Material delivering robot with visual detecting function

A visual inspection and robot technology, applied in manipulators, manufacturing tools, metal processing, etc., can solve the problems of complex robot structure, poor positioning accuracy, and narrow application range, and achieve good clamping effect, low production cost, and easy maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

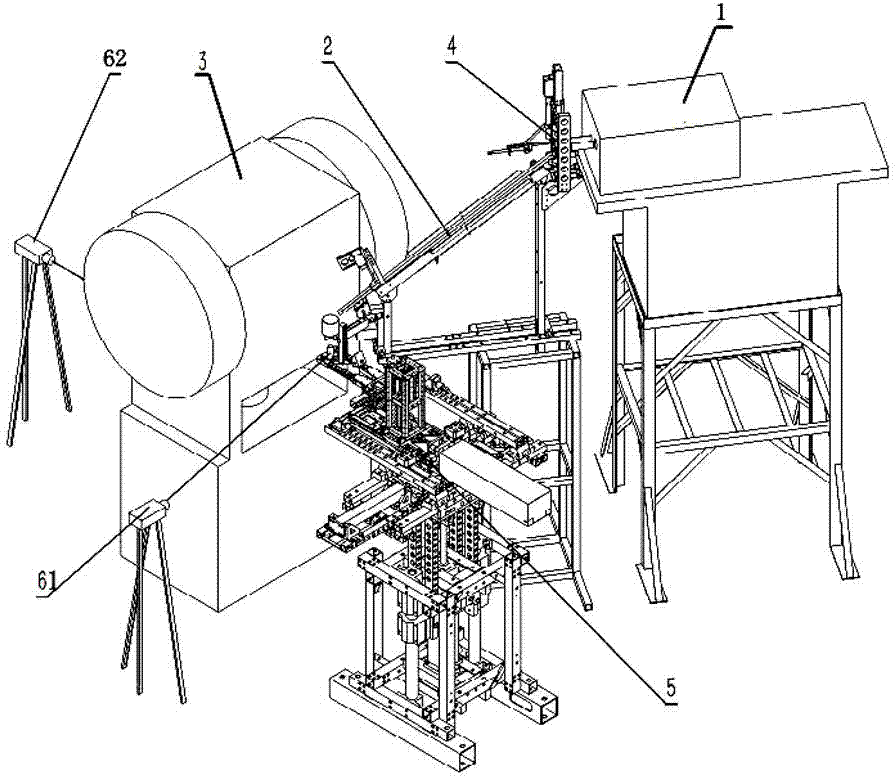

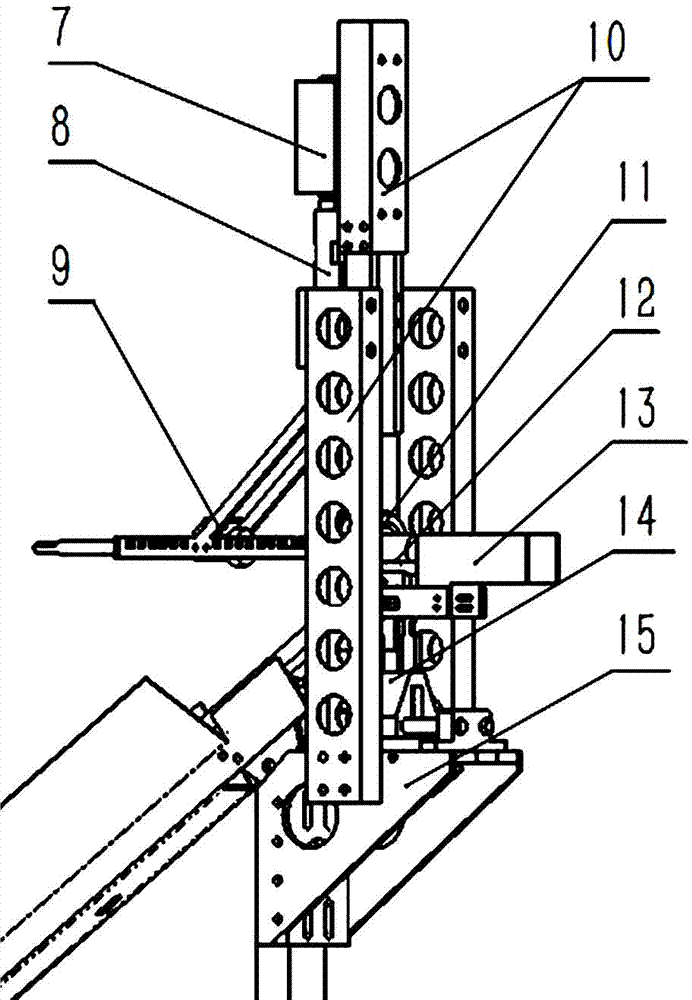

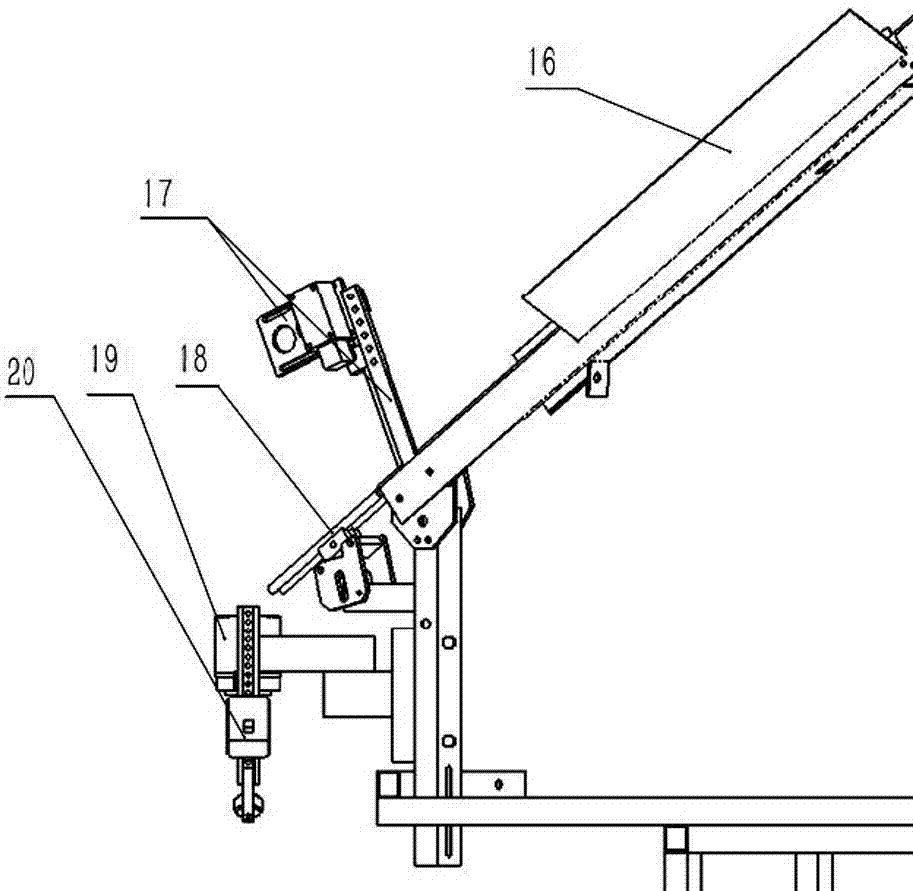

[0035] A material transfer robot with a visual detection function is provided with a control system, a visual detection system and a material transfer system respectively connected to the control system, and the material transfer system is provided with a material sliding mechanism 2 and a feeding manipulator 5 .

[0036] Such as figure 1 As shown, the material transfer system is set between the discharge port of the intermediate frequency furnace 1 and the forging machine tool 3 , and the rods coming out of the intermediate frequency furnace 1 are transported to a position close to the forging machine tool 3 through the material sliding mechanism 2 . The visual detection system is provided with a camera device and a processor module for image analysis, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com