A fan blade pre-embedded root flange device

A technology for fan blades and flanges, which is applied in the field of pre-embedded root flange devices for fan blades, can solve problems such as not easy to disassemble, affect positioning accuracy, and axial misalignment, and achieve improved stability and accuracy, large contact area, The effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

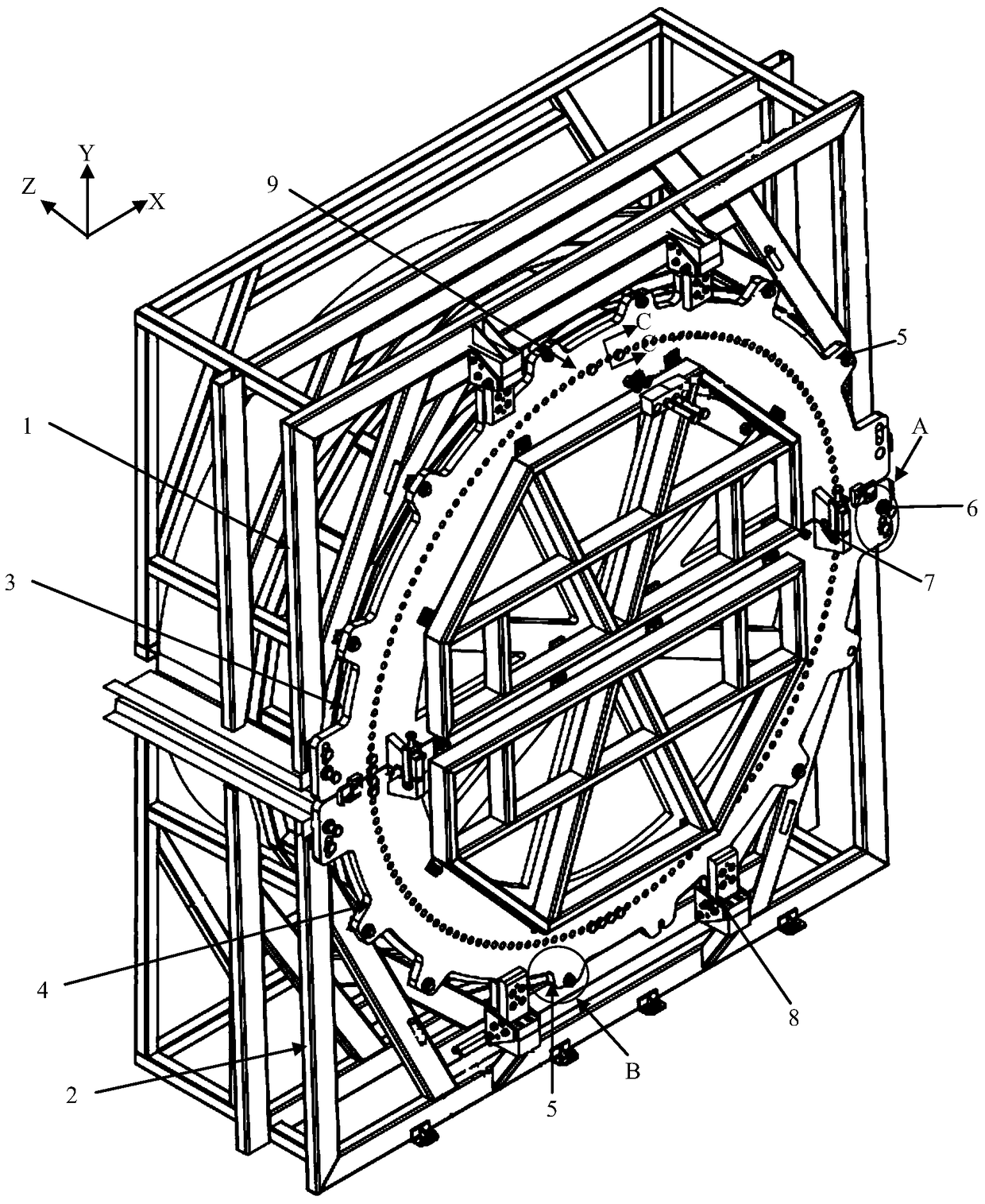

[0036] In the following description, the Y-axis direction is taken as the longitudinal direction, the Z-axis direction is taken as the axial direction, and the X-axis direction is taken as the transverse direction.

