Deep laser hole linearity detecting device having rotation preventing mechanism

A detection device and straightness technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of difficult axial positioning of the probe and affect the detection results, and achieve high reliability, high strength, and accurate axial positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

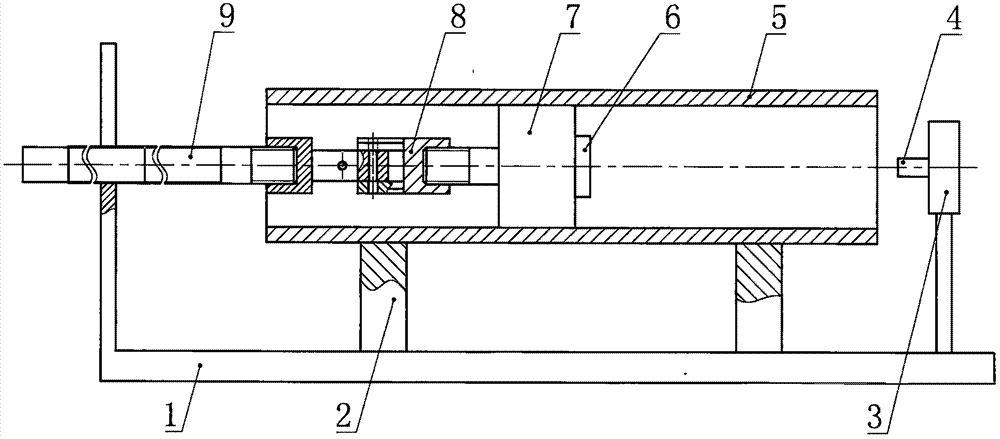

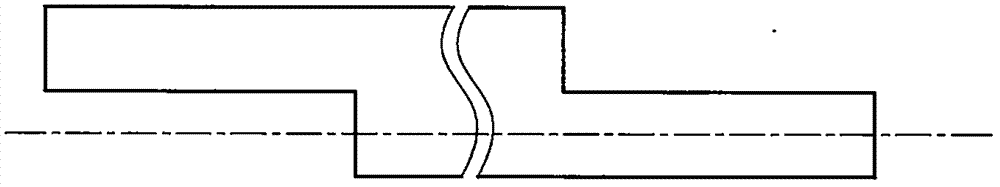

[0024] Two V-shaped blocks 2 are placed on the detection frame 1, the workpiece 5 to be tested is placed on the V-shaped block 2, the PSD sensor 6 is fixed on the probe 7, and the probe 7 is placed in the deep hole. The rigid measuring rod 9 and The measuring head 7 is connected, the laser emitter 4 is fixed on the laser adjustment frame 3 and placed outside the deep hole of the workpiece 5 to be measured, and the antenna is drawn from the PSD sensor 6 in the deep hole to the outside of the deep hole of the workpiece 5 to be measured.

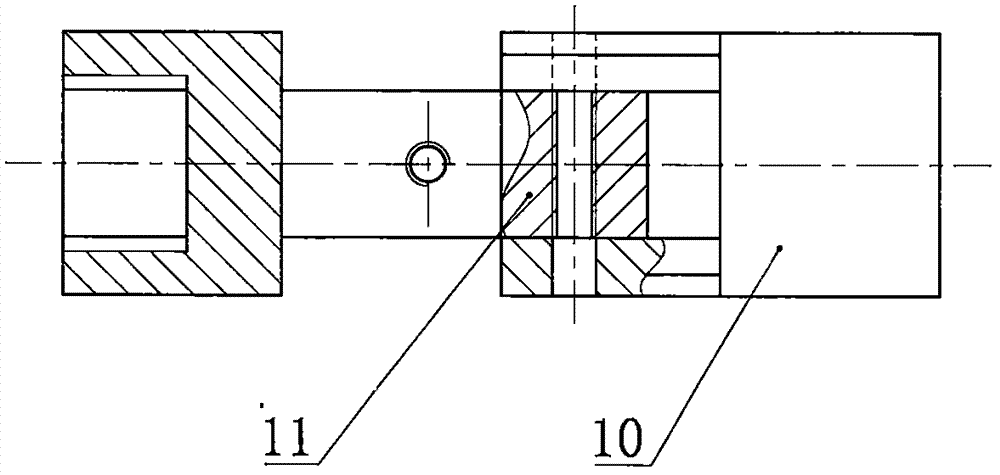

[0025] One end of the universal joint 8 is connected to the measuring head 7, and the other end is connected to the measuring rod 9. The measuring rod 9 is connected by multiple short rods of the same length.

specific Embodiment approach 2

[0026] Two V-shaped blocks 2 are placed on the detection frame 1, the workpiece 5 to be tested is placed on the V-shaped block 2, the PSD sensor 6 is fixed on the probe 7, and the probe 7 is placed in the deep hole. The rigid measuring rod 9 and The measuring head 7 is connected, the laser emitter 4 is fixed on the laser adjustment frame 3 and placed outside the deep hole of the workpiece 5 to be measured, and the antenna is drawn from the PSD sensor 6 in the deep hole to the outside of the deep hole of the workpiece 5 to be measured.

[0027] One end of the universal joint 8 is connected to the measuring head 7, and the other end is connected to the measuring rod 9. The measuring rod 9 is connected by multiple short rods of the same length.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com