Totally-closed maintenance-free threaded fitting

A maintenance-free, fully enclosed technology, applied in the direction of pipes/pipe joints/fittings, through components, sealing surface connections, etc., can solve the problems of non-disassembly, increased difficulty of pipeline maintenance and cleaning, and increased maintenance costs. Achieve the effects of low cost of accessories, reduced maintenance cost, and reliable sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

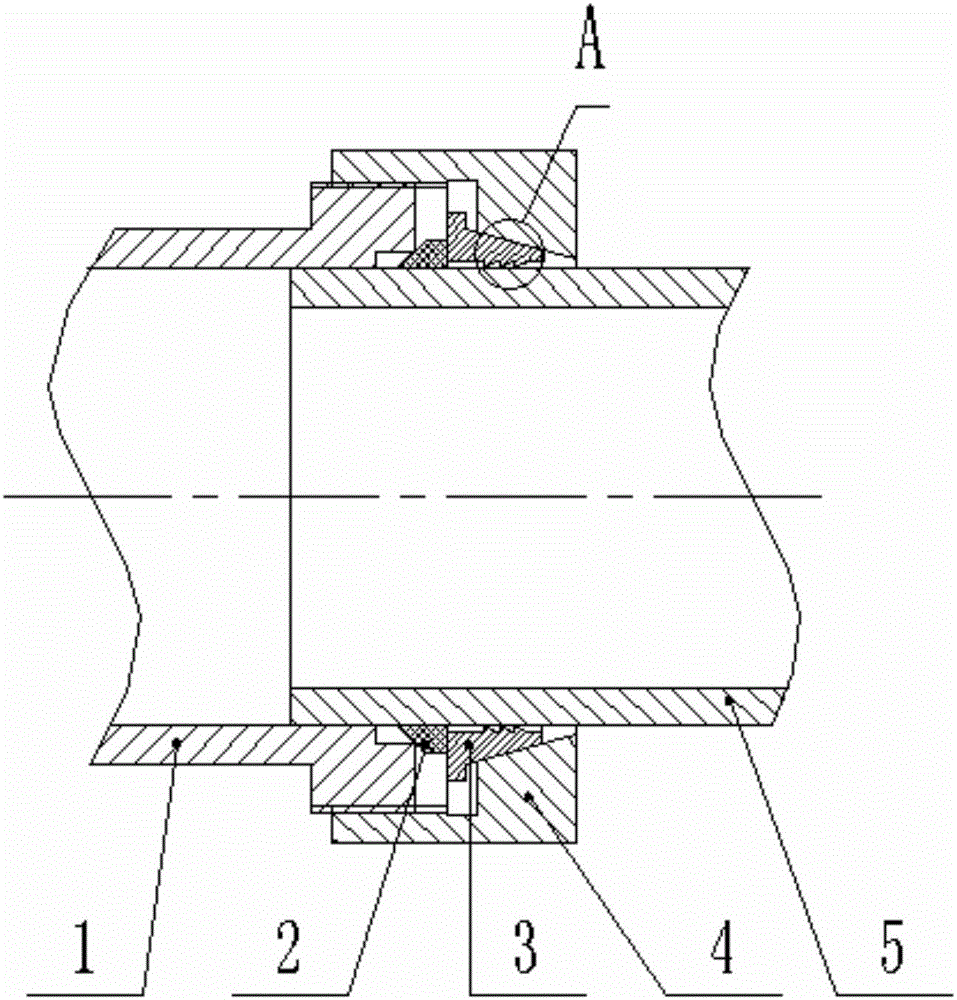

[0011] The present invention will be further described below in conjunction with accompanying drawing:

