A piezomagnetic bearing integrated tooling

A magnetic pad and bearing technology is applied in the field of integrated tooling of pressed magnetic pad bearings, which can solve the problems of magnetic pad impact, magnetic pad damage, and increase production difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

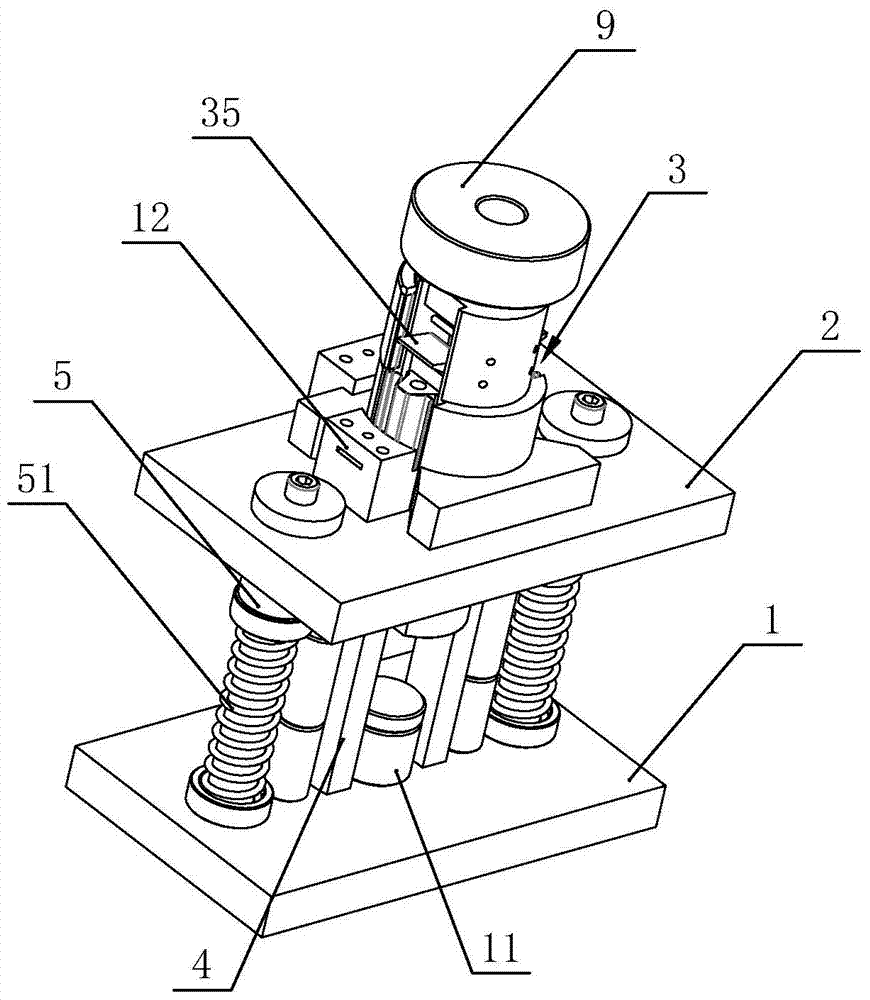

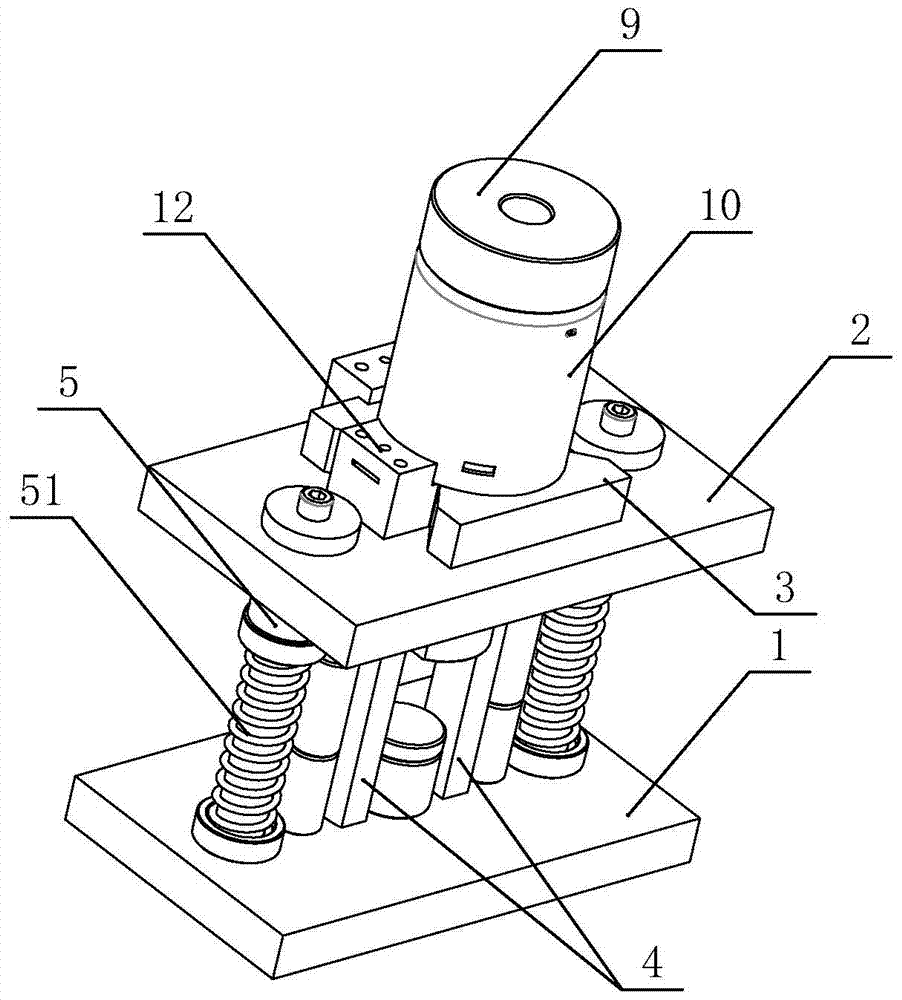

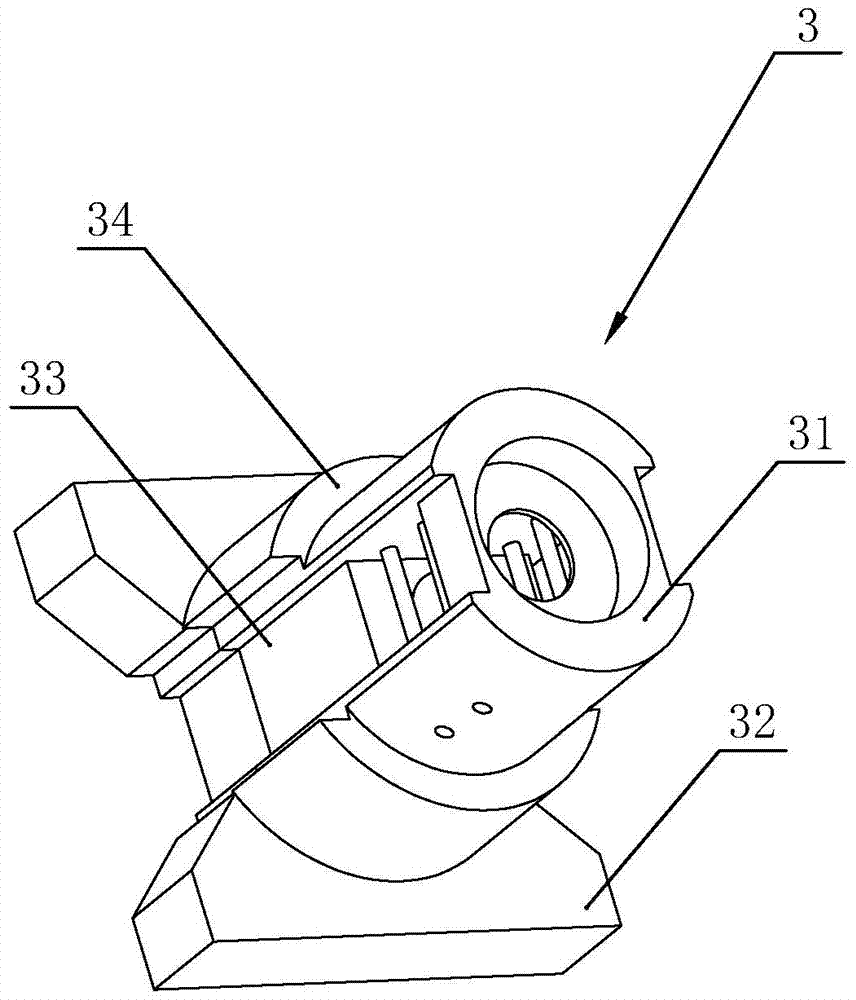

[0027] Such as Figure 1-Figure 7 As shown, this specific embodiment is an integrated tooling for piezomagnetic tile bearings, including a machine base 1, a lifting plate 2 arranged directly above the machine base, a magnetic tile fixing table 3 fixed on the upper surface of the lifting plate, and even-numbered solids. Connected to the upper surface of the machine base and set through the lifting plate to clamp the feeding rod 4, there are at least two guide posts 5 between the machine base 1 and the lifting plate 2, and the lifting plate 2 and the guide posts 5 form a guiding sliding fit , the part of the guide post 5 between the machine base 1 and the lifting plate 2 is sleeved with a return spring 51 . The magnetic tile fixing table 3 includes a magnetic tile fixing base 32 and a cylindrical magnetic tile fixing column 31, and a magnetic tile installation shoulder 34 is formed on the position where the magnetic tile fixing base 32 and the cylindrical magnetic tile fixing co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com