Multi-station SCARA industrial robot

An industrial robot and multi-station technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of SCARA robot positioning and repeat positioning accuracy, reduce the reliability of SCARA robots, and high equipment purchase costs, so as to reduce the purchase cost. The effect of reducing cost, reducing floor space, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

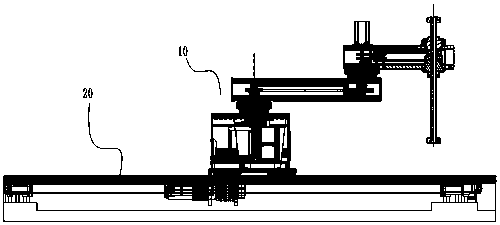

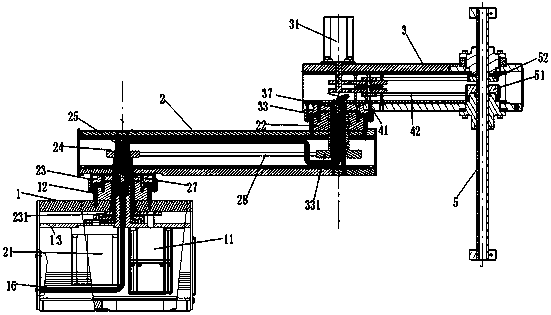

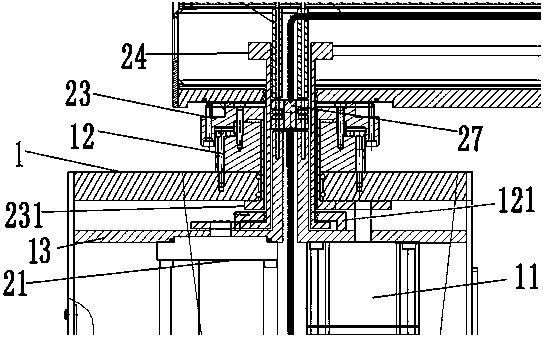

[0025] Such as Figure 1-7 As shown, the present invention is a multi-station SCARA industrial robot, including a SCARA robot mechanism 10 and a displacement drive mechanism 20 . The SCARA robot mechanism 10 includes a base 1, a first arm 2, a first arm driver, a second arm 3, a second arm driver, a ball spline screw 5 and a power supply cable 16; the base 1 A mounting plate 13 is fixed inside.

[0026] The first driving device includes a first motor 11 and a first transmission assembly, the first motor 11 is fixed on the mounting plate 13 and a first driving gear is installed on the output shaft of the first motor 11; the first transmission assembly includes the first A mounting seat 12, a first rotating cylinder with a first driven gear 231 at the lower end and a first connection plate 23 fixed on the upper end of the first rotating cylinder, the first mounting seat 12 is fixed on the base 1, and the first rotating cylinder The barrel is movably installed on the first moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com