Device for controlling automatic centering of cold-rolling strip steel uncoiler

A technology for automatic centering and cold-rolling of strip steel, which is used in manufacturing tools, metal processing, metal processing equipment, etc., and can solve the problems of inoperable control systems, high prices, and affecting the normal operation of cold rolling mills.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

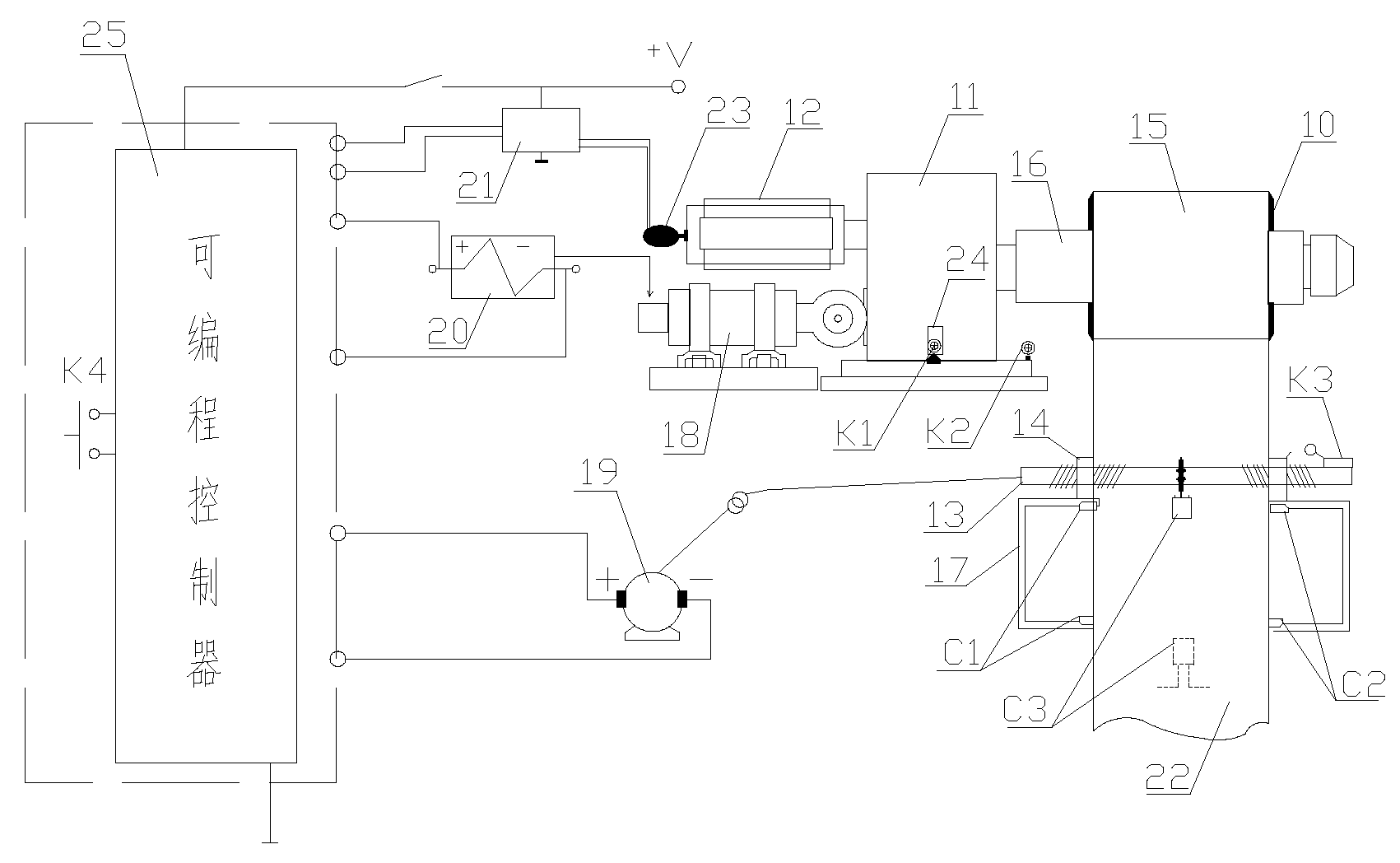

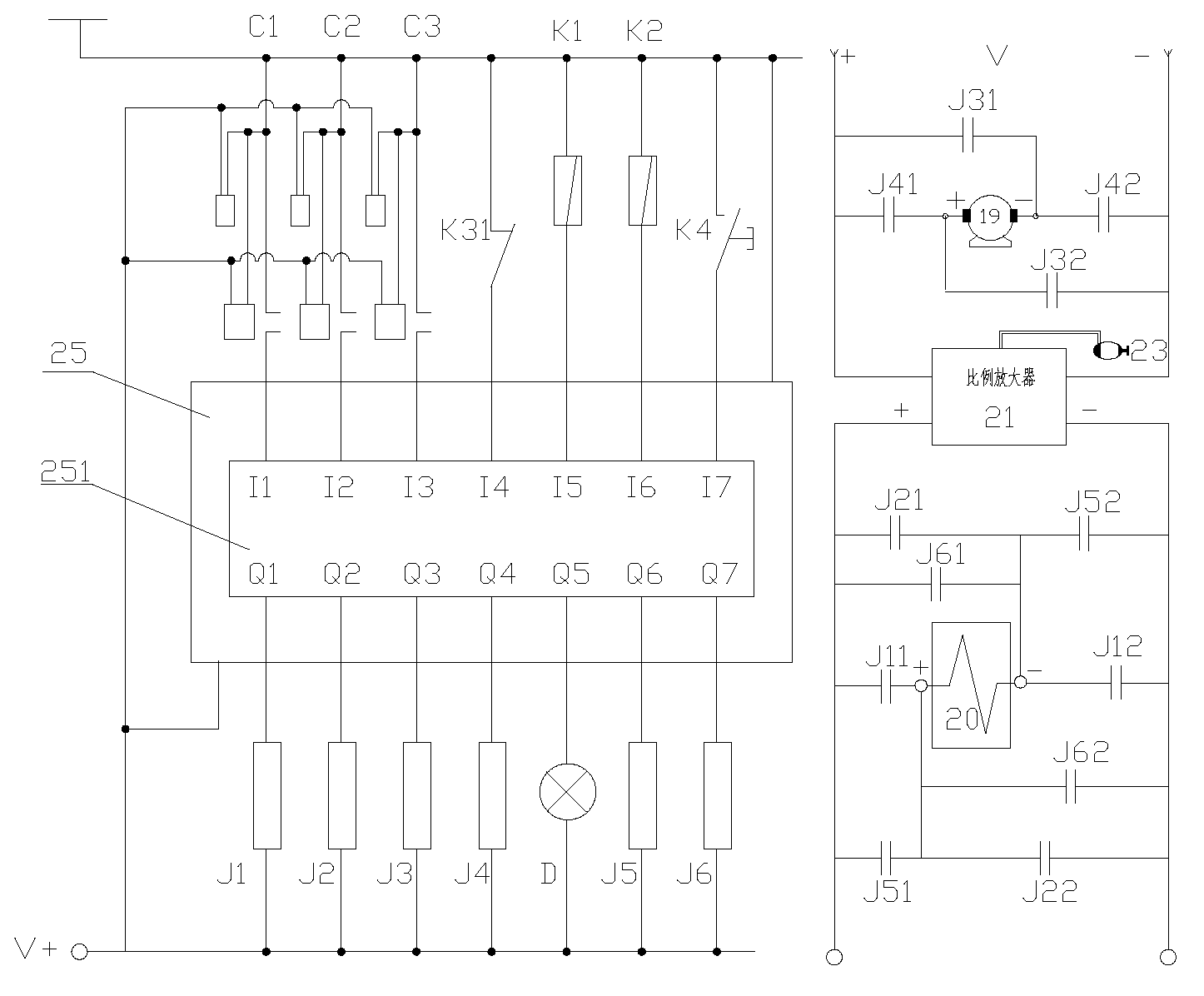

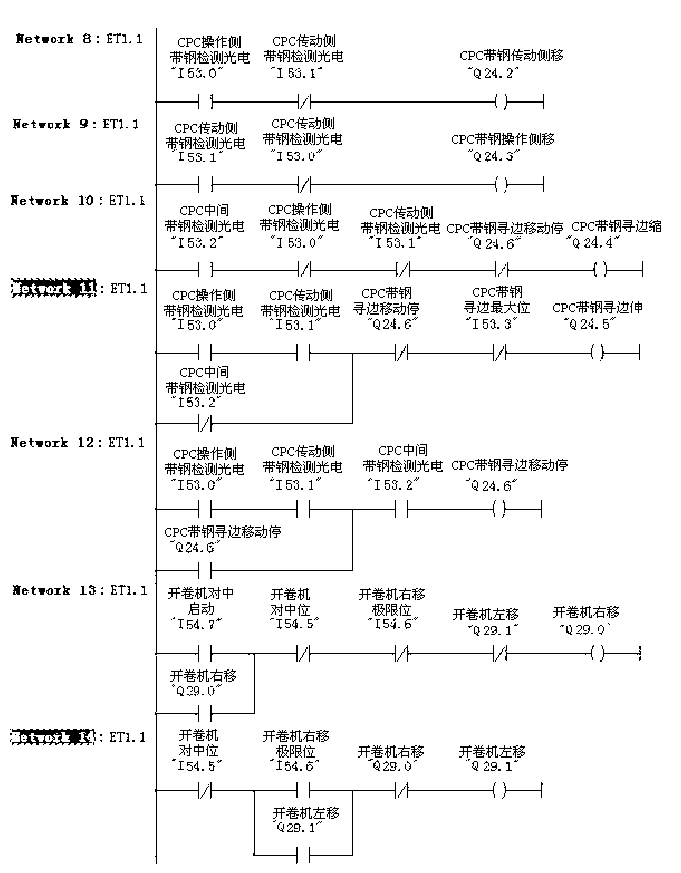

[0012] Such as figure 1 with figure 2As shown, the automatic centering control device of the cold-rolled strip uncoiler of the present invention includes a control power supply V, an uncoiler 10 driven by a drive motor 12 and a gearbox 11, a C-shaped frame 17 located at the front of the uncoiler 10, and a The opposite threaded screw rods 13 on one side of the mold frame 17, the fixed-width blocks 14 respectively arranged at both ends of the screw rods 13, the fixed-width motors 19 for driving the screw rods 13, the hydraulic cylinders 18 for controlling the lateral movement of the uncoiler 10, and the control hydraulic cylinders 18 The proportional amplifier 21 and the reversing proportional valve 20 also include a programmable controller 25, a tachogenerator 23 connected to the rotating shaft of the drive motor 12, a first infrared photoelectric sensor C1, a second infrared photoelectric sensor C2, a third infrared photoelectric sensor Sensor C3, first electromagnetic induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com