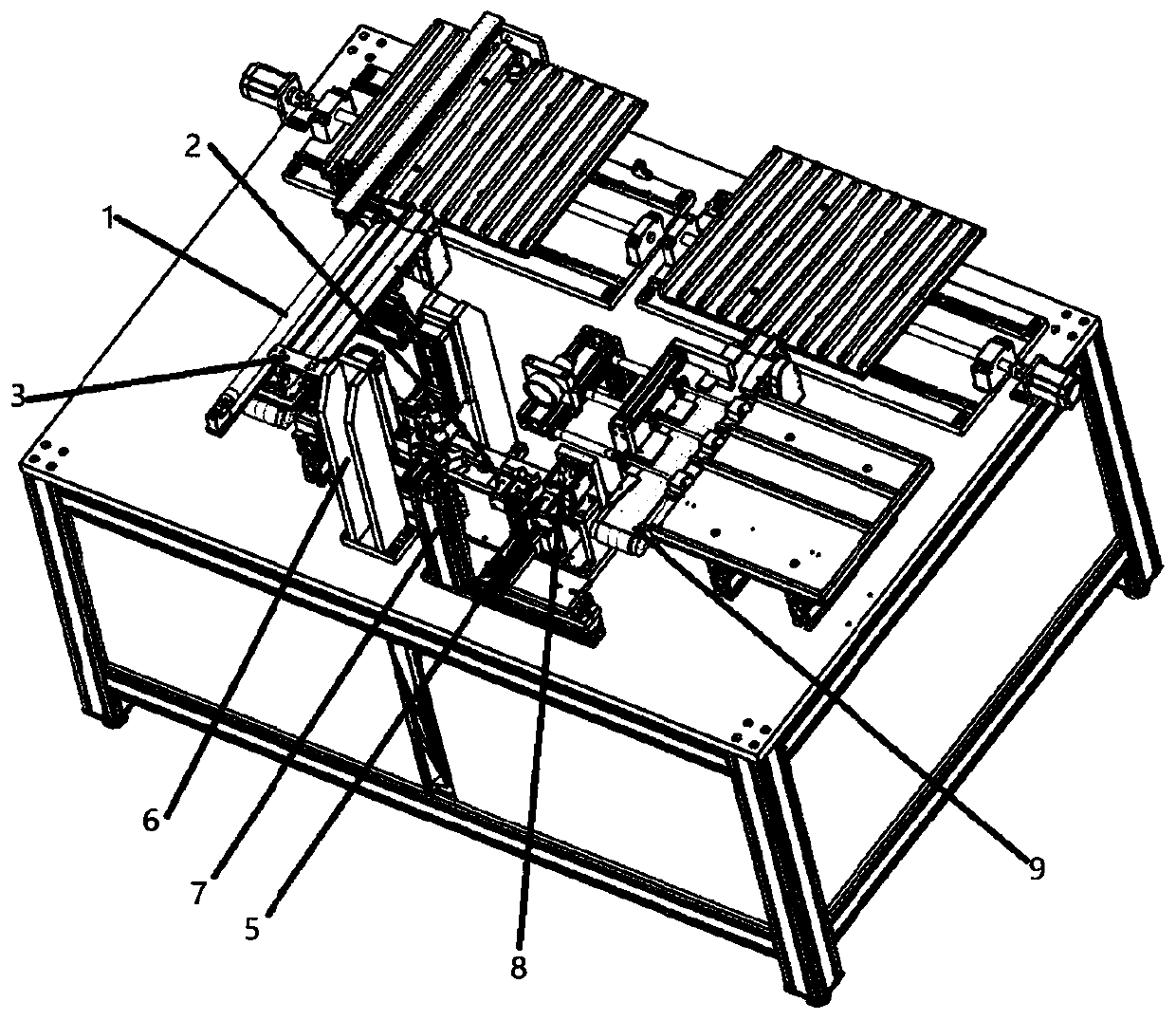

Box opening separating plate machine

The invention discloses a box opening separating plate machine. The box opening separating plate machine comprises a box opening separating plate machine frame (9), and there stations including the box opening station, the lower separating plate station and the side separating plate station or four stations including the box opening station, the lower separating plate station, the gasket station and the side separating plate station are sequentially arranged in the box opening separating plate machine frame (9) in the running direction of a package box conveying line (100); the above stationsare correspondingly provided with a storage feeder (1) fixed to a chassis of the box opening separating plate machine frame (9) and a conveying module (4) fixed to the top of the box opening separating plate machine frame (9); and a box opening machine (2) and a box supporting clamping apparatus (3) are further arranged at the box opening station, a lower separating clamping apparatus (5) is arranged at the lower separating plate station, a gasket clamping apparatus (6) is arranged at the gasket station, and a side separating plate forming mechanism (7) and a side separating plate clamping apparatus (8) are arranged at the side separating plate station. The box opening separating plate machine is specially designed for smiley bags and milk bags, the structure is simple, the box opening separating plate machine is precise and high in efficiency.

