Cold-bending forming machine for high corrugated steel floor deck

A cold-bending forming machine and cold-bending forming technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of the large size of the wave bevel, damage to the surface coating or coating of the product, and affect the appearance of the product sheet, etc. To achieve the effect of good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

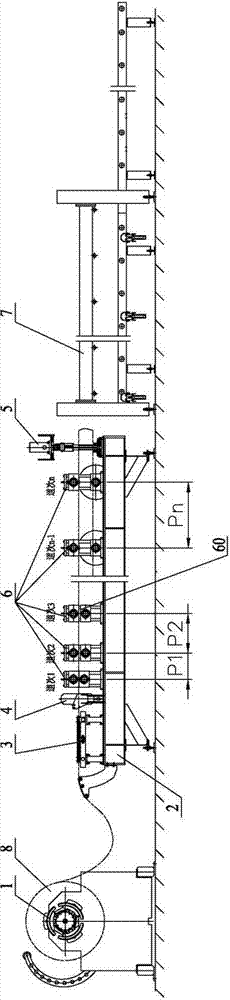

[0024] Please refer to the attached figure 1 to attach Image 6 As shown, the present invention is a cold-bending forming machine for high corrugated steel floor decks, which consists of an automatic uncoiler 1, a frame 2, a guiding device 3, a lubricating device 4, a cold-bending roll group 6, a hydraulic cutting device 5 and Palletizer 7 and other parts.

[0025] Wherein, the automatic uncoiler 1 is located on one side of the frame 2 , and the palletizer 7 is located on the other side of the frame 2 . A cylindrical coil material 8 is installed on the automatic uncoiler 1, and the automatic uncoiler 1 unwinds the cylindrical coil material 8, and realizes continuous or intermittent, fast or slow feeding through the electrical control of the automatic uncoiler 1 . And described stacker 7 stacks finished products, and sends out machine.

[0026] The guide device 3 , the lubricating device 4 , the cold roll forming roll group 6 and the hydraulic cutting device 5 are sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com