Adjustable axial positioning device of lathe

A technology for axial positioning and lathes, applied in the field of machinery, can solve the problems of worn spindle holes, lack of versatility, high cost of positioning fixtures, etc., and achieve the effects of fast and accurate axial positioning, compact structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, so as to help those skilled in the art have a more complete and in-depth understanding of the present invention.

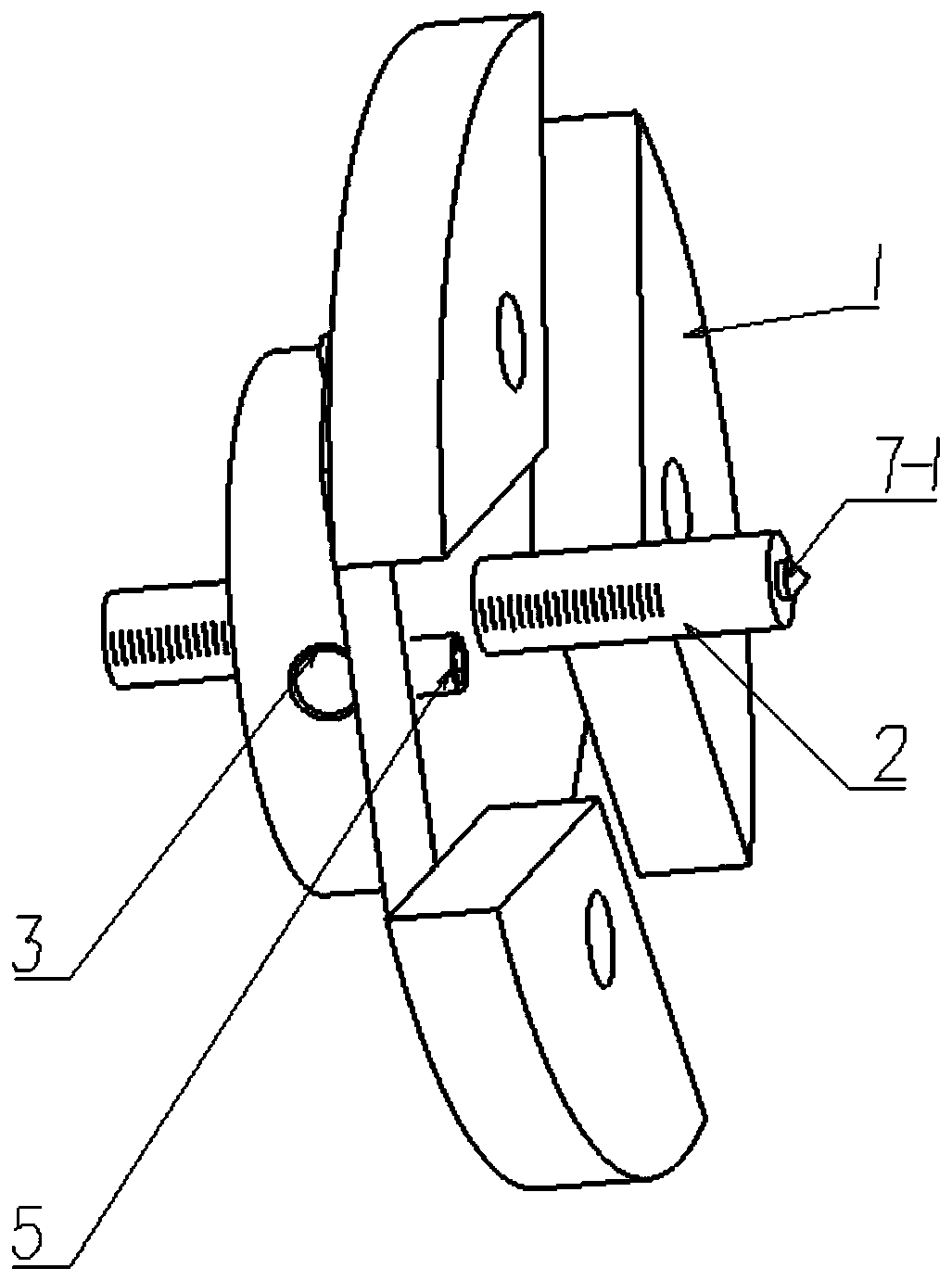

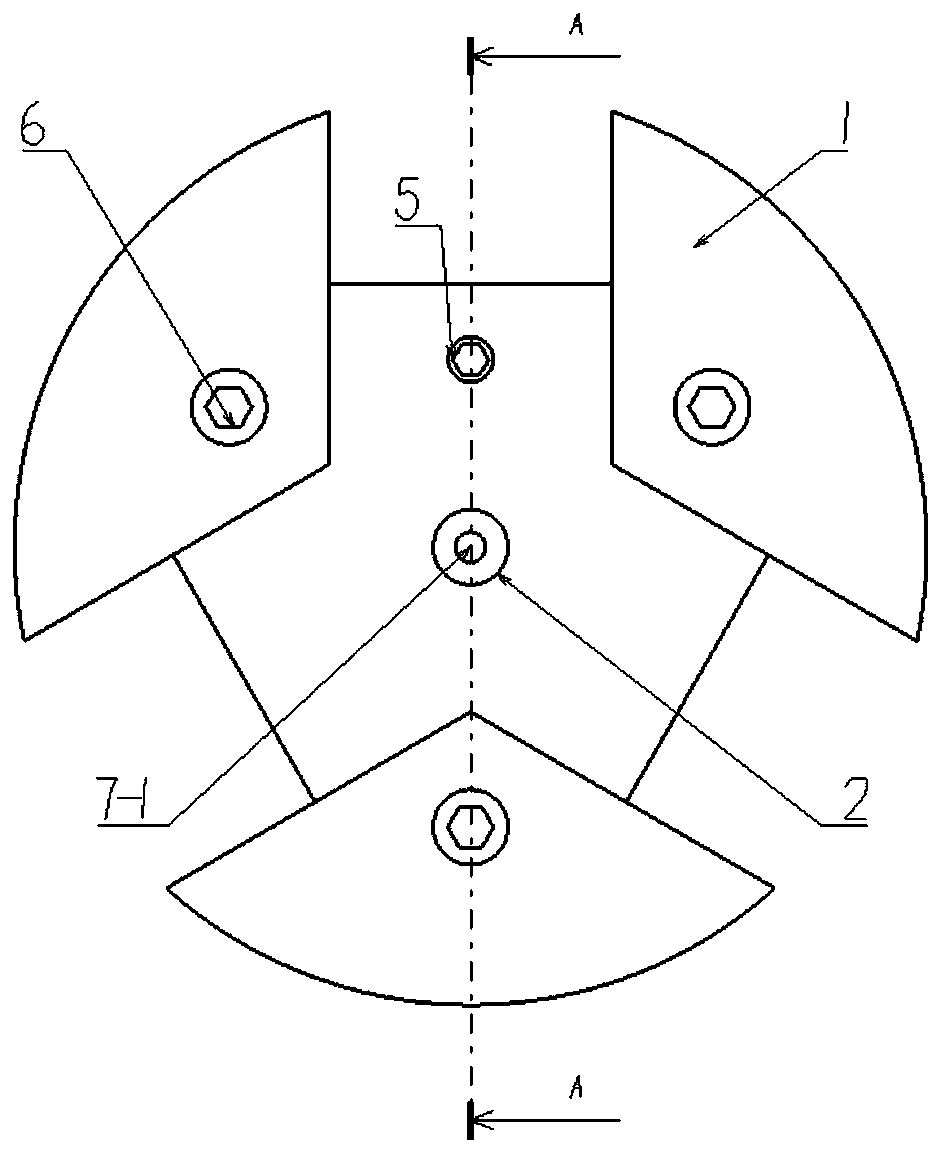

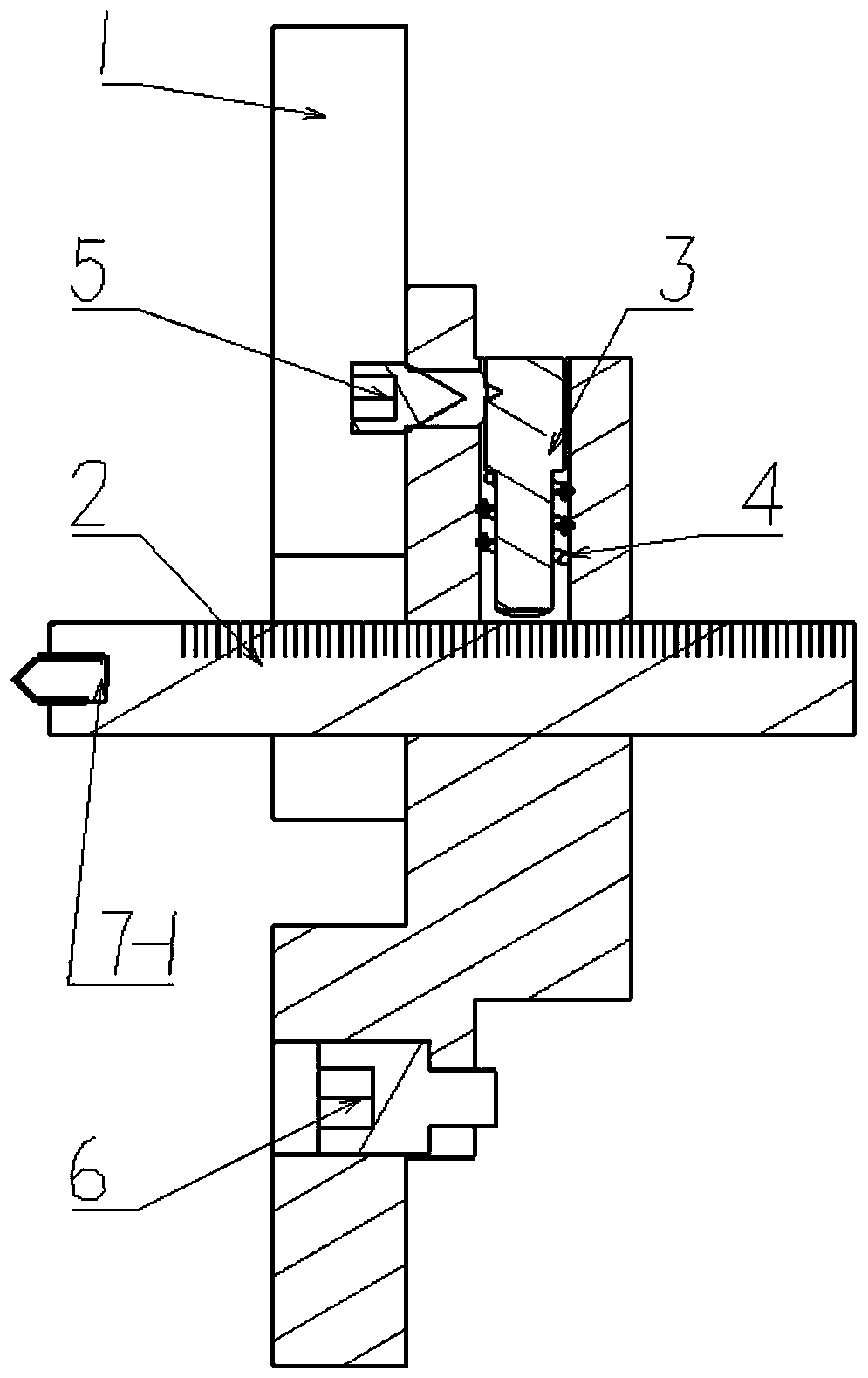

[0026] like figure 1 and Figure 5 As shown, an adjustable axial positioning device for a lathe includes a main body plate 1, a positioning rod 2, a clamping pin 3, a spring 4, a locking screw 5, a fastening bolt 6 and a positioning cap.

[0027] According to the positioning needs of the processed parts, select the required positioning cap: when processing slender rod parts that require top positioning, select the positioning cap A7-1, and connect the external thread of the positioning cap A7-1 with the internal thread hole 2 of the positioning rod -2 is connected through thread fitting; when processing large-diameter parts that require end face positioning, select the positioning cap B7-2, and connect the internal thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com