Patents

Literature

70results about How to "Short transport distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

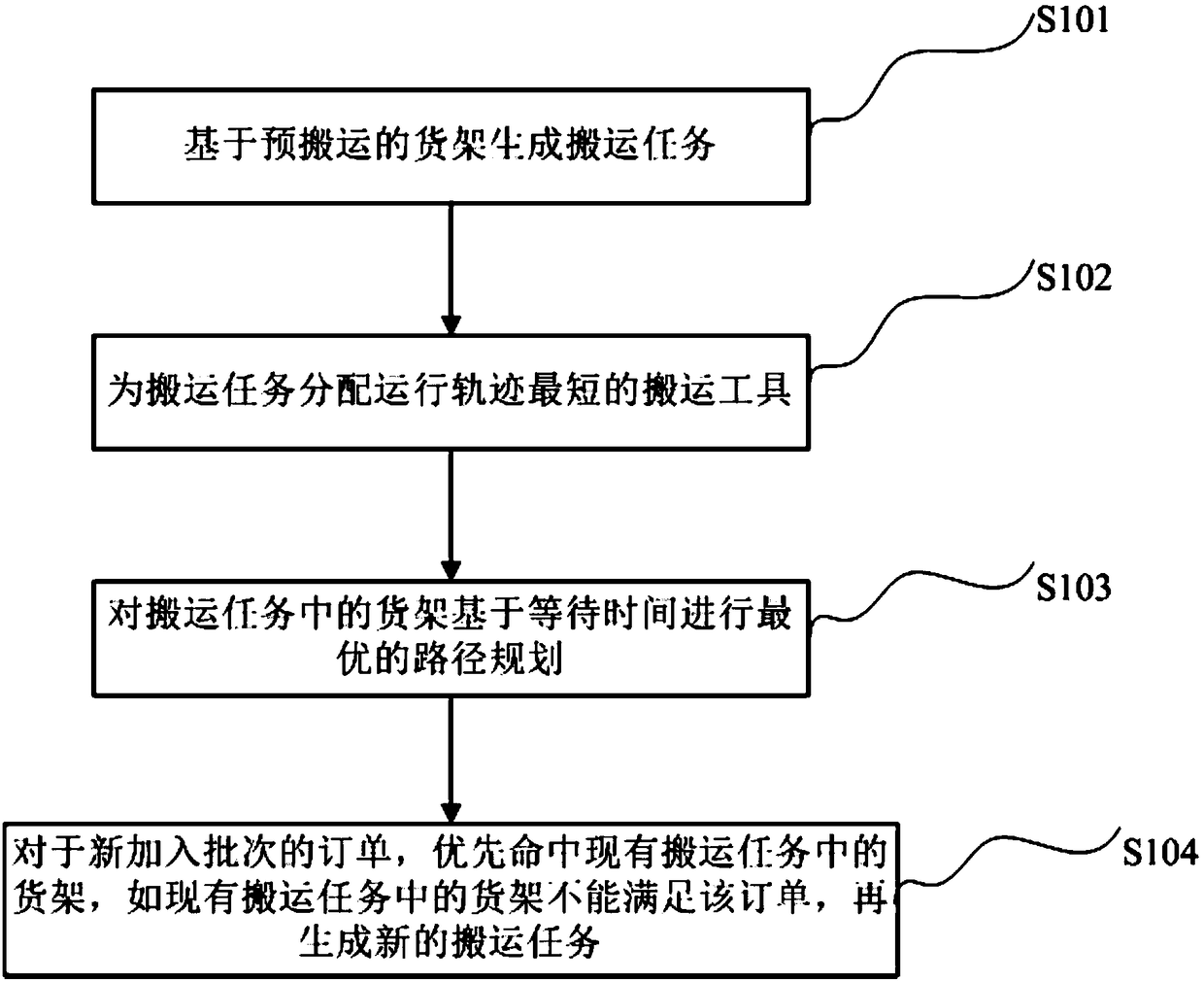

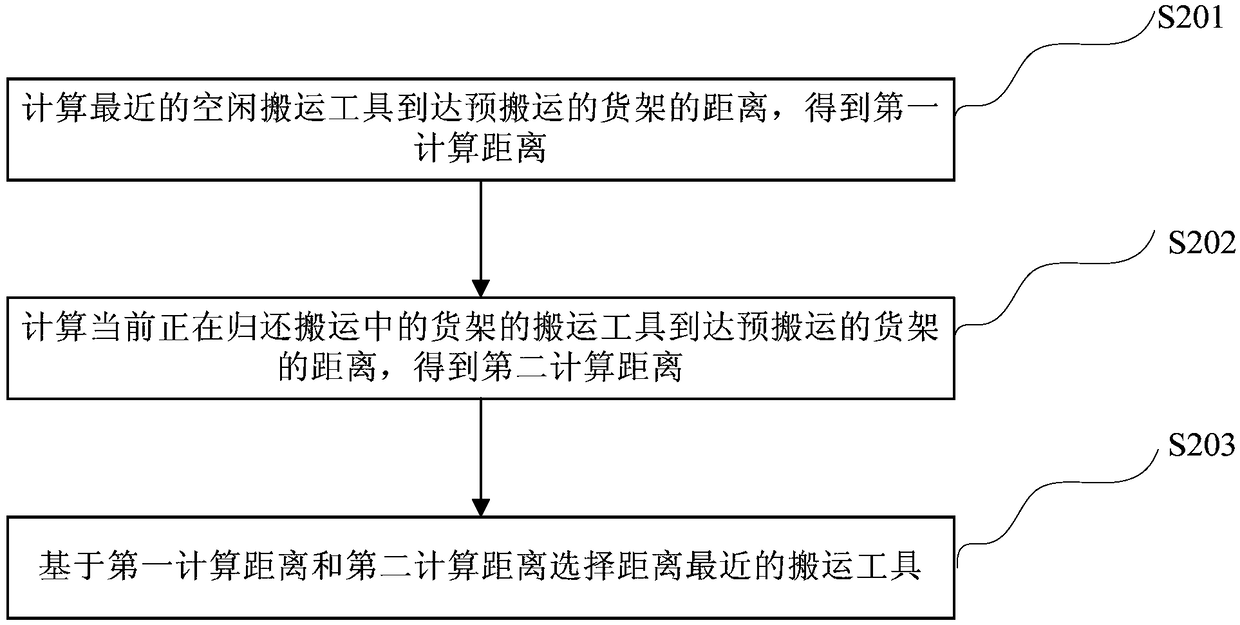

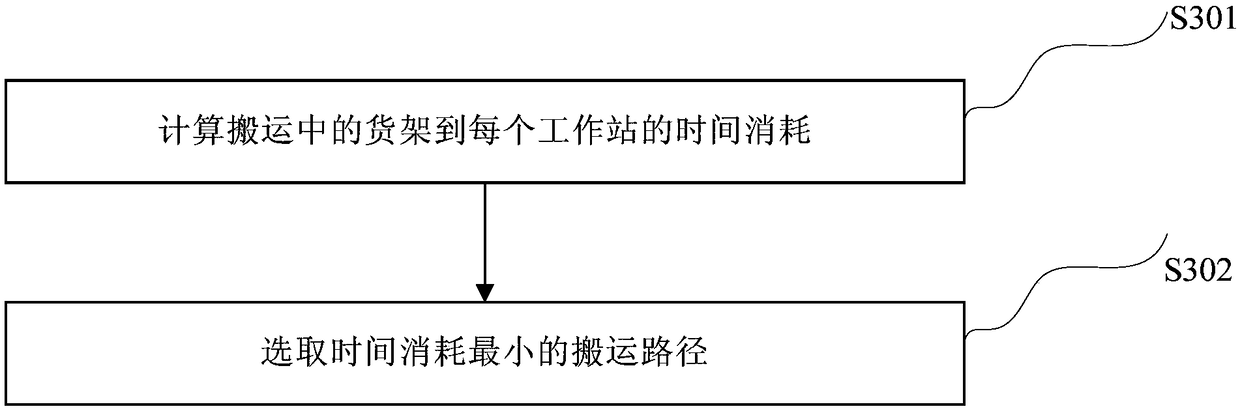

Goods shelf carrying method, device and system applied to goods-to-person system

ActiveCN108921327AImprove efficiencyShort transport distanceForecastingLogisticsOrder formLogistics management

The invention discloses a goods shelf carrying method, device and system applied to a goods-to-person system and relates to the field of logistics automation. The goods shelf carrying method applied to the goods-to-person system comprises the steps that a carrying task is generated based on to-be-carried goods shelves; a carrying tool with the shortest moving track is allocated to the carrying task; optimal path planning is performed on the goods shelves in the carrying task based on waiting time; and for an order in a new batch, the goods shelves in the existing carrying task are named first,and if the goods shelves in the existing carrying task cannot meet the requirement of the order, a new carrying task is generated. The system corresponding to the method comprises the carrying tool used for carrying the goods shelves; the goods shelves used for arranging goods positions for commodity placement and capable of being carried by the carrying tool; a goods shelf area used for storingthe goods shelves; and a server used for executing the goods shelf carrying method applied to the goods-to-person system to perform scheduling configuration on the carrying tool and the goods shelves.Through the goods shelf carrying method, device and system, the purpose of improving the efficiency of the goods-to-person system is achieved.

