Mechanical splice

A technology of mechanical joints and steps, applied in the direction of mechanical equipment, pipes/pipe joints/fittings, sealing surface connections, etc., can solve leakage, mechanical joint jackets have no anti-off structure, and the degree of connection firmness cannot adapt to higher pressure occasions, etc. problems, to achieve the effect of increasing service life, saving material consumption, and reducing overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The solutions of the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

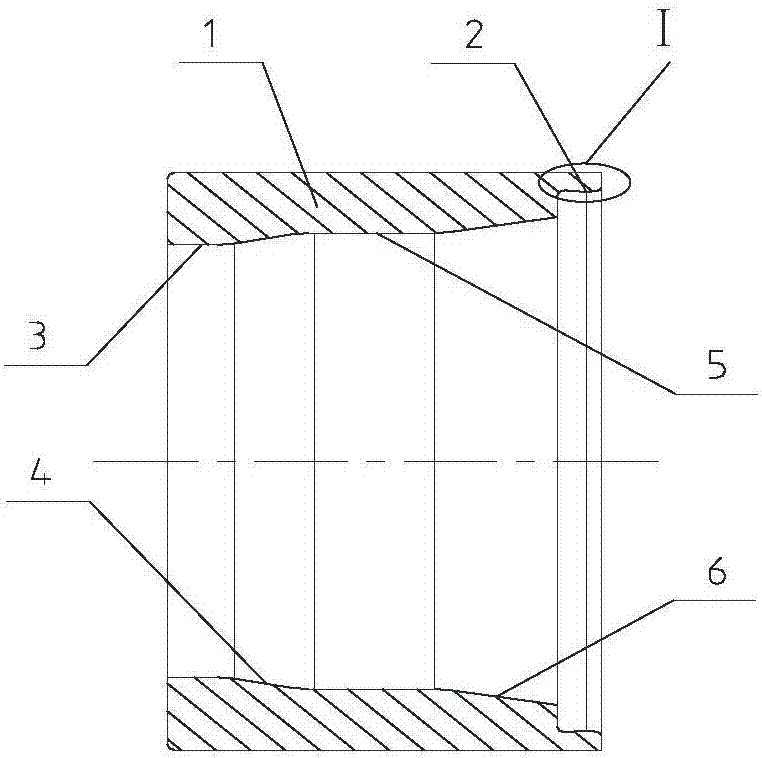

[0027] Such as figure 1 As shown, the inner hole of the jacket 1 from the small end to the large end is cylindrical surface 1 3, conical surface 1 4, cylindrical surface 2 5, conical surface 2 6, and anti-off ring 2;

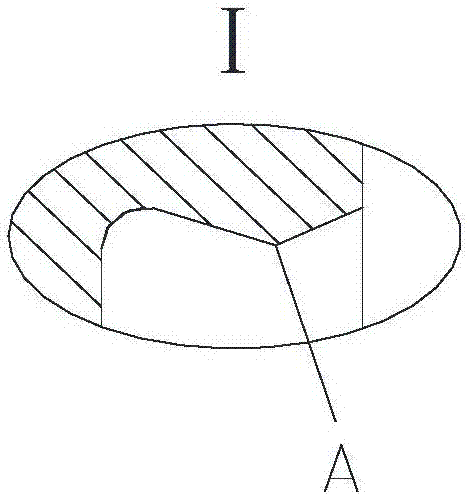

[0028] Such as figure 2 As shown, the anti-off ring is an annular protrusion with a triangular cross-section, and A is the raised apex of the annular protrusion, which is the smallest inner diameter on the anti-off ring;

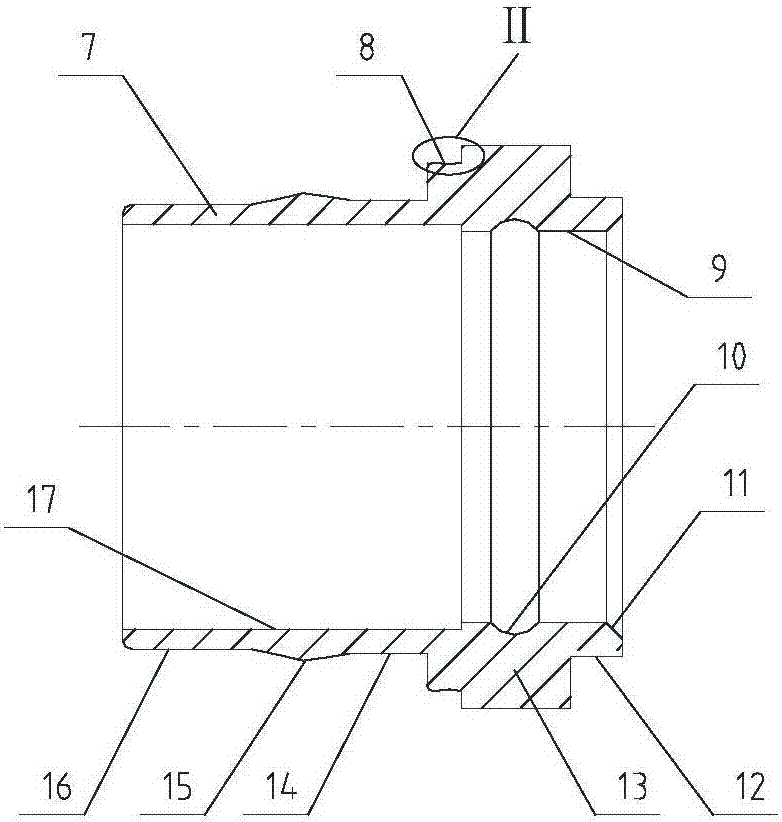

[0029] Such as image 3 As shown, the main body 7 shaft shoulder 13 is provided with an anti-off groove 8, and the outer circumference of the main body is sequentially provided with a stepped outer circle 12, a shaft shoulder 13, a stepped outer circle 2 14, and a stepped outer circle 3 16, and a stepped outer circle 2 14 is in contact with the stepped outer circle 3 16, which is an arc-shaped protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com