Circular rotating disc mechanism for transferring microneedles

A turntable mechanism and micro-needle technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as high precision requirements, inability to meet production needs, automation, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

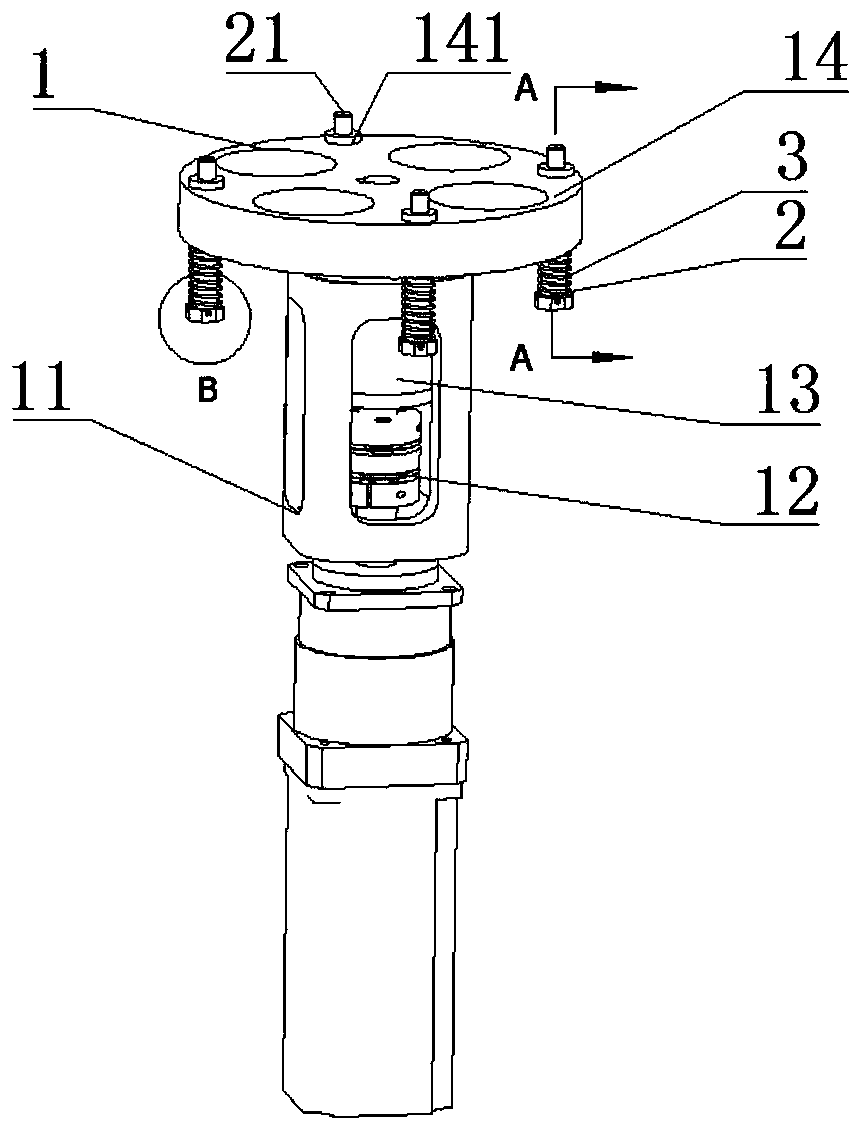

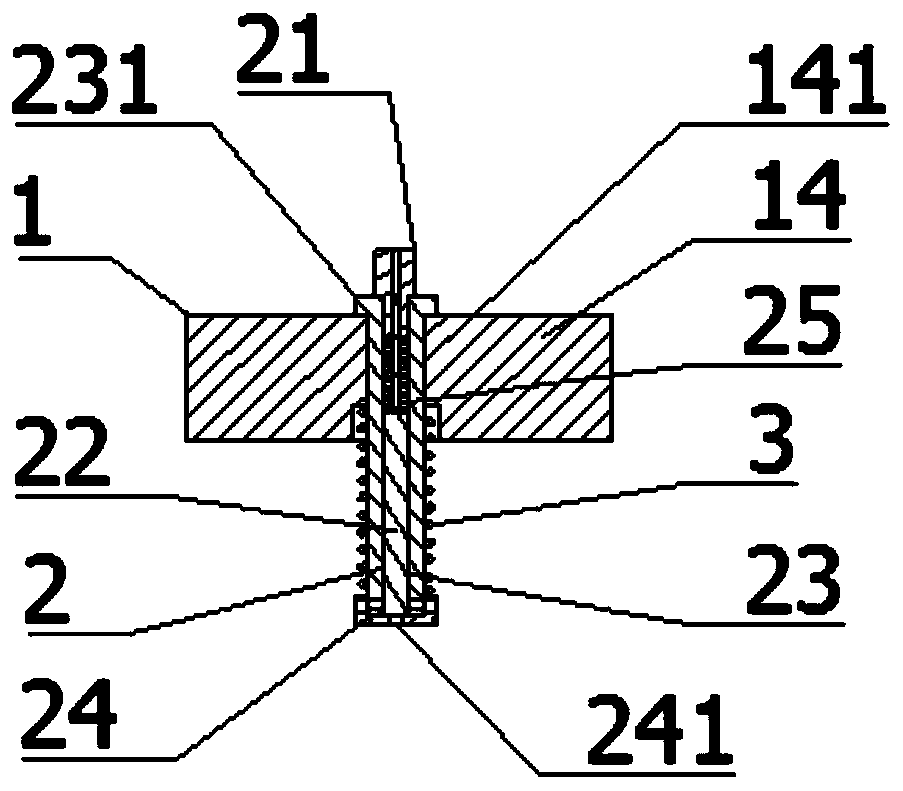

[0027] refer to figure 1 , figure 2 , the present invention includes a driving platform 1, a chuck assembly 2 and a second spring 3; the driving platform 1 is composed of a base 11, a stepping motor 12, a bearing 13 and a circular turntable 14; the base 11 is vertically arranged There is a frame member with a motor seat and a bearing seat; a rotating