Horizontal-type high-speed fine grinding linear double-edge edge grinding machine for glass

A kind of edging machine, high-speed technology, applied in the direction of machine tools, grinding machines, grinding/polishing equipment, etc. suitable for grinding the edge of the workpiece, it can solve the problem that the rotational speed and precision of the grinding head cannot meet the requirements of high-speed edging, and increase the synchronous belt drive Problems such as synchronicity and bottom edge polishing cannot be automatically compensated to achieve the effect of improving rigidity, improving surface quality, and quickly positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

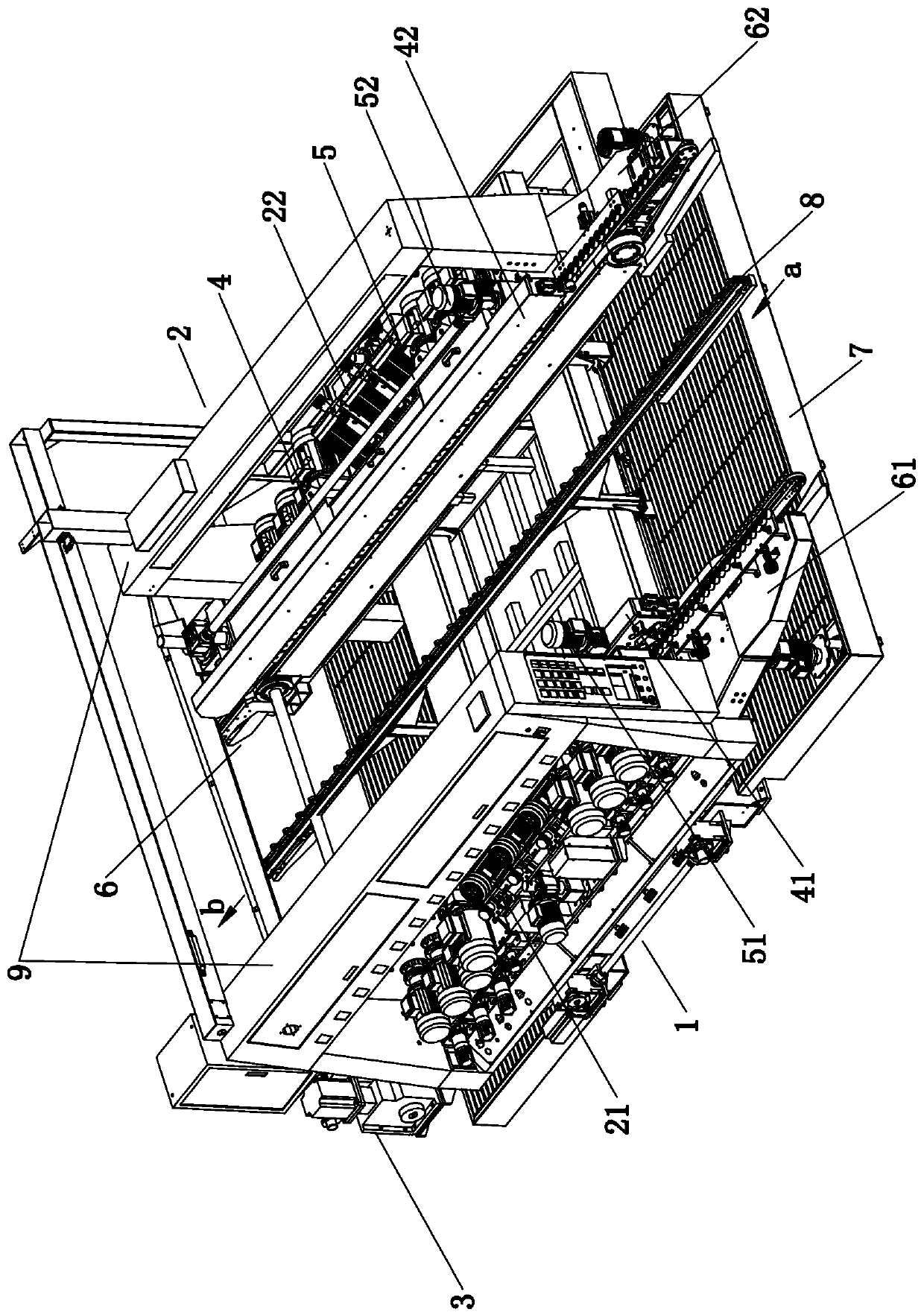

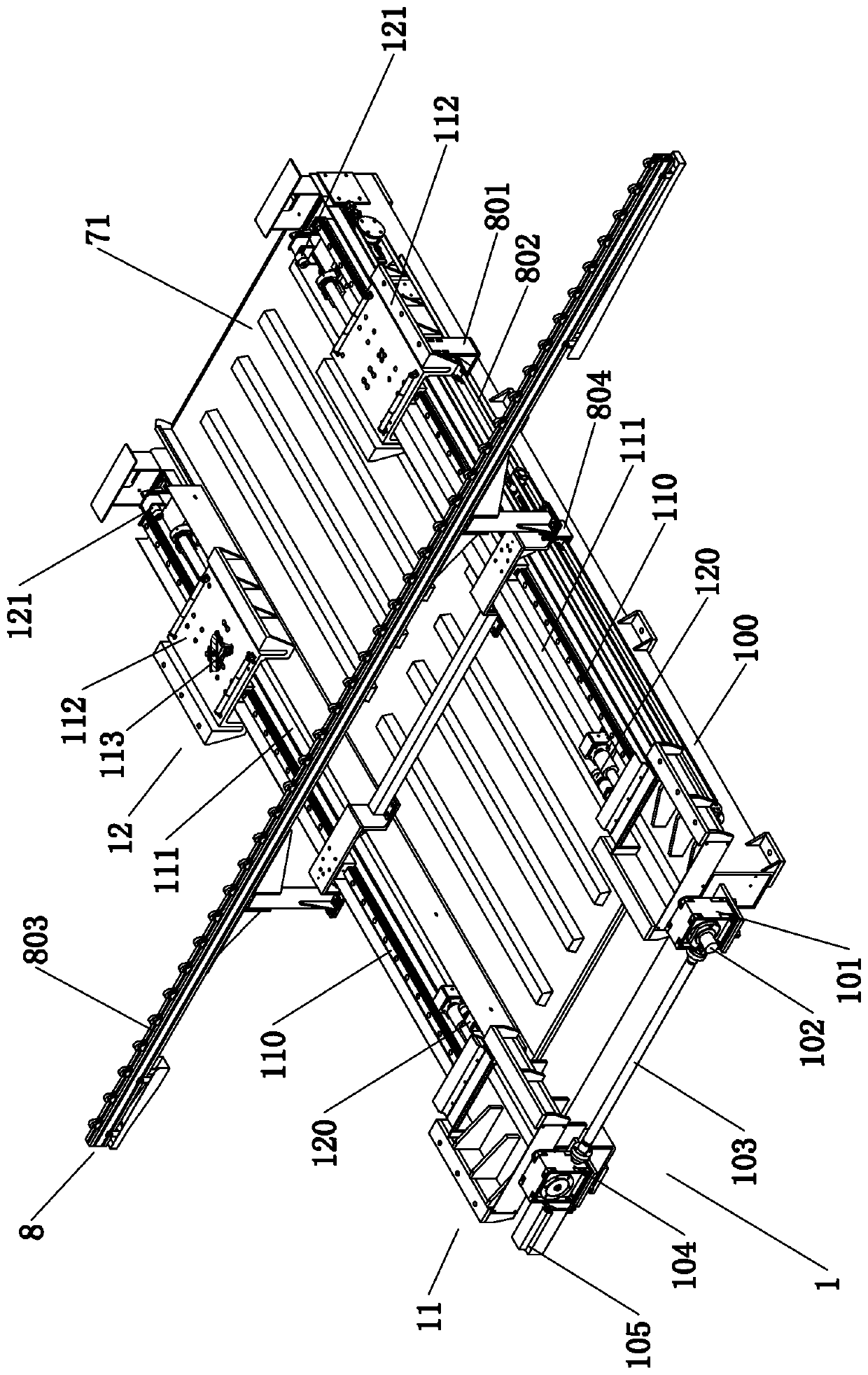

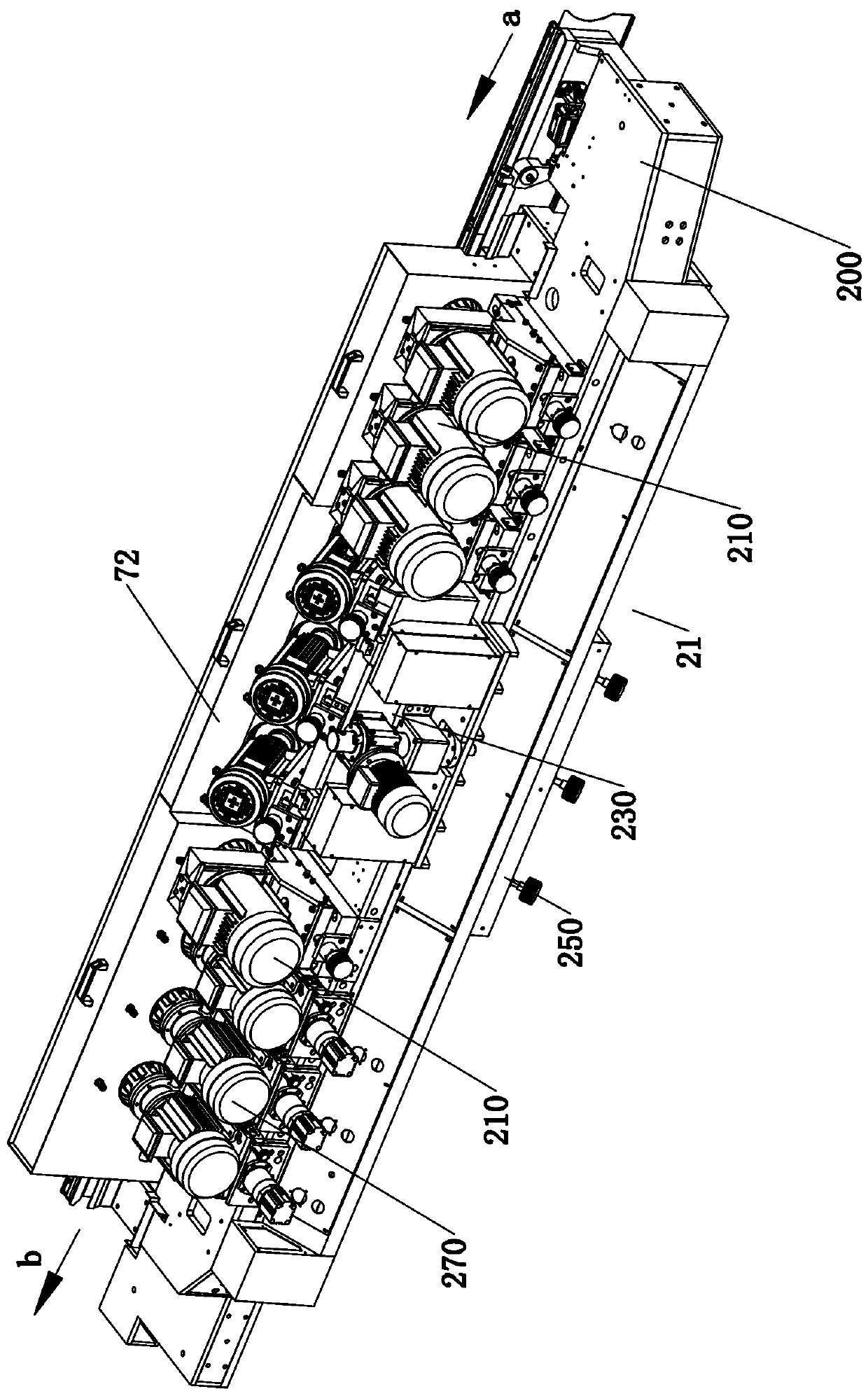

[0045] see figure 1 As shown, a high-speed fine-grinding linear bilateral edging machine includes a bed opening and closing mechanism 1, a box grinding wheel group arrangement mechanism 2, a main transmission mechanism 3, a pressing frame mechanism 4, a pressing frame lifting mechanism 5, and a feeding and discharging mechanism. Guide mechanism 6, cooling water circulation system 7, automatic center bracket mechanism 8 and electric cabinet control mechanism 9; the box grinding wheel group arrangement mechanism 2 is installed on the bed opening and closing mechanism 1, and the front and rear of the box body grinding wheel group arrangement mechanism 2 The two ends are respectively provided with a feed end a and a discharge end b, and the left and right ends of the bed opening and closing mechanism 1 are respectively provided with a fixed end 11 and a mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com