Electric follow-up turning device

A follow-up and electrical technology, applied in the direction of turning equipment, auxiliary devices, tool holder accessories, etc., to achieve the effects of fast mechanical response, high guiding precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

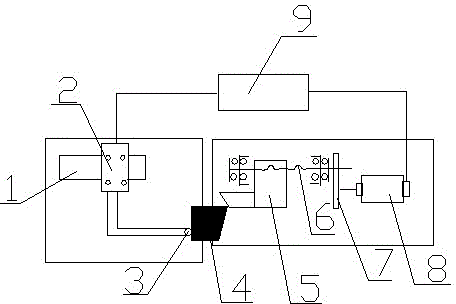

[0013] Below, combine figure 1 The present invention will be further described.

[0014] like figure 1 An electric follow-up turning device is shown, including an instant measurement feedback device, a high-speed data processing and control system, and an electric follow-up tool holder. The instant measurement feedback device consists of a grating ruler (1), a linear rolling guide (2) and The real-time tracking measurement device (3) is composed of the measuring head of the real-time measurement feedback device and the inner wall of the non-circular body (4), and the CNC vertical lathe table is started to rotate, and the measurement feedback device can immediately measure the non-circular body (4) ) The change in radial dimension, this signal is transmitted to the high-speed data processing and control system (9), to control the high-speed tracking servo motor (8) to drive the follow-up tool holder to track in real time, so that the change of the displacement of the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com