Blast furnace slag slurry conveying conversion device not liable to be damaged

A technology for conveying and converting blast furnace slag, applied in valve devices, mechanical equipment, engine components, etc., can solve the problems of long replacement time, difficulty in improving equipment maintenance, damage to surrounding environment, etc., so as to reduce the difficulty of equipment maintenance and avoid unstable factors. , The effect of saving the cost of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

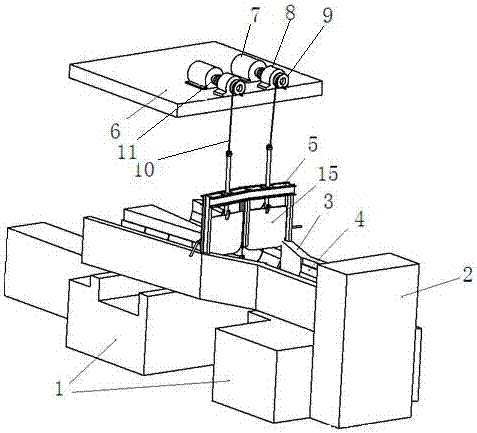

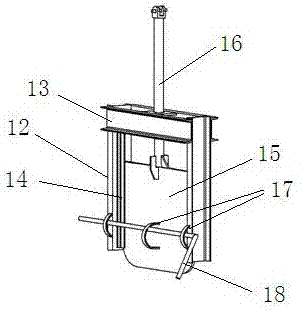

[0018] The invention consists of a foundation platform 1, a slag separating pipeline 3, a liner plate 4, a gate 5, a lifting platform 6 and a lifting mechanism.

[0019] figure 1 It shows that the foundation platform 1 for pouring concrete is located between the slag ditch 2 and the two filter tanks, and the slag separating pipeline 3 is located on the foundation platform 1 . The level of the foundation platform 1 on the side of the slag ditch 2 is higher than the level on the side of the two filter tanks, and the level of the bottom surface of the slag separating pipeline 3 on the side of the slag ditch 2 is higher than that on the side of the two filter tanks . The pouring height of the foundation platform 1 and the slag separating pipeline 3 is inclined from the slag ditch 2 to the direction of the two filter tanks, and a certain slope is maintained to facilitate the automatic flow of the slag slurry from the slag ditch 2 to the filter tanks.

[0020] figure 1 It shows t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com