Box opening separating plate machine

The technology of a separator and unpacking machine, which is applied in packaging and other directions, can solve the problems of increasing the difficulty of grabbing or clamping the packaging box, the difficult vertical state of the packaging box, and delaying the upgrading speed of large-scale consumer packaging technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087]The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

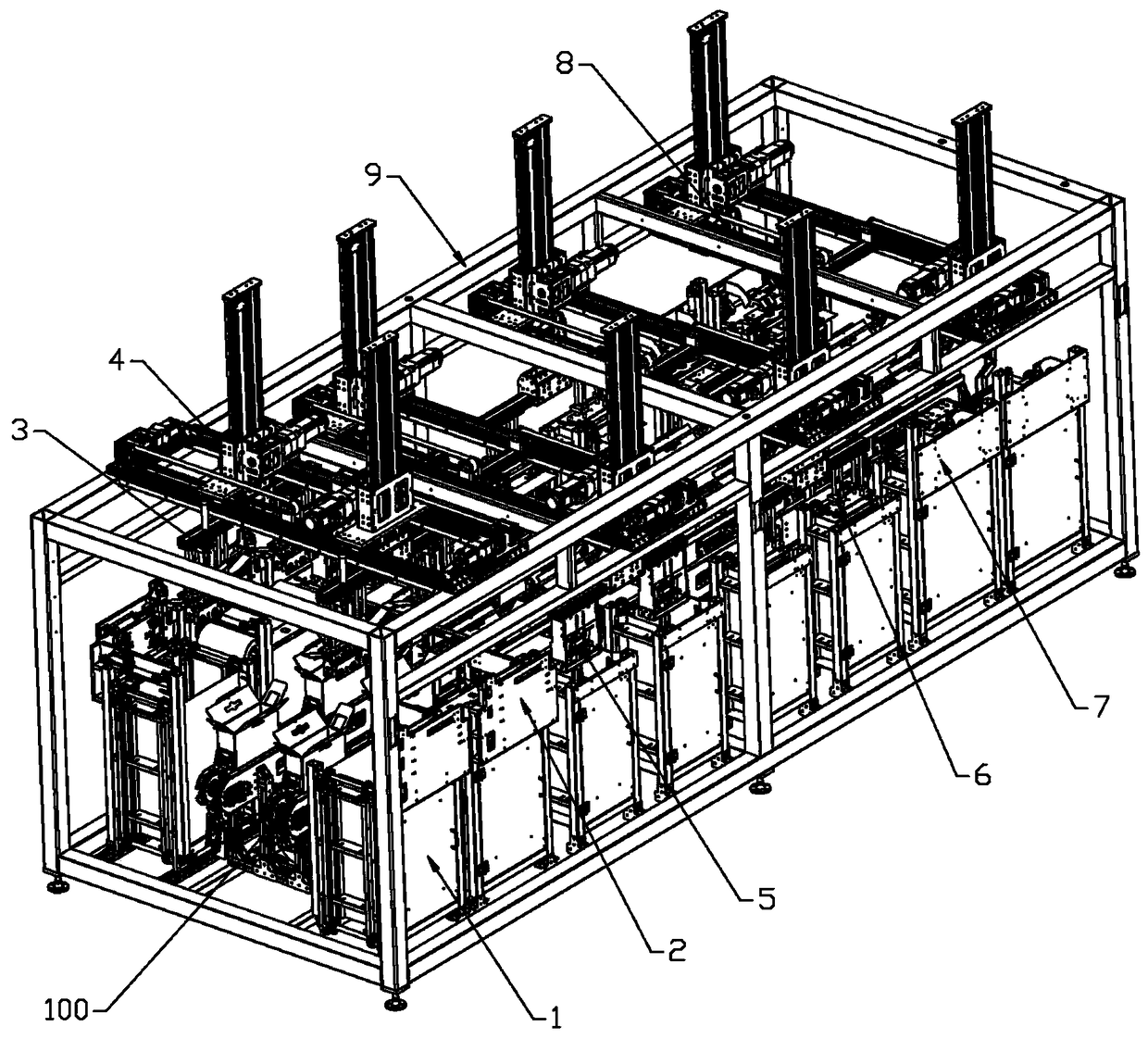

