High-speed stable linear rail plate 3D printer based on UM structural design

A 3D printer and structural design technology, which is applied to 3D object support structures, coating devices, metal processing equipment, etc. The effect of seat positioning, improving printing speed and improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

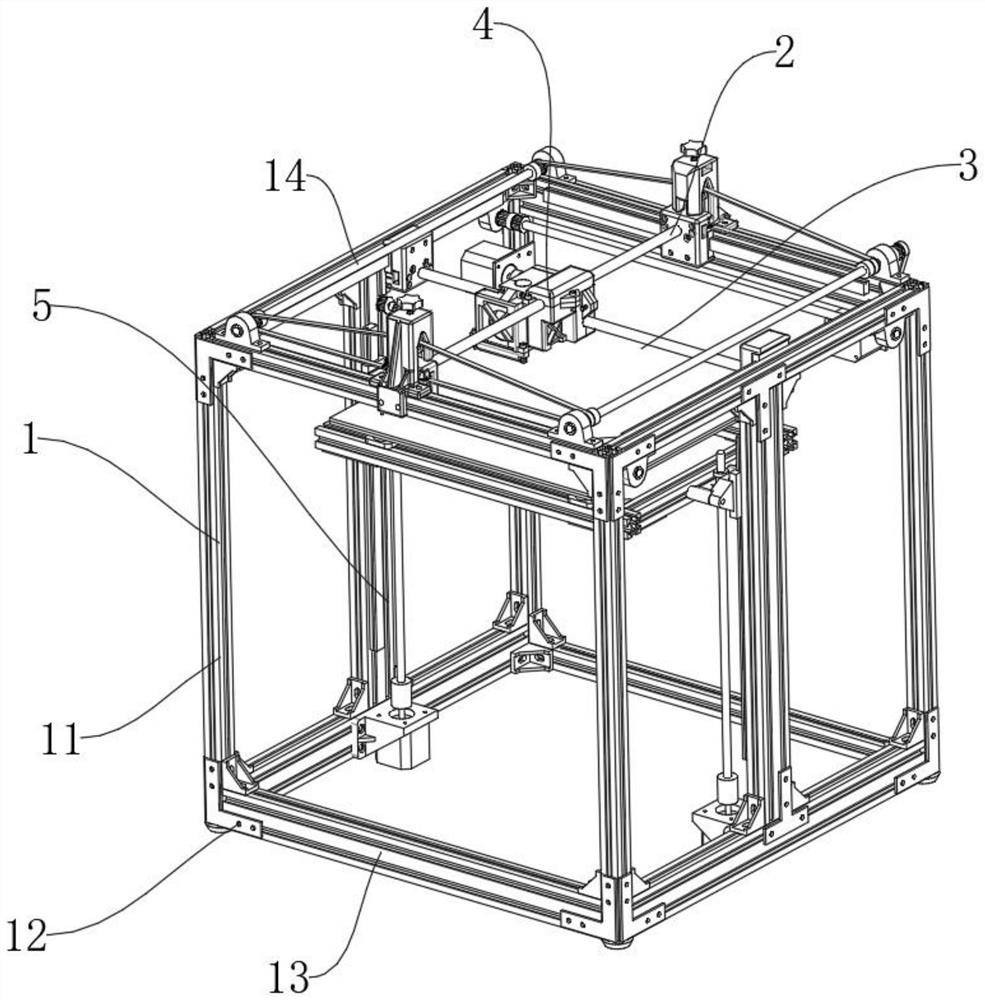

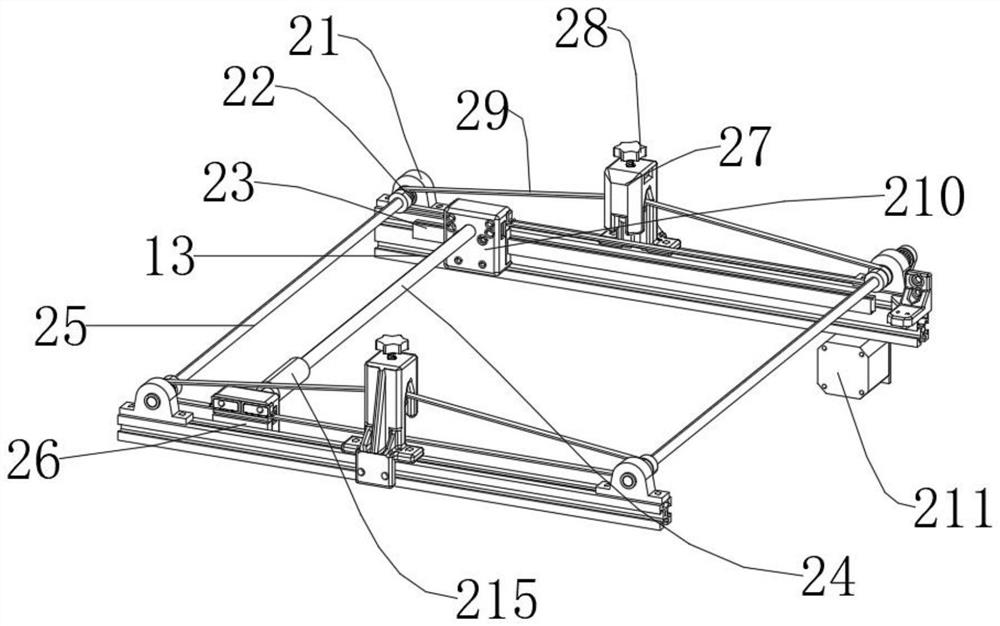

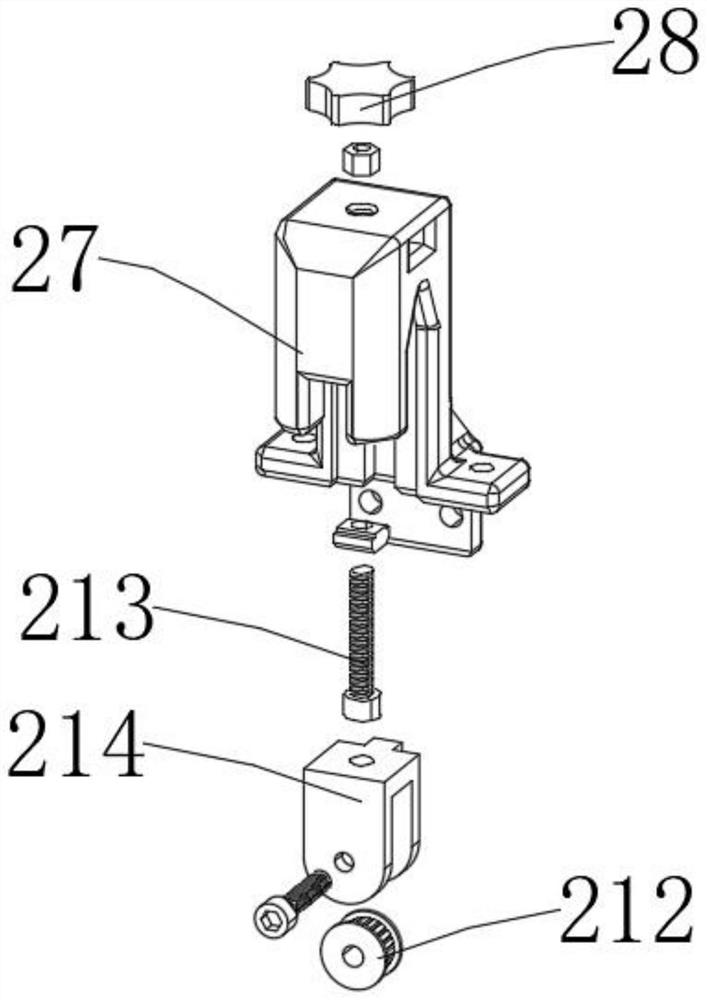

[0050] like Figure 1-Figure 8 As shown, a high-speed and stable linear rail version 3D printer based on UM structure design includes an external support mechanism 1 for external support, a nozzle mechanism 4 for printing raw materials, and an X movement for adjusting the position of the nozzle mechanism 4 Mechanism 2, Y moving mechanism 3, X moving mechanism 2 is installed on the upper end of the outer support mechanism 1, Y moving mechanism 3 is connected to the lower end of the X moving mechanism 2, and a nozzle mechanism 4 is installed between the X moving mechanism 2 and the Y moving mechanism 3. A Z moving mechanism 5 is arranged on the lower side of the mechanism 4;

[0051] The external support mechanism 1 includes a column 11, an L connecting block 12, a cross bar 13, and a vertical bar 14. The vertical column 11, the horizontal bar 13, and the vertical bar 14 are connected by the L connecting block 12 to form a cubic frame;

[0052] The X moving mechanism 2 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com