Laser plane coordinate calibration device

A technology of plane coordinates and standard devices, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve problems such as insufficient calibration methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

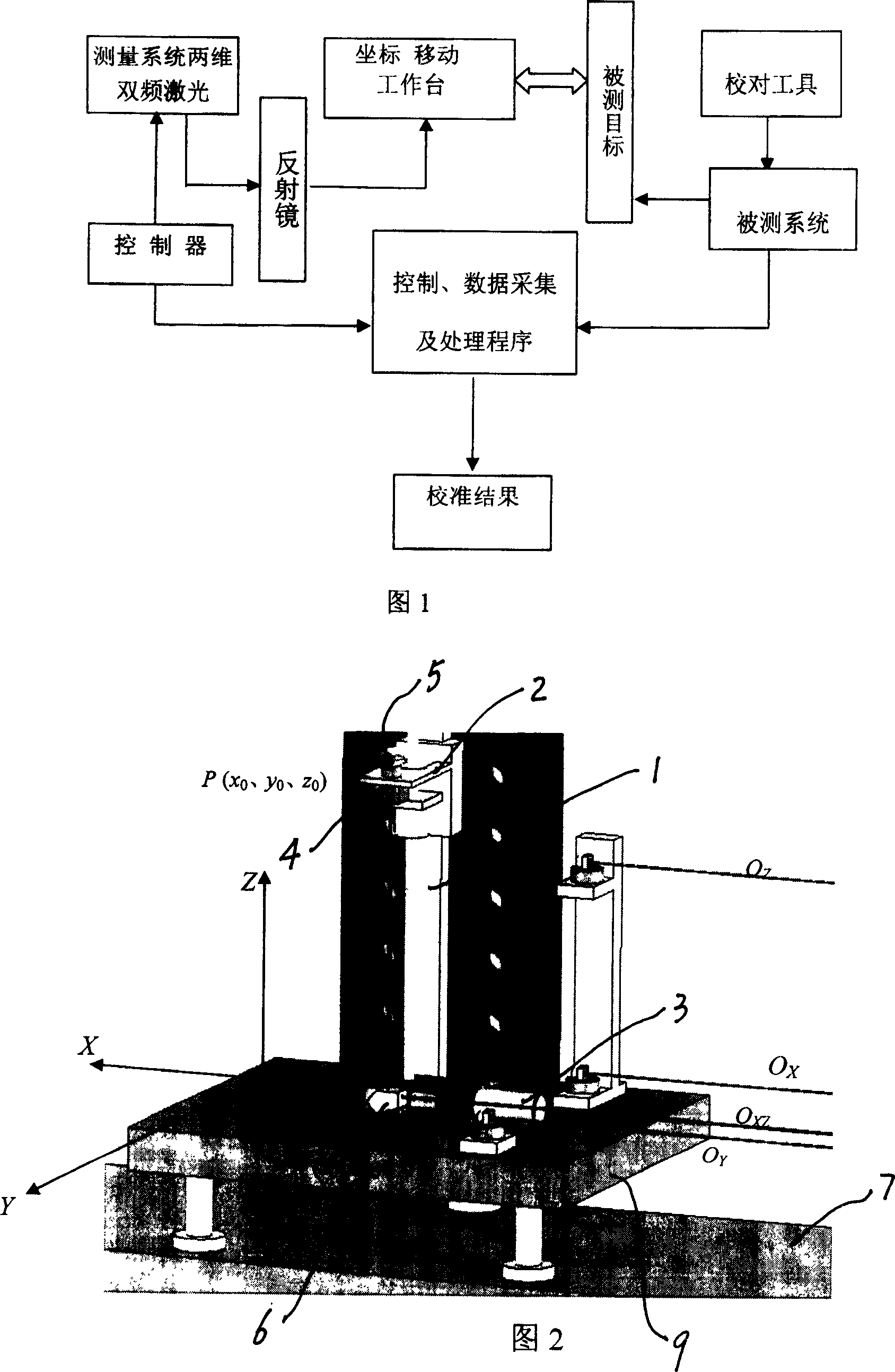

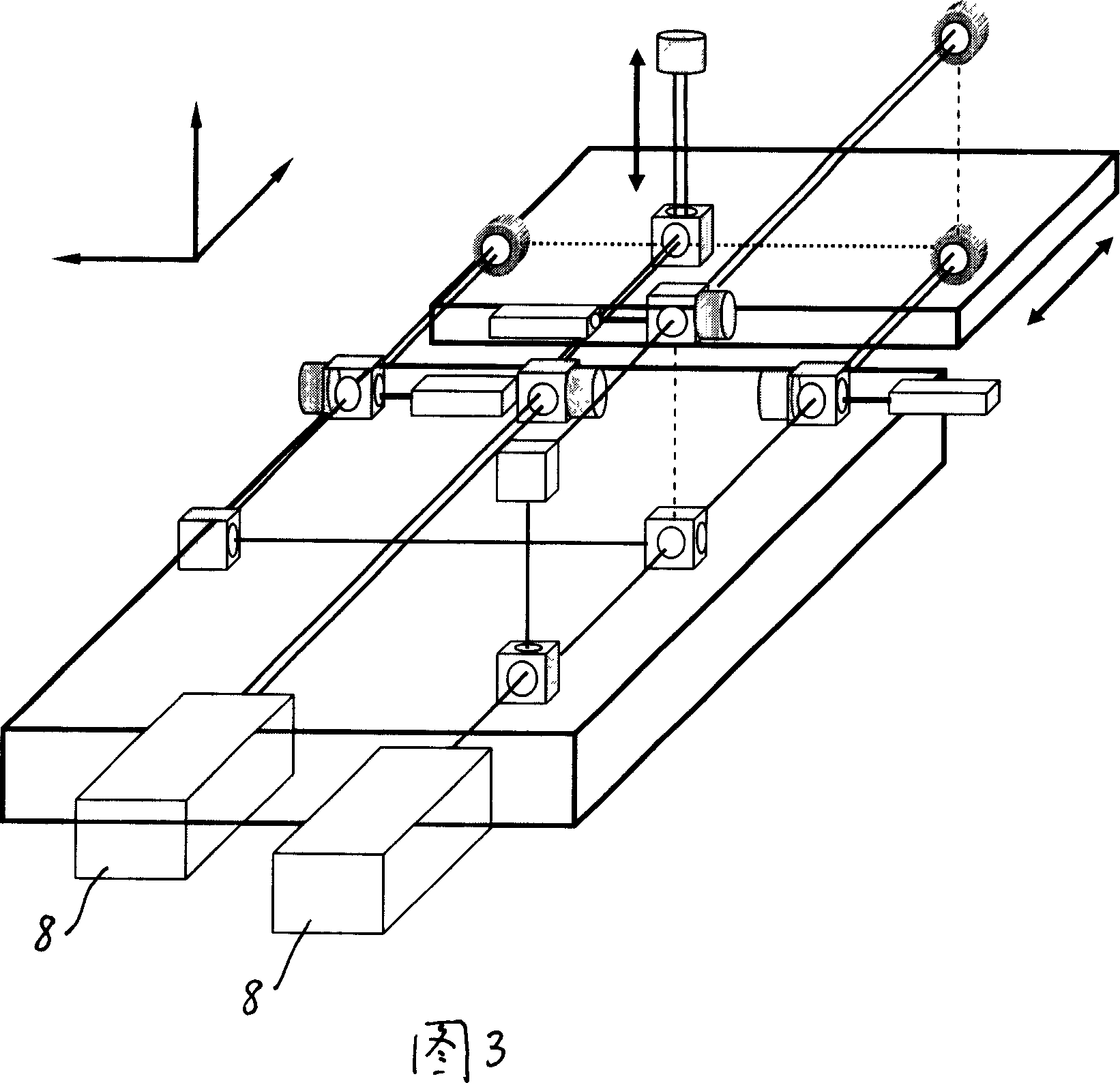

[0015] Referring to shown in accompanying drawing 1~3, laser plane coordinate standard device described in the present invention comprises the three-way laser interferometry optical path of measuring horizontal axial coordinate, and it comprises horizontal main optical path OX, auxiliary optical path OY, OZ, and its main body is Marble linear guide rail 7, with a total length of 36 meters, is spliced by nine pieces of marble. It is located on an independent foundation and supported by a jack. At one end, the target reflector is placed on the air-floating workbench 9, and the air-floating workbench 9 is driven by a motor to run along the marble linear guide rail, and the moving distance is measured by the interferometer 8. A set of laser interferometry optical path for measuring the vertical axis coordinates is added on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com