Owner:BEIJING JIZHIJIA TECH CO LTD

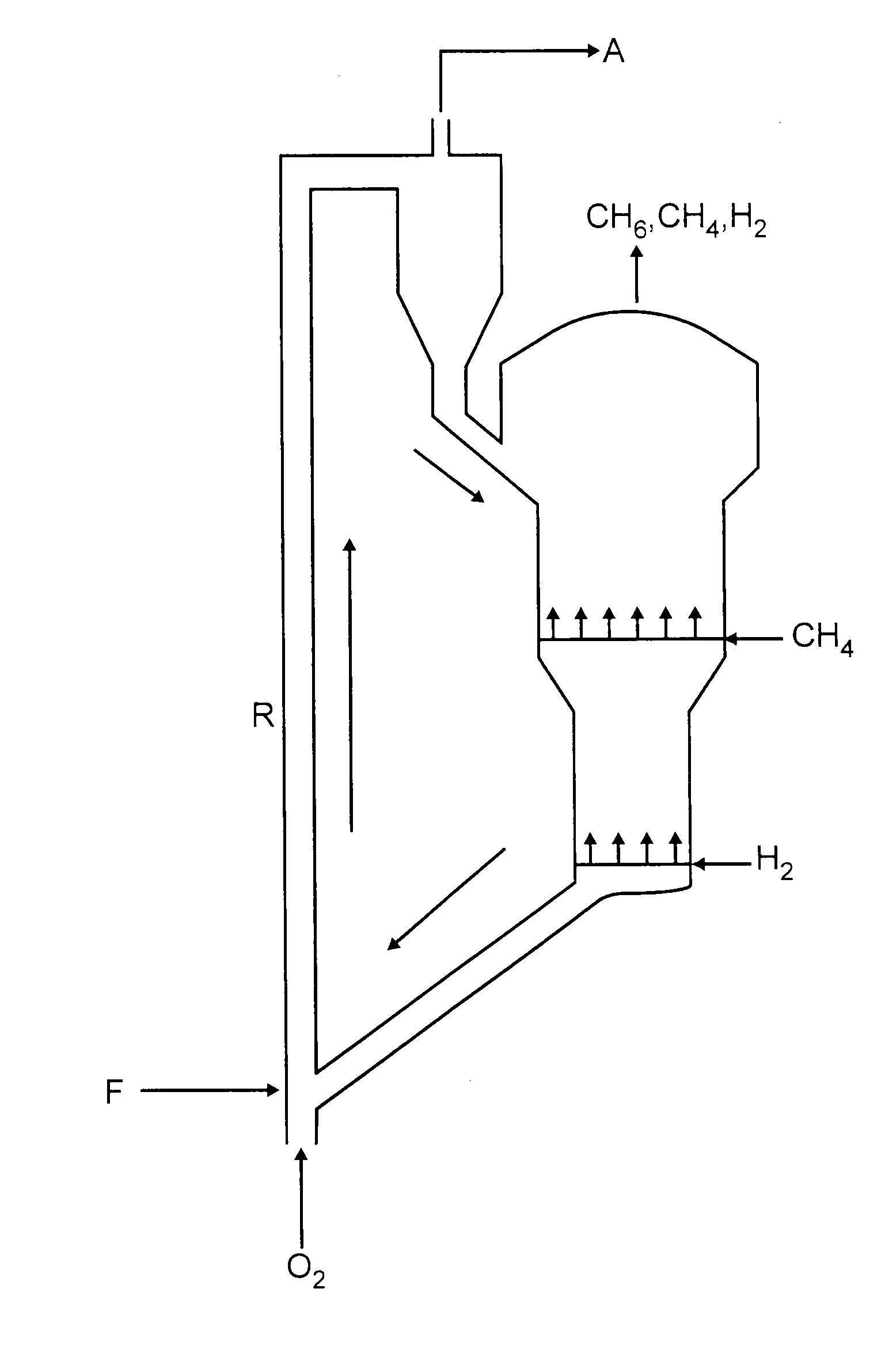

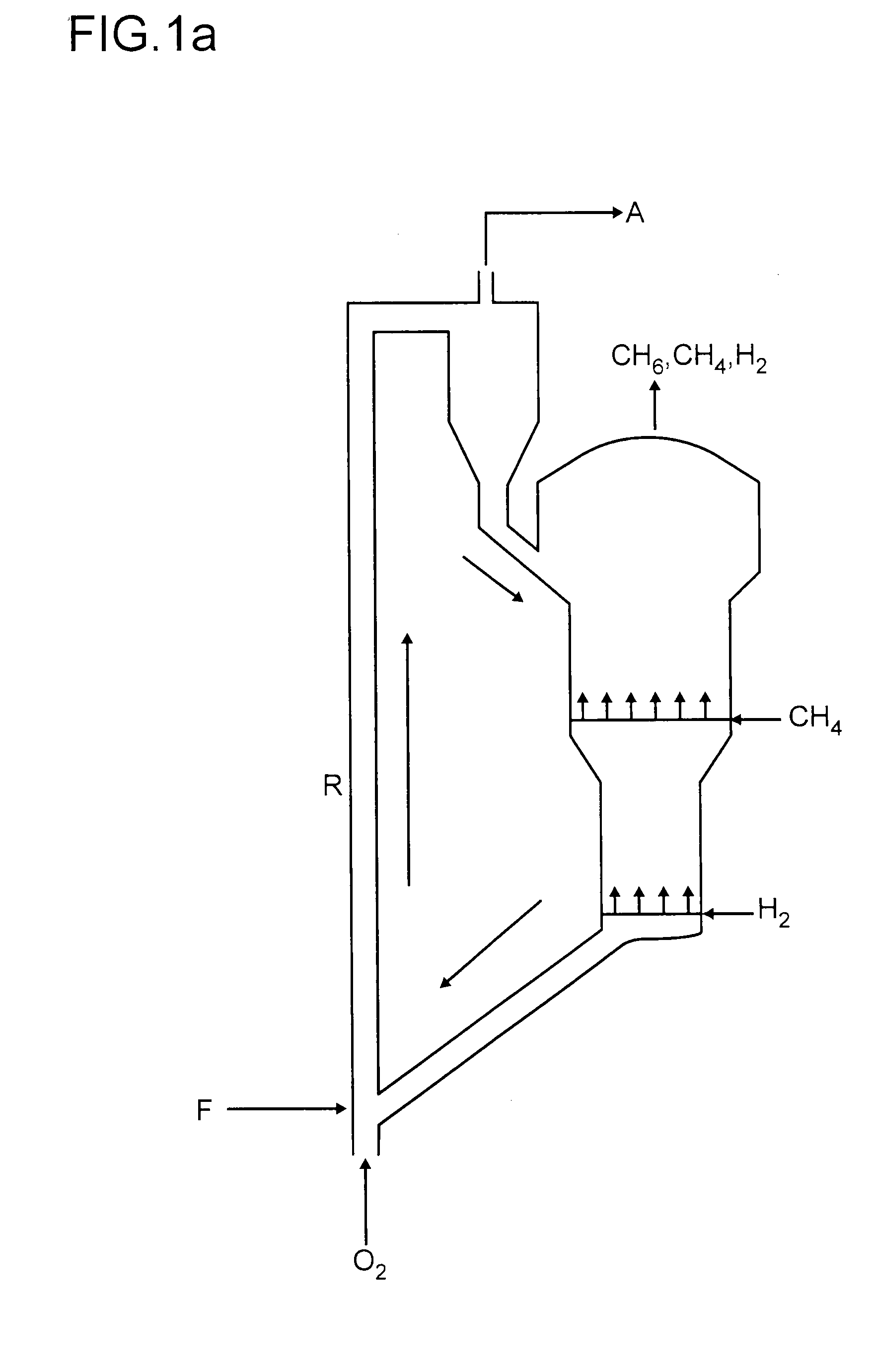

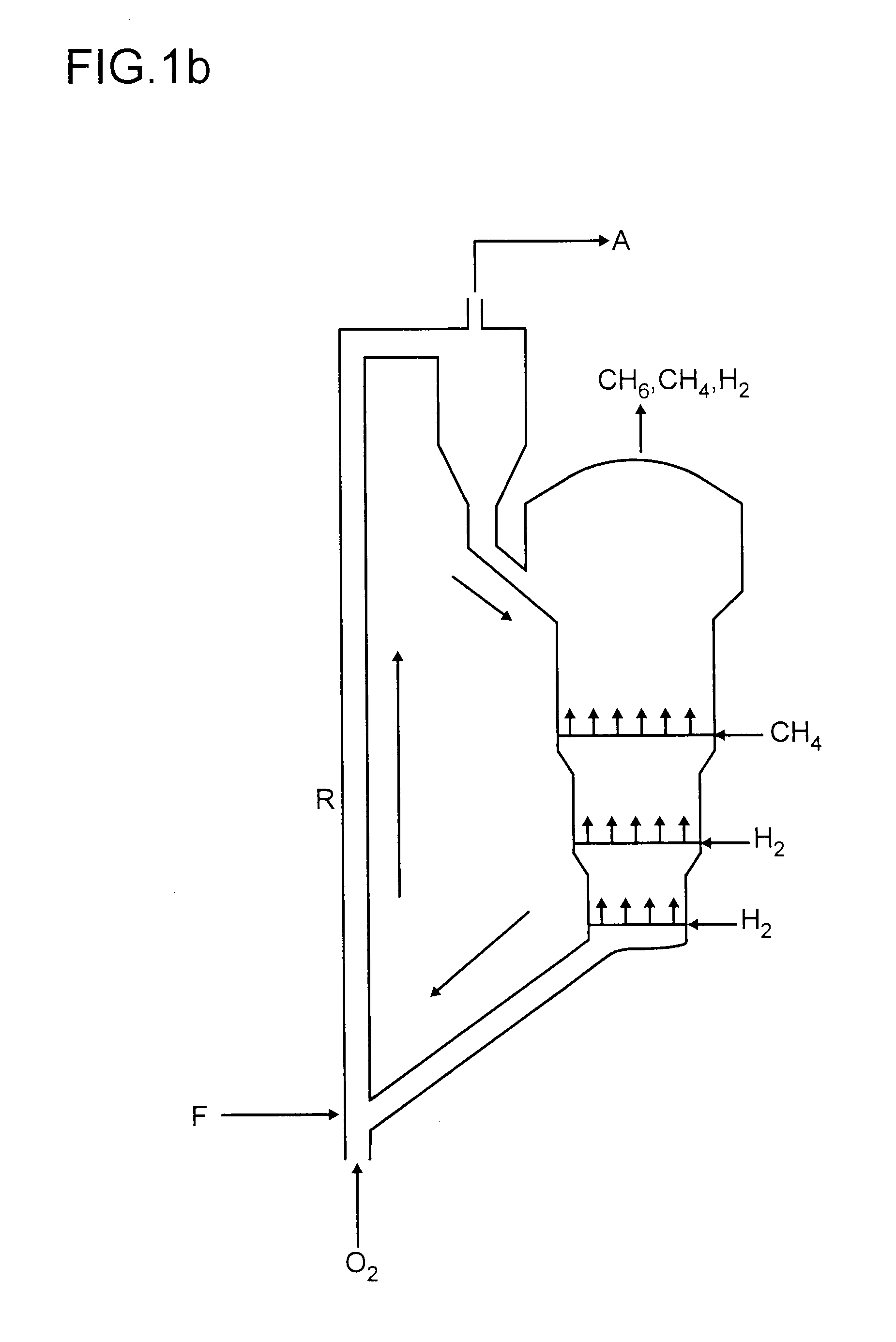

Process for preparing aromatics from methane

InactiveUS20120022310A1Extended service lifeShort transport distanceCatalystsHydrocarbon preparation catalystsPtru catalystNon oxidative

The present invention relates to a process for carrying out endothermic, heterogeneously catalyzed reactions in which the reaction of the starting materials is carried out in the presence of a mixture of inert heat transfer particles and catalyst particles, where the catalyst particles are regenerated in a nonoxidative atmosphere at regular intervals and the heat of reaction required is introduced by separating off the inert heat transfer particles, heating the heat transfer particles in a heating zone and recirculating the heated heat transfer particles to the reaction zone. The process of the invention is particularly suitable for the nonoxidative dehydroaromatization of C1-C4-aliphatics in the presence of zeolite-comprising catalysts.

Owner:BASF AG

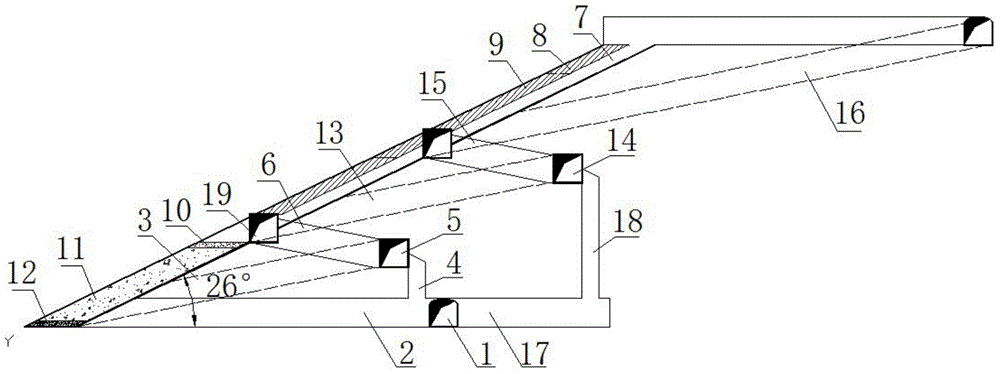

Trackless mining method for gently inclined ore vein

ActiveCN104100270AAvoid Procurement QuantitiesIncrease production capacityUnderground miningSurface miningVeinSafe operation

The invention discloses a trackless mining method for a gently inclined ore vein. The method comprises the steps of: vein partition and ore block arrangement, rock drilling tunnel arrangement, and sublevel filling. During vein partition, the ore vein is partitioned into stages along the ore vein vertical height, a stage falls into substages, and a stope is partitioned along the strike; at an ore vein footwall, a substage orepass is tunnelled in advance; an exo-vein orepass connection roadway is formed on one side of the orepass; orepass connection ramps upward and downward connecting each substage bottom are formed at both ends of the orepass connection roadway respectively; the upward and downward orepass connection ramps and the orepass connection roadway realize passing and stay of trackless mining equipment, staff and materials; and ores are removed out of the mine through each substage orepass. With the characteristics of small exo-vein mining preparation project amount, high production efficiency, and safe operation, etc., the method provided by the invention solves the technical problems of large exo-vein mining preparation amount, difficult self-slip of ores, low mechanization degree, large labor intensity and low efficiency of the gently inclined thin ore vein, and realizes trackless mechanized efficient mining of the gently inclined thin ore vein.

