Process for stoping low coal seam containing ferric sulfide concretions and hard parting bands and hydraulic support thereof for fully mechanized mining

A technology of hydraulic support and iron sulfide, which is applied in the direction of pillar/support, ground mining, mining equipment, etc., can solve the problems of poor efficiency, high labor intensity, poor safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with drawings and embodiments.

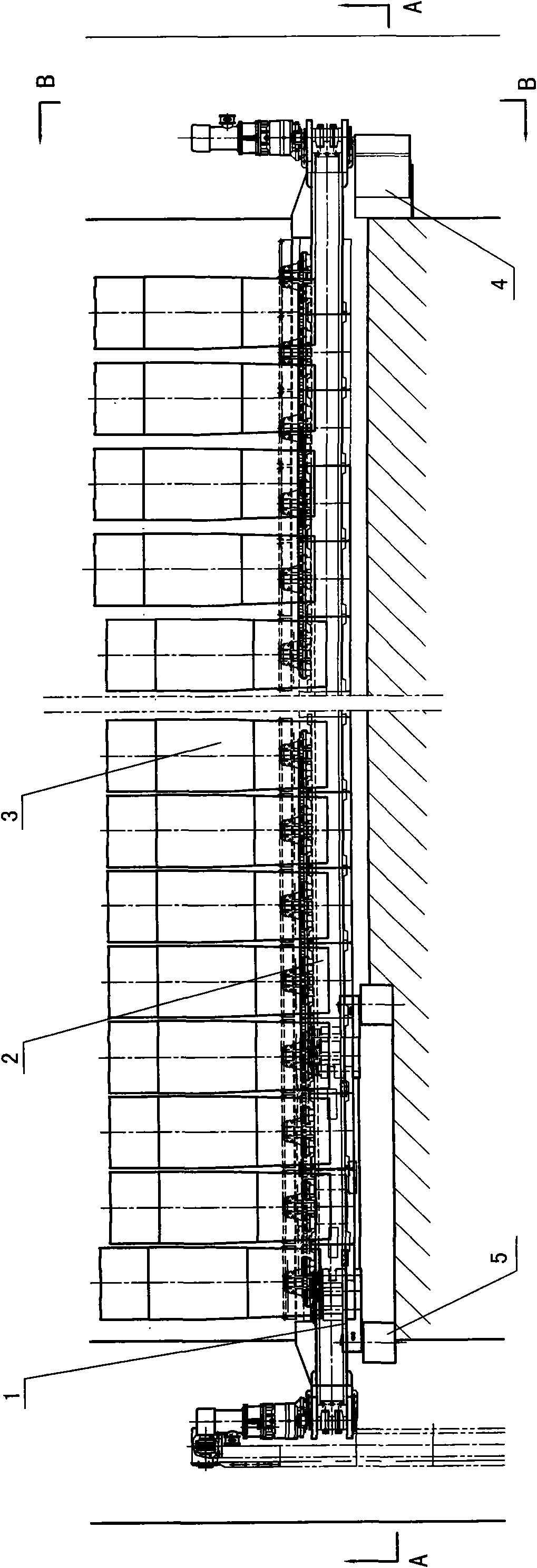

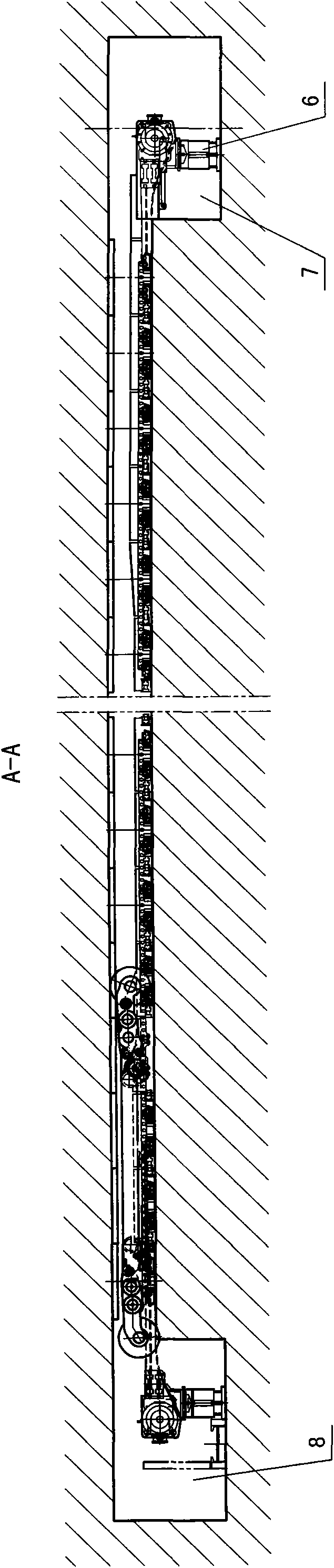

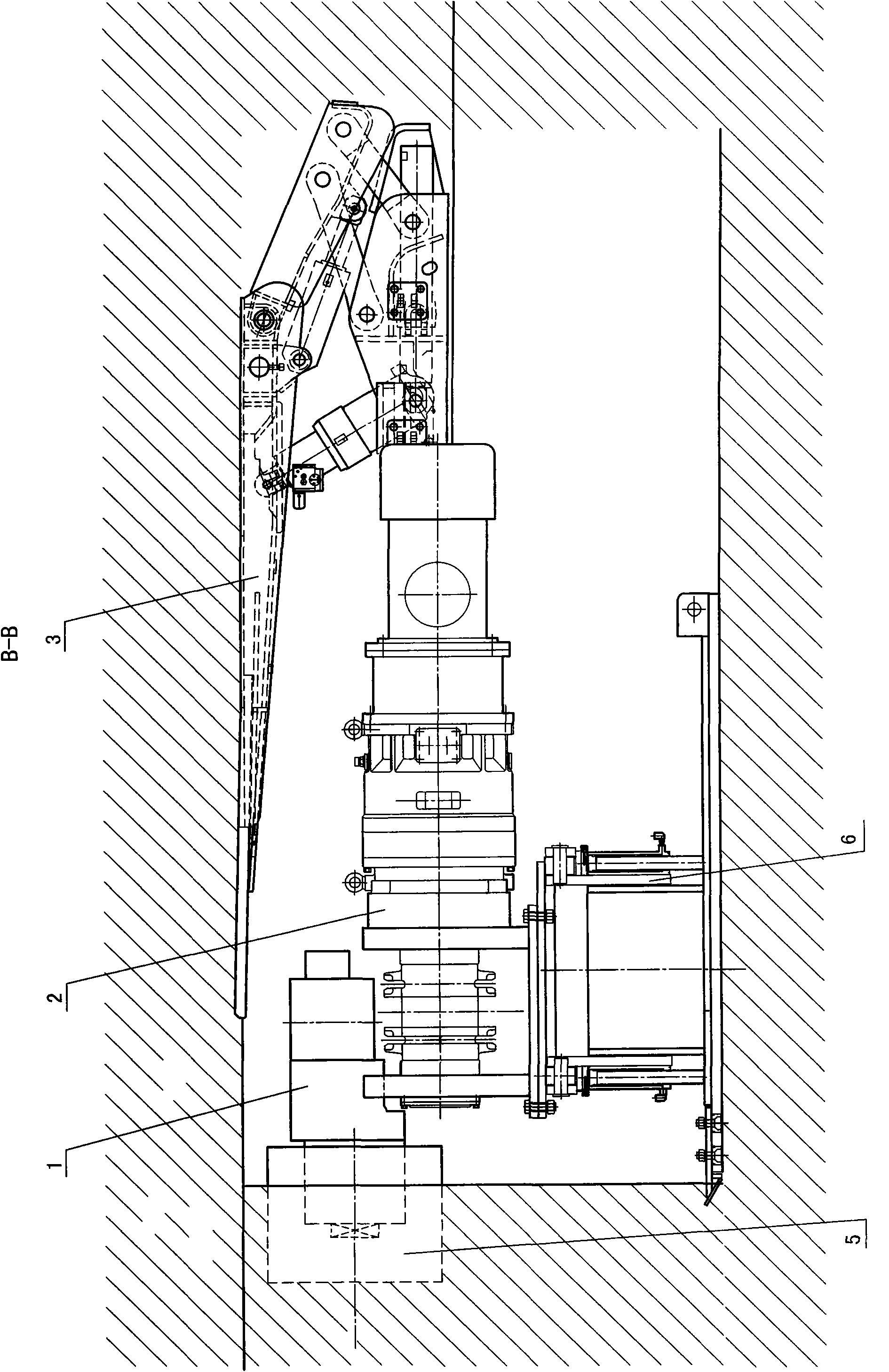

[0045] exist Figure 1~3 The arrangement of fully mechanized mining equipment in the coal mining face of the present invention is shown in the thin coal seam recovery technology containing iron sulfide nodules and hard gangue. Its fully mechanized mining equipment is composed of drum shearer 1, hydraulic support 2 and scraper conveyor 3 and so on. In order to solve the problem of comprehensive mechanized mining of thin coal seams containing iron sulfide nodules and hard gangue, the following new measures are mainly adopted in fully mechanized mining equipment and coal mining technology:

[0046] a. The drum shearer adopts a high-power shearer, a high-strength wide drum, and a shallow cutting depth to cut coal, that is, the cutting depth is smaller than the width of the drum.

[0047] b. The hydraulic support adopts the cover-type hydraulic support, which is pushed quanti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com