Correction device and correction method capable of improving tracking precision of pinch roller of reeling machine

A technology of tracking accuracy and correction method, which is applied in the field of hot rolling and coiling technology, can solve the problems of unreachable pressure, difficult maintenance, unstable pressure signal of pinch roll, etc., so as to reduce the cost of production and spare parts, improve tracking accuracy, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

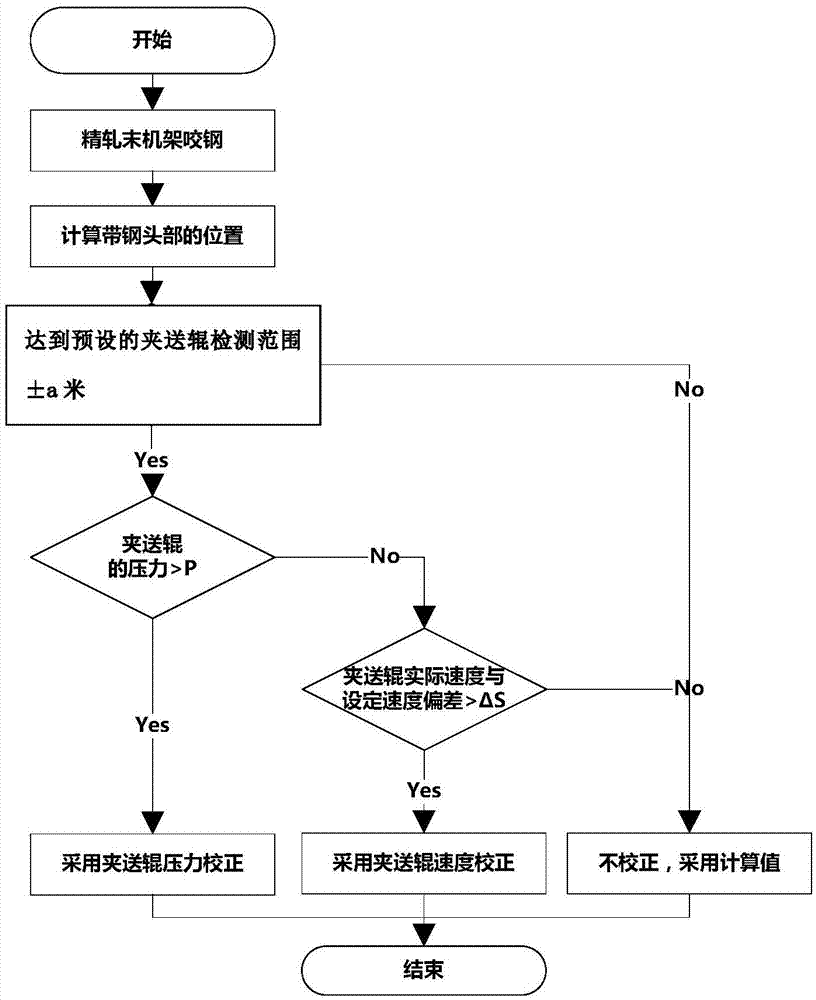

[0041] Take the 2050 unit coiling unit for steel production as an example.

[0042] Pinch roller detection range a value: 3.5 meters;

[0043] Limit value P value: 12KN;

[0044] Deviation ΔS value: 0.1m / s. The specific implementation steps are as follows:

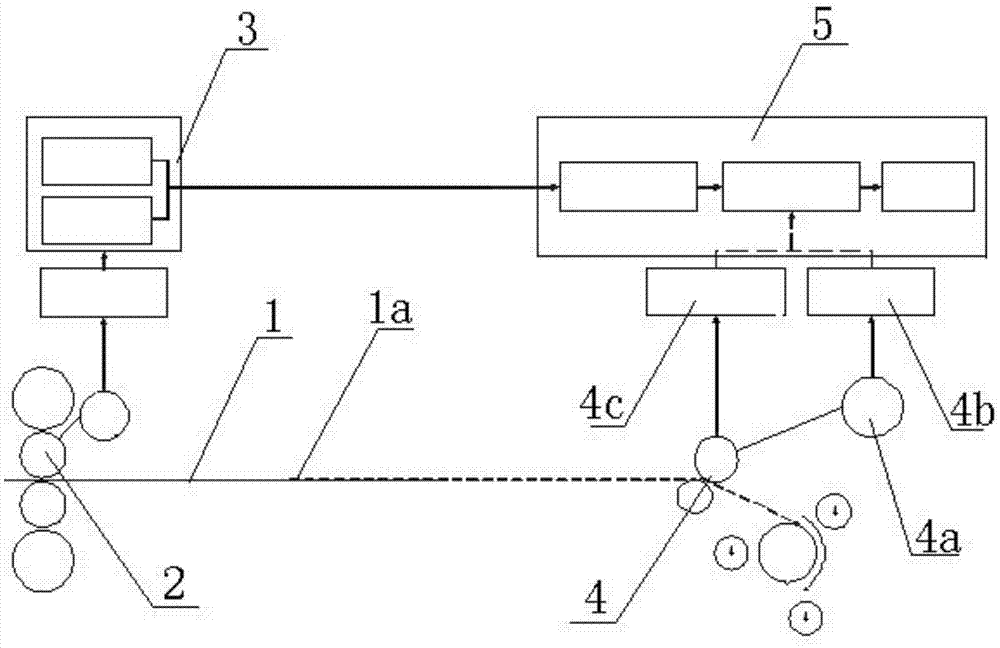

[0045] 1) When the strip steel 1 bites into the final stand 2 of the finishing mill, the basic automation computer for finishing rolling 3 sends the steel strip bite signal, roll diameter and rotational speed to the coiling basic automation computer 5, and the coiling basic automation computer Calculate the position of the strip head 1a according to the obtained steel bite signal, roll diameter and rotating speed;

[0046] 2) Judgment of signal reliability: In order to prevent wrong tracking and correction caused by wrong signals, the credibility of the pressure detection signal obtained by the pinch roller pressure detection device 4c of the pinch roller assembly 4 and the pinch roller speed reduction signal is judged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com