Owner:贵州开磷设计研究院有限责任公司 +1

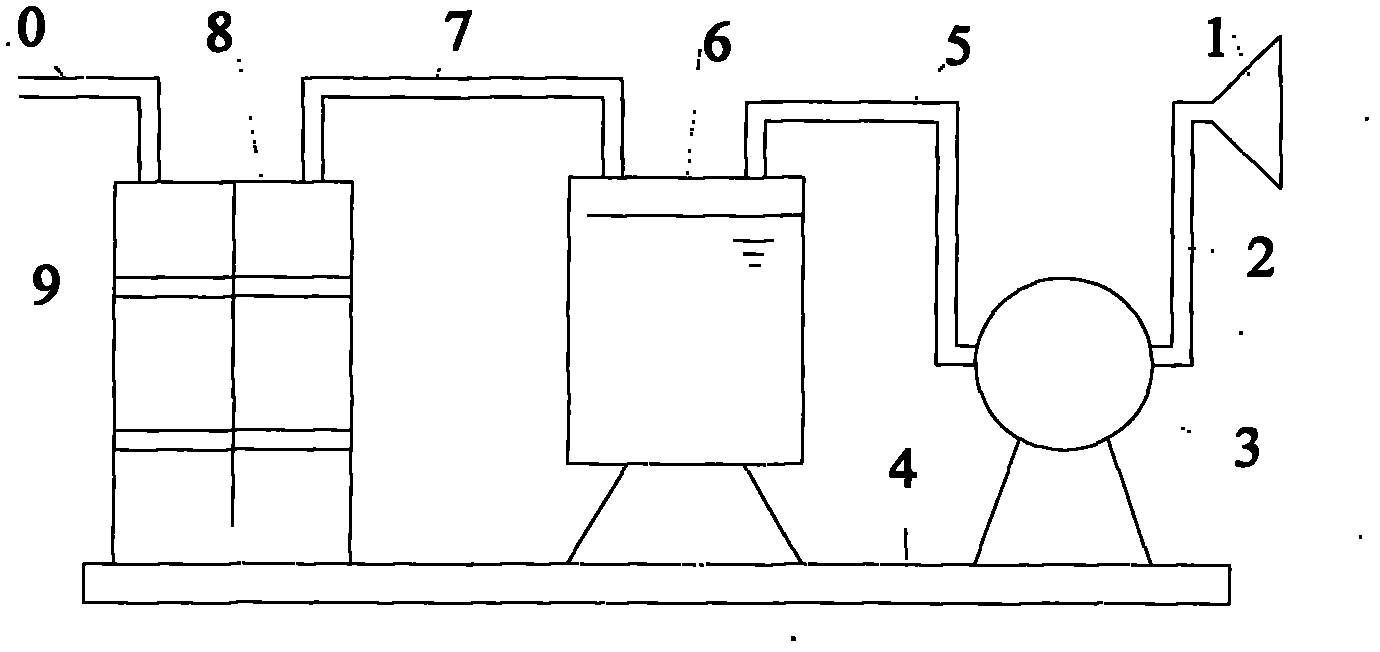

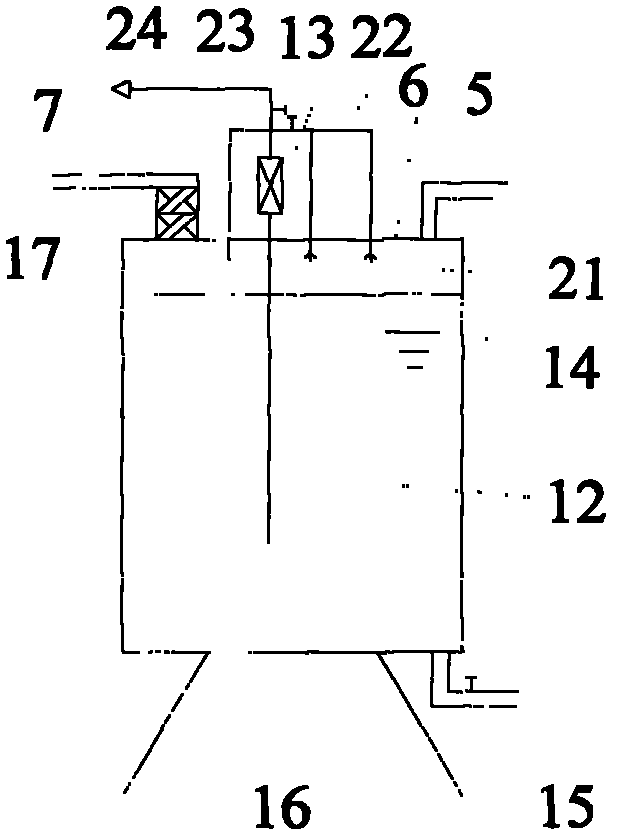

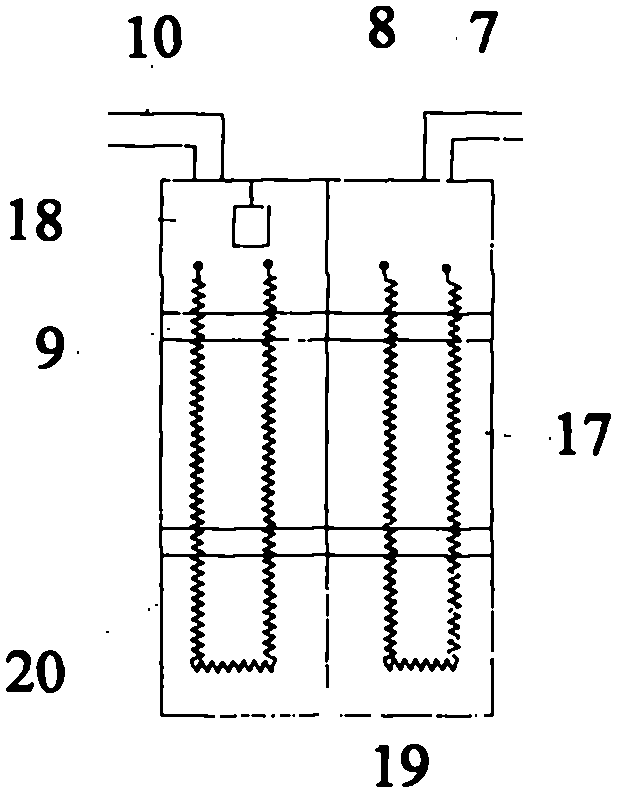

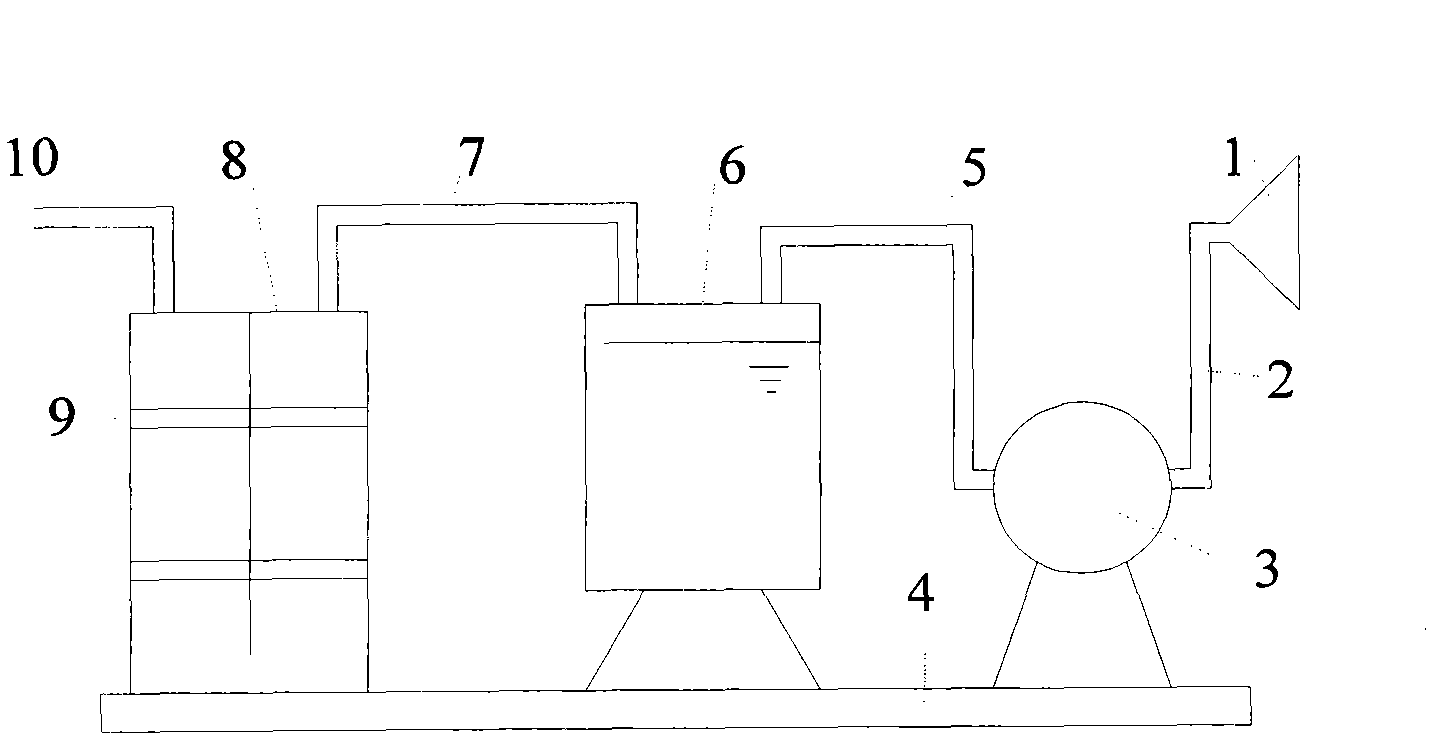

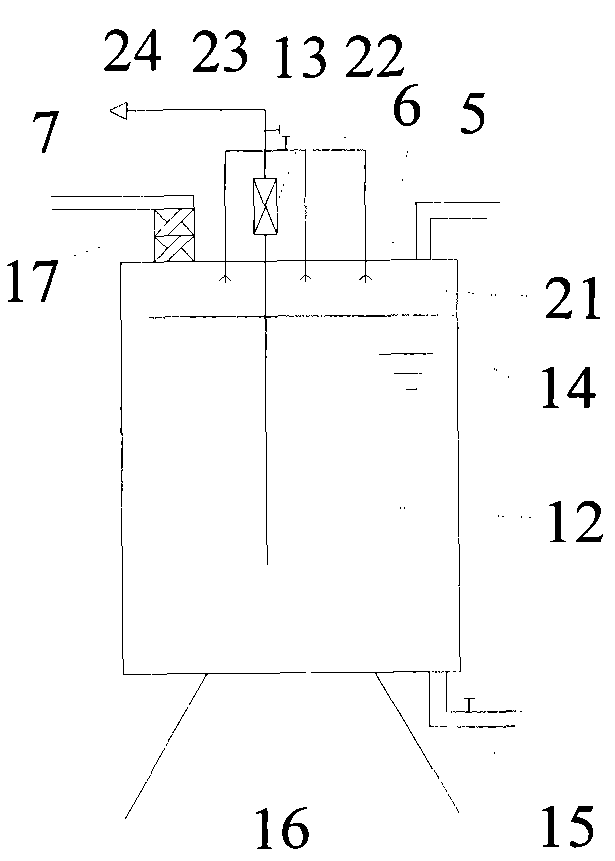

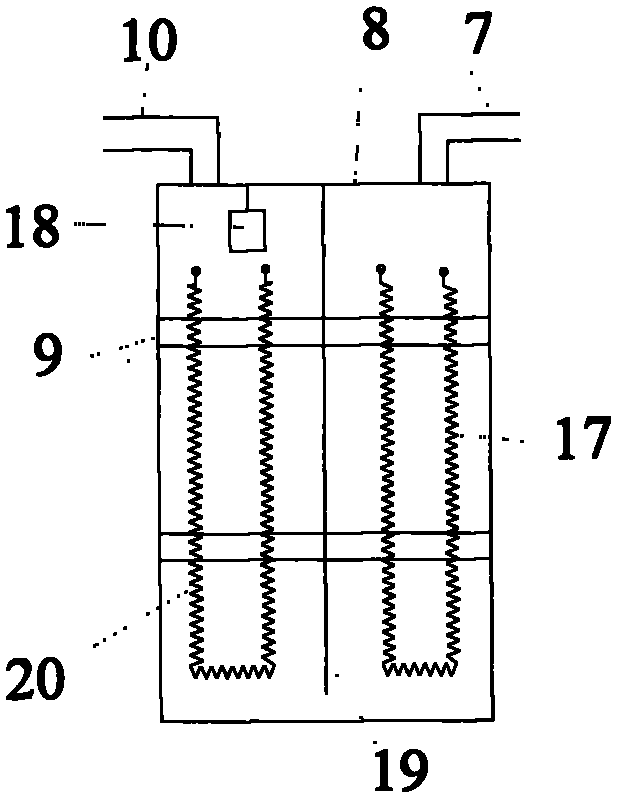

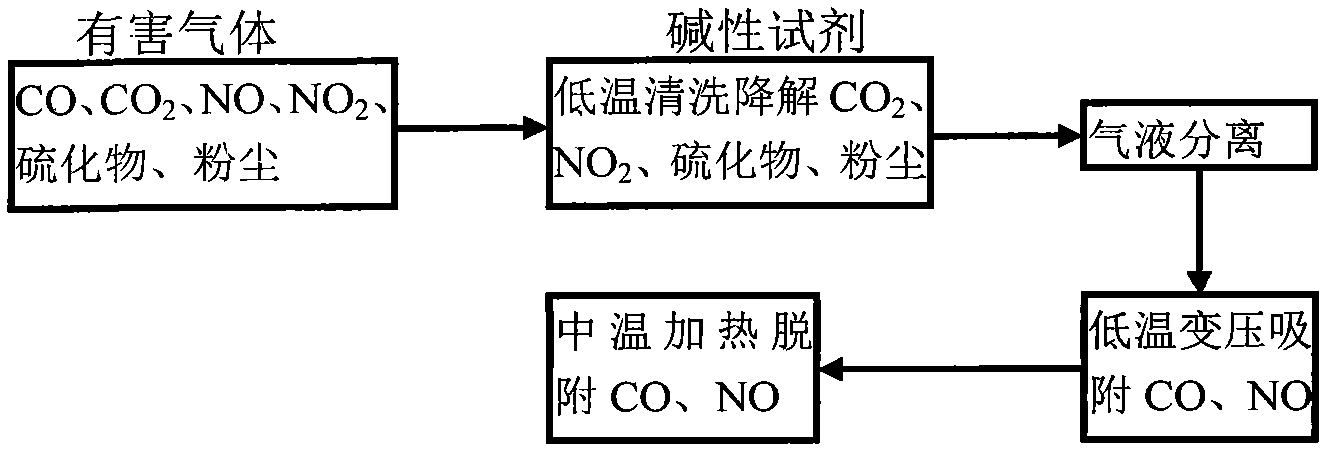

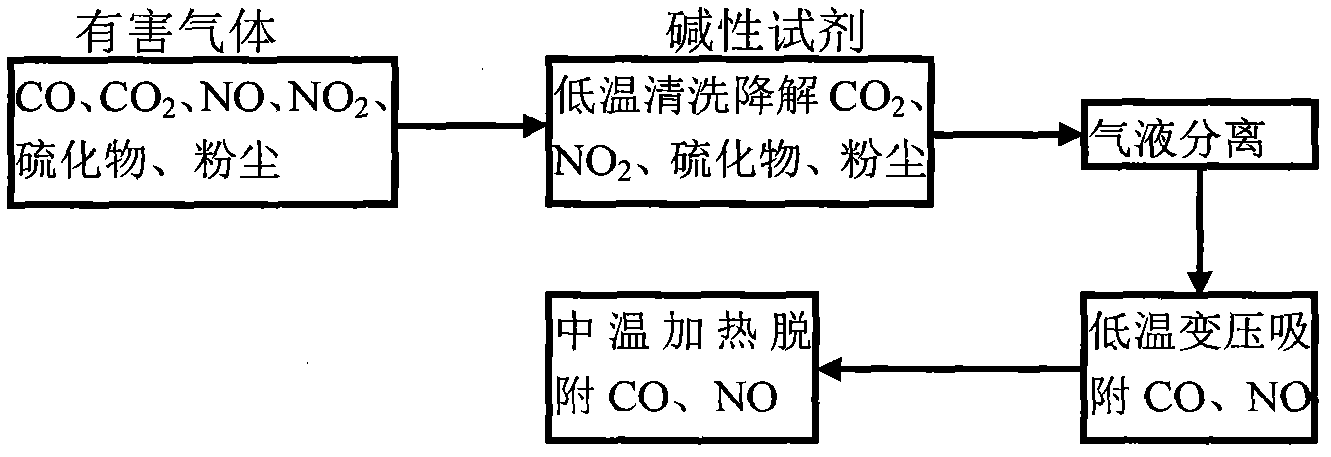

Air purifier for clearing away harmful gases and dust for long tunneling working surface

InactiveCN102434183AQuality improvementReduce ventilation timeDust removalDispersed particle separationFiltrationWater vapor

The invention relates to an air purifier for clearing away harmful gases and dust for a long tunneling working surface, aiming at solving the problem that the ventilation for the tunneling working surface for construction of a long tunnel is difficult. A centrifugal fan is used to send harmful gases CO, CO2, NO, NO2, sulfides and dust in the tunnel into a degrading tool through a suction guard and a connecting pipe. The CO and NO, which are left after the reaction degradation, are sent into an absorption box through the connecting pipe, and the residual gases are filtered off water vapors by a porous fiber separating membrane, and the CO and a little of NO, which are left after the degradation and membrane filtration, are absorbed by a low-temperature pressure swing adsorption tower; the pressure swing absorption tower which absorbs the CO and NO is transported out of the tunnel, wherein the tower is heated to 80-135 DEG C by an electric heating tape in the tower to desorb the CO and NO. The air purifier can effectively prevent pollution to the tunneling working surface from harmful gases, and is suitable for clearing off harmful gases and dust.