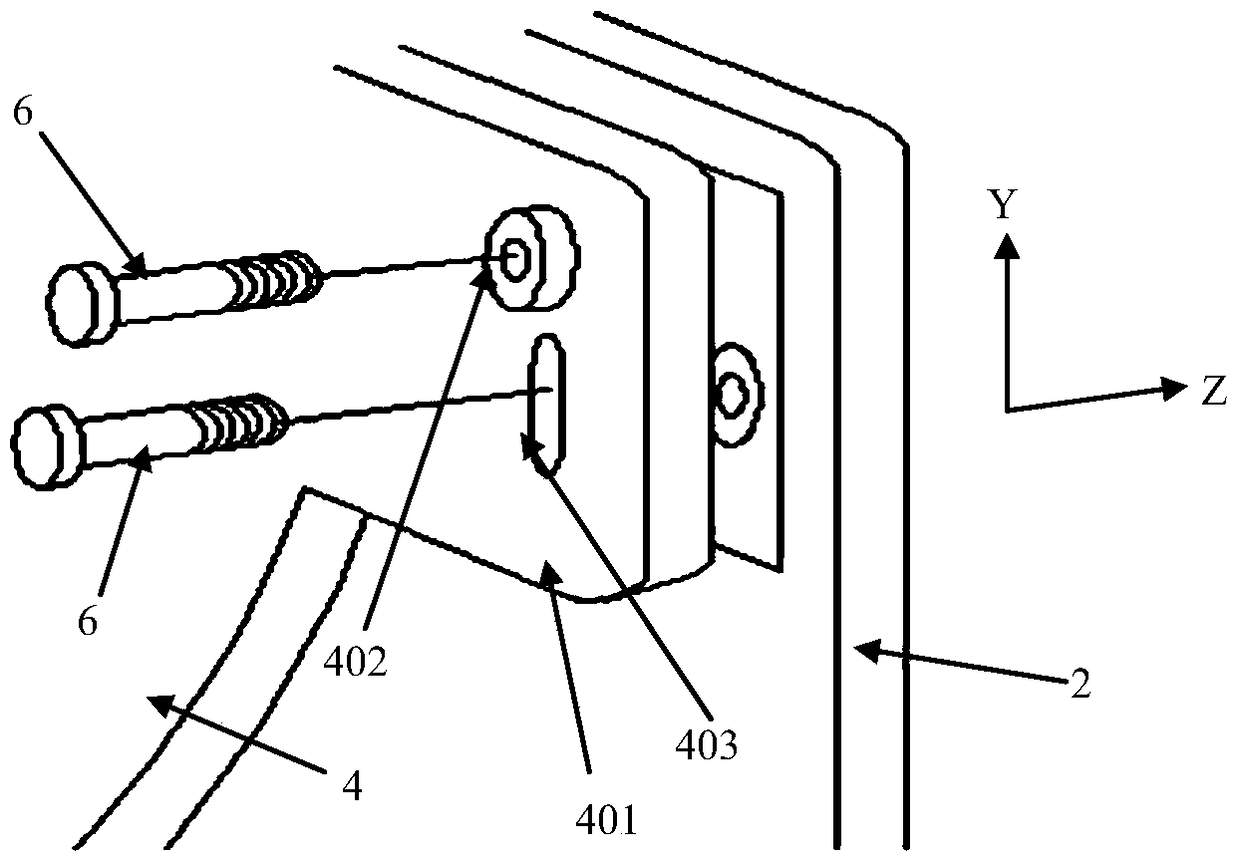

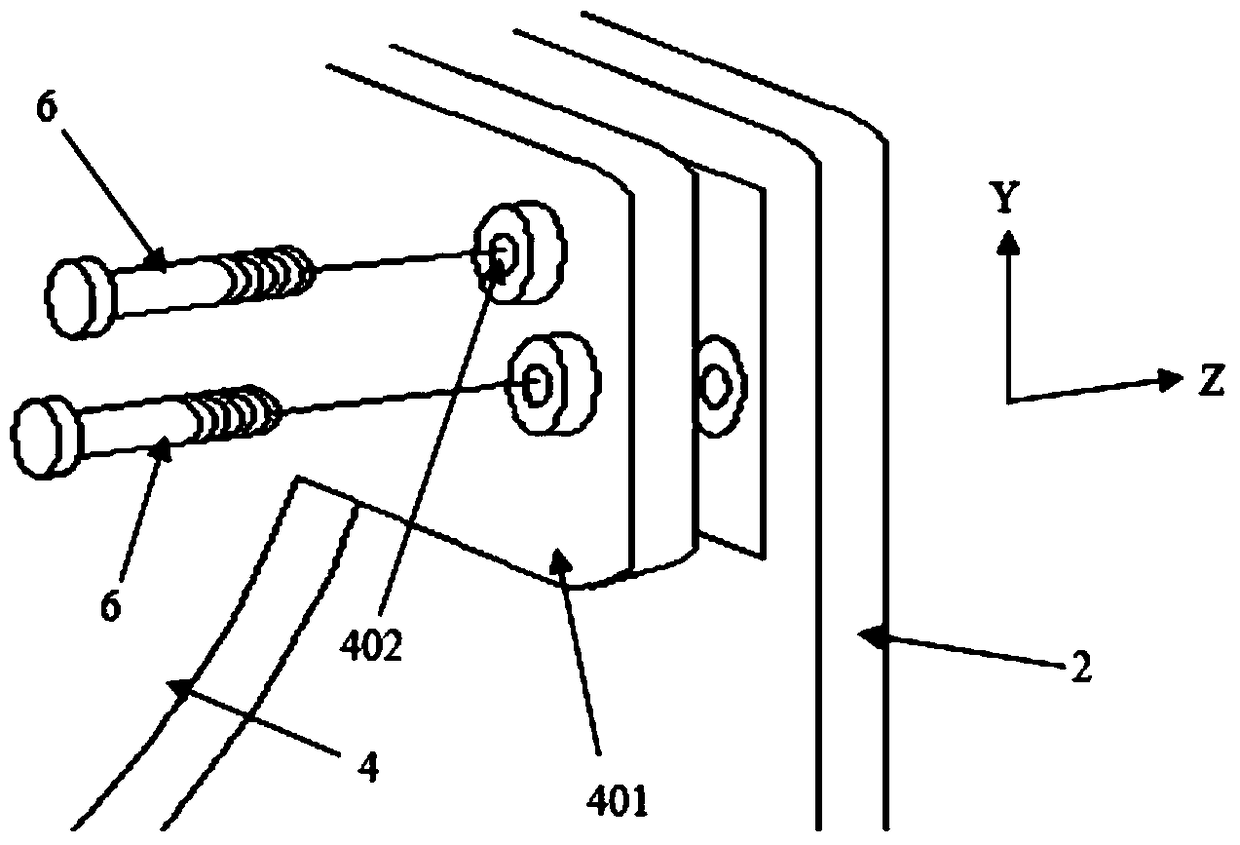

[0037] refer to figure 1 , the pre-embedded root flange device of the fan blade in this embodiment includes: an upper half flange 3, a lower half flange 4, an upper half mold 1 and a lower half mold 2, and the upper half flange 3 is connected by an iron foot 8, a side Bolts 6, foot connecting bolts 5 and root-end connecting bolts 9 are installed on the upper half-mold 1. Similarly, the lower half-flange 4 is installed on the lower half-mold 2 through iron feet 8, side connecting bolts 5 and root-end connecting bolts 9. superior. That is to say, the installation structure of the upper half flange 3 and the upper half mold 1 is basically the same as the installation structure of the lower half flange 4 and the lower half mold 2, so in the following description, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com