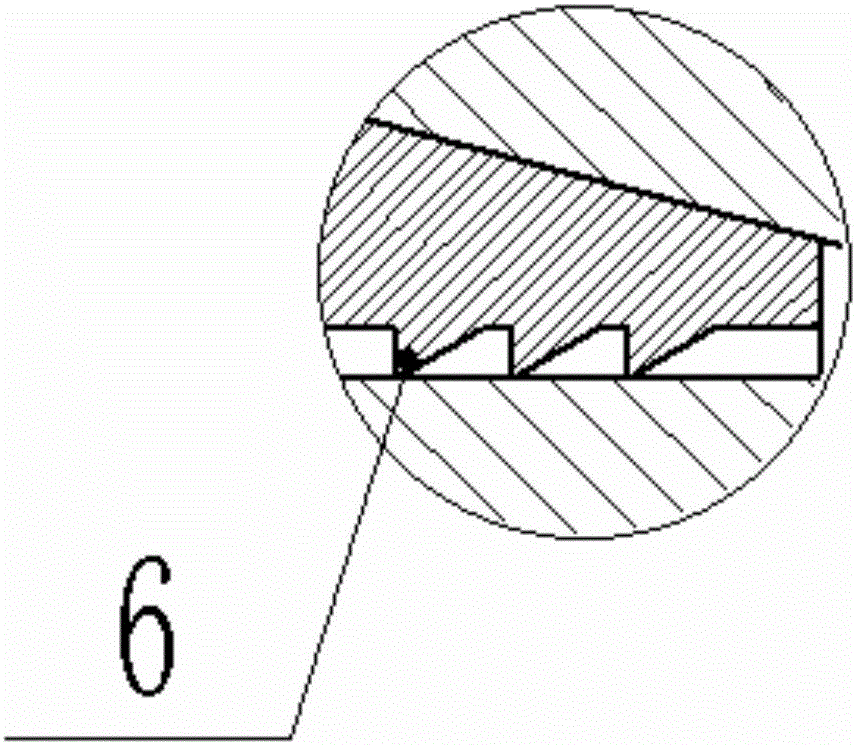

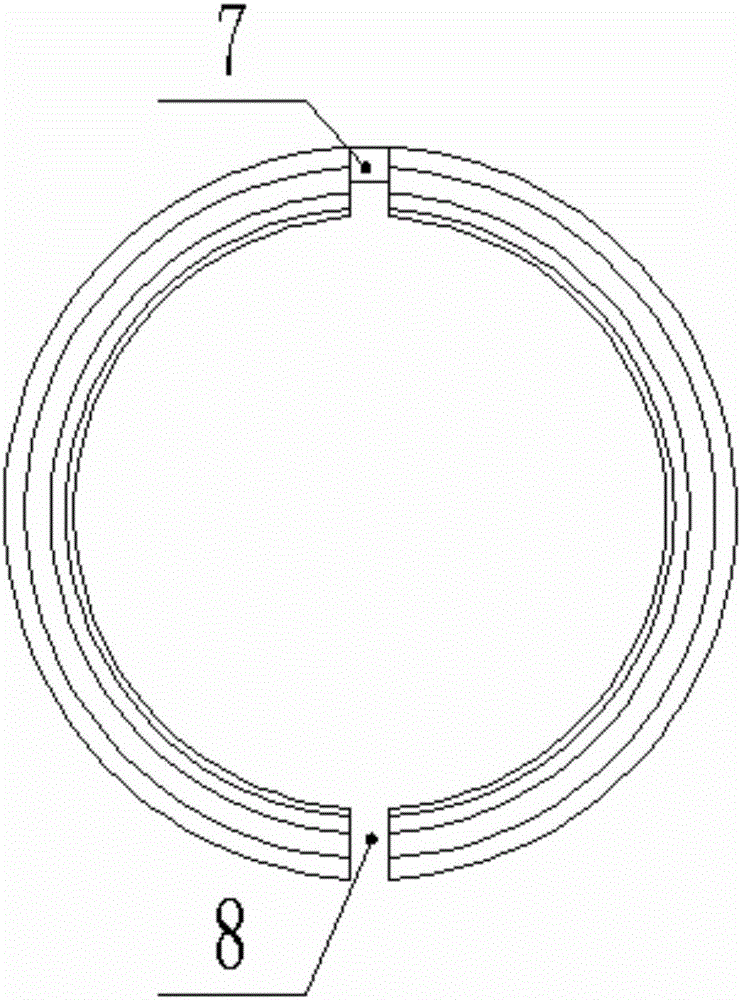

[0012] This embodiment includes a joint 1 and a pipe body 5. The end of the pipe body 5 is inserted into the joint 1. In the prior art, whether it is a hot-melt connection structure or a connection structure that is sealed and connected by any gasket, the connection Sometimes there are special requirements for the cut flatness of the end face of the pipe body 5 or the prefabricated structure outside the end of the pipe body 5, the operation difficulty of the connection is high, and the versatility of the pipe fittings is relatively poor. Compared with the above two connection methods, the plug-in connection method adopted here does not have any requirements on the flatness of the end surface of the pipe body 5, and does not need to prefabricate any connection structure at the end of the pipe body 5, which not only reduces the difficulty of operation, but also improves It no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com