Elastic self-positioning pre-slicing device and method

A self-positioning and elastic technology, applied in rhizome seed cutting machines, seed and rhizome processing, agriculture, etc., can solve the problems of low efficiency of manual seed potato cutting, high degree of mechanization, waste of seed potatoes, etc., to overcome unstable factors , High utilization rate and uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

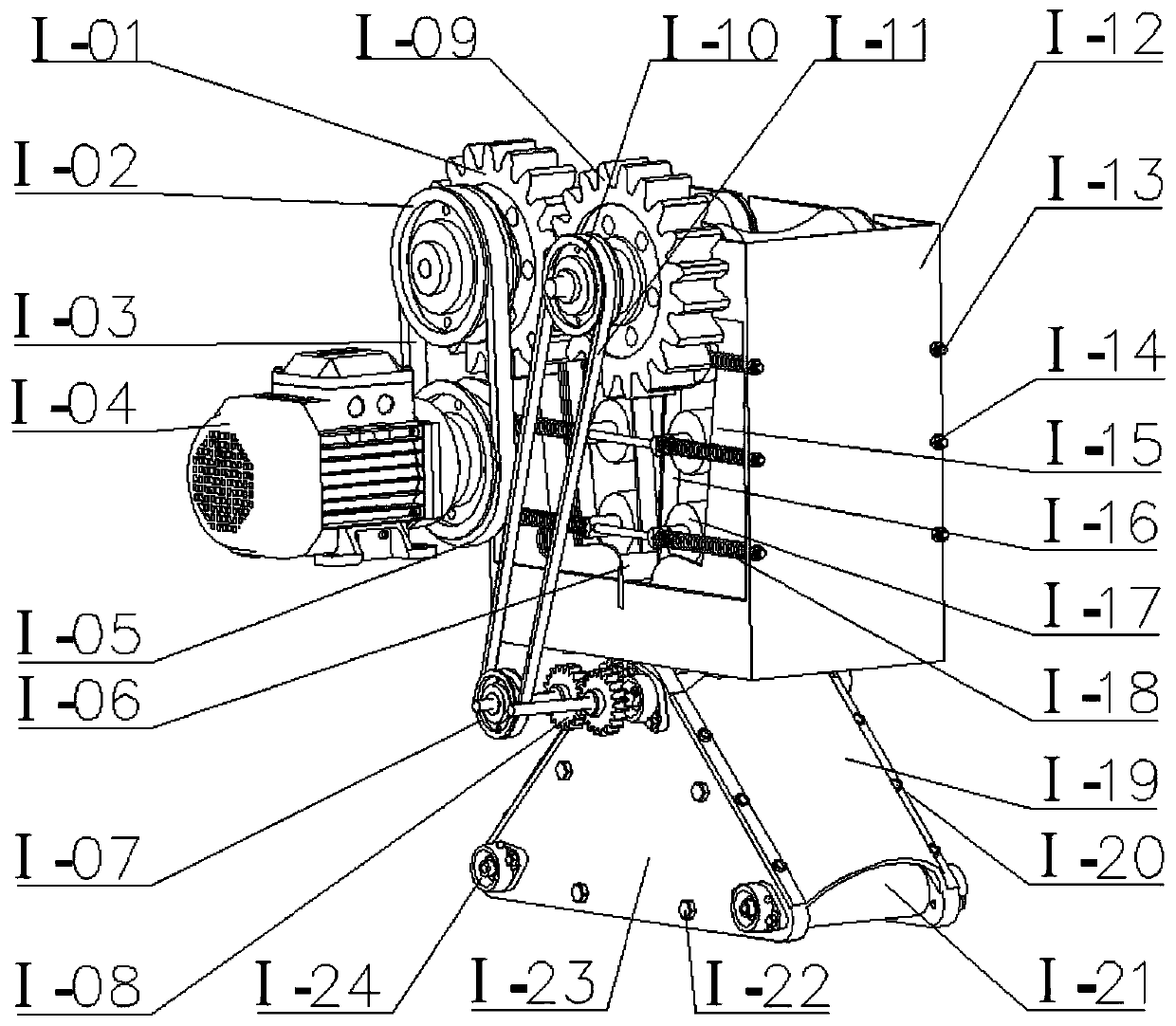

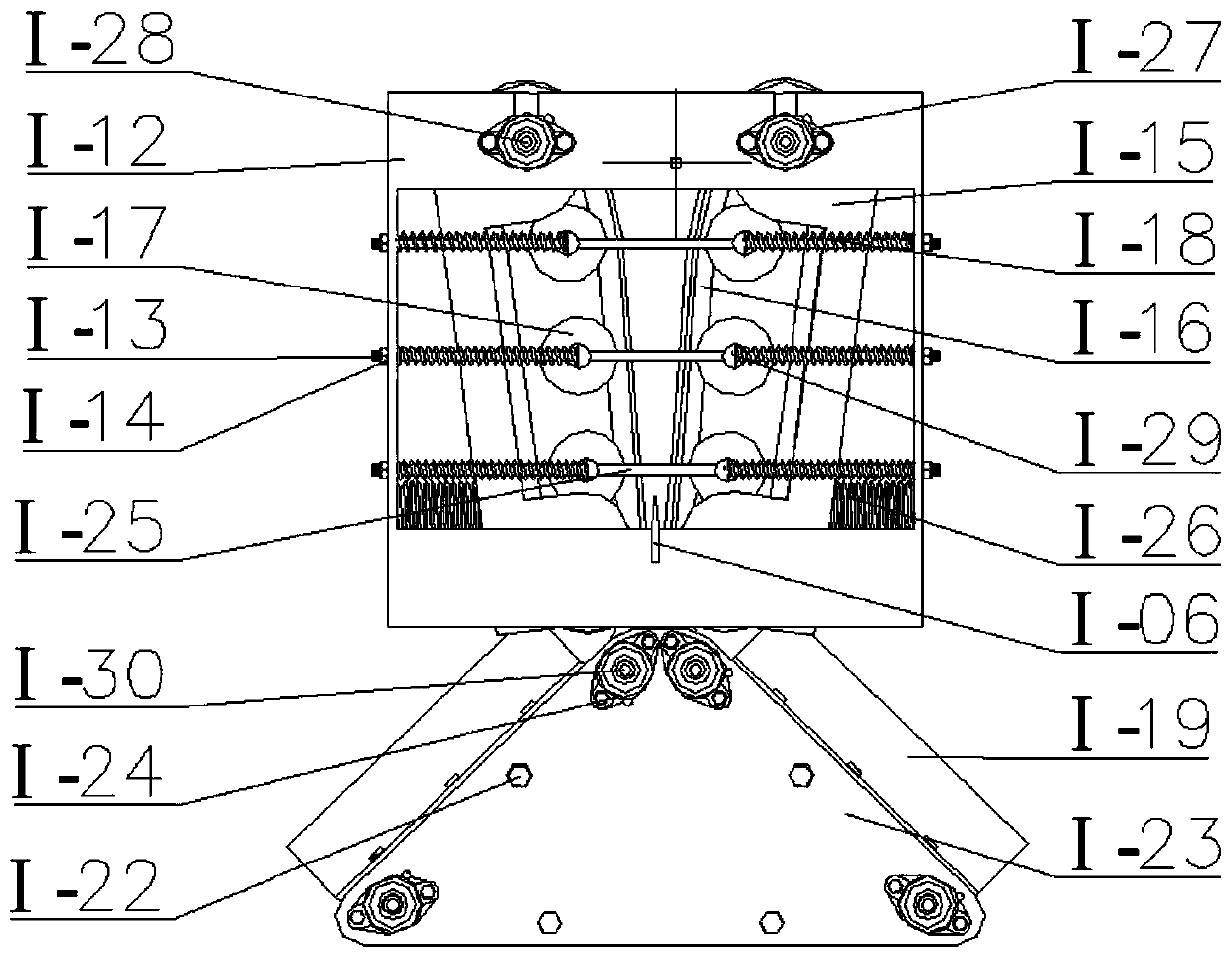

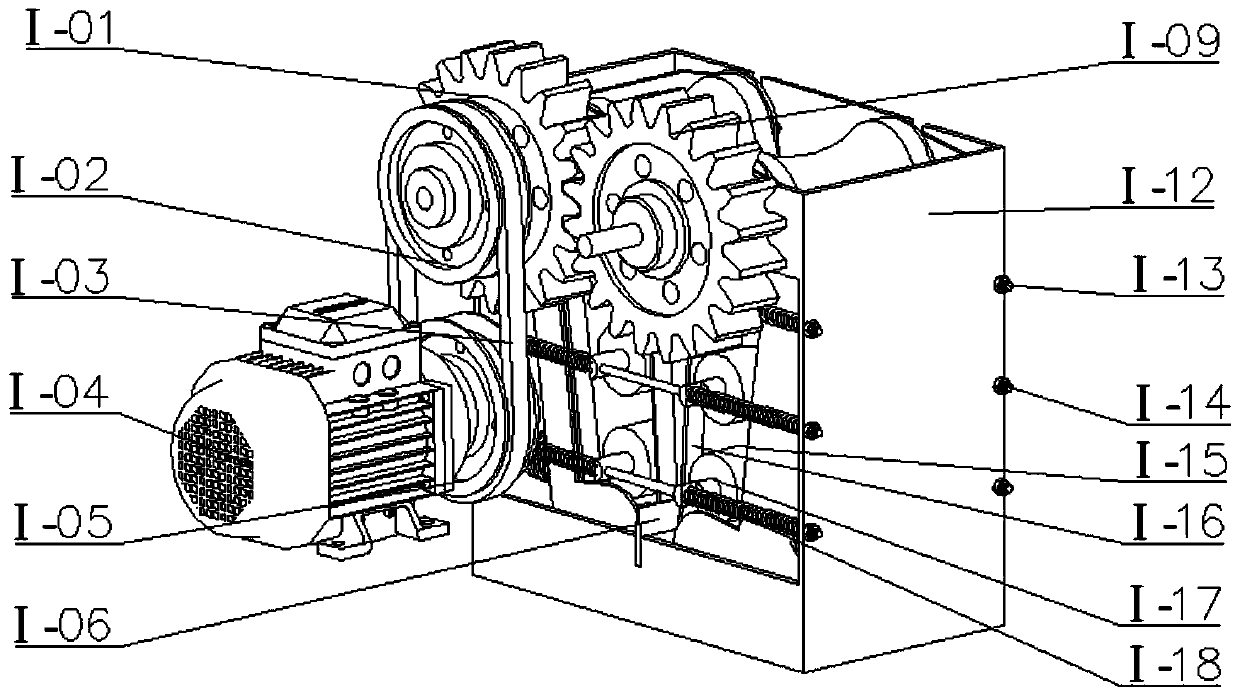

[0027] As introduced in the background technology, in order to solve the deficiencies in the prior art, this embodiment proposes an elastic self-positioning pre-cutting device, such as figure 1 As shown, it includes: elastic V-shaped self-positioning device, streamlined cutter I-06, and triangular separation