Numerical control engraving sanding composite machining center

A compound machining center and sanding technology, applied in engraving, metal processing equipment, manufacturing tools, etc., can solve problems such as complex operation procedures, achieve the effects of simplifying procedures, reducing procedures, improving quality and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention will be further described below in conjunction with the accompanying drawings.

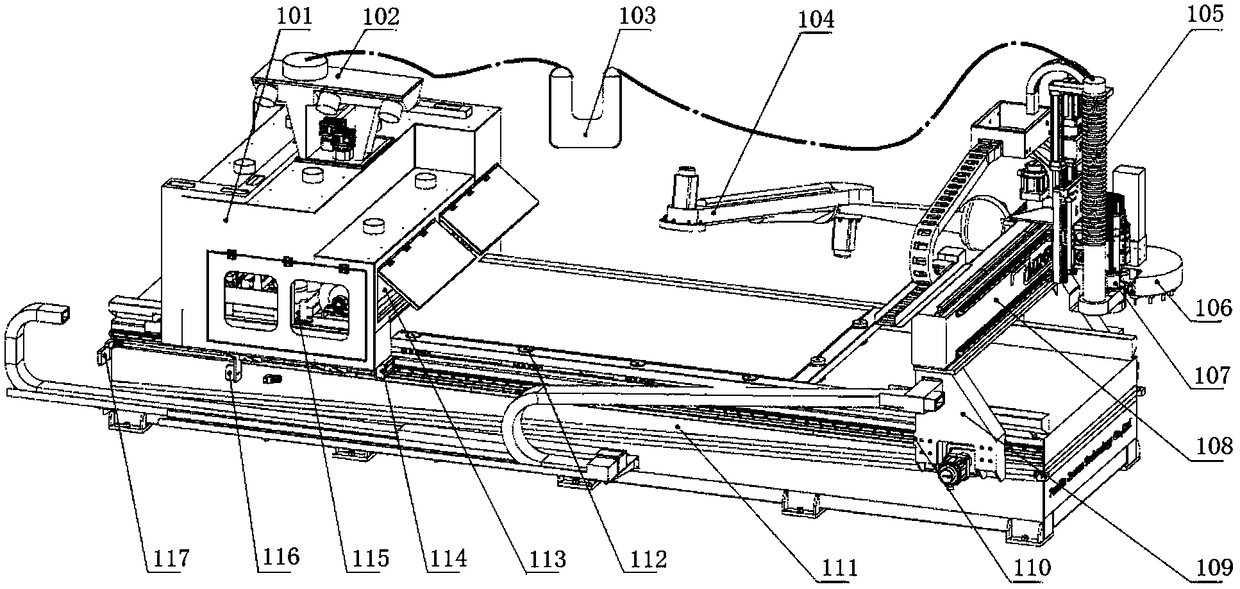

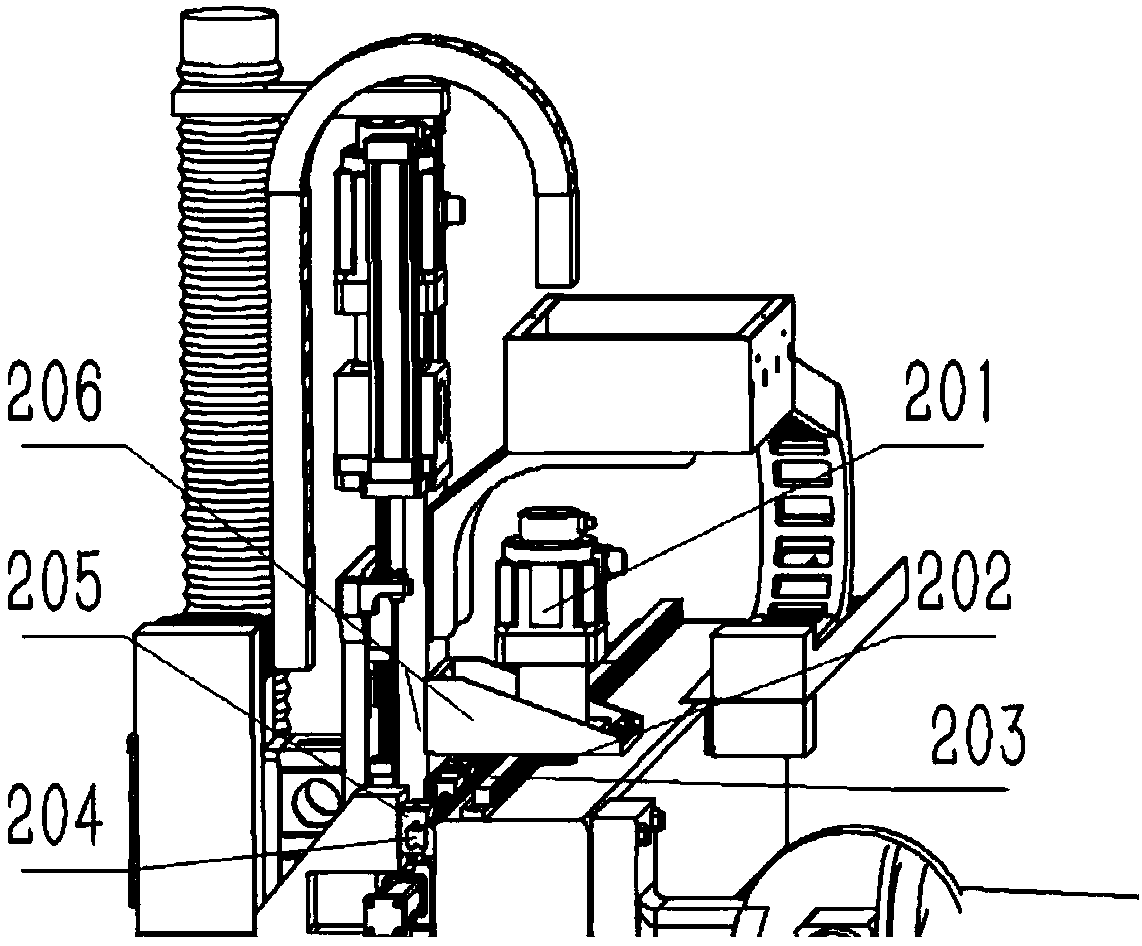

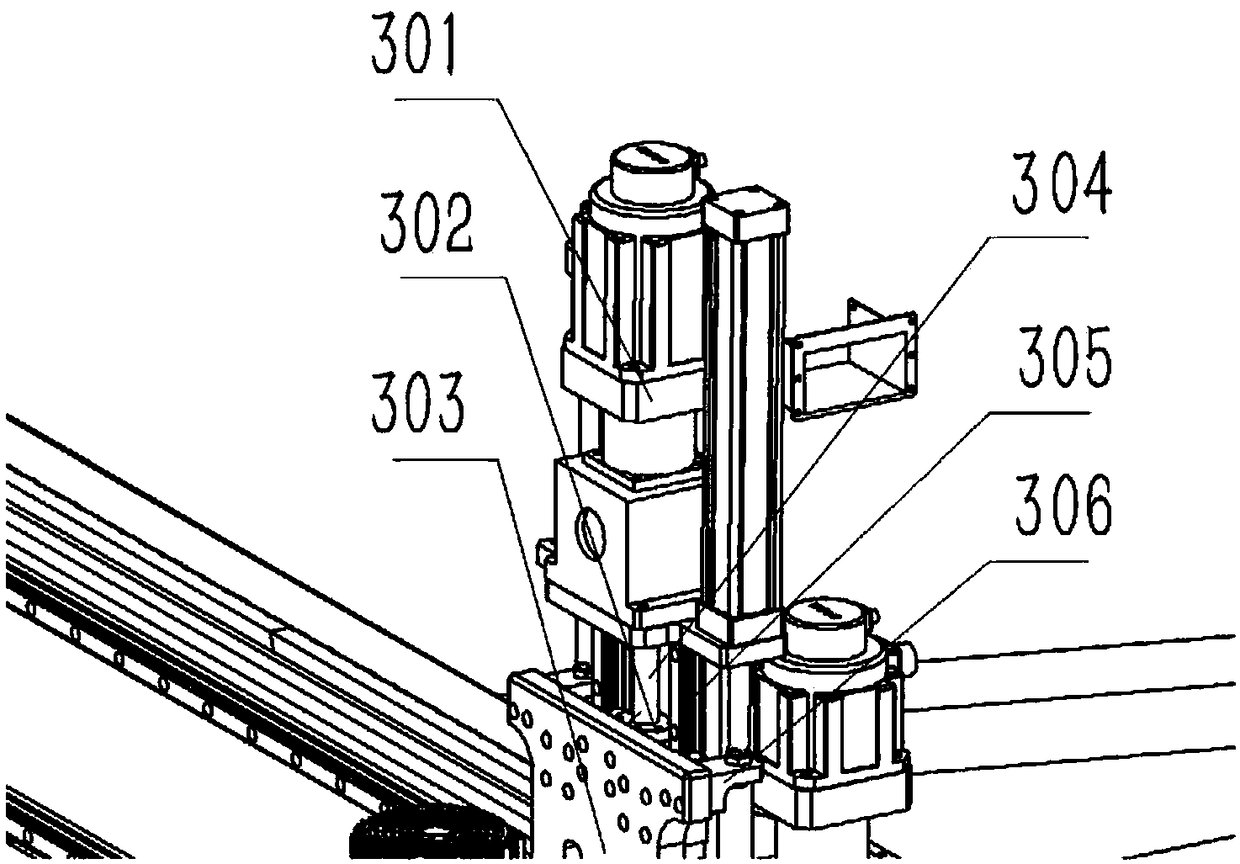

[0029] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the CNC engraving and sanding composite machining center of the present invention is used for automatic feeding, cutting, engraving, sanding, and blanking of materials such as composite panels and wood panels, which mainly include: sanding machine master Device 101, dust collection device 102, vacuum cleaner 103, manipulator unloading device 104, spindle suction pipe 105, tool magazine 106, spindle 107, beam 108, side plate 109, adsorption electromagnet fixing plate 110, bed 111, pneumatic positioning Block 112, large sand roller 113, adsorption electromagnet 114, small sand disc 115, suction cup electromagnet 116, suction cup electromagnet fixing plate 117, X-axis servo motor 201, X gear shaft 202, X rack 203, X-direction guide 204 , X slider 205, X slider 206, Z axis servo motor 301,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com