Modified carbon nanotube ionic liquid layered liquid crystal lubricant and preparation method thereof

An ionic liquid, layered liquid crystal technology, applied in the field of lubrication, can solve problems such as leakage and creep that have not been effectively solved, achieve a good balance, reduce creep and leakage, and improve dispersion and lubricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Preparation of modified carbon nanotubes

[0030] Weigh 0.5 g of carbon nanotubes and place them in 50 mL of sulfuric acid / nitric acid (v / v 3:1) mixed solution for ultrasonic dispersion for 1 h, then reflux in a water bath at 80 °C for 4 h, filter, and wash repeatedly with a large amount of deionized water and acetone until The filtrate was neutral, dried and ground; the ground carbon nanotubes were placed in 50mL SOCl 2 , ultrasonically treated for 0.5h, using DMF as a catalyst, stirred and refluxed at 80°C for 2h, filtered, dried, and ground for later use; the treated Carbon nanotubes and stearyl alcohol are placed in a DMF solution, ultrasonically dispersed for 0.5 h, stirred and refluxed at 80° C. for 24 h, filtered, washed, and dried to obtain stearyl alcohol-modified carbon nanotubes.

Embodiment 2

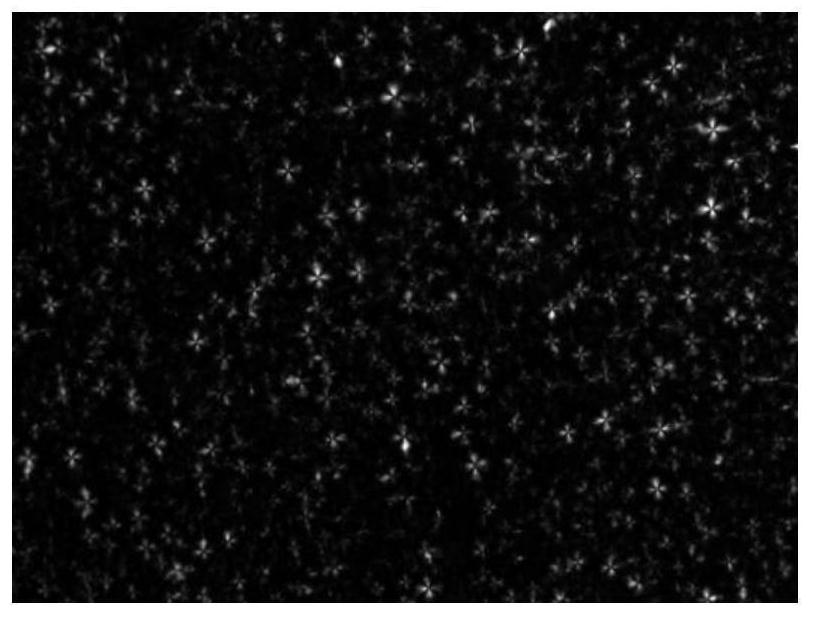

[0031] Embodiment 2: Preparation of 0.05% S-CNT ionic liquid lamellar liquid crystal lubricant

[0032] Weigh 0.1g of Brij30 in a 100mL beaker to obtain an aqueous solution of 0.1wt% Brij30; then add 50mg of the modified carbon nanotubes in Example 1 to the solution, and the mixture is ultrasonically ultrasonicated for 24h in an ultrasonic cleaner to finally obtain Uniform black dispersion. According to mass ratio Brij30 / BP304 / H 2 O=55:13:32, weigh with carbon nanotube dispersion instead of water, then mix evenly at about 70°C, centrifuge, stir, and repeat these two steps to make the sample fully mixed. Put it in a constant temperature box (25±0.1)°C for more than two weeks to make it reach equilibrium, and prepare a carbon nanotube ionic liquid lamellar liquid crystal lubricant.

Embodiment 3

[0033] Embodiment 3: Preparation of 0.1% S-CNT ionic liquid lamellar liquid crystal lubricant

[0034] Weigh 0.1g of Brij30 in a 100mL beaker to obtain an aqueous solution of 0.1wt% Brij30; then add 100mg of the modified carbon nanotubes in Example 1 to the solution, and the mixture is ultrasonically ultrasonicated for 24h in an ultrasonic cleaner to finally obtain Uniform black dispersion. According to mass ratio Brij30 / BP304 / H 2 O=55:13:32, the carbon nanotube dispersion was used instead of water to weigh, and the rest of the steps were the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com