Owner:谢飞鸿

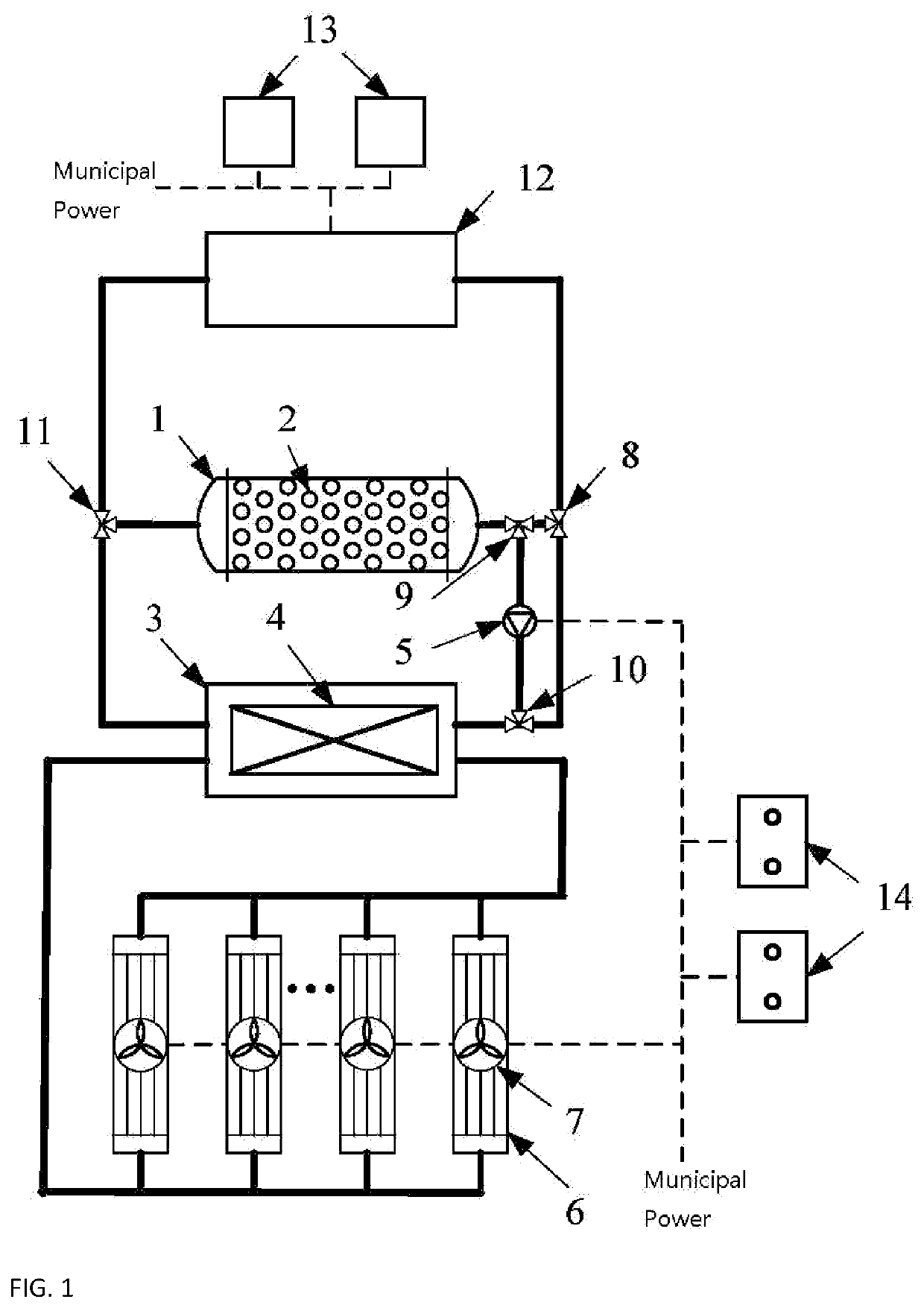

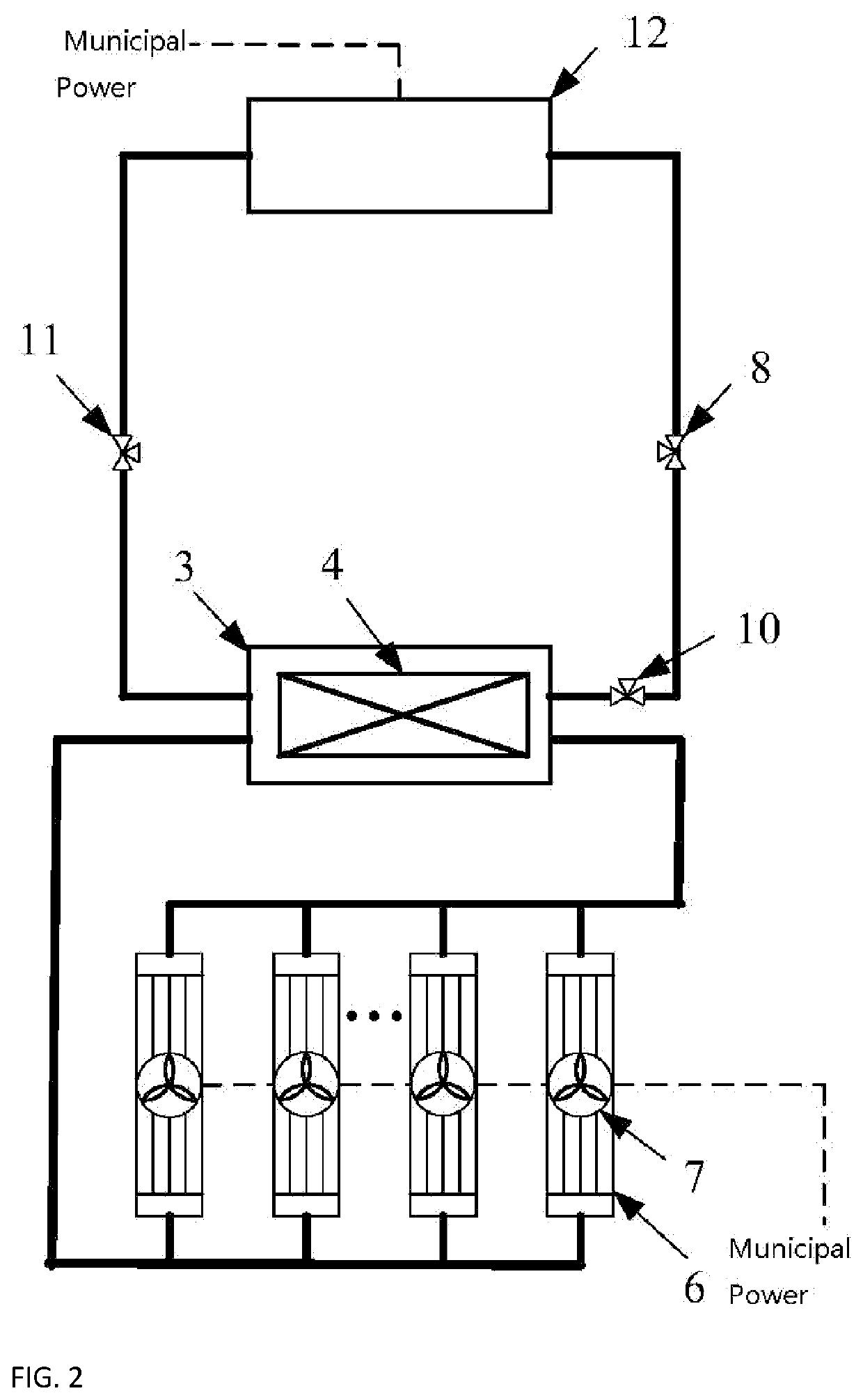

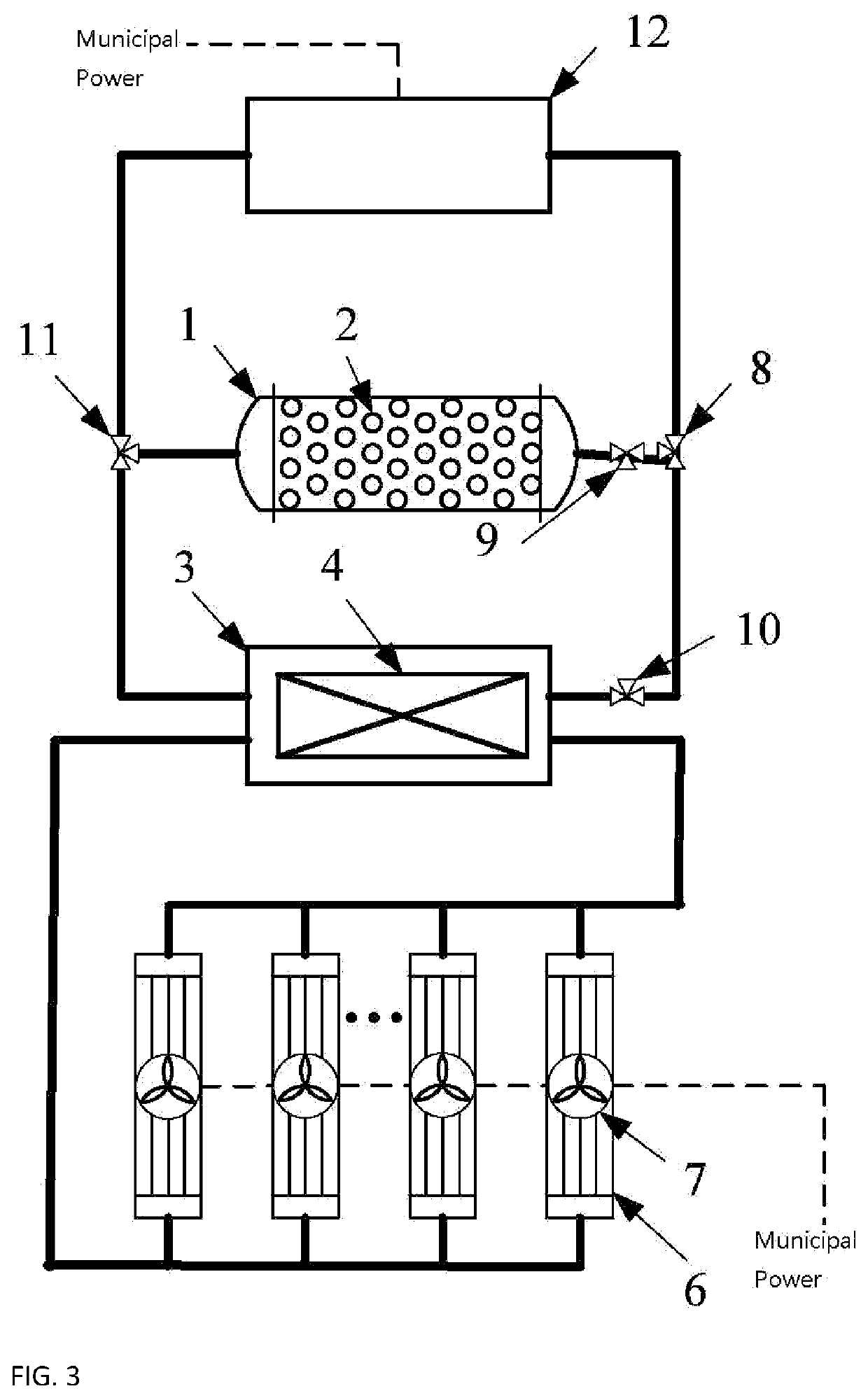

Computer room heat-pipe air conditioning system with emergency cooling function and control and method thereof

ActiveUS20210045265A1Ensure safetyReduce cooling effectMechanical apparatusModifications using liquid coolingStandby powerEngineering

A computer room heat-pipe air conditioning system with an emergency cooling control method. The system comprises a phase-change energy storage module, a phase-change material packaging body, a condenser housing, a condenser, a cold releasing pump, evaporators, evaporation fans, four three-way valves, a cooling unit, standby power generators and storage batteries. The three-way valves are opened and closed based on a preset heat-pipe cooling criteria in combination with phase-change energy storage technology.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

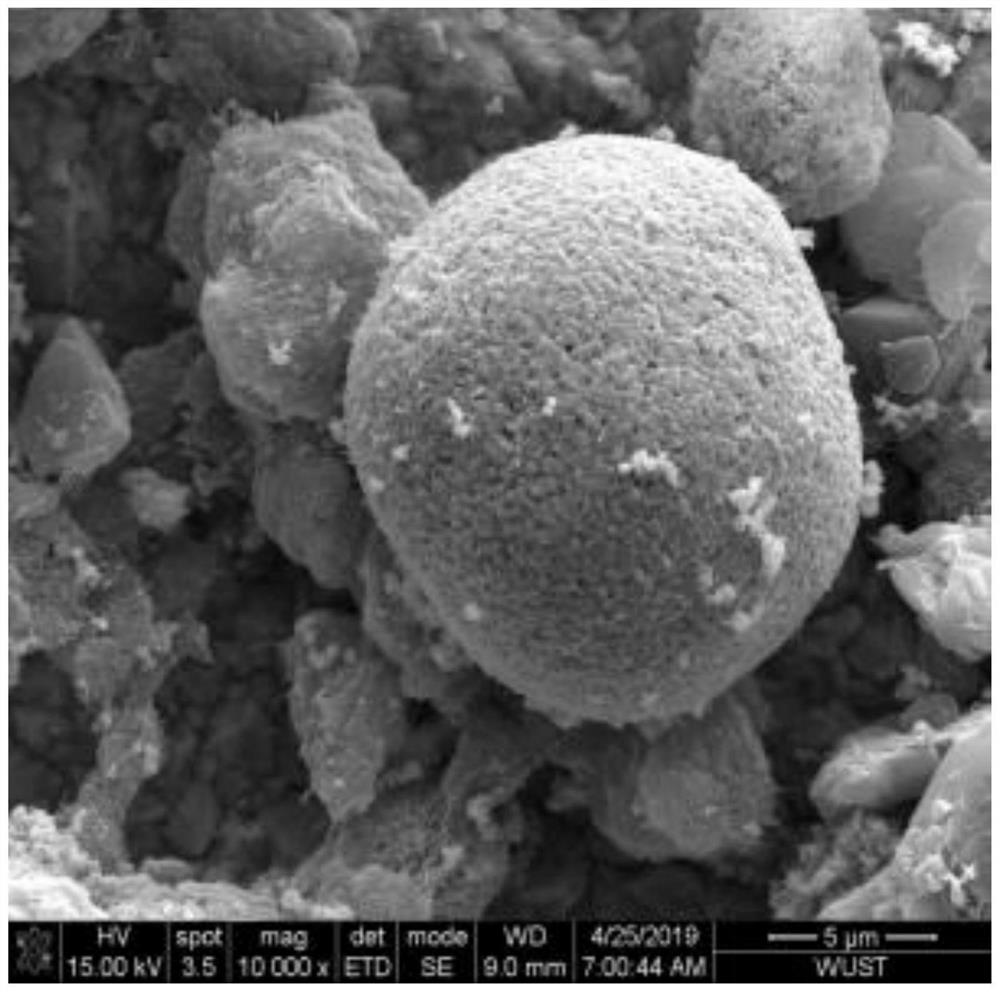

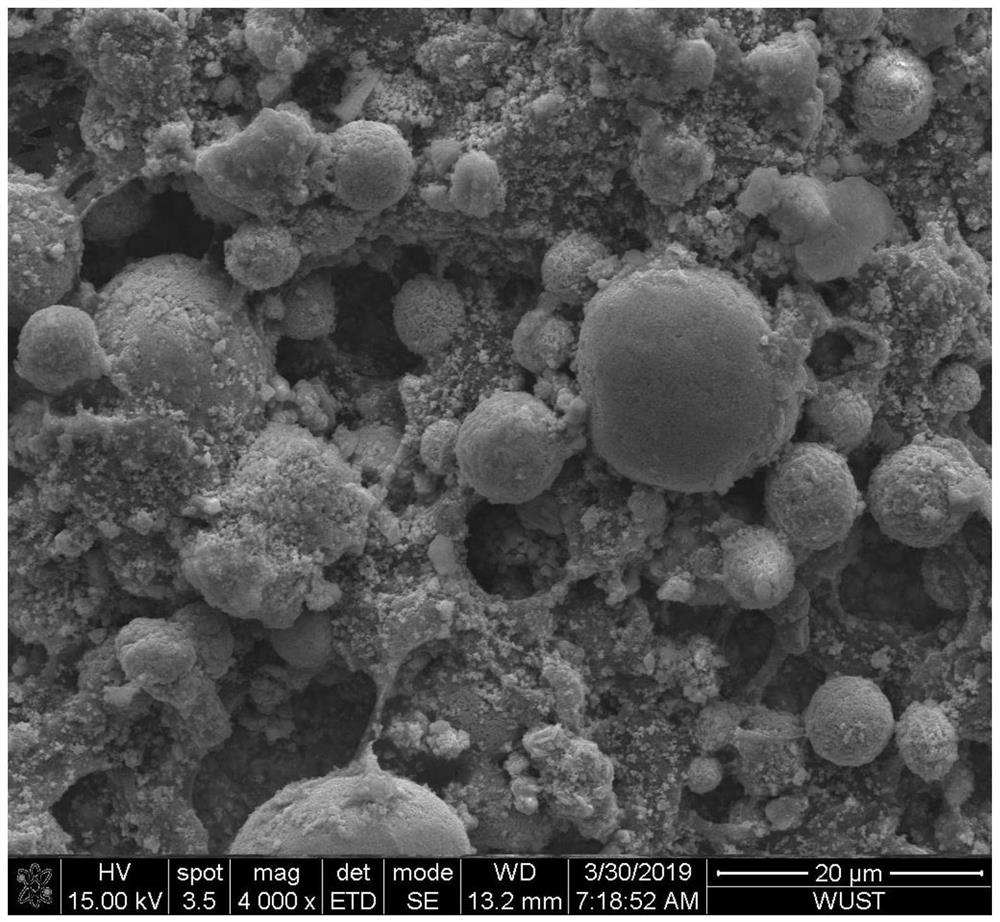

Three-dimensional composite current collector and preparation method thereof

PendingCN112670516AHigh specific surface areaReduce the actual current densityElectrode carriers/collectorsSecondary cellsComposite materialLithium dendrite

The invention provides a three-dimensional composite current collector and a preparation method thereof. The three-dimensional composite current collector provided by the invention comprises a copper foil base layer and a lithium battery negative electrode lithium-philic material coating coated on the copper foil base layer, wherein the lithium battery negative electrode lithium-philic material coating comprises a plurality of micron-sized three-dimensional spherical structures, and the lithium battery negative electrode lithium-philic material is composed of a carbon material, a lithium-philic metal oxide, a binder and a lithium salt. The preparation method comprises the following steps: firstly, preparing lithium battery negative electrode lithium-philic material slurry, then coating a copper foil base layer with the slurry to form a lithium battery negative electrode lithium-philic material coating, and preparing the lithium battery negative electrode three-dimensional composite current collector. According to the lithium battery negative electrode lithium-philic material, a copper foil is coated with a composite coating with a micron-sized three-dimensional spherical structure, so that the current density of a lithium metal negative electrode can be effectively reduced, the generation of lithium dendrites is effectively relieved and reduced, and the cycle performance and the safety performance of a lithium metal battery are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Organic amine oriented hydrothermal method for preparation of molybdenum disulfide with multiple morphologies

ActiveCN108083336ARich varietyGood removal effectNanotechnologyMolybdenum sulfidesSynthesis methodsFiltration

The invention discloses an organic amine oriented hydrothermal method for preparation of molybdenum disulfide with multiple morphologies. The method includes the steps of: dissolving a certain amountof a molybdenum source, a sulfur source and organic amine in deionized water to form a solution, controlling the concentration of the molybdenum source at 0.1-0.3M, the S / Mo atom ratio of the raw materials at 2:1-4:1, and the ratio of organic amine to the molybdenum source at 2-6; placing the prepared solution in an airtight hydrothermal reaction kettle for reaction for 12-72h, and controlling thereaction temperature at 160-240DEG C; and at the end of reaction, conducting cooling, pumping filtration, washing and drying, thus obtaining MoS2 products of multiple morphologies. The synthesis method provided by the invention has the advantages of mild conditions, simple operation and high controllability, and the prepared products have flower shape, globularity, cylindrical shape and other geometric shapes.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