shaft is arranged on the center of the circular turntable 14, and four chuck assembly seats 141 are evenly distributed on the circumference; the bearing 13 is arranged on the bearing seat of the base 11, The stepping motor 12 is arranged on the motor base of the base 11 , and the circular turntable 14 is arranged on the top of the base 11 , the rotating shaft of the circular turntable 14 is hinged with the bearing 13 and connected with the output shaft of the stepper motor 12 .

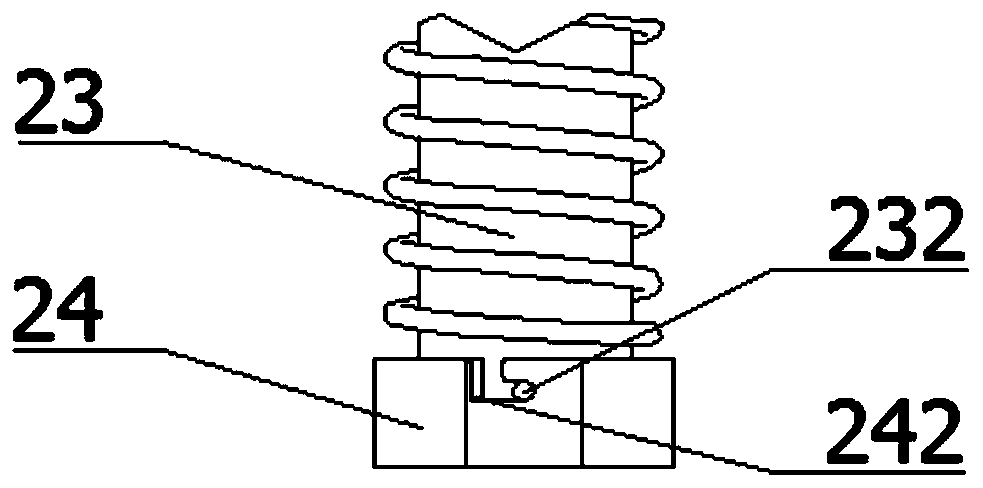

[0028] refer to figure 1 , figure 2 , image 3 , the chuck assembly 2 is composed of a chuck 21, a feeding push rod 22, a carrier 23, a cover 24 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com