Dynamic revising method of three-coordinate measuring machine

A three-coordinate measuring machine and dynamic correction technology, applied to measuring devices, instruments, optical devices, etc., can solve the problems of slow measurement speed and low efficiency, and achieve the effect of eliminating influence, low application cost and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

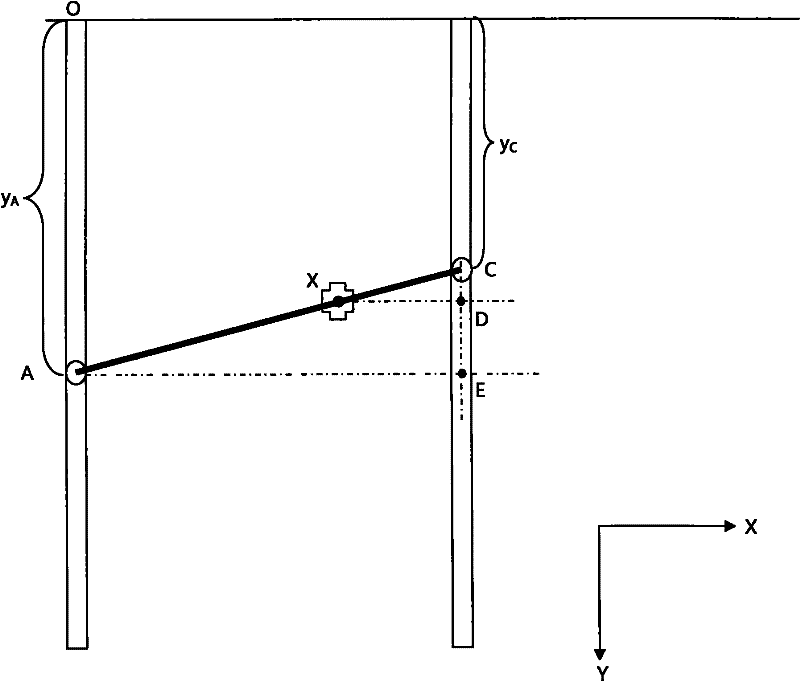

[0032] The dynamic correction method of the three-coordinate measuring machine can be used to eliminate the Abbe error of various existing three-coordinate measuring machines, such as three-coordinate measuring machines that require double Y-axis guide rails, such as mobile bridge type, single-side elevated type, and gantry beam type three-coordinate measuring machines. measuring machine.

[0033] First, a corresponding displacement measuring device needs to be installed on the three-coordinate measuring machine, and the displacement measuring device can adopt a grating measuring device including a grating ruler and a scanning head. The two parallel Y-axis guide rail sides and the X-axis moving beam are respectively provided with displacement measuring devices.

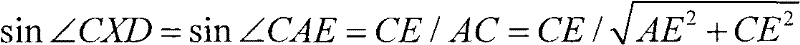

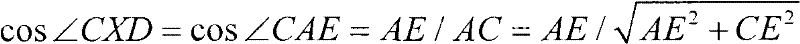

[0034] When performing three-coordinate measurement on a measuring point, in addition to using the measuring probe to obtain the displacement data in the Z-axis of the measuring point, the displacement measuring devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com