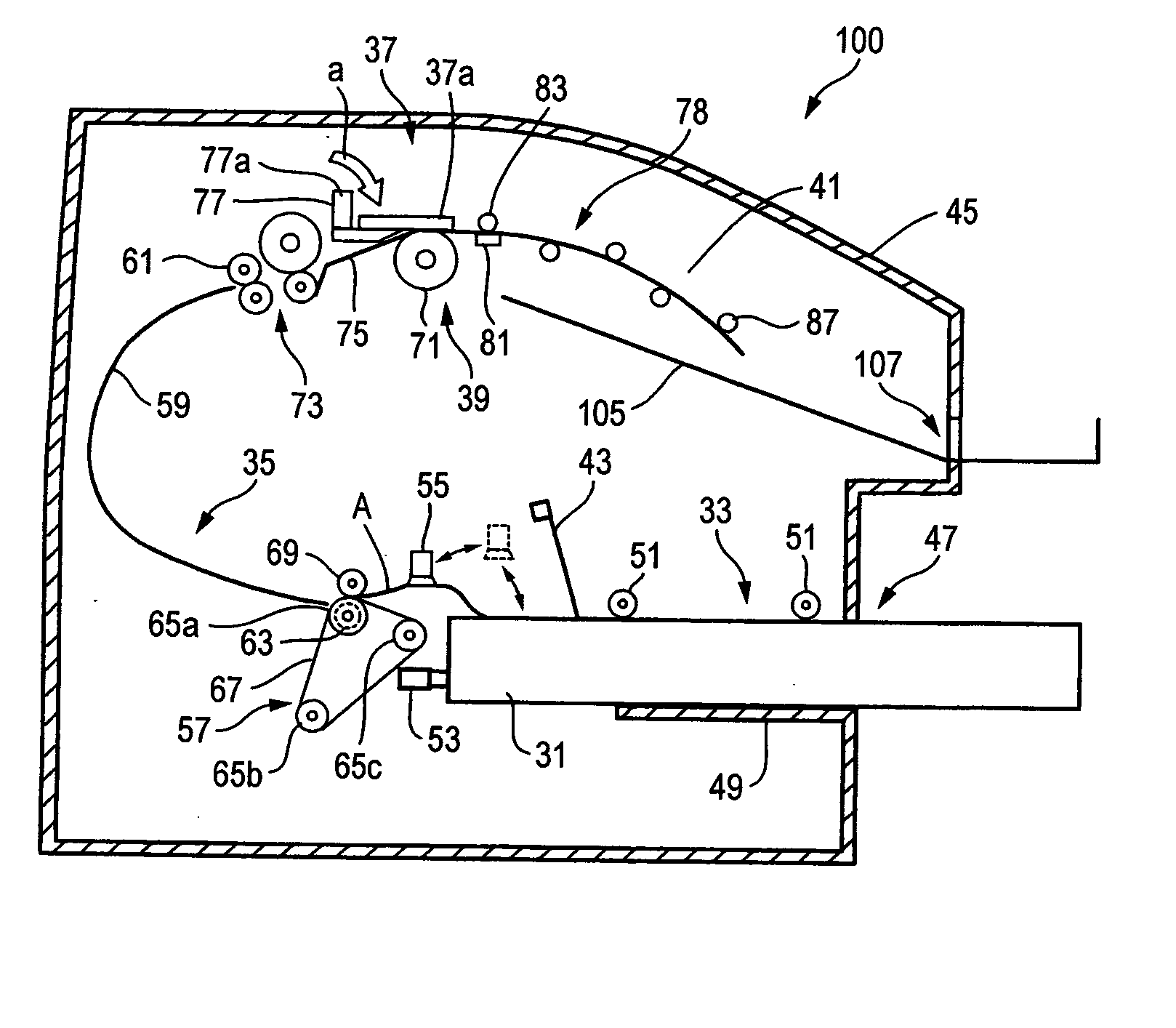

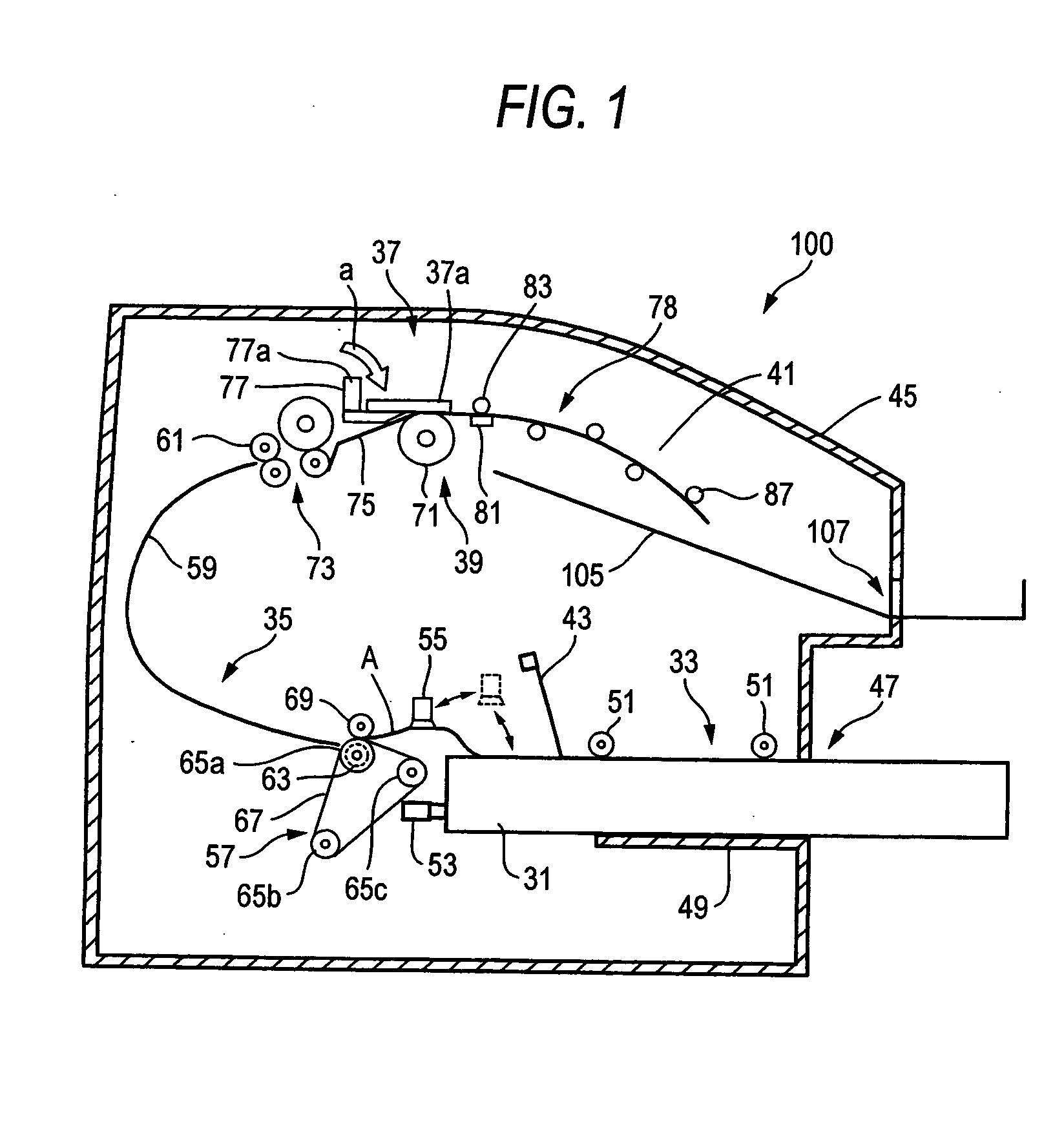

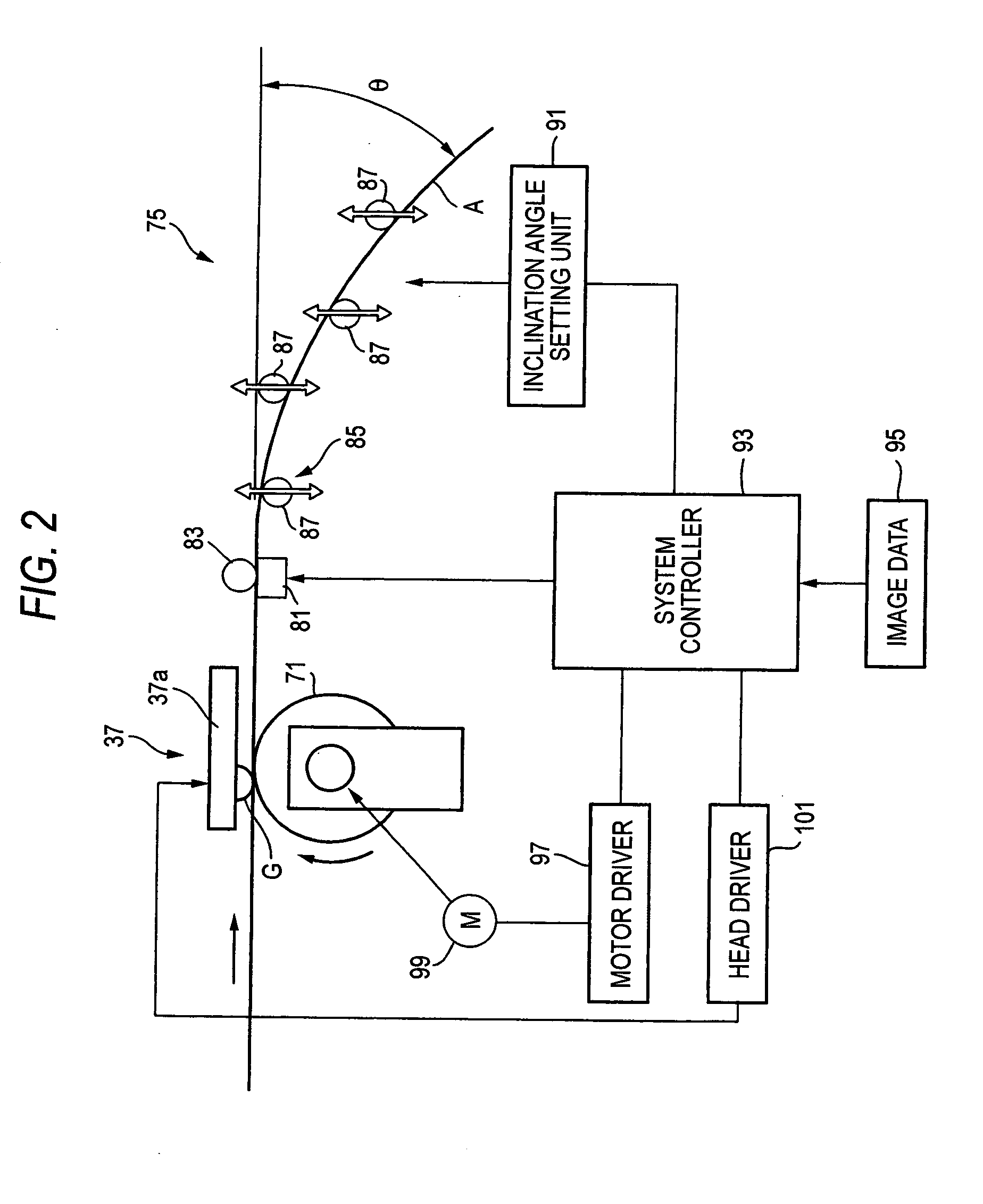

Thermal image recording apparatus

InactiveUS20050068410A1Production costNoise level can be suppressedRecording apparatusInking apparatusImage recordingHeat sensitive

A thermal image recording apparatus has: a thermal head having a glaze in which thermal recording dots are arranged in a one direction, the thermal head conducting thermal recording on a thermal recording material that is to be in contact with the glaze, and transporting the thermal recording material in a direction perpendicular to the arrangement direction of the thermal recording dots; heating unit, disposed downstream from the thermal head in the transport direction, for reheating the rear face opposite to the recording surface of the thermal recording material; and correcting and cooling unit for cooling the reheated thermal recording material while causing the rear face to be concaved.