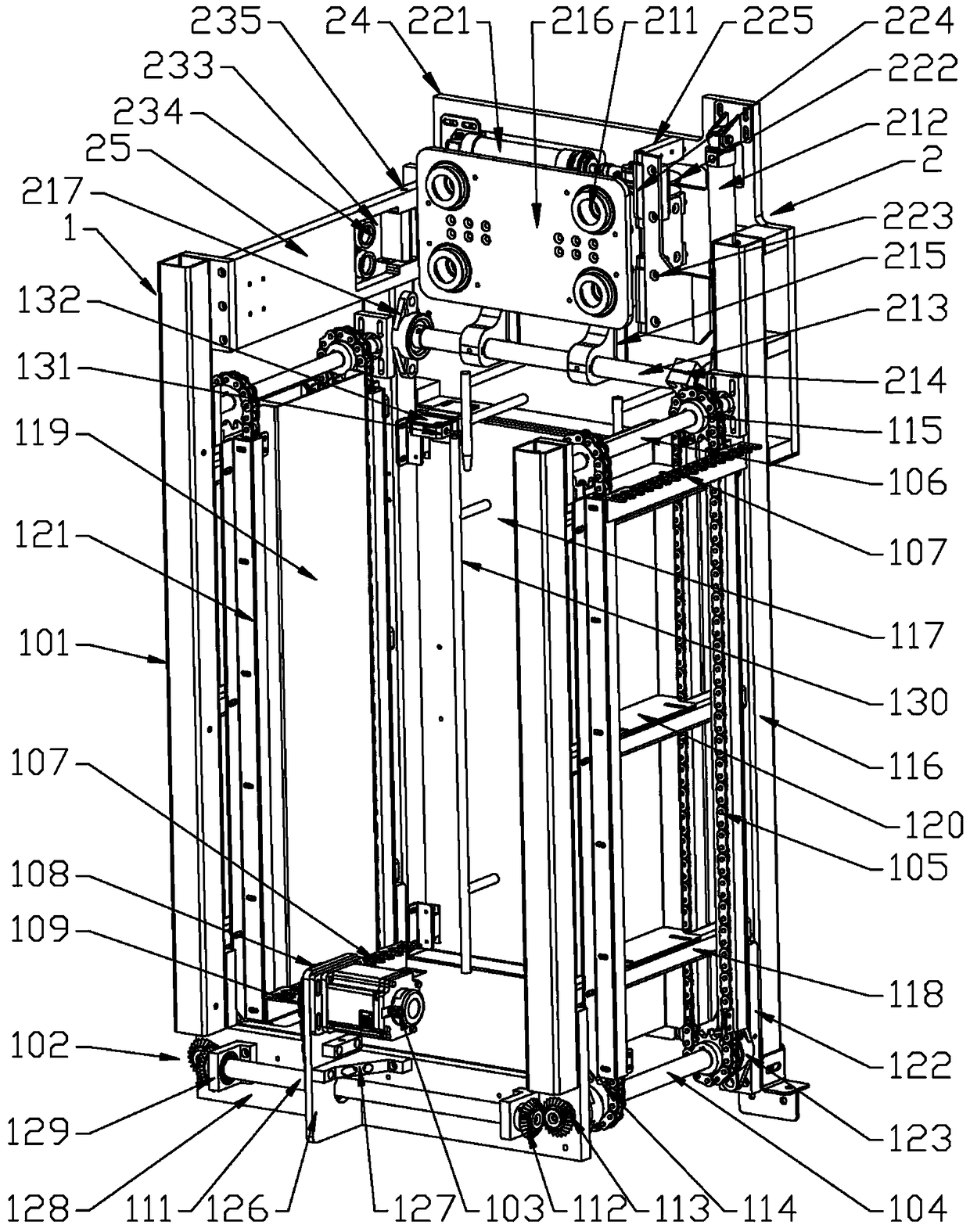

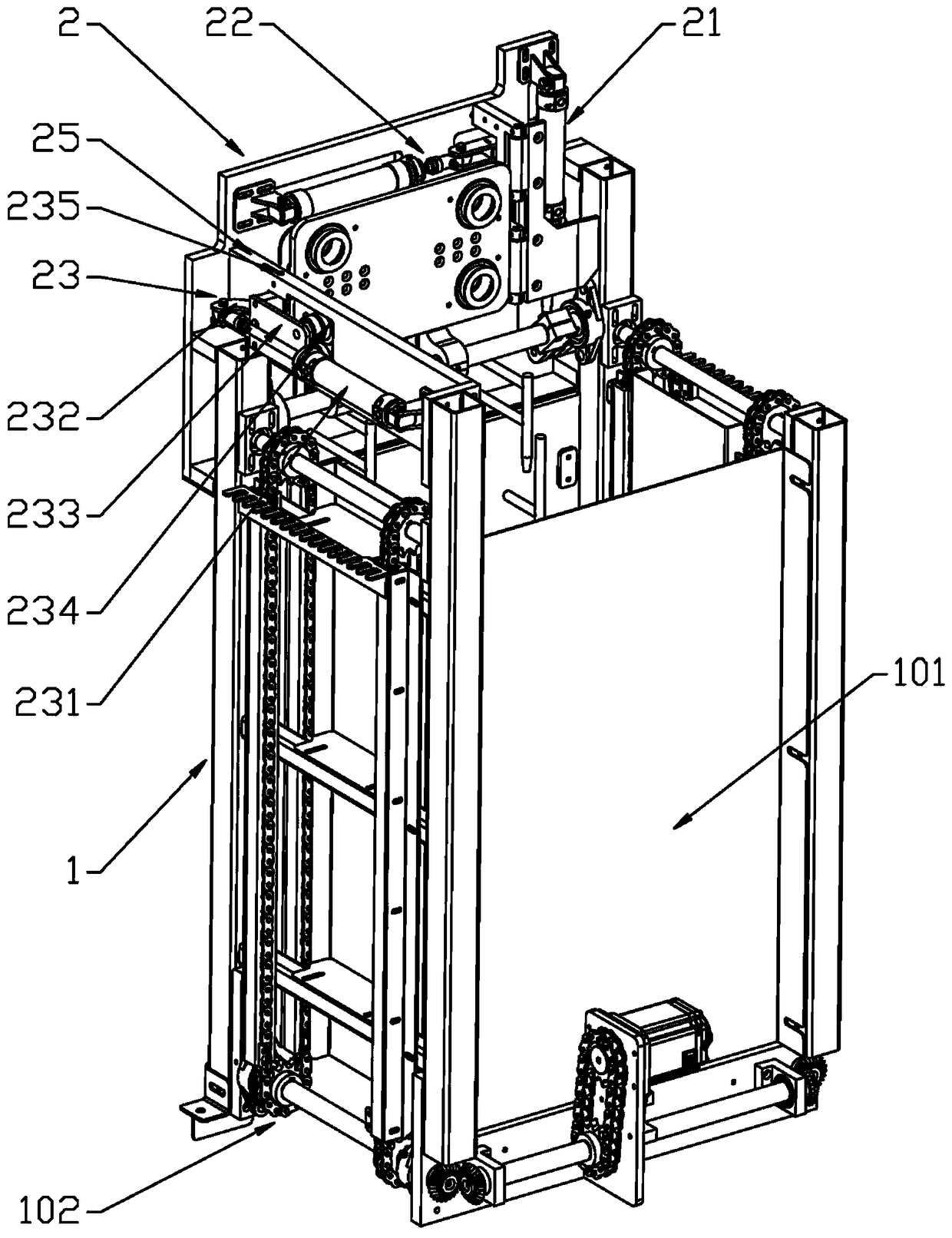

[0088] Such as figure 1 Shown: a kind of unpacking bulkhead machine, comprises unpacking bulkhead frame 9 and packing box conveying line 100, in the unpacking bulkhead frame 9 and along the running direction of packing box conveying line 100, be provided with including Three stations of unpacking station, lower partition station, and side partition station, or four stations including unpacking station, lower partition station, gasket station, and side partition station; the above-mentioned The stations are all correspondingly provided with a material storage feeder 1 fixed on the chassis of the unpacking partition frame 9 and a conveying module 4 fixed on the top of the unpacking partition frame 9, and the storage material at the unpacking station The top of the feeder 1 is equipped with a case unpacking machine 2 and the bottom of the conveying module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com