A film tearing device for a light guide plate of an LED lamp

A technology for LED lights and light guide plates, applied in the directions of layered products, lamination auxiliary operations, lamination, etc., can solve the problems of high cost of lamination operation, scratched light guide plates, dust pollution, etc., to achieve less dust pollution, save money Tape, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

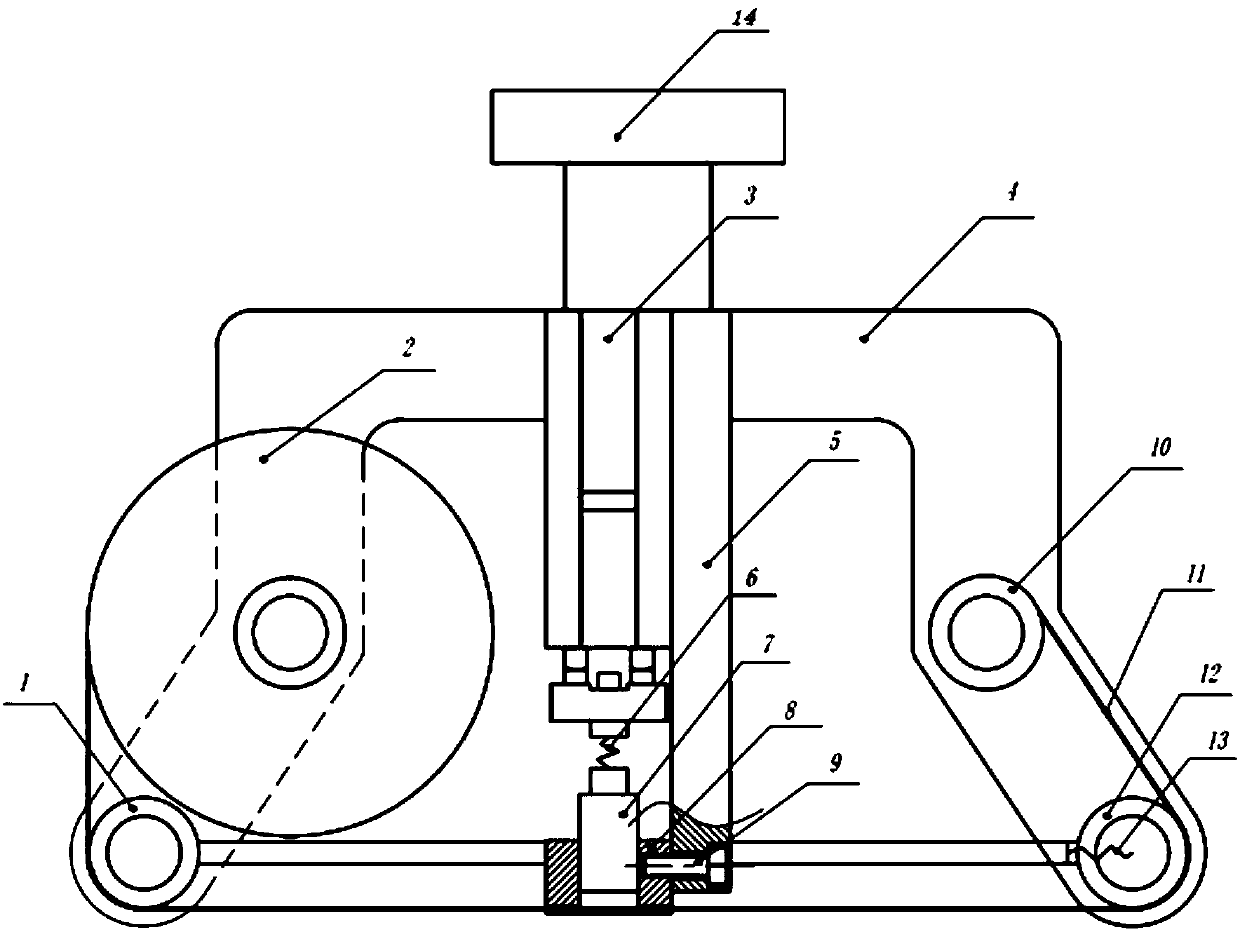

[0024] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0025] In the prior art, manually tearing off the film coating on the surface of the light guide plate of the LED lamp is costly and inefficient, and it is easy to introduce dust pollution and scratch the light guide plate. In the field of liquid crystal display production, there is also the problem of tearing off the surface film of optical board devices. Adhesive rollers are often used to paste the tear film. This kind of film tearing device needs to replace the adhesive roller regularly, which reduces the efficiency of tearing the film and increases the cost of tearing the film. This sticky roller film tearing device needs to be adjusted and modified according to different film sizes, and the versatility of the device is low.

[0026] The invention proposes a film tearing device for a light guide plate of an LED lamp. The film tearing device for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com