Owner:苏州澳昆智能机器人技术有限公司

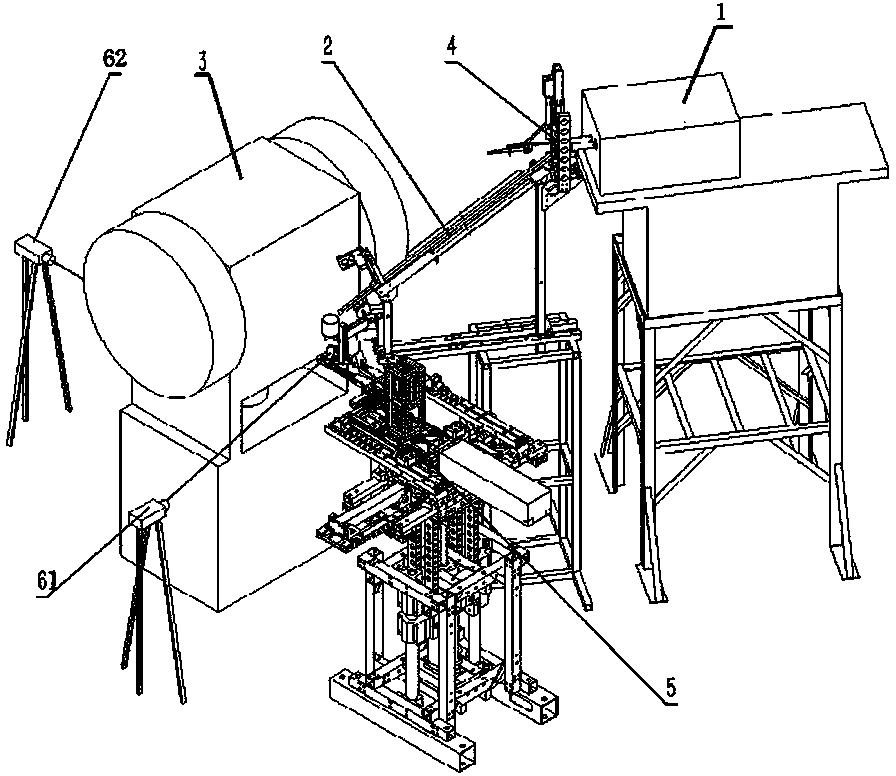

Method for grabbing specified part of shaft workpiece for feeding

ActiveCN113500593AAvoid damageEasy accessProgramme-controlled manipulatorMetal working apparatusEngineeringMechanical engineering

The invention discloses a method for grabbing a specified part of a shaft workpiece for feeding. The method comprises the following steps of identifying rectangular stickers with specific colors at four corners of a material box to obtain three-dimensional coordinates of the center of the material box and an area where the shaft workpiece is located; selecting a workpiece contour from the area for rough drawing, and obtaining the mass center and the axis of the workpiece according to the outer edge of a rough contour; rotating a left image shot by a camera to enable the axis of the workpiece in the left image to be horizontal, obtaining the minimum enclosing rectangle of the workpiece at the moment, and establishing a relation between the minimum enclosing rectangle and a pre-stored template image, so as to obtain three-dimensional coordinates of corresponding points of the workpiece in the left image according to a to-be-clamped point and a chuck clamping point marked in the template image; and clamping the to-be-clamped point of the workpiece by an end effector on a mechanical arm, sending the workpiece to a machine tool chuck, and clamping the workpiece at the chuck clamping point. The method can specify a clamping part, and is suitable for various shaft workpieces, and high in practicability.

Owner:TIANJIN UNIV

Material delivering robot with visual detecting function

ActiveCN102825605BHigh operating precisionEasy to controlJointsMetal working apparatusControl systemEngineering

Owner:KUNSHAN HAIWEI AUTOMATION

Flexible gear driven corridor elevator walking mechanism

PendingCN112645183ANormal traffic is not affectedSmall footprintPortable liftingBuilding liftsGear driveGear wheel

The invention relates to a flexible gear driven corridor elevator walking mechanism, and belongs to the technical field of general equipment of elevators. The flexible gear driven corridor elevator walking mechanism comprises a load bearing wheel assembly, a machine frame, a power assembly and a supporting wheel assembly, wherein the load bearing wheel assembly comprises a wheel frame, a load bearing wheel and guide wheels; the cross section of the wheel frame is like a door frame; the load bearing wheel is positioned in the middle of the wheel frame and is horizontally arranged; the guide wheels are positioned at two wings of the load bearing wheel and are vertically arranged; the load bearing wheel and the guide wheels form a structure like a Chinese character 'pin'; and a load bearing guide rail is encircled in the center. The machine frame is an elevator body framework and is mechanically connected with the load bearing wheel assembly through a hanging plate. The power assembly comprises a speed reducing motor and a gear; the gear and the speed reducing motor are flexibly connected, and are meshed with a rack on a corridor; and support wheels are positioned below the gear. The flexible gear driven corridor elevator walking mechanism has the main characteristics that the width of each of the guide rails and the rack protruding a guardrail does not exceed 5 cm, and the normal passage of the corridor is not influenced basically. In addition, the rack is positioned between the bearing guide rail and a supporting guide rail, and an unbalance-loading crawling phenomenon can be relieved.

Owner:NANJING INST OF TECH

Insecticidal ointment containing cyclohexyl flusulfamide and prothioconazole

InactiveCN109874795AGood systemicHas photoactivated poisonous effectBiocideAnimal repellantsFlusulfamideToxicology

The invention relates to an insecticidal ointment containing cyclohexyl flusulfamide and prothioconazole, and belongs to the field of pesticides and preparations thereof. The insecticidal ointment isprepared by mixing cyclohexyl flusulfamide, prothioconazole and an auxiliary agent, the cyclohexyl flusulfamide accounts for 0.1-40% of the total weight of the insecticidal ointment, the prothioconazole accounts for 0.1-50% of the total weight of the insecticidal ointment, and the balance is the auxiliary agent. The insecticidal ointment is prepared from cyclohexyl flusulfamide and prothioconazolein a weight ratio of 5:1, 2:1, 1:1, 1:2 or 1:5. The ointment disclosed by the invention is long in lasting period, small in environmental pollution and simple and convenient to apply.

Owner:蒋宏伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com