Owner:FUJIFILM HLDG CORP +1

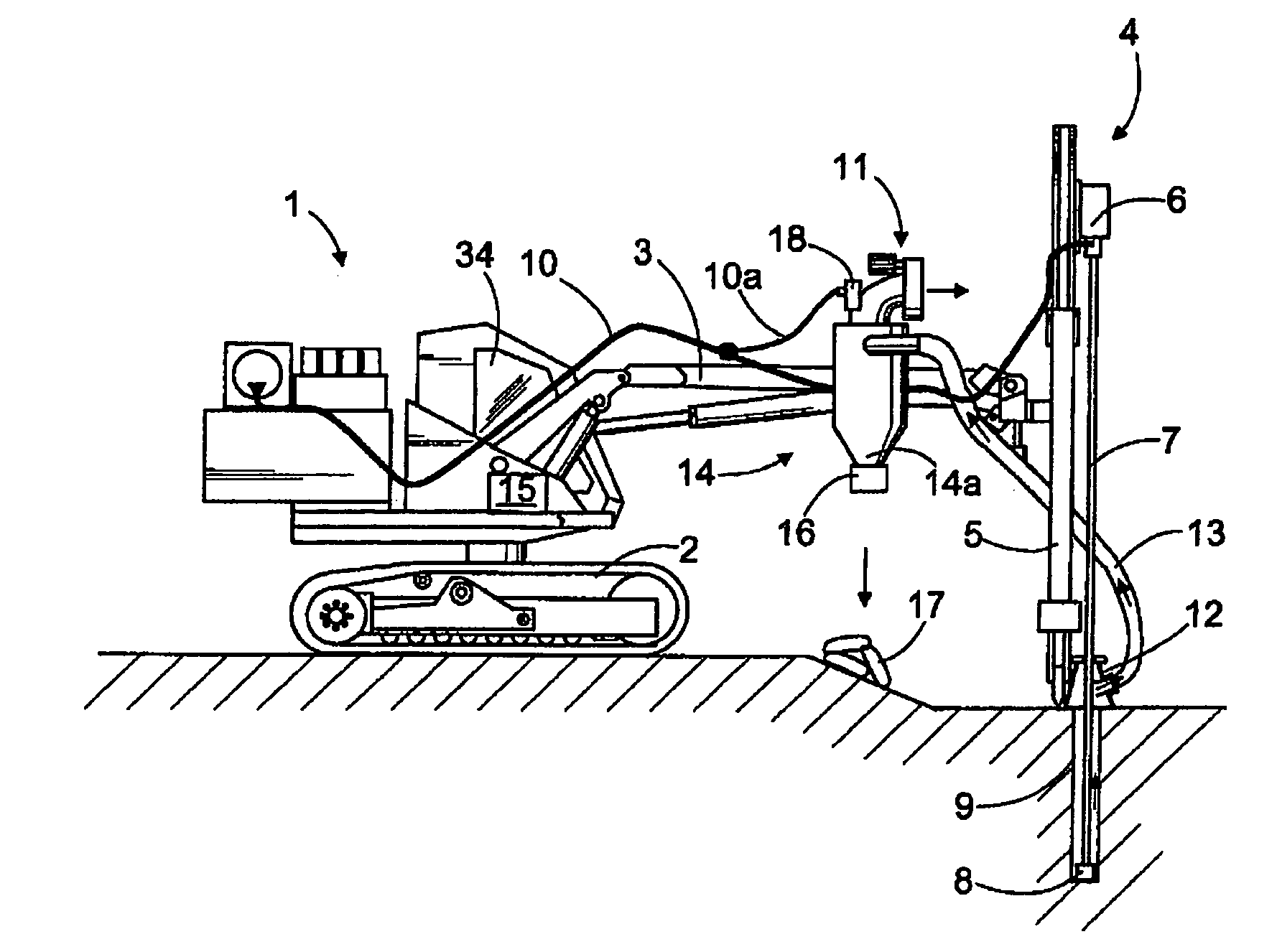

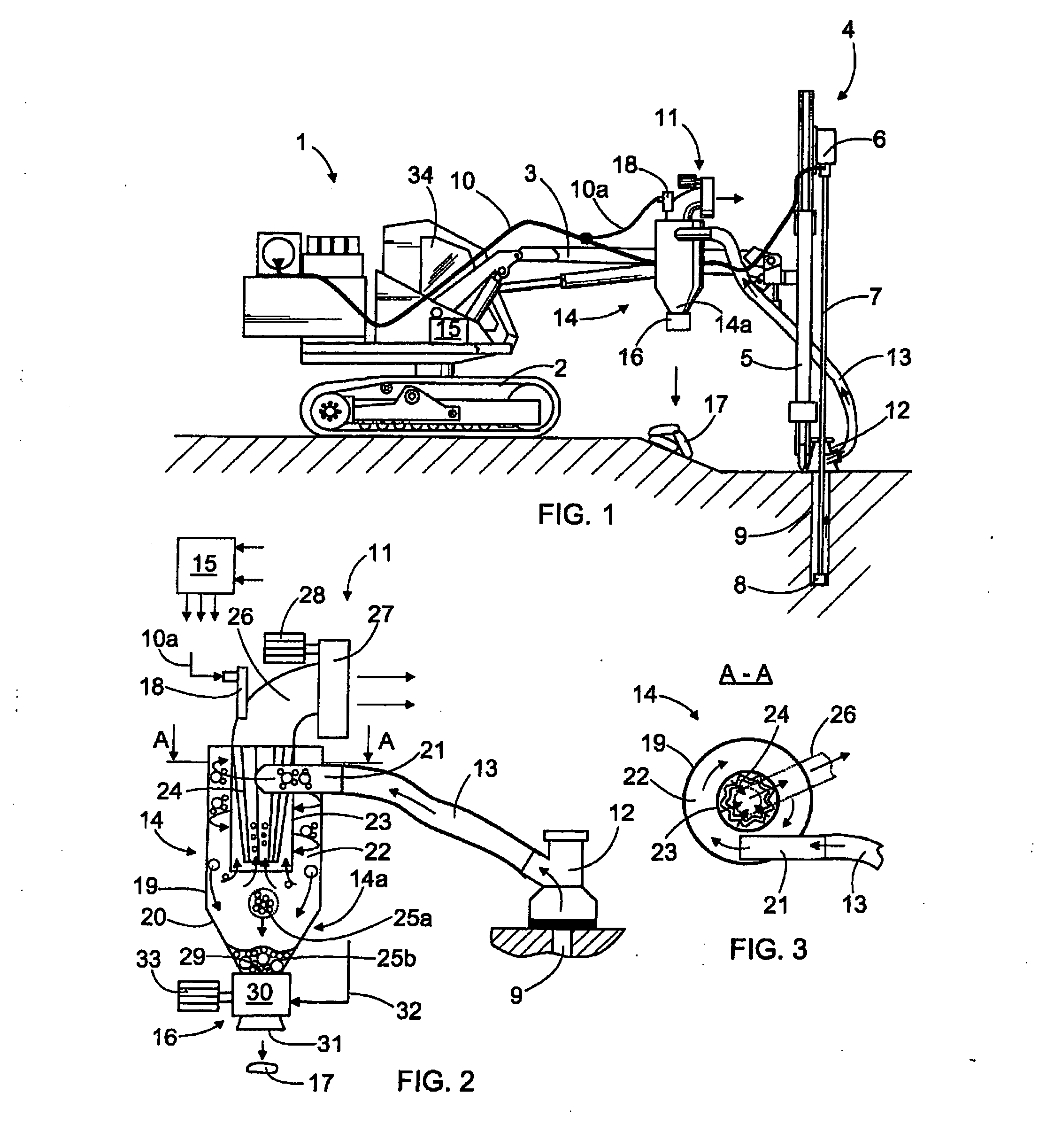

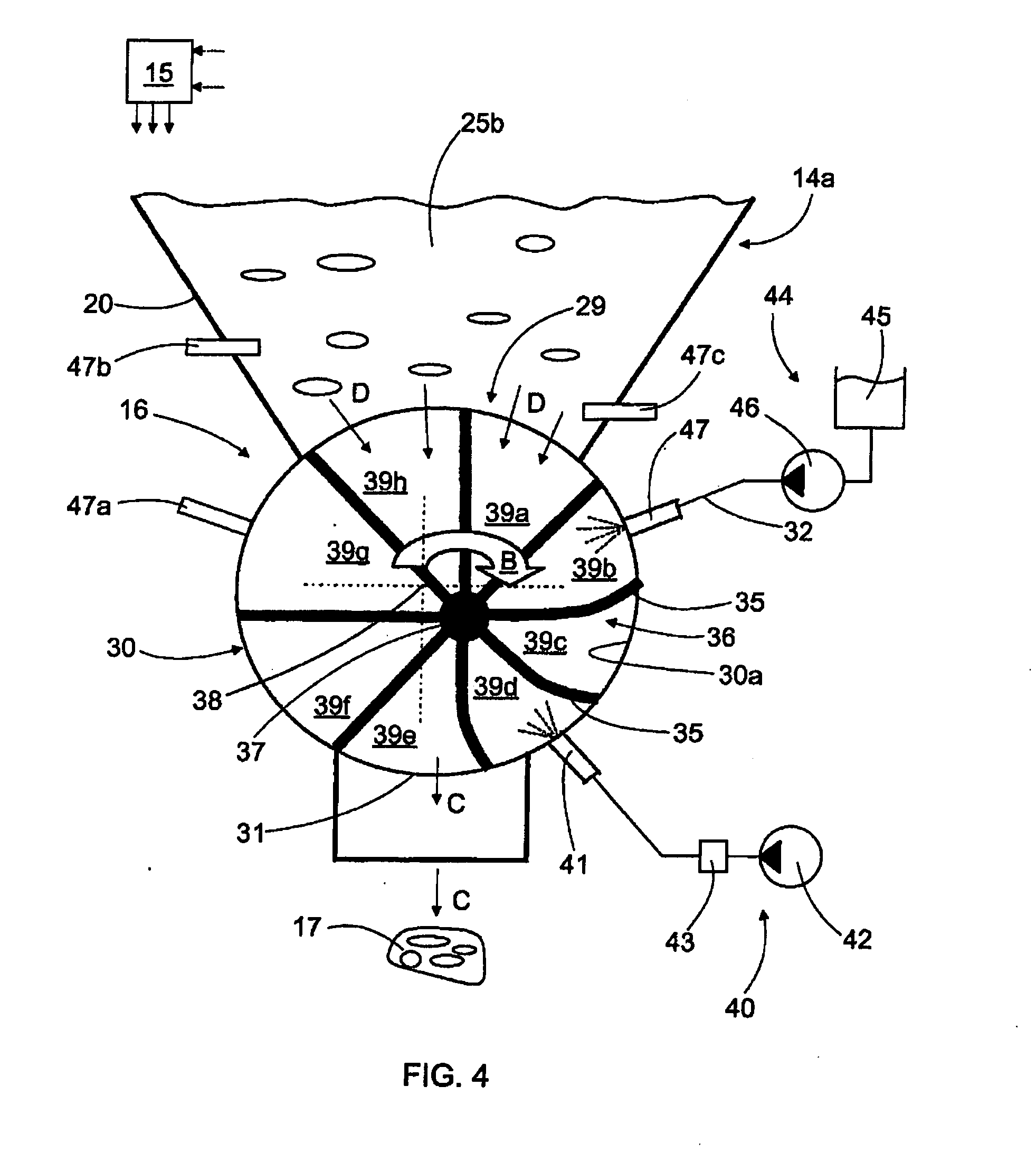

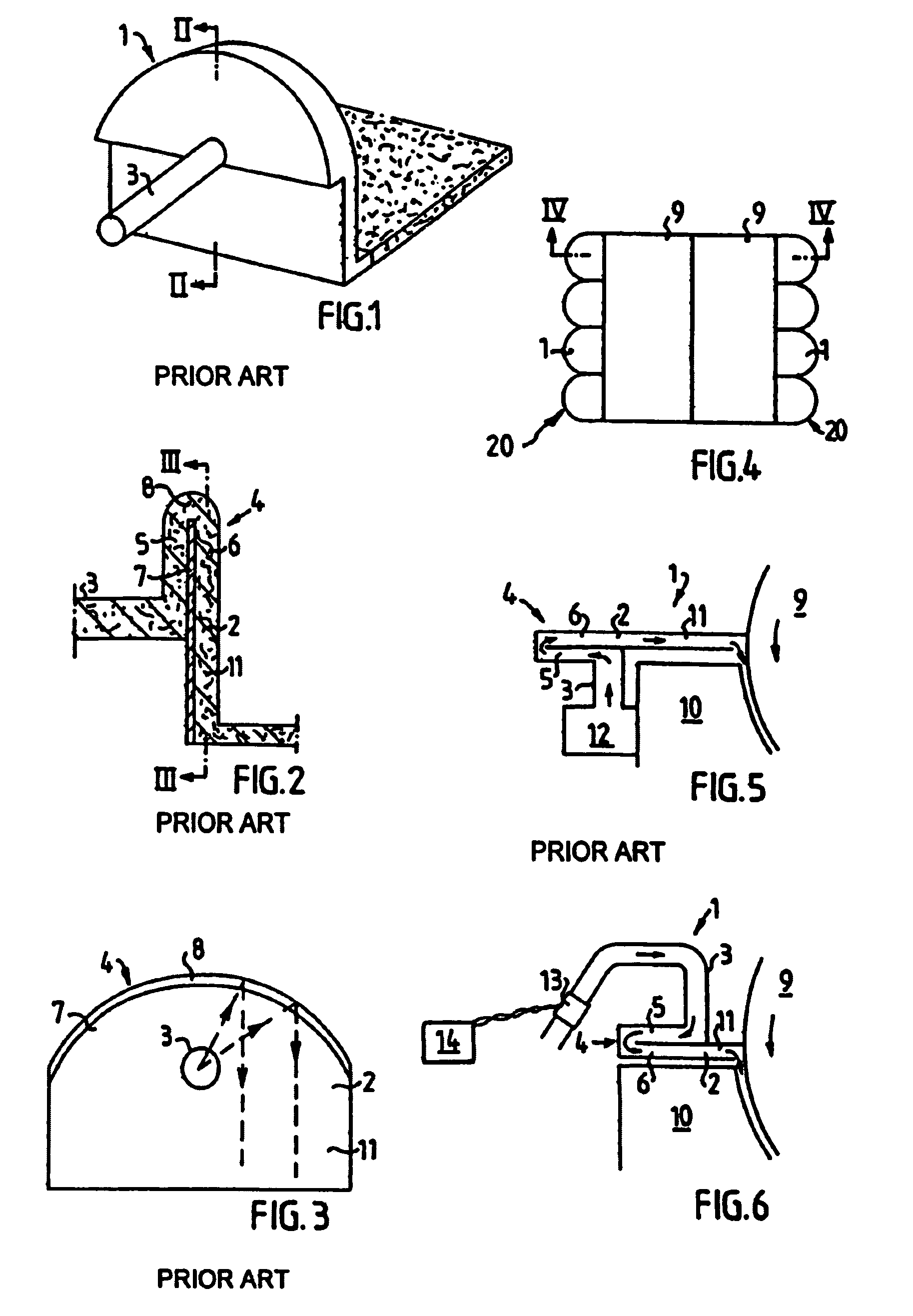

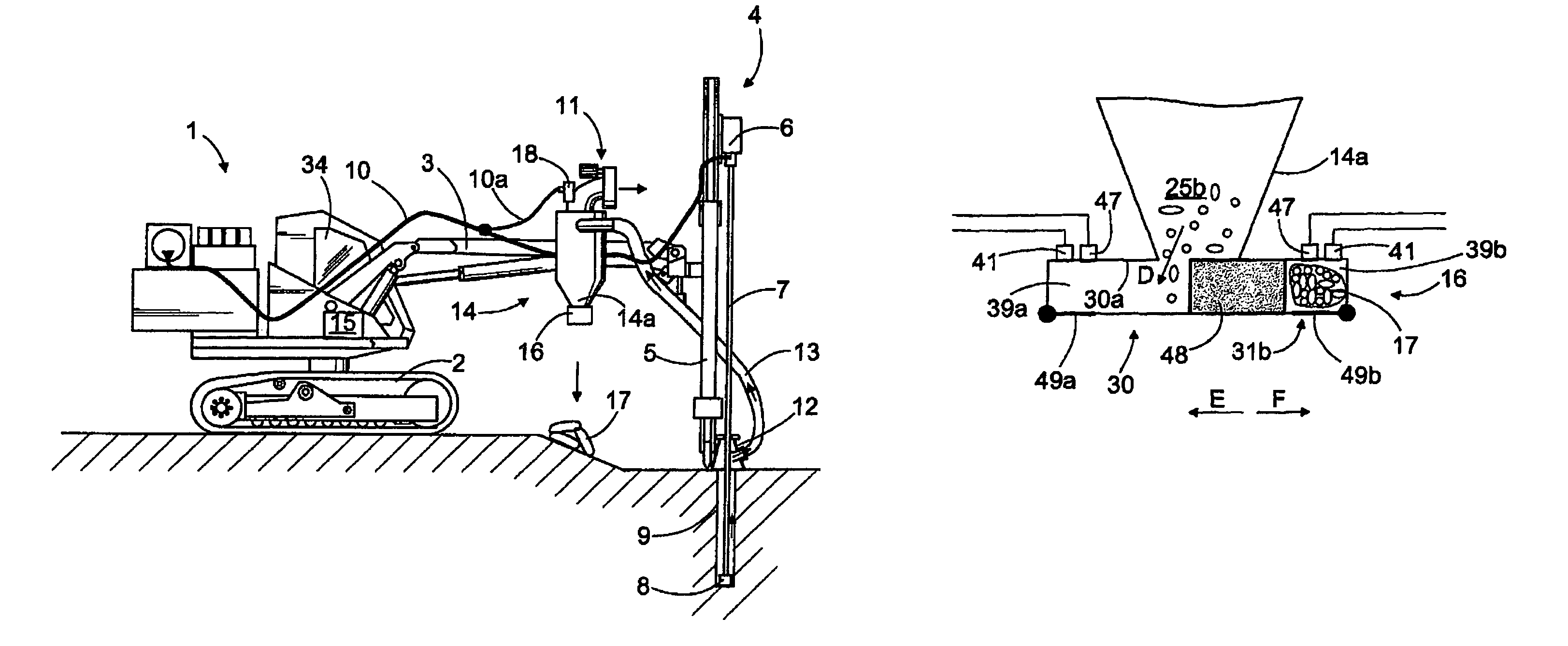

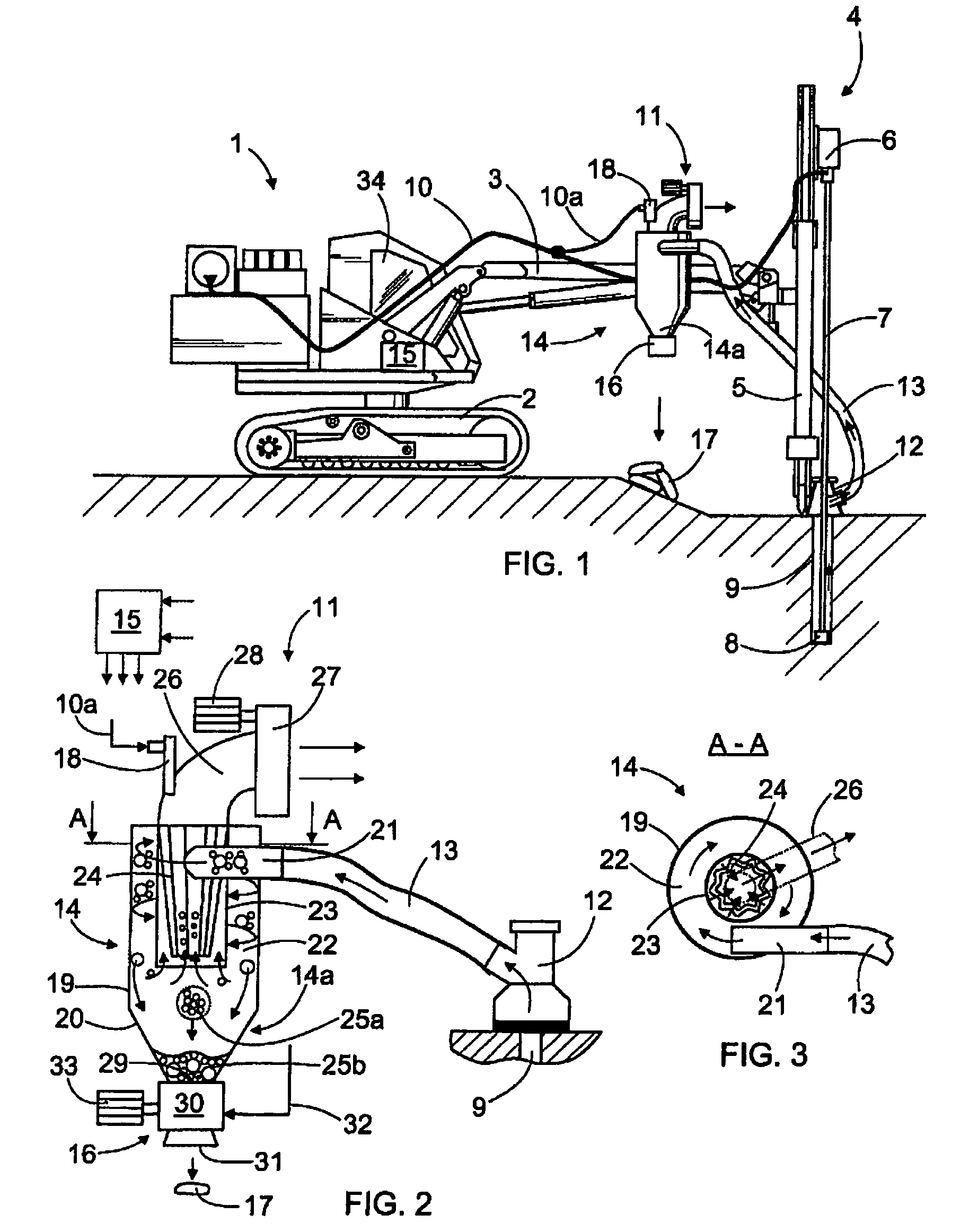

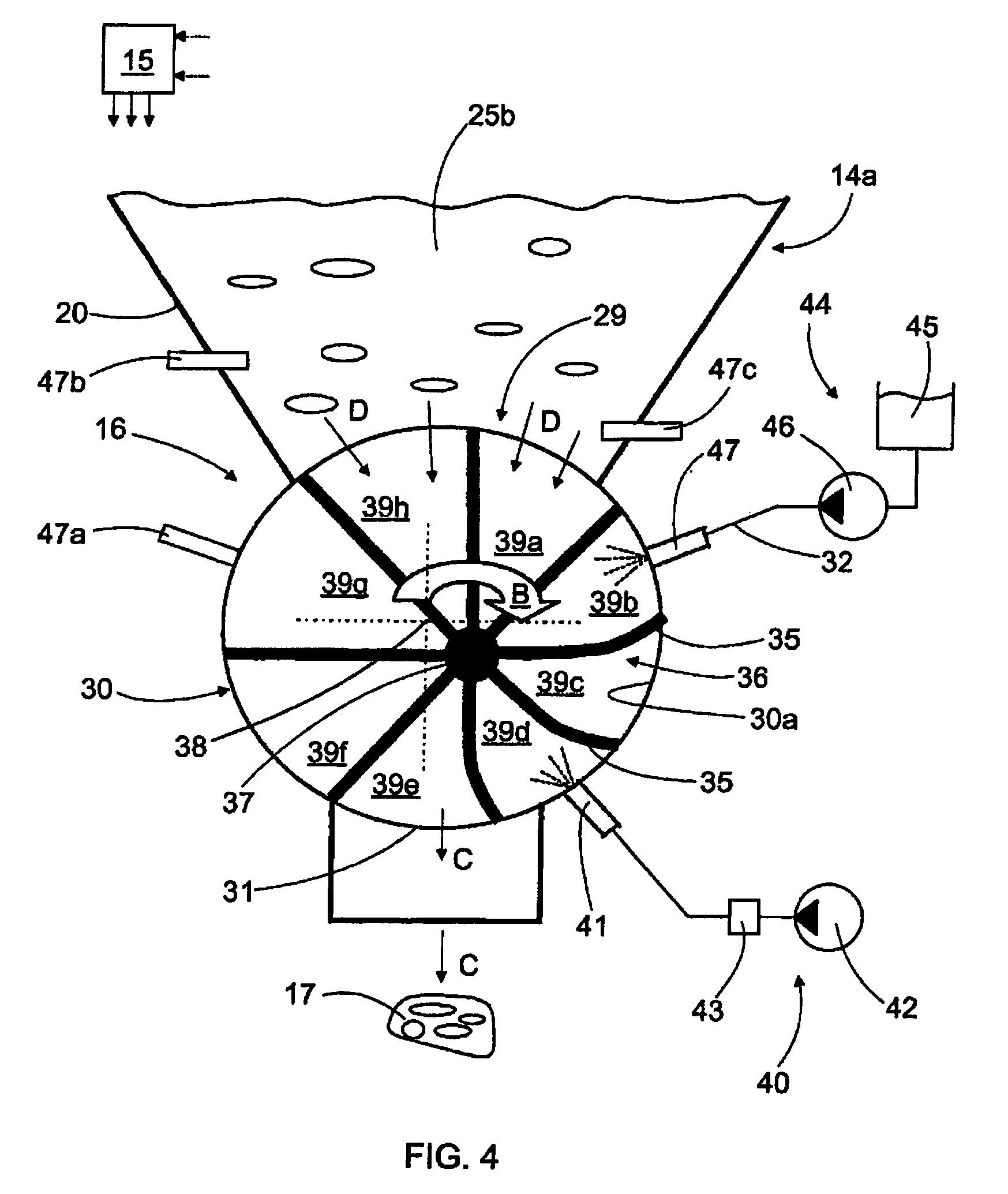

Arrangement for processing dust

ActiveUS20100320000A1Large capacitySpace minimizationCombination devicesConstructionsEngineeringSolid matter

The invention relates to a method for processing dust when breaking rock, to a dust separator, and further to a rock-drilling rig. Rock material and air sucked from a borehole or some other operating location is separated from each other in the dust separator. The