Rod double-length flying shear control method and device

A technology of double-footed flying shears and control devices, applied in shearing machine control devices, shearing devices, manufacturing tools, etc., can solve the problems of no shearing, hot metal detectors always on, cooling water backflow, etc., to save axial flow Effects of fans or compressed air, reduced spare parts and maintenance costs, lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

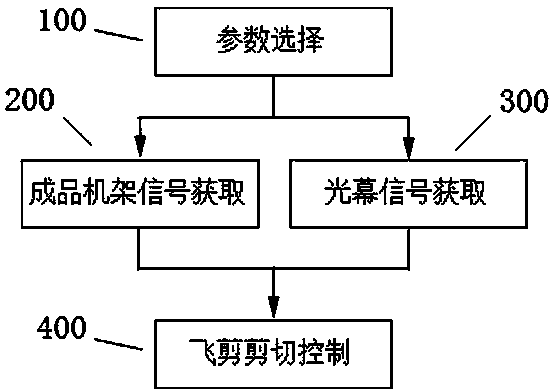

Method used

Image

Examples

Embodiment

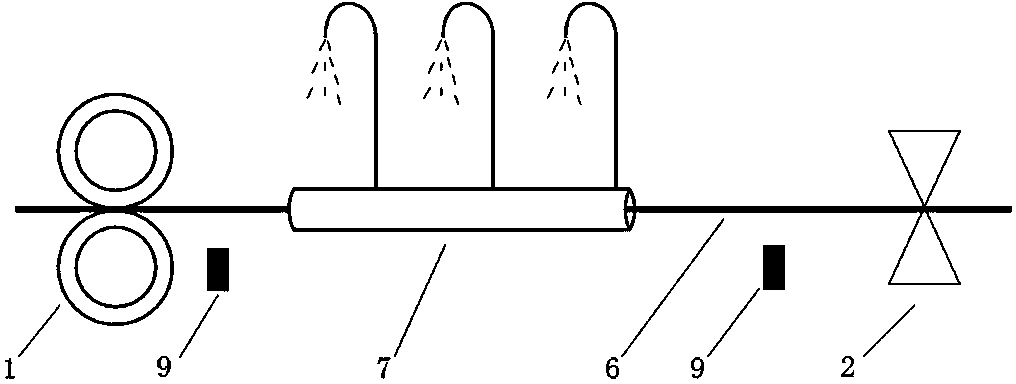

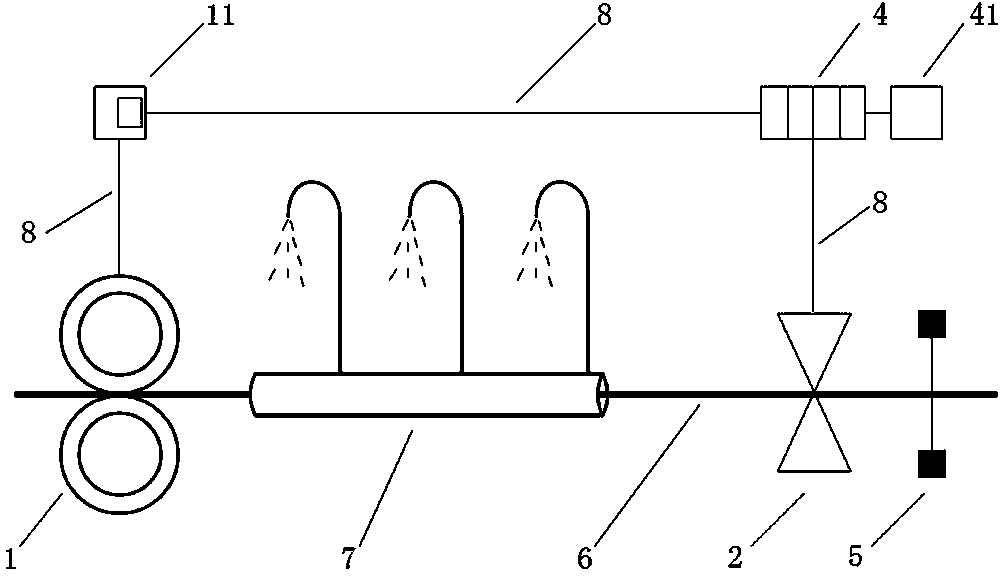

[0039] First, set the bar cutting length L, finished product frame number, and the working roll diameter D of the corresponding finished product frame to the PLC system through the input device k .

[0040] Then, the PLC system judges the finished frame. Taking the configuration of 18 rolling mills, only 14, 16 and 18 can be used as the bar line of the finished frame as an example: if 16 and 18 are selected as "empty If 18 racks are selected as "empty" racks, then 16 racks are judged as finished racks; if 18 racks are not selected as "empty" racks, Then 18 are finished racks.

[0041] Secondly, through the communication message between the PLC system and the inverter corresponding to the main shaft motor of the finished rack, the current value I of the selected finished rack 反馈 read out.

[0042] The PLC system is connected to the signal between the light curtains set at the rear end of the double-foot flying shear to obtain the light curtain signal.

[0043] The PLC syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com