Proximity switch for oil cylinder

A technology of a proximity switch and an oil cylinder, which is applied in fluid pressure actuators, servometer circuits, and fluid pressure actuator system tests, etc. It can solve the problems of difficult axial position, poor interchangeability, and easy change of the position of the probe 10, etc. Accurate axial positioning, easy installation and good interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

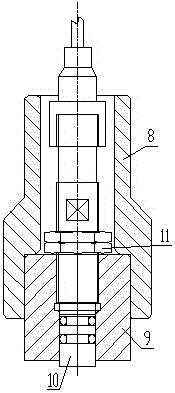

Image

Examples

Embodiment Construction

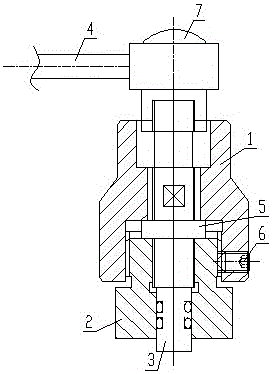

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] Such as figure 2 As shown, the proximity switch for an oil cylinder in this embodiment includes a protective cover 1, a mounting base 2, a probe 3 placed in the two, and a connecting wire 4 connected to the rear end of the probe 3; the protective cover 1 is provided with a stepped hole, and the probe There is a shoulder 5 in the middle of 3, and the mounting base 2 is connected with the protective cover 1 through threads and radial set screws 6. The probe 3 is located in the inner hole of the protective cover 1 and the mounting base 2, and the shoulder 5 of the probe 3 is stuck on the Between the end face of the stepped hole of the protective cover 1 and the rear end face of the installation base 2; the connecting line 4 at the rear end of the probe 3 is provided with an LED indicator 7;

[0012] In the present invention, since the probe 3 is pressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com