A molten iron transportation system

A transportation system and molten iron technology, which is applied in the direction of rails, buildings, roads, etc., can solve the problems that the operation rate of the crane cannot meet the requirements of molten iron transportation, the operation period of molten iron is long, and the arrangement of blast furnaces is scattered, so as to reduce the loss of molten iron back-transportation and save transportation The effect of short time and transportation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

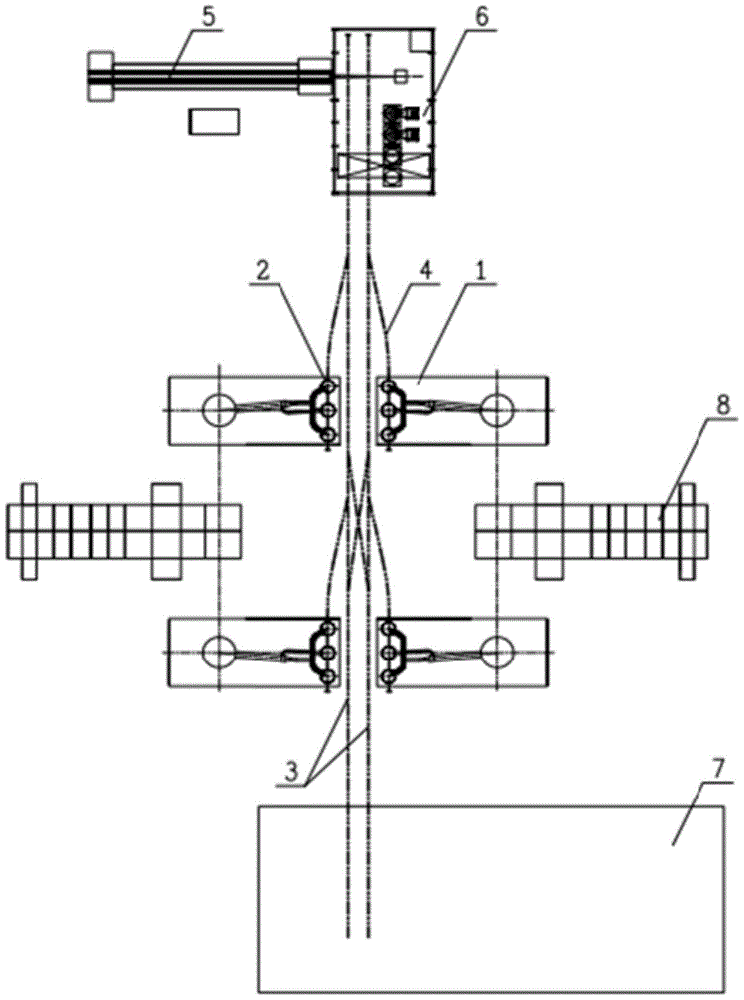

[0015] In order to better understand the purpose, structure and function of the present invention, a molten iron transportation system of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, the molten iron transportation system of the present invention is suitable for the transportation of molten iron between multiple blast furnaces and steelmaking workshops in the steelmaking workshop. Specifically, the molten iron transportation system of the present invention includes a casthouse 1 and a steelmaking workshop 7 of the ironmaking blast furnace, wherein two parallel rails are arranged between the casting yard 1 and the steelmaking workshop 7 of the ironmaking blast furnace. Line 3. It should be noted that, in this embodiment, the track running lines 3 are two parallel straight lines. Of course, according to actual needs, the track running lines 3 can also be set to be more or curved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com