High jump cross bar

A crossbar and high jump technology, applied in jumping equipment, sports accessories, gymnastics equipment, etc., can solve the problems of easily broken replacement equipment, low reuse rate, unsuitable for general occasions, etc., and shorten the time for correct action dynamics , Excellent anti-excessive bending performance, and the effect of improving the repeated use rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

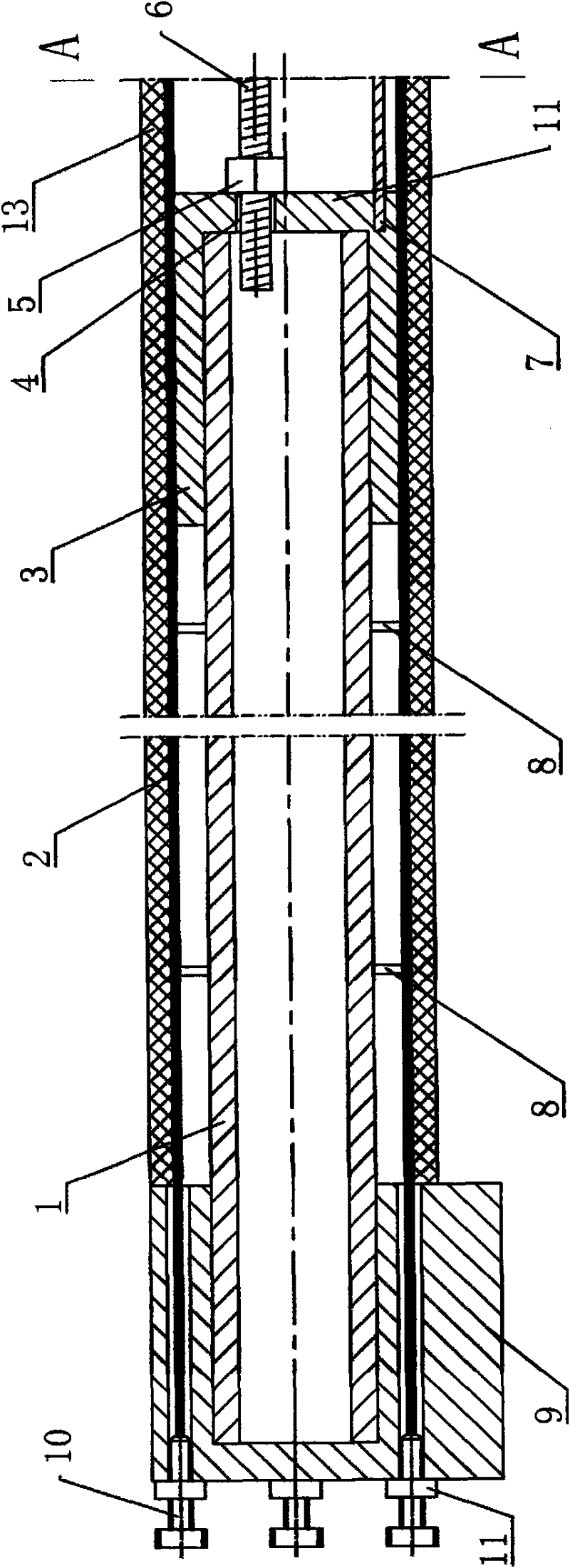

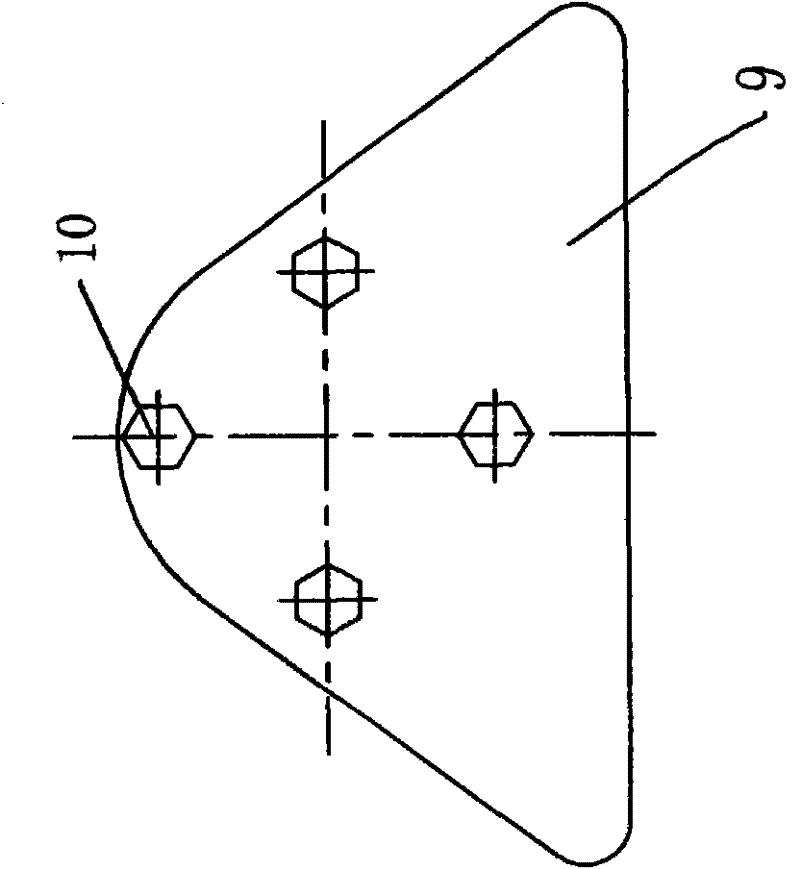

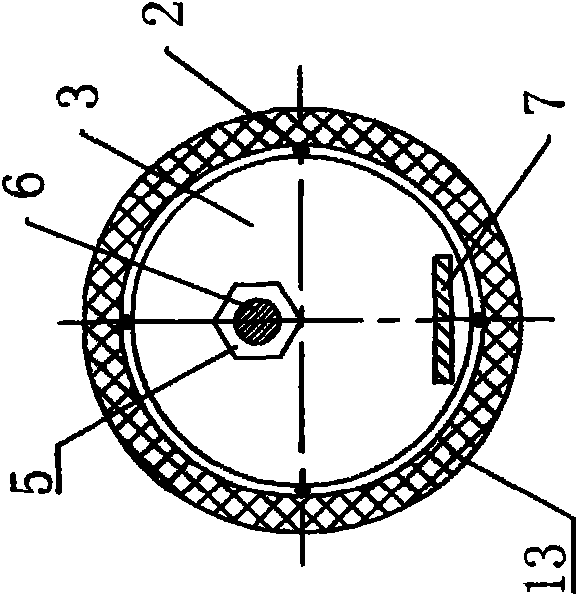

[0024] A high jump bar such as figure 1 , figure 2 and image 3 Commonly shown, of course, figure 1 Only shows the cross-sectional view of the left half of the high jump bar, and the right half should be symmetrical with it.

[0025] The high jump cross bar includes two cross bar halves 1, and the material of the cross bar halves 1 is preferably a bamboo pole or a plastic pipe, which not only saves cost, but also does not cause injury to athletes during use.

[0026] A connector is provided between the two sections of cross bar halves 1, and the function of the connector is to connect the two cross bar halves together and adjust their levelness. The connector described in this embodiment adopts the following specific structure: the adjacent ends of the half body of the cross bar 1 are respectively fixed with a connecting pipe body 3, and the inner diameter of the connecting pipe body 3 is the same as that of the half body of the cross bar. 1. The outer diameters are match...

Embodiment 2

[0031] like Figure 4 As shown, it is a structural cross-sectional view of Embodiment 2 of the present invention. The difference between this embodiment and Embodiment 1 is that the metal wire 2 in this embodiment passes through the center of the cross bar half body 1 and the connecting pipe body 3, and the rest structure and figure 1 are the same and will not be repeated here.

[0032] This solution can also prevent excessive bending of the high jump crossbar when it is bent by an external force.

[0033] The high jump bar disclosed by the present invention can be formed by connecting two sections of bamboo poles or plastic pipes with a diameter of 2.0 cm and a length of 190 cm through a connector. It is controlled within 1-2cm, and has the advantages of low price, good levelness and high reuse rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com