Technology for spraying rubber sealing strip on line

A technology of rubber sealing strip and process, which is applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., can solve the problems of large investment and high production cost, achieve reasonable process steps, reduce equipment investment, simplify The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

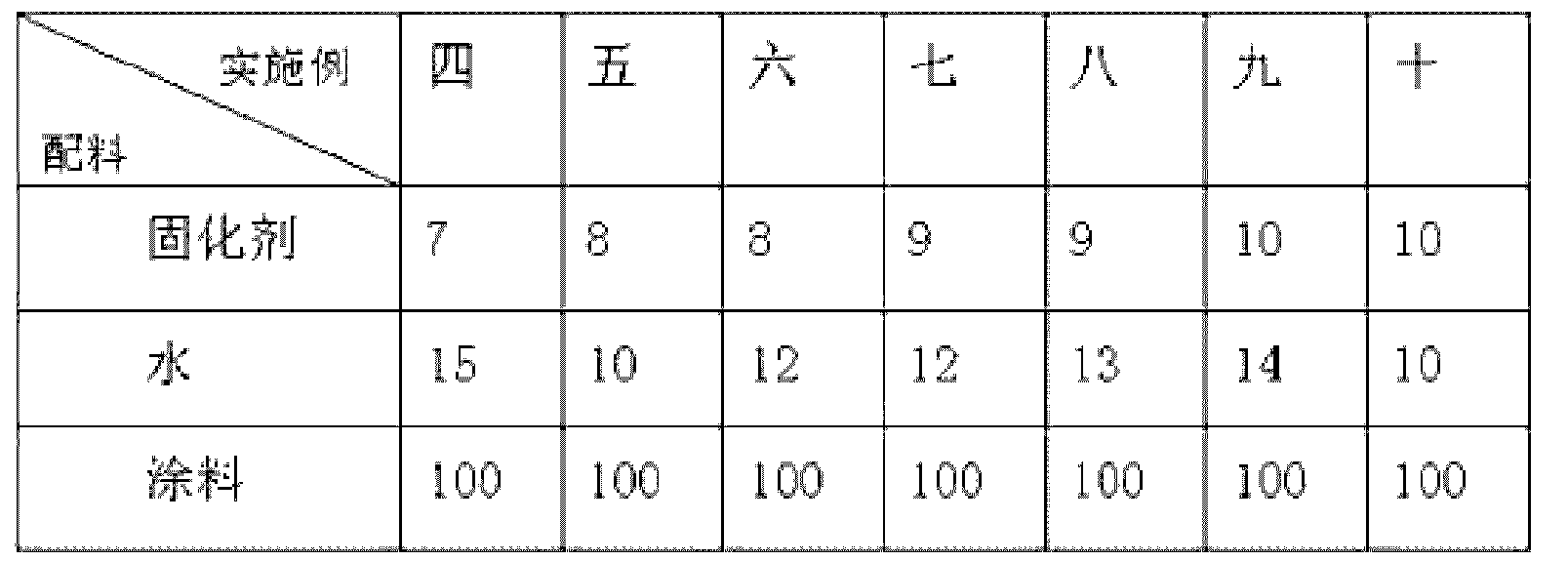

Examples

Embodiment 1

[0018] Rubber sealing strip online spraying process of the present invention, this technique is positioned between the microwave vulcanization operation of rubber sealing strip and the hot air vulcanization operation, and this technique comprises the following steps: 1) prepare materials, prepare required curing agent, water, coating; 2 ) Stir in the early stage, fully stir the paint before batching, check whether the paint has hard lumps at the bottom, stir the paint with a blade agitator for 8 minutes, and only after stirring evenly can the batching be carried out according to the proportioning requirements; 3) batching, the weight of each batching The numbers are: 7 parts of curing agent, 10 parts of water, and 100 parts of paint. If it is too thick, add water in an appropriate amount; 4) Fully stir the measured curing agent and water for 5 minutes, so that the curing agent is completely dispersed in water to form a curing agent mixture. 5) Slowly add the curing agent mixtur...

Embodiment 2

[0020] Rubber sealing strip online spraying process of the present invention, this technique is positioned between the microwave vulcanization operation of rubber sealing strip and the hot air vulcanization operation, and this technique comprises the following steps: 1) prepare materials, prepare required curing agent, water, coating; 2 ) Stirring in the early stage, fully stir the paint before batching, check whether the paint has hard lumps at the bottom, stir the paint with a blade agitator for 10 minutes, and only after stirring evenly can the batching be carried out according to the proportioning requirements; 3) batching, the weight of each batching The numbers are: 8 parts of curing agent, 12 parts of water, and 100 parts of paint. If it is too thick, add water in an appropriate amount; 4) Fully stir the measured curing agent and water for 8 minutes, so that the curing agent is completely dispersed in water to form a curing agent mixture. ; 5) Slowly add the curing agent...

Embodiment 3

[0022] Rubber sealing strip online spraying process of the present invention, this technique is positioned between the microwave vulcanization operation of rubber sealing strip and the hot air vulcanization operation, and this technique comprises the following steps: 1) prepare materials, prepare required curing agent, water, coating; 2 ) Stir in the early stage, fully stir the paint before batching, check whether the paint has hard lumps at the bottom, stir the paint with a blade agitator for 12 minutes, and only after stirring evenly can the batching be carried out according to the proportioning requirements; 3) batching, the weight of each batching The numbers are: 10 parts of curing agent, 15 parts of water, and 100 parts of paint. If it is too thick, add water in an appropriate amount; 4) Fully stir the measured curing agent and water for 10 minutes to completely disperse the curing agent in water to form a curing agent mixture. 5) When the coating is stirred, slowly add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com