Precise axial displacement transmission device

An axial displacement and transmission technology, applied in transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of axial displacement transmission accuracy limitation, follow-up response, error, etc., to improve the minimum precision scale, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

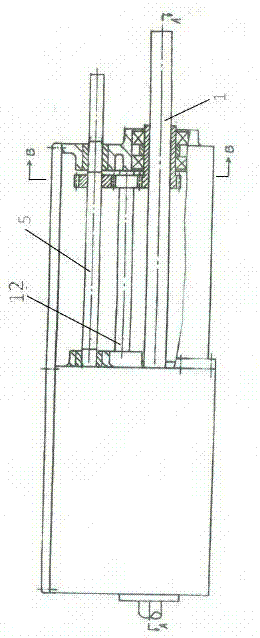

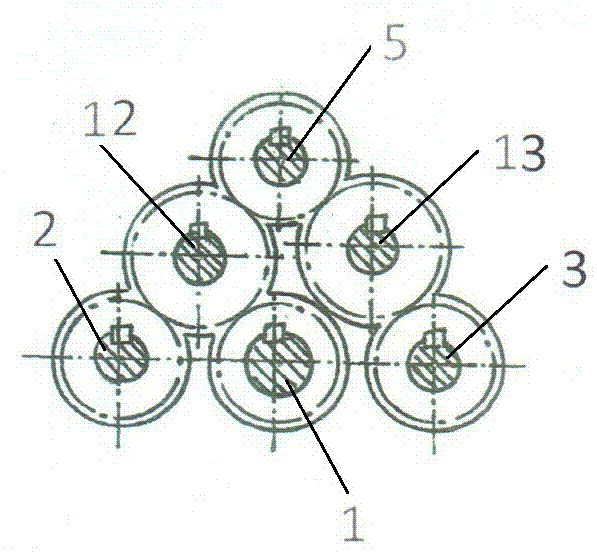

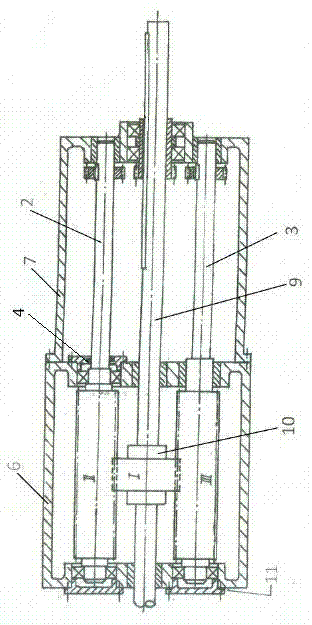

[0028] like Figure 1-3 As shown, a precision axial displacement transmission device with a box structure includes a box body, an input shaft 5, a transmission shaft I, a transmission shaft II, and three screw shafts 1, 2, and 3 with coplanar axes to form a parallel meshing Screw transmission pair.

[0029] The box includes a front box 6 and a rear box 7 .

[0030] The input shaft is supported on the upper part of the rear case through a pair of sliding bearings.

[0031] Two transmission shafts are located in the middle part of the rear box body, and the two transmission shafts mesh with the gears on the input shaft respectively through gears, and the two transmission shafts and the input shaft are arranged in parallel.

[0032] The thread transmission pair is located at the lower part of the box body, and the thread transmission pair includes two long-thread screw shafts II and III and one short-thread screw shaft I. Two long-thread screw shafts, one short-thread screw sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com