Single-motor and wide-speed-regulation range crucible rod operation speed regulating system and speed regulation method

A technology of speed regulation system and wide speed regulation, which is applied in chemical instruments and methods, single crystal growth, self-solidification method, etc., and can solve problems such as narrow speed range, high processing and manufacturing costs, and discontinuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

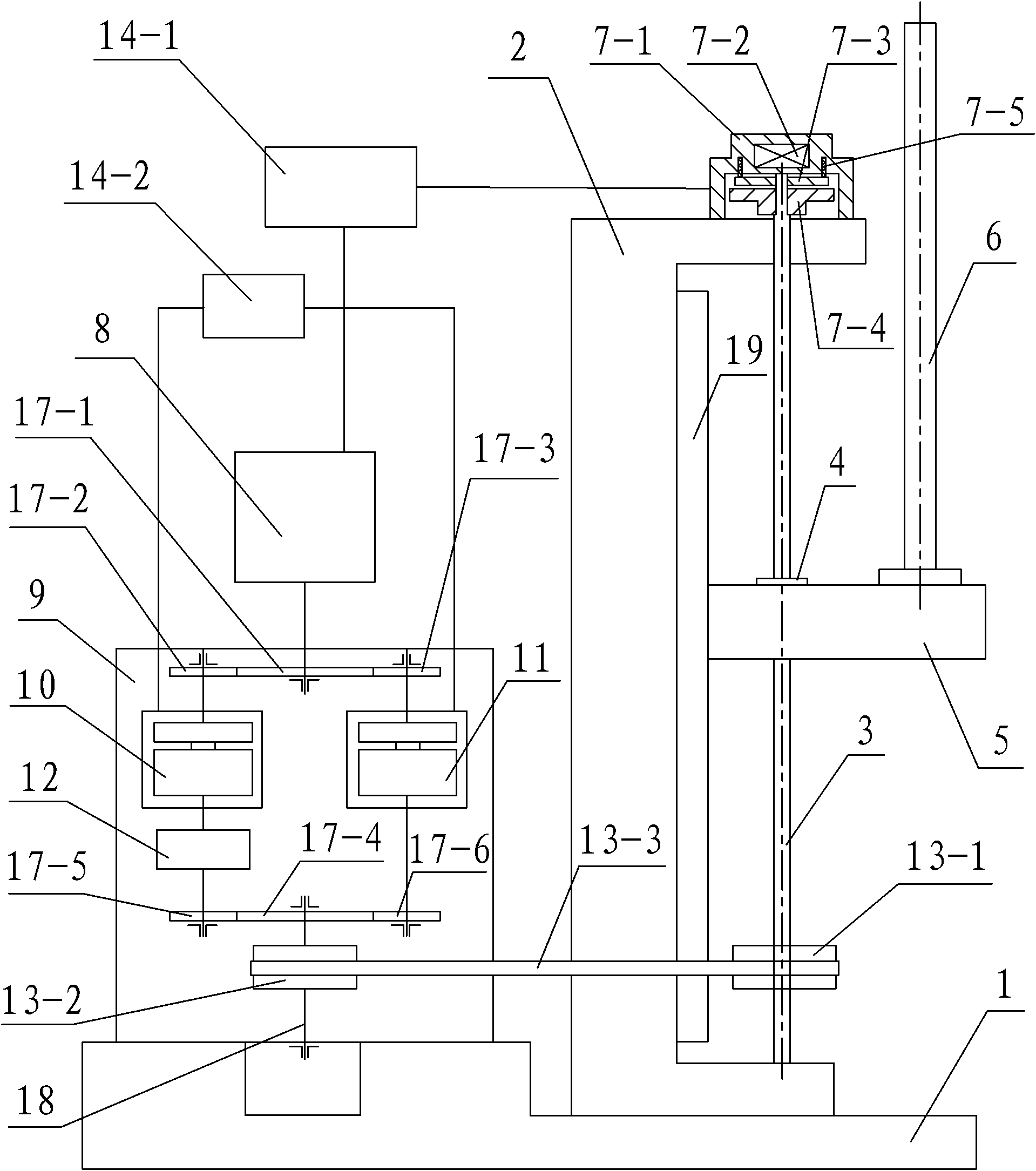

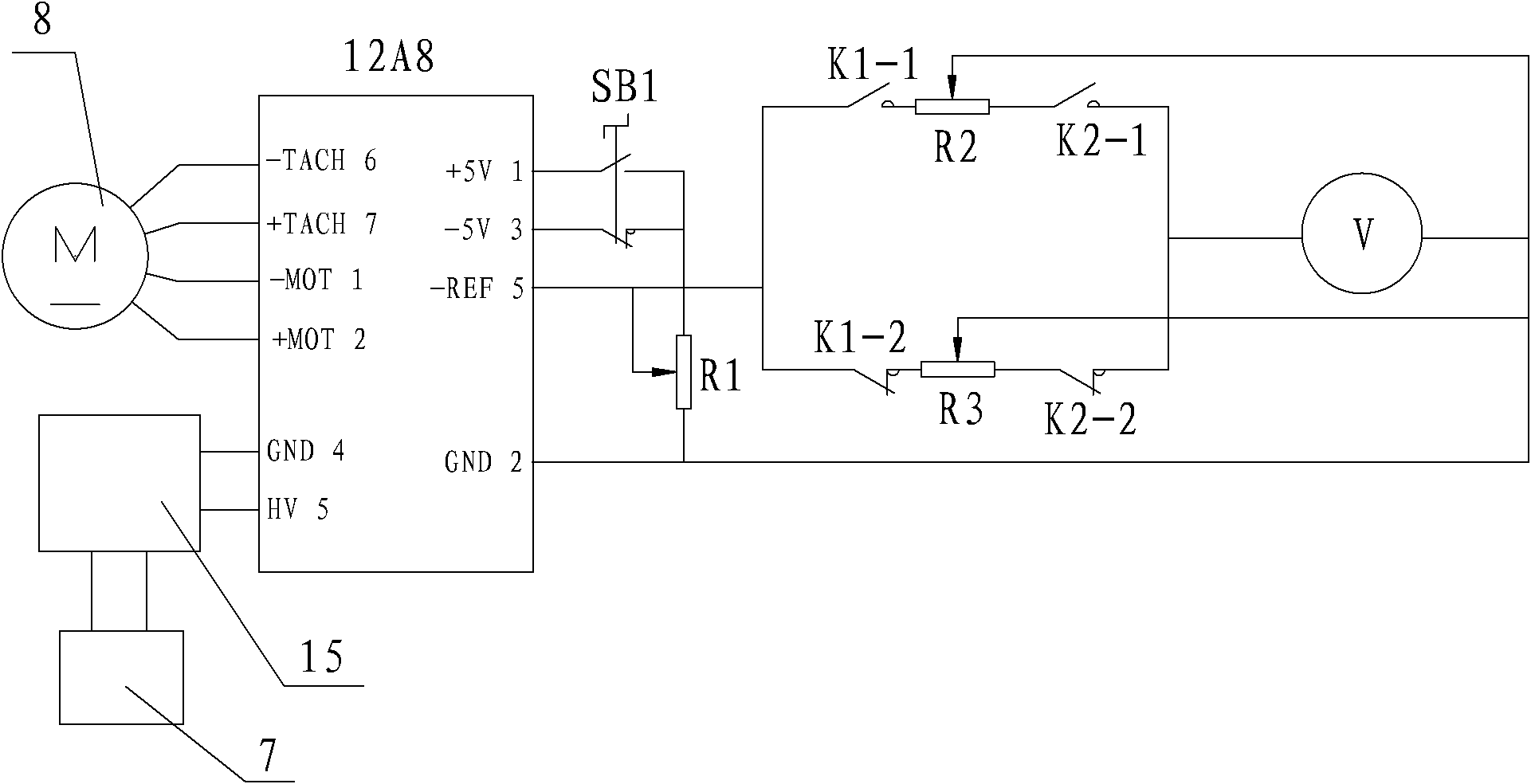

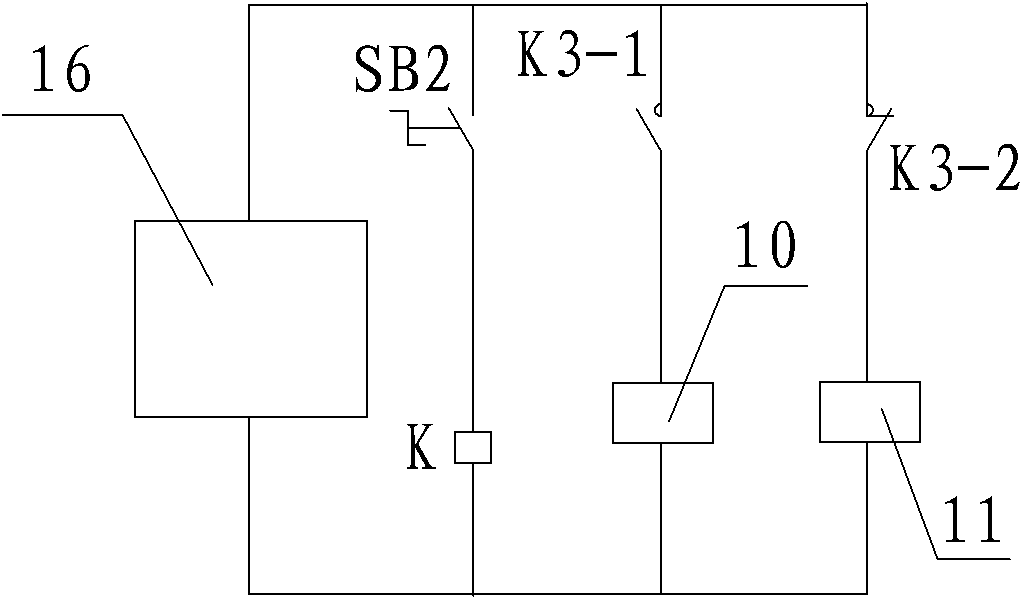

[0061] Such as figure 1 , figure 2 and image 3 As shown, the crucible rod operation speed regulation system with a wide speed regulation range of single motor according to the present invention includes a base 1, the top of the base 1 is provided with a crucible rod operating device, a power connected to the crucible rod operating device and The speed regulation system, and the operation and speed regulation control system connected with the crucible rod operating device and the power and speed regulation system;

[0062] The crucible rod running device includes a column 2 whose bottom end is connected to the base 1, a ball linear guide 19 fixedly connected to the side wall of the column 2, a ball screw 3 rotatably connected to the column 2 and parallel to the ball linear guide 19 , the ball screw nut 4 sleeved on the ball screw 3, the slider 5 that is connected with the ball screw nut 4 and the ball linear guide rail 19 and runs up and down on the ball screw rod 3 along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com