Thin film hybrid integrated circuit electroplating method

A hybrid integrated circuit and thin film technology, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of reduced production efficiency, high production cost, waste of precious metals, etc., and achieve high production efficiency, low production cost, circuit high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

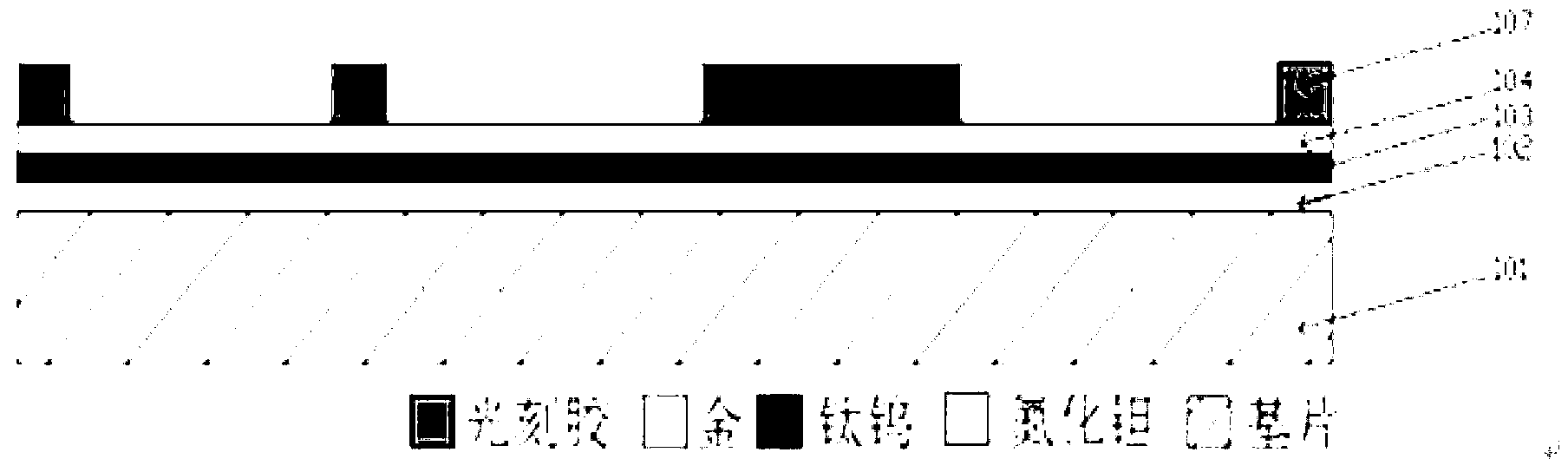

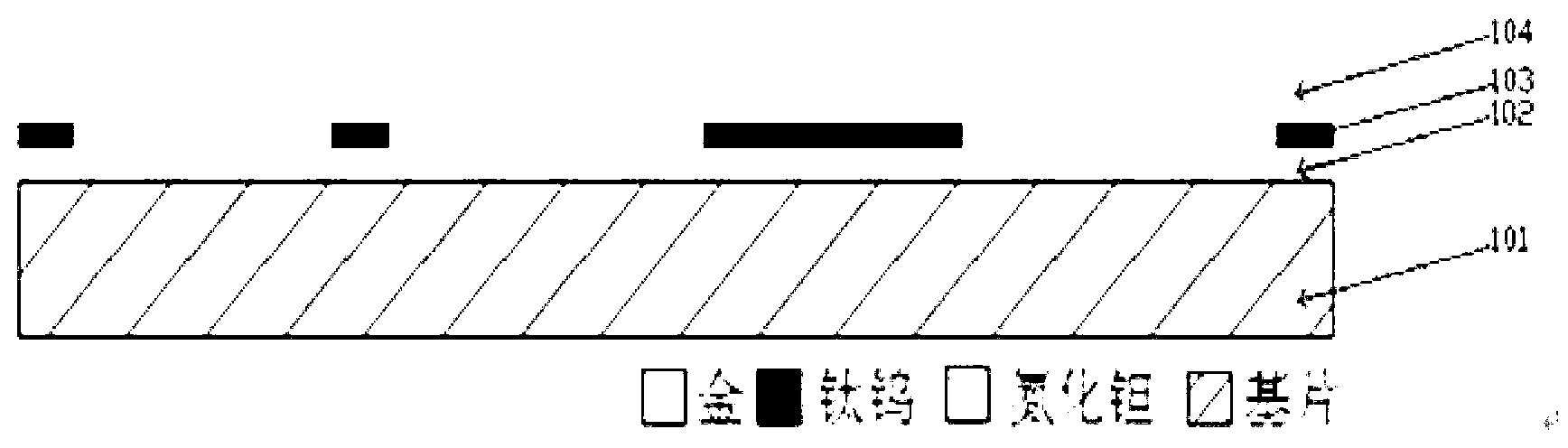

[0041] like Figure 1a to Figure 3 As shown, the present application provides a technical solution. The overall technical solution of the present invention is to utilize a magnetron vacuum sputtering machine to deposit TaN-TiWu-Au composite thin films sequentially on a microstrip substrate, and adjust the reaction gas flow ratio and time by controlling, Control the square resistance value of the film after sputtering to be lower than the design value of 5Ω∽15Ω, and the sputtering thickness of TiWu layer and Au layer is sputtered according to the design requirements; then use photoresist as a mask, and wet etching process Etch away the gold layer and titanium-tungsten layer and keep the tantalum nitride layer intact to realize the interconnection of the partial island circuit plating; then perform thermal oxidation treatment in a drying oven at 200°C--280°C 180min∽360min, so that a layer of tantalum oxide is produced on the surface of the tantalum nitride layer. After the above...

