Laser eyeglass protection method and apparatus based on laser composite life-prolonging technique

A protective device and laser technology, applied in laser welding equipment, instruments, optics, etc., can solve pollution and other problems, and achieve the effect of simplifying the cleaning process, efficient removal, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

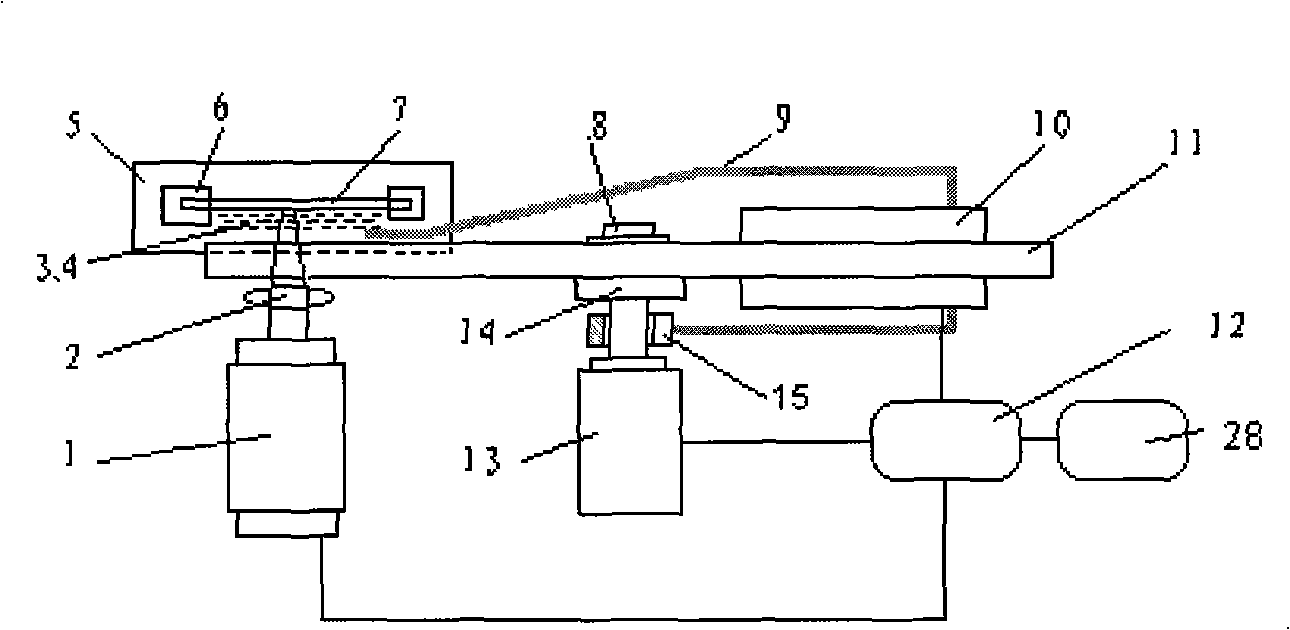

[0030] Such as figure 1 As shown, the device of the present invention includes a protective disc 11, a servo motor 13, a protective glass cleaning device 10, a support 15, a protective cover 9, and a control system.

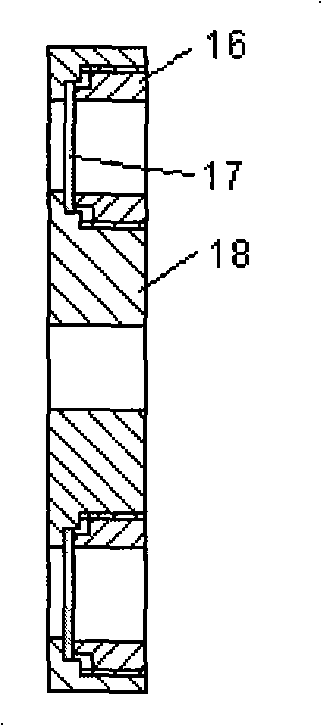

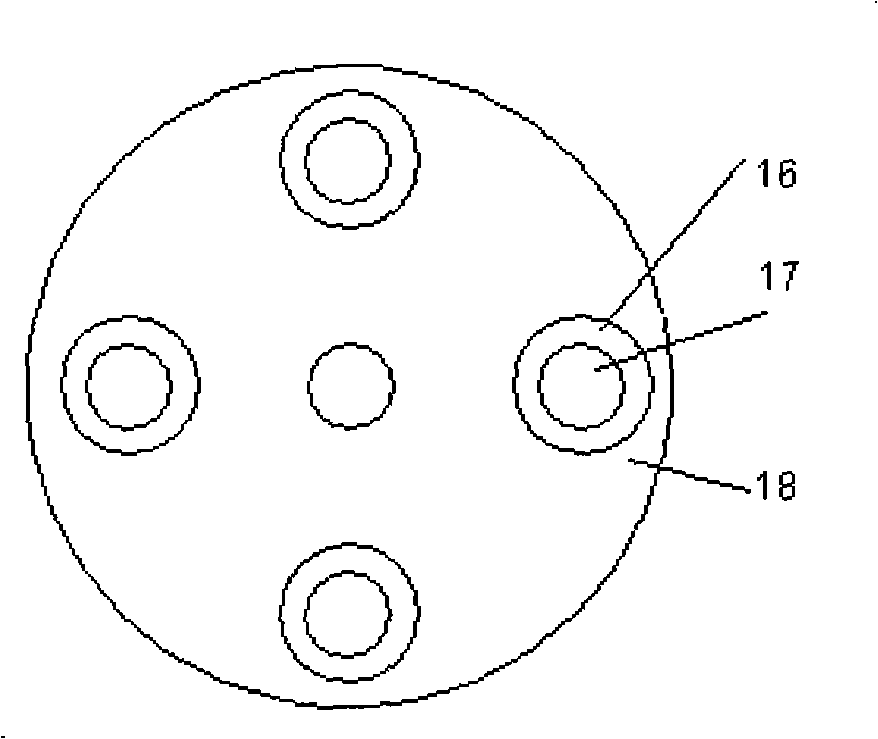

[0031] figure 2 , image 3 It is a schematic diagram of the protective structure, and the protective plate 11 is composed of a plate body 18, a protective glass 17, a positioning plate 14, and a protective glass pressing device connected in sequence. Four pieces of protective glass 17 are symmetrically fixed on the reserved holes on the disc body 18 through the pressing device (pressing nut 16). When the protective glass is damaged or the pollution is very serious, the pressing nut 16 is removed and a new protective glass is replaced. Laser processing again.

[0032] The protective disc 11 is connected with the positioning disc 14 at the end of the servo motor 13 installed on the bracket 15 through the coupling screw 8 .

[0033] Both sides of the protective...

Embodiment 2

[0042] Basically the same as Example 1, the difference is that, as Figure 4 , Figure 5 Shown, protective glass pressing device is made up of pressing screw 19 and pressing plate 20. The ring-shaped protective glass 17 is fixed on the periphery of the disc body 18 through the compression screw 19 and the pressing plate 20 .

[0043] When the protective glass is damaged or polluted very seriously, remove the compression screw 19 and the pressing plate 20, replace a new protective glass plate, and carry out laser shock again.

[0044] In this embodiment, the protective glass sheet is easy to replace, the production efficiency is high, the protective glass is large, and the price is high, which is convenient for multi-point continuous work, and is suitable for the application of laser shock composite life extension engineering with long working hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com