separated rock material falls into a discharge part of the dust separator, from which it can be dosed in batches into a discharging device. The discharging device comprises a closed compression space in which the rock material batch is compressed into a more compact state. This forms a solid matter cake that is removed from the dust separator.

Owner:SANDVIK MINING & CONSTR OY

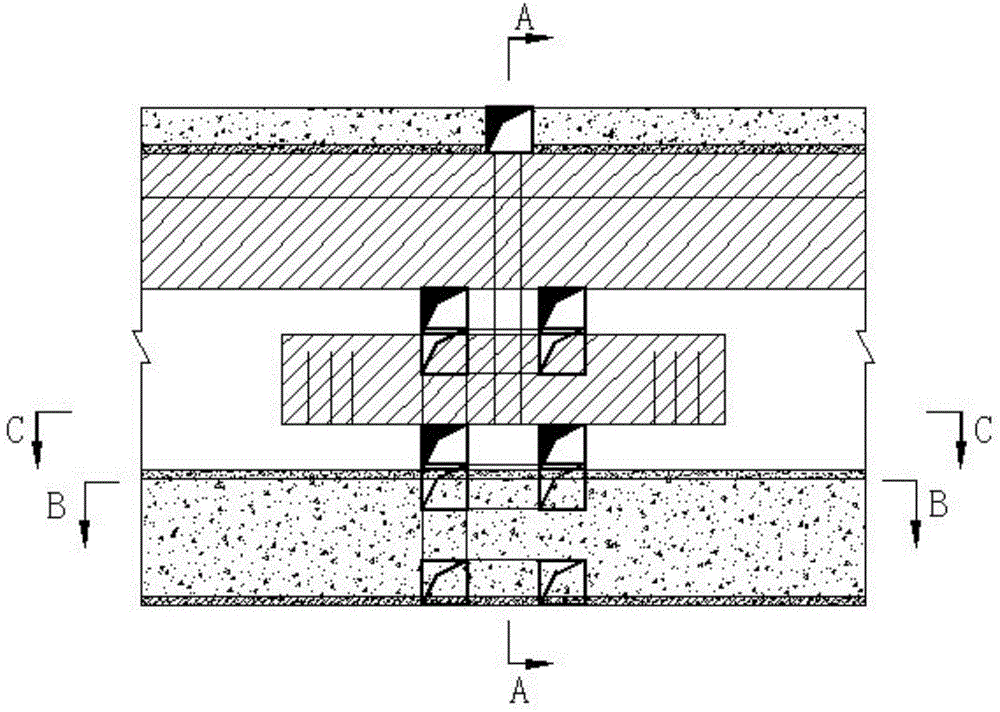

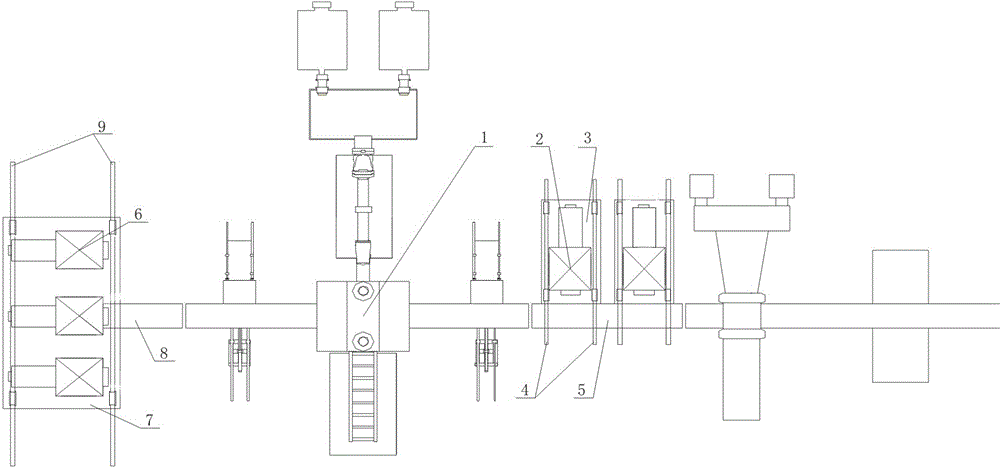

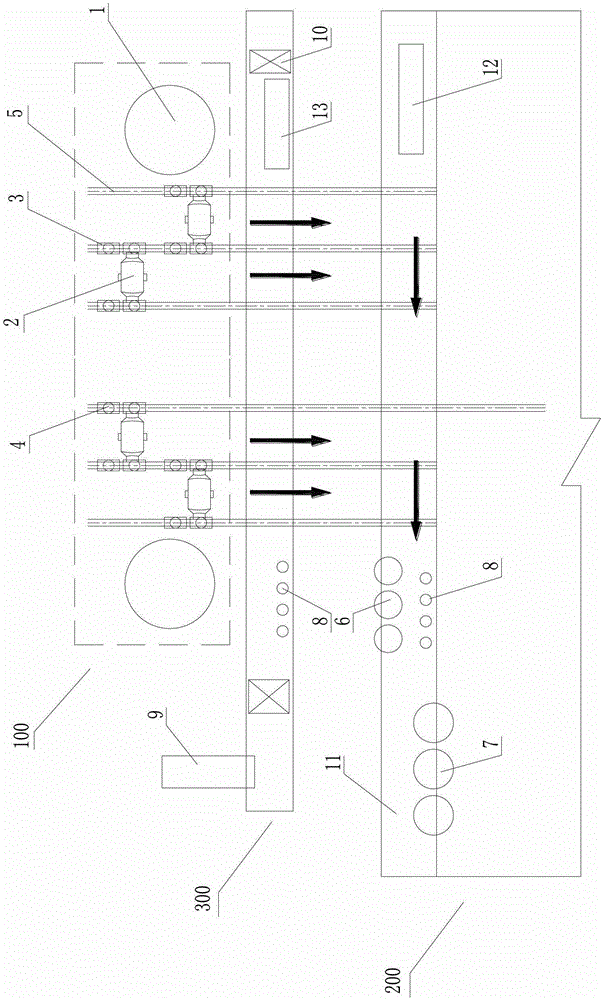

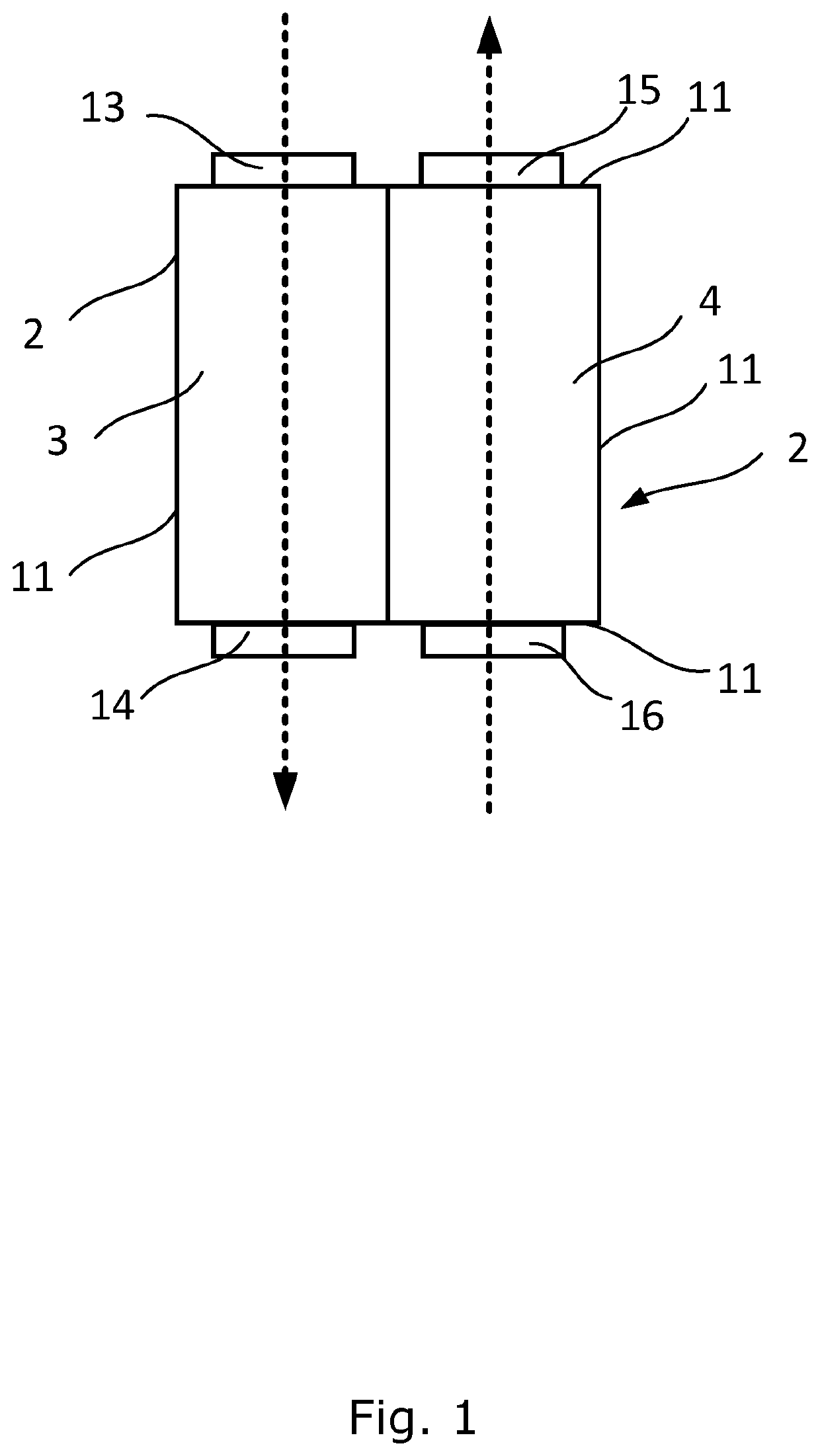

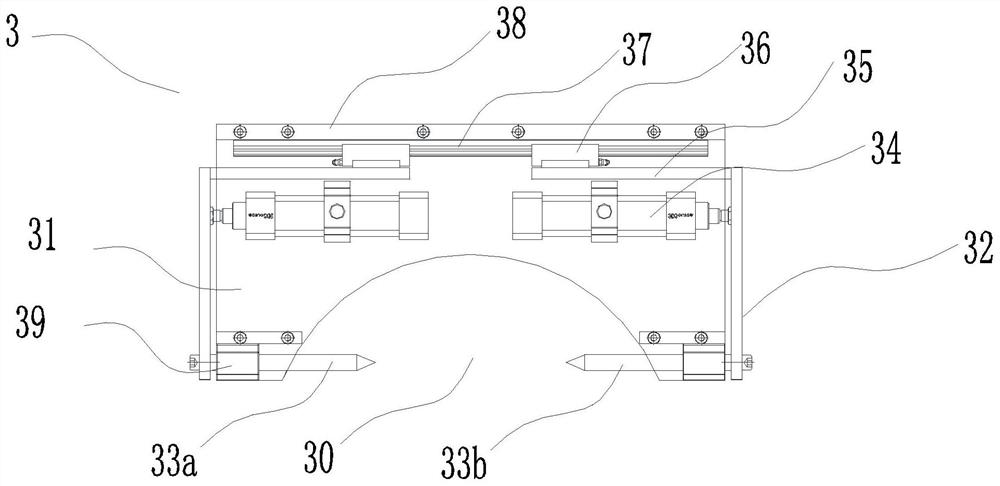

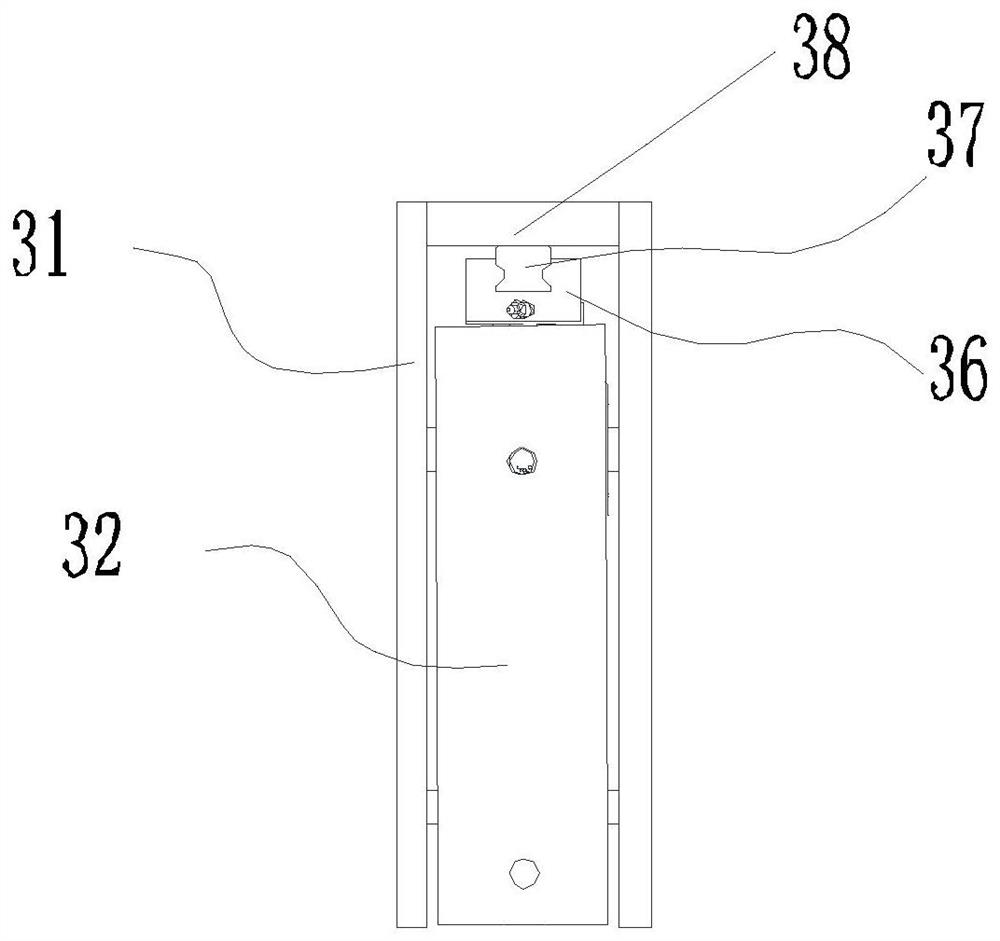

Heating furnace and hot rolling mill distribution mode on tungsten and molybdenum plate production line