Embodiment 2

[0043] On the basis of the above embodiments, the production of a 50Ω / □ thin film hybrid integrated circuit is taken as an example to perform partial gold plating.

[0044] As shown in FIG. 1 , a circuit pattern is etched on the magnetron sputtering film with the tantalum nitride layer completely preserved.

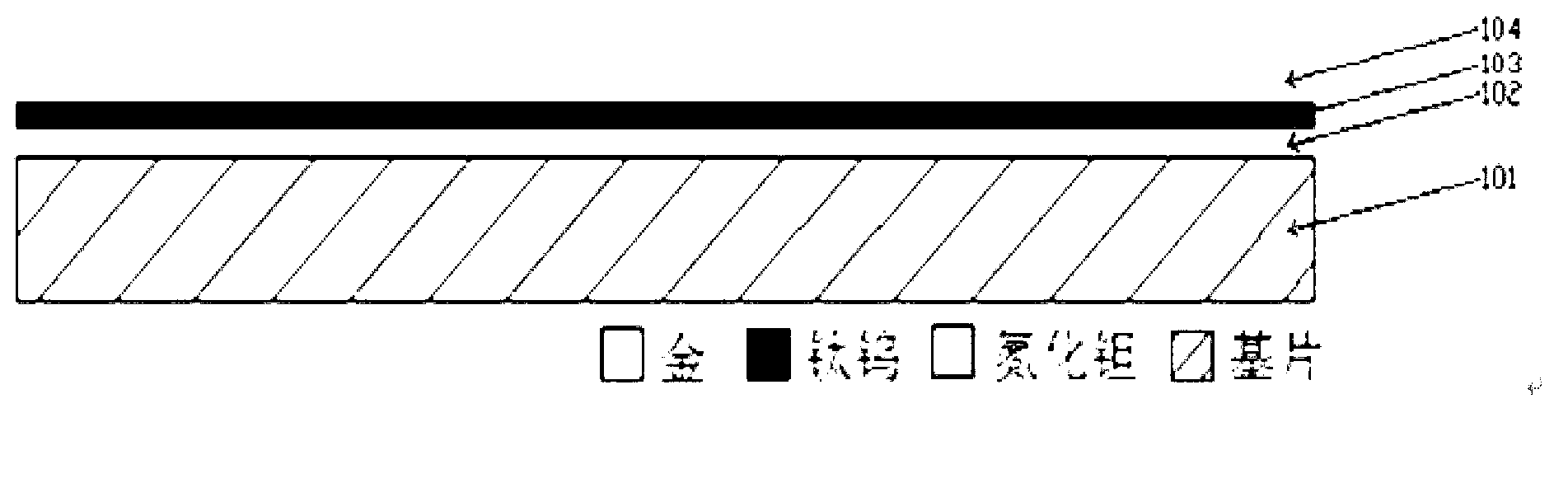

[0045] like Figure 1a As shown, a tantalum nitride thin film resistor 102 is deposited on a substrate 101 by magnetron sputtering, using a high-purity tantalum target, the sputtering reaction gas is nitrogen and argon, and the gas flow partial pressure ratio is N2:Ar=1:35 , the thickness of the tantalum nitride film is 0.06 microns, and the square resistance of the film obtained by sputtering is 36∽45Ω / □, and then a titanium-tungsten target and a high-purity gold target are used, the sputtering reaction gas is argon, and the gas flow rate is 70sccm. A titanium-tungsten thin film 103 with a thickness of 0.05 micron and a gold thin film 104 with a thickness of 0.2 micron a...

Embodiment 3

[0055] On the basis of the above examples, if Figure 1a to Figure 3 Shown, a thin film hybrid integrated circuit electroplating method, wherein, comprises the following steps:

[0056] A: The tantalum nitride film resistor is deposited on the substrate by magnetron sputtering, using a high-purity tantalum target, and the sputtering reaction gas is nitrogen and argon;

[0057] B: Sputtering titanium-tungsten film and gold film on the tantalum nitride film in sequence, using titanium-tungsten target and high-purity gold target, and the sputtering reaction gas is argon;

[0058] C: Use photoresist as a mask, use a gold etching solution prepared with a mixed aqueous solution of iodine and potassium iodide to etch away unnecessary gold other than the design pattern, and use a titanium-tungsten etching solution to wet etch away the unnecessary gold outside the design pattern Titanium tungsten film;

[0059] D: After removing the photoresist with potassium hydroxide solution, rins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com