Low coal seam coverture type hydraulic support

A technology of hydraulic support and thin coal seam, which is applied to mine roof support, mining equipment, earthwork drilling, etc., can solve the problems of small lifting space, confusion and complex geological conditions of the roof beam of the hydraulic support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

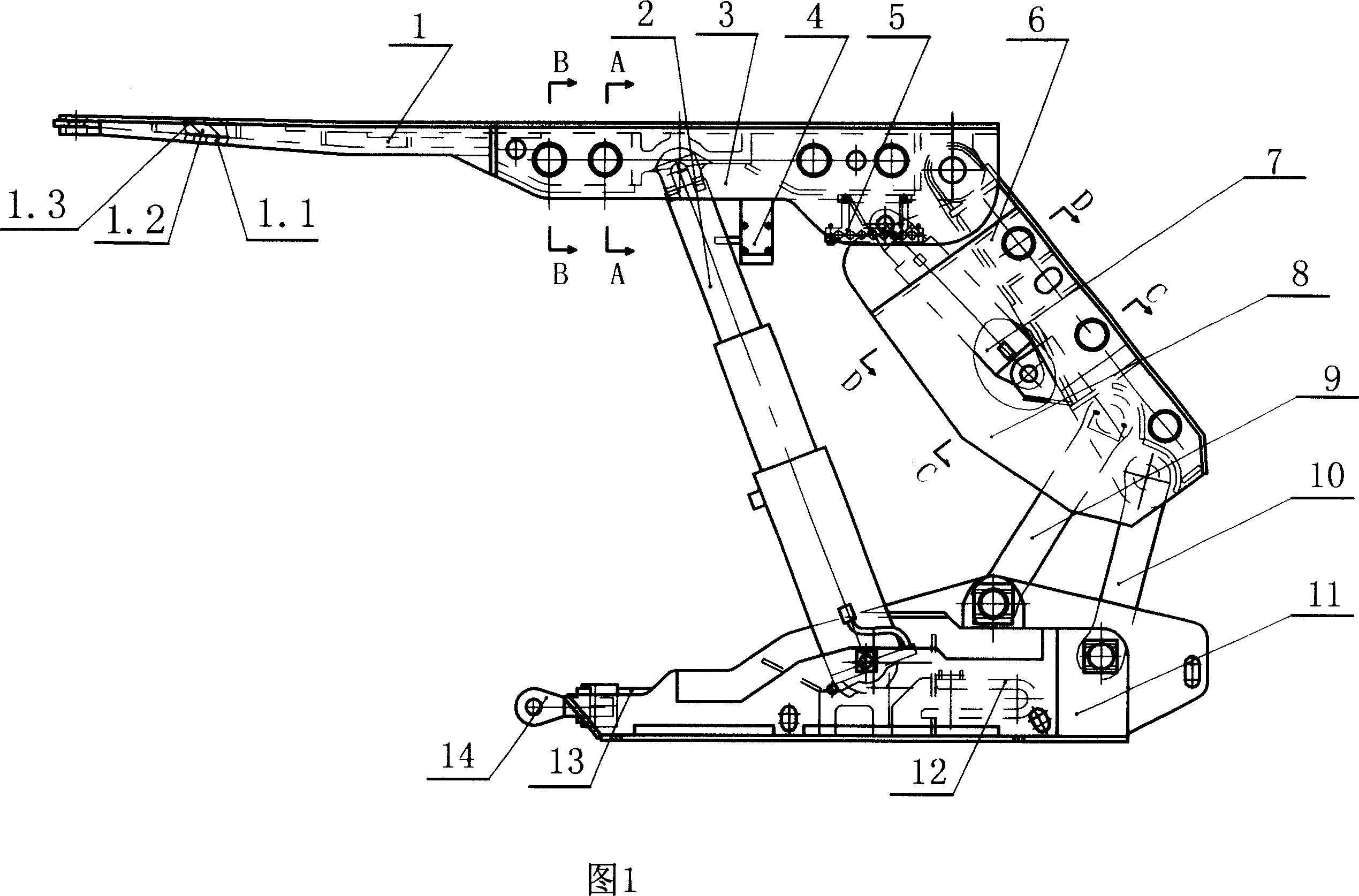

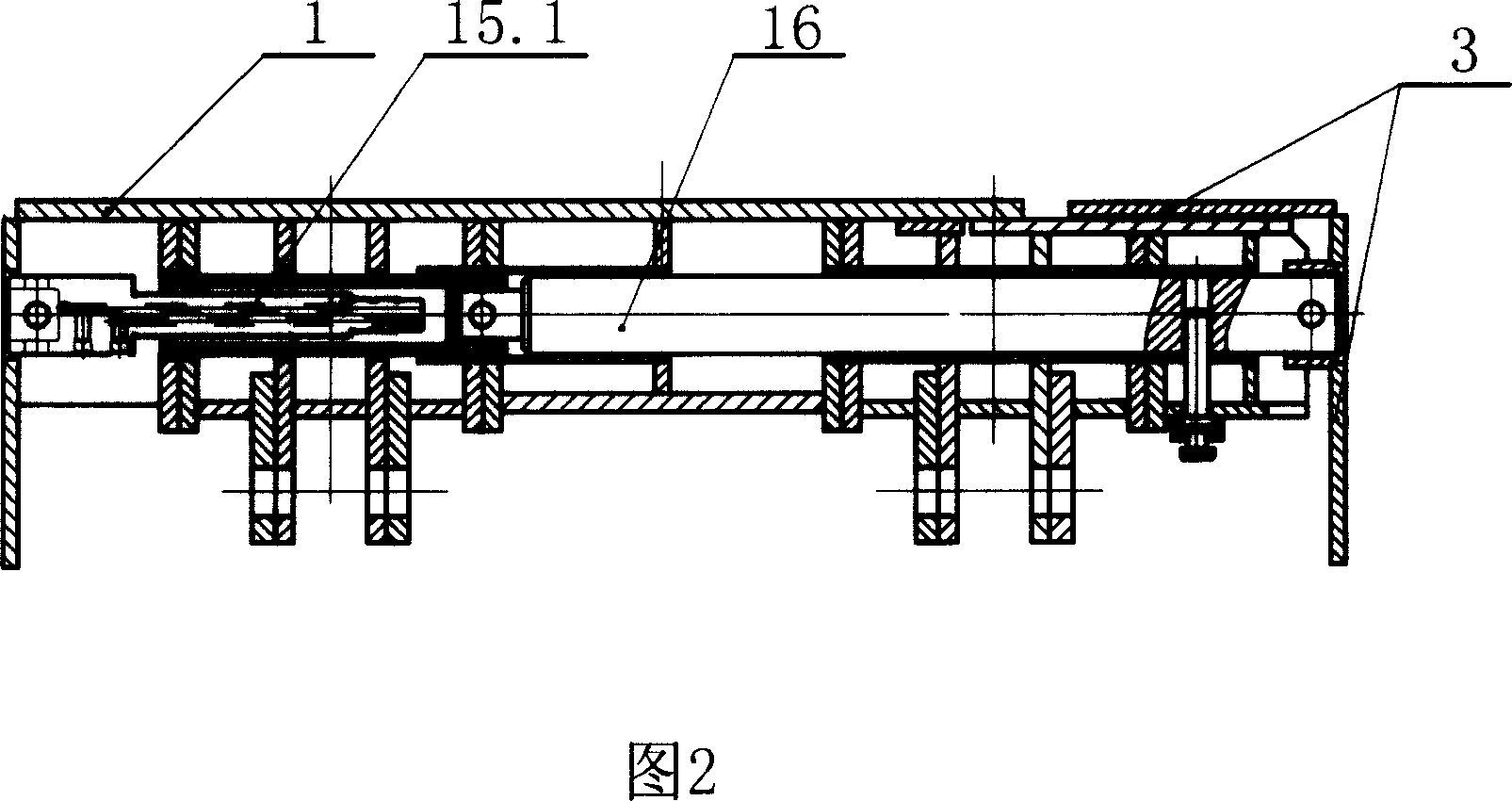