ActiveCN104984996AShort transport distanceReasonable and compact production layoutMetal rolling arrangementsTungstenHeating furnace

The invention discloses a heating furnace and hot rolling mill distribution mode on a tungsten and molybdenum plate production line. Heating furnace devices are distributed on one side of a feeding roller way of a hot rolling mill. A heat compensating furnace device is distributed at the end of a discharge roller way of the hot rolling mill. At least two heating furnace devices are arranged. Each heating furnace device comprises a heating furnace, a conveying device A and a rail A, wherein the rail A is perpendicular to the feeding roller way, the heating furnace is fixedly connected to the conveying device A, and the conveying device A is assembled on the rail A. The heat compensating furnace device comprises a heat compensating furnace, a conveying device B and a rail B, wherein the rail B is distributed at the end of the discharge roller way, the rail B is perpendicular to the discharge roller way, the conveying device B is assembled to the rail B, and the heat compensating furnace is fixedly connected to the conveying device B. Production layout is reasonable and compact, the occupied area is small, blank conveying distance is short, tungsten plate products and molybdenum plate products high in quality and the percent of pass can be produced, and the productivity of the production line can be effectively improved.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

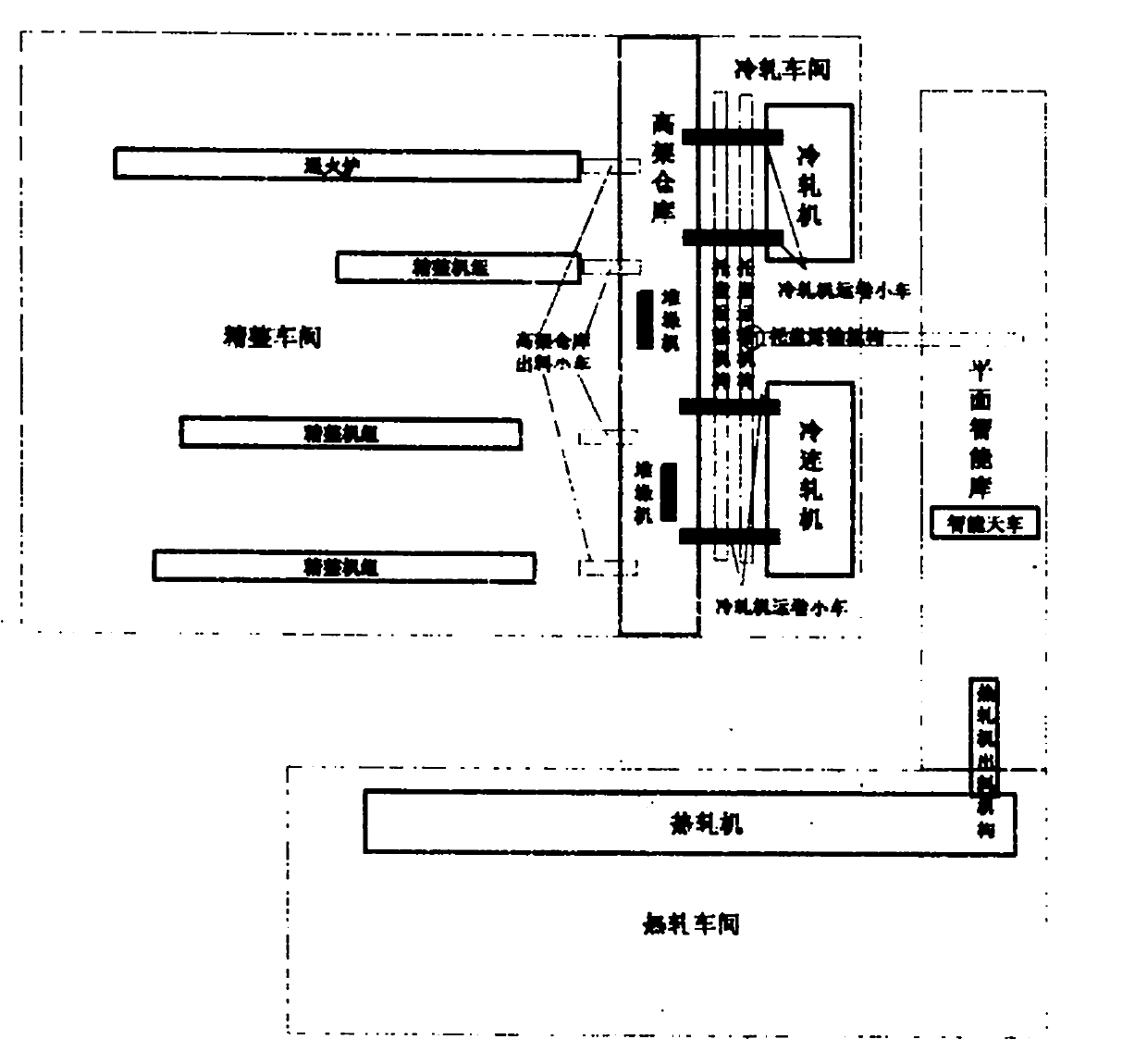

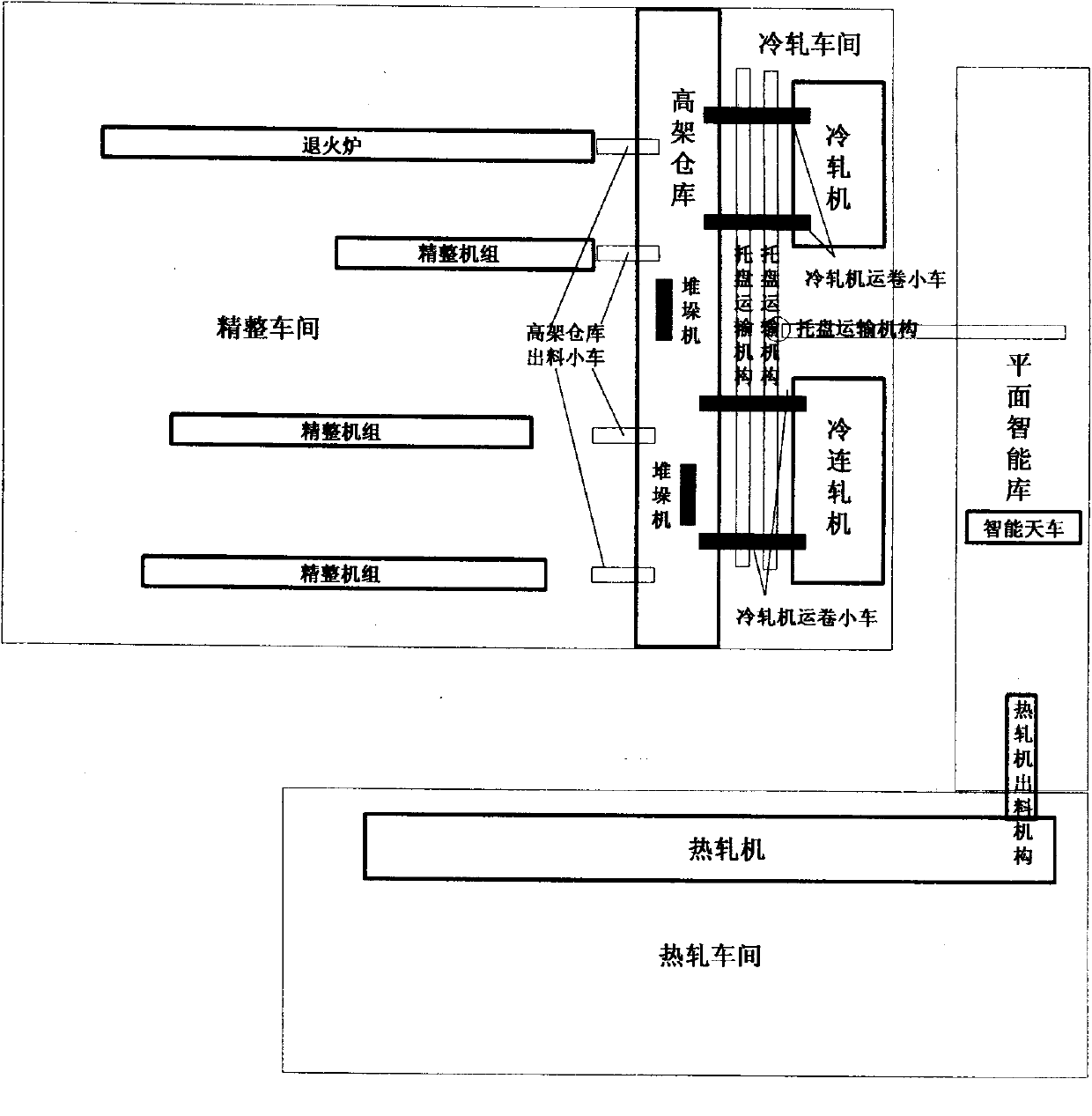

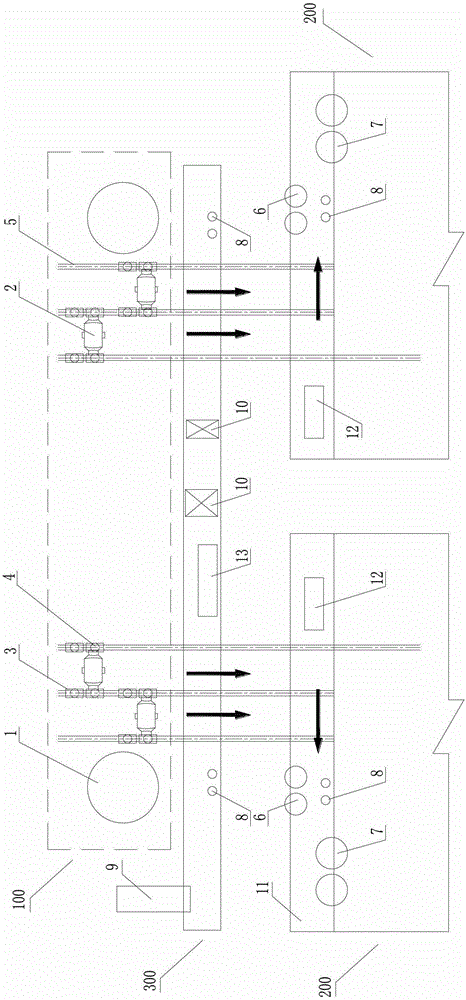

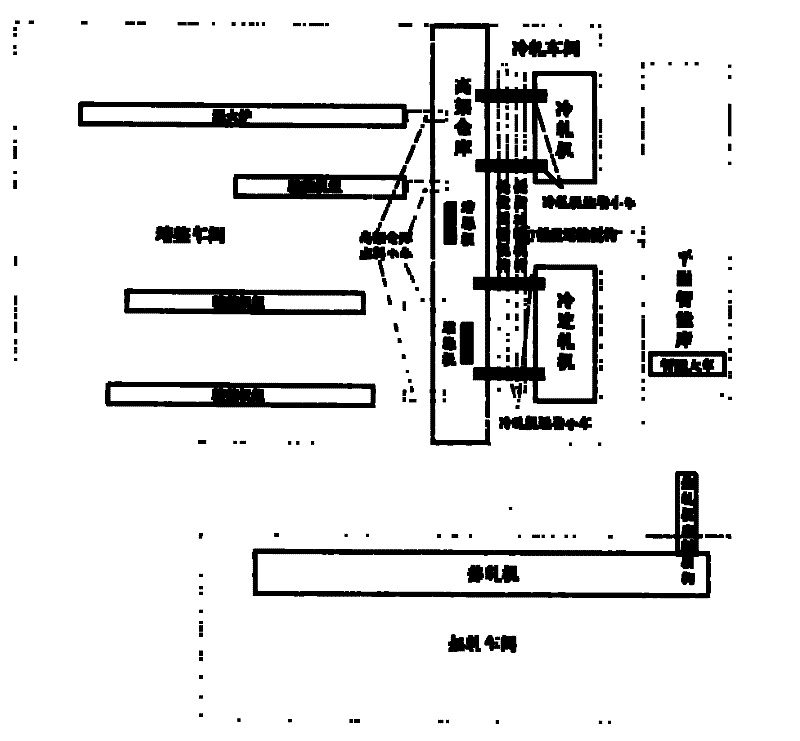

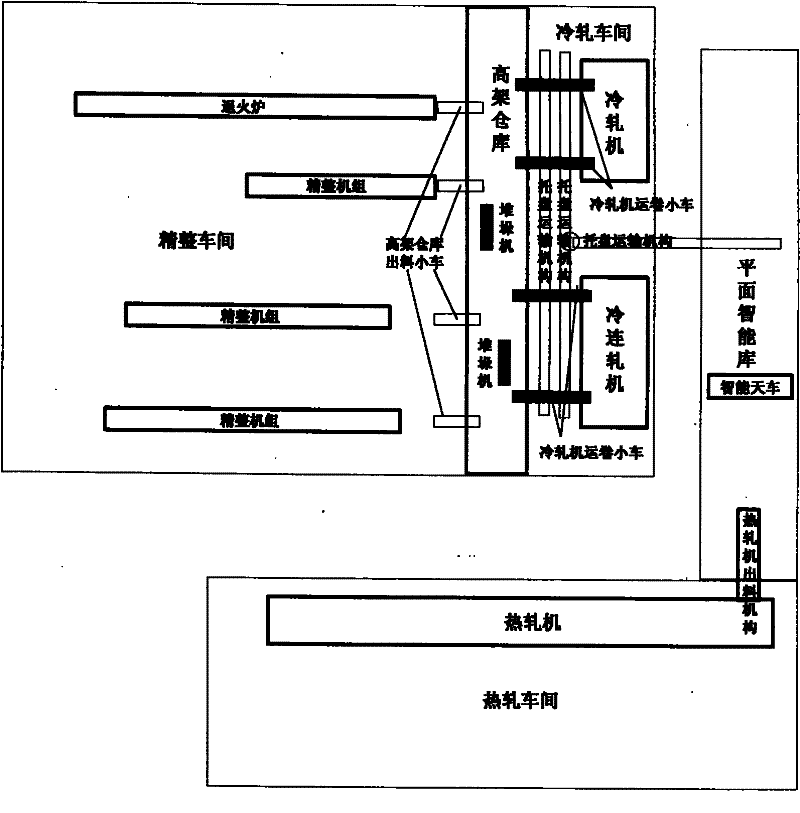

Collocation method for fusing intelligent plane warehouse and overhead warehouse in aluminum plate strip production equipment

ActiveCN101947547AScientific and orderly configurationReduce the use of areaMetal rolling arrangementsStackerManufacturing engineering

The invention discloses a collocation method for fusing an intelligent plane warehouse and an overhead warehouse in aluminum plate strip production equipment. The intelligent plane warehouse is arranged between a hot rolling workshop and a cold rolling workshop; the overhead warehouse is arranged among an annealing furnace, each finishing unit and a tray conveying mechanism; a track for running of a plurality of coil cars is mutually vertical to the tray conveying mechanism; and a track for a plurality of discharge cars in the overhead warehouse extends beside the annealing furnace or the each finishing unit. Hot-rolled coils on a hot mill discharge mechanism are hoisted to the corresponding positions for storage or cooling through an intelligent crane in the intelligent plane warehouse, and cold-rolled coils are stored at the corresponding positions through a stacker or cooled in the overhead warehouse. The aluminum plate strip production equipment collocated with the intelligent plane warehouse and the overhead warehouse is totally adjoined, needs no transport equipment such as the crane, a forklift or an automatic vehicle and the like, has the effect on shortest transport distance, realizes good circulation of low-carbon production of aluminum plate strips, and has the characteristics of lowest product storage quantity and shortest production period.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