device. The above three devices are coaxial to ensure the tightness of the three processes of seed potato linear transportation, seed potato cutting in half and half-cut transportation. connect.

[0028] The elastic V-shaped self-positioning device includes: the first elastic conveying surface and the second elastic conveying surface, the first elastic conveying surface and the second elastic conveying surface form a V-shaped conveying space, and the material reaches the two elastic conveying surfaces with the operation of the elastic conveying surface. When the bottom between the two surfaces is kept in a vertical state; the bottom between the two elastic conveying surfac...

Embodiment 2

[0081] In some embodiments, a method of resilient self-positioning pre-cutting is disclosed, comprising the following process:

[0082] The conical self-positioning limit feeding system (that is, the previous station) sends the seed potatoes into the elastic self-positioning pre-cutting system in an orderly manner. At this time, the long axis of the seed potatoes is in the vertical direction and falls into the elastic V-shaped self-positioning system. The V-shaped space entrance of the device is wrapped by the V-shaped profile of the flexible silicone conveyor belt Ⅰ-16. The rotation of the transmission shaft Ⅰ-28 drives the movement of the flexible silicone conveyor belt Ⅰ-16, and the seed potatoes are further conveyed in a straight line. Here are 3 pairs of Ⅰ-16 in the middle position. The 17V-type roller adapts to the shape and size of the seed potato under the action of the elasticity of the first spring I-18, ensuring the stability and reliability of the linear conveying p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com