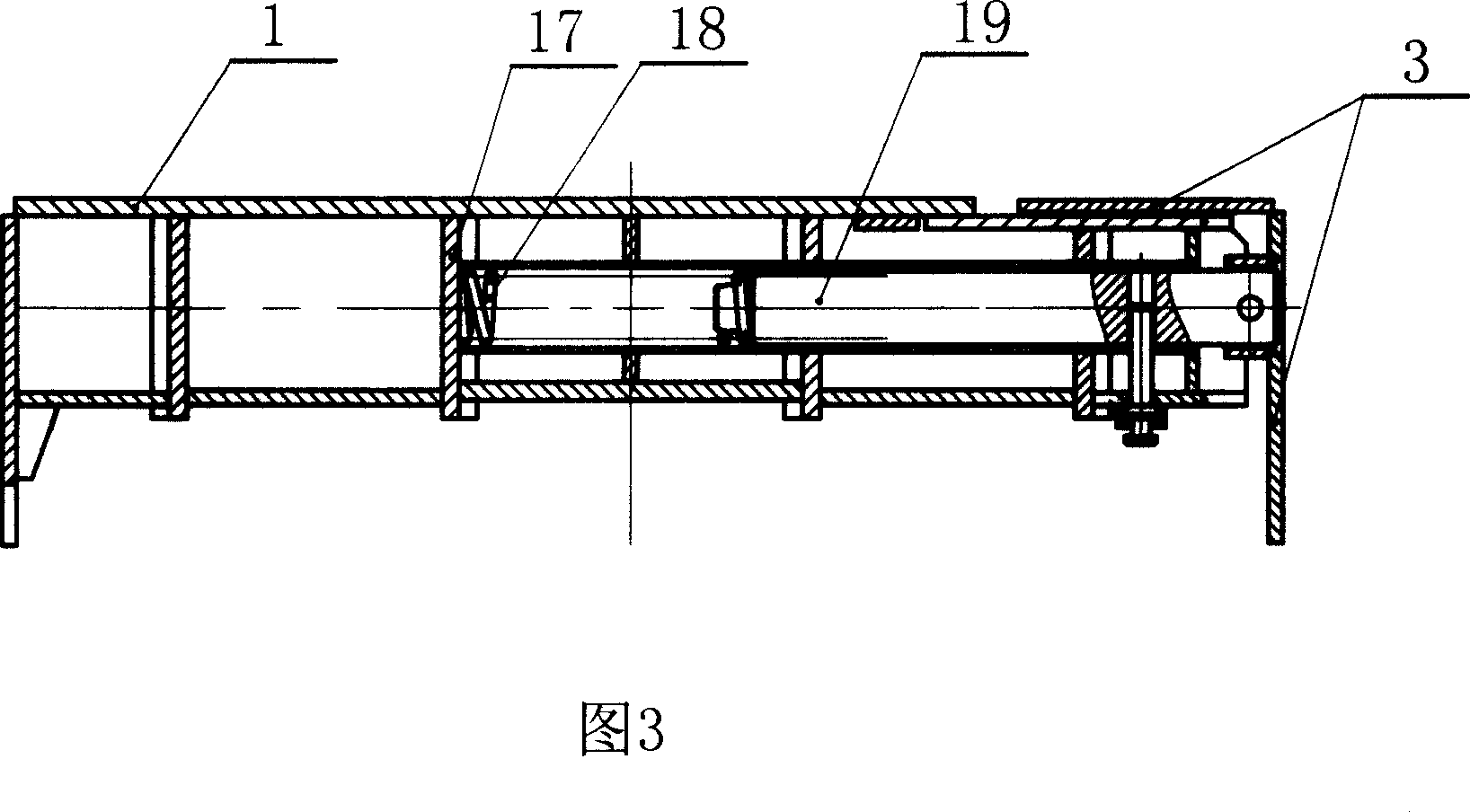

[0013]A kind of thin coal seam shield type hydraulic support, as shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, comprises top beam 1 with inner chamber, shield beam 6 with inner chamber, base 11, Two columns 2, balance jack 7, front connecting rod 9, rear connecting rod 10, push jack 12 and control valve group 4; the left side of the top beam 1 is equipped with a top beam side guard plate 3 that can be moved left and right; the top beam A side push jack 15.1 is installed in the cavity of 1, ribs 17 are arranged in the cavity of the top beam 1, and a long guide rod 16 and a short guide rod 19 of the top beam are also installed in the cavity of the top beam 1. The beam long guide rod 16 and the top beam short guide rod 19 are respectively slidingly connected with the inner cavity of the corresponding top beam 1; The left end is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com