A limit installation method of curtain wall embedded parts and the installation mold used therefor

A technology of embedded parts and limit molds, which is applied in the processing of building materials, construction, and building construction. It can solve the problems of complex equipment configuration, high construction cost, and impact on the construction period, and achieve simple operation and fast installation during the installation process. Fast and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The content of the present invention will be further explained and illustrated below in conjunction with the accompanying drawings.

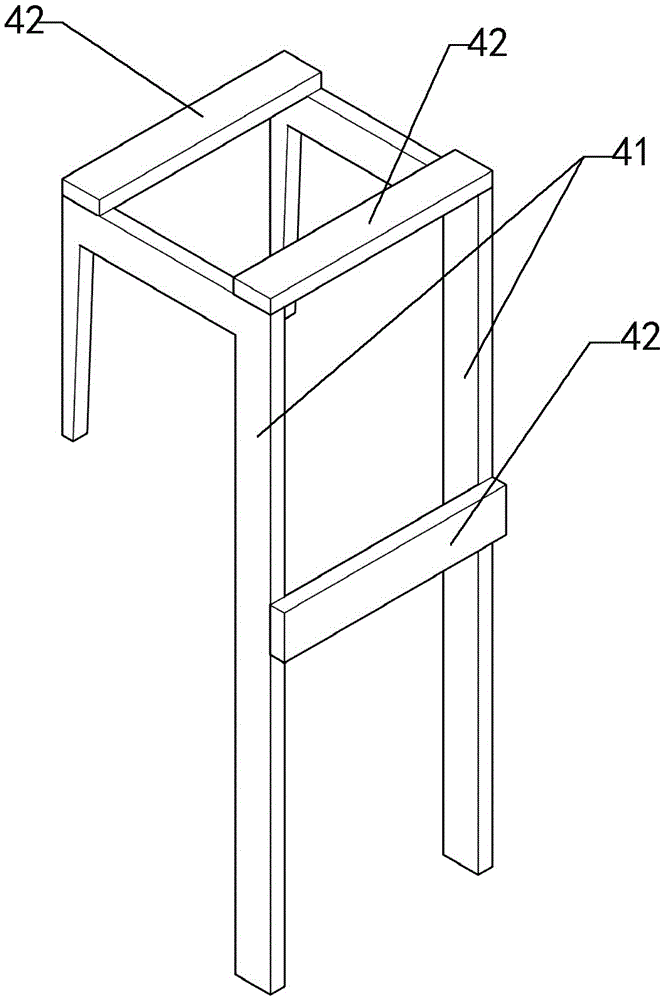

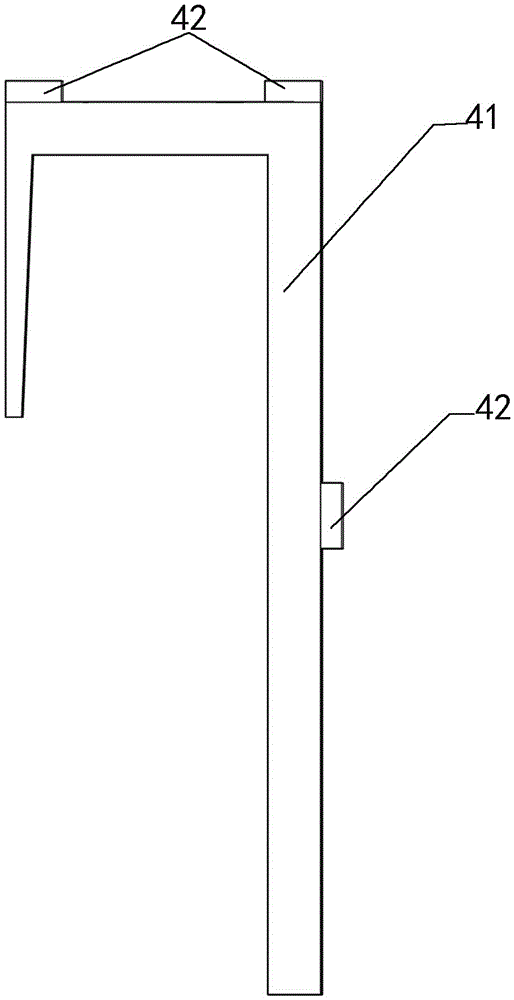

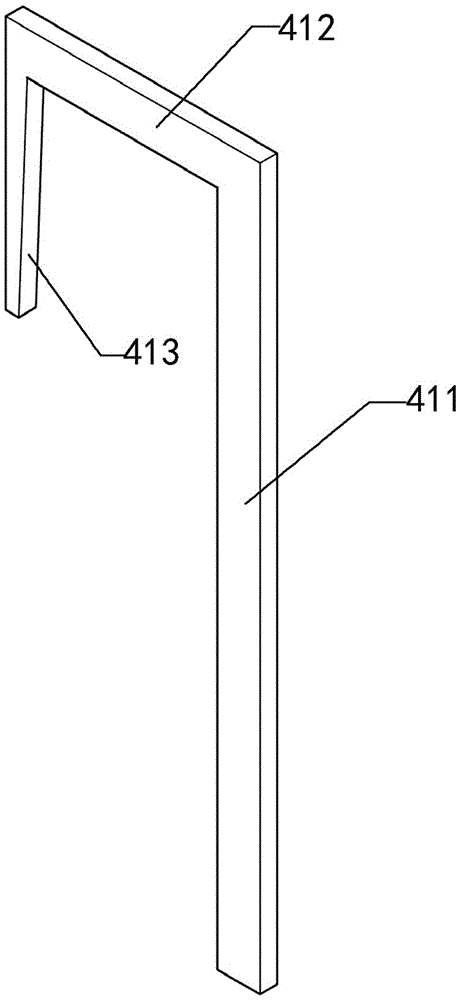

[0035] Such as figure 1 and figure 2 As shown, a curtain wall embedded part installation mold is used to accurately locate the installation position of the curtain wall embedded part 1 on the beam structure steel skeleton 2, and the curtain wall embedded part 1 is connected by welding. Composed of anchor bars 12, the embedded steel plate 11 needs to be fixed close to the outer surface of the steel bar skeleton 2 of the beam structure, and is characterized in that: image 3 As shown, the installation mold is a "7"-shaped double row frame mold, including two identical "7"-shaped limit mold frames 41 and two "7"-shaped limit mold frames. Horizontal connecting rod 42; the "7"-shaped limiting mold frame 41 is an integrally formed structure, which is composed of the outermost long column 411, the middle horizontal beam 412 and the inner shor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com