Rolling method for large-wall-thickness pipeline steel

A pipeline steel and temperature control technology, applied in metal rolling and other directions, can solve the problems of unsatisfactory DWTT performance of steel plates, high online tempering cost, uneven dispersion, etc., to save labor costs, spare parts costs, and online tempering. cost, the effect of reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

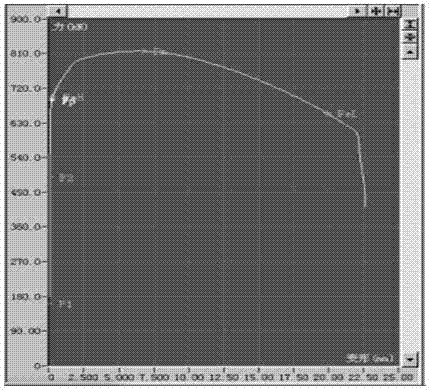

Image

Examples

Embodiment 1

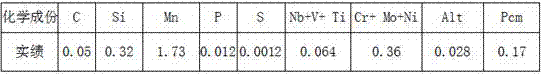

[0017] The billet size is 261mm×2283mm×3150mm, and its melting composition is shown in Table 1.

[0018] Table 1 Example 1 30.8mmX80 melting composition performance (%)

[0019]

[0020] Process steps:

[0021] (1) Heating

[0022] Preheating section: heating speed 4.7min / cm, temperature control at 800~867℃

[0023] Heating section: heating speed 7.8min / cm, temperature control at 1160~1180℃, soaking section: holding time 137min, furnace temperature 1167℃ (center) and 1178℃ (surface)

[0024] (2) Rolling

[0025] Rough rolling: start rolling temperature 1146~1151℃, cross rolling and widening 3 passes, longitudinal rolling 9 passes, final rolling temperature 1052~1068℃. The reduction rates of the last two passes of longitudinal rolling were 25.5% and 27.1%, respectively.

[0026] Finishing rolling: the thickness of the intermediate billet is 85mm, the opening temperature is 830℃, the surface temperature is 797℃ after two rolling passes, and then the continuous rolling 9 passes, the final ro...

Embodiment 2

[0030] The billet size is 269mm×2281mm×3150mm, and its melting composition is shown in Table 2.

[0031] Table 2 Example 2 30.8mmX80 melting composition performance (%)

[0032]

[0033] Process steps:

[0034] (1) Heating:

[0035] Preheating section: heating speed 4.8min / cm, temperature control at 810~887℃

[0036] Heating section: heating speed 7.6min / cm, temperature control at 1165~1180℃, soaking section: holding time 132min, furnace temperature 1163℃ (center) and 1175℃ (surface)

[0037] (2) Rolling

[0038] Rough rolling: start rolling temperature 1145~1155℃, cross rolling and widening 3 passes, longitudinal rolling 9 passes, final rolling temperature 1041~1055℃. The reduction rates of the last two passes of longitudinal rolling were 26.2% and 27.7%, respectively.

[0039] Finishing rolling: the thickness of the intermediate billet is 85mm, the opening temperature is 830℃, the surface temperature is 791℃ after two rolling passes, and then the continuous rolling 9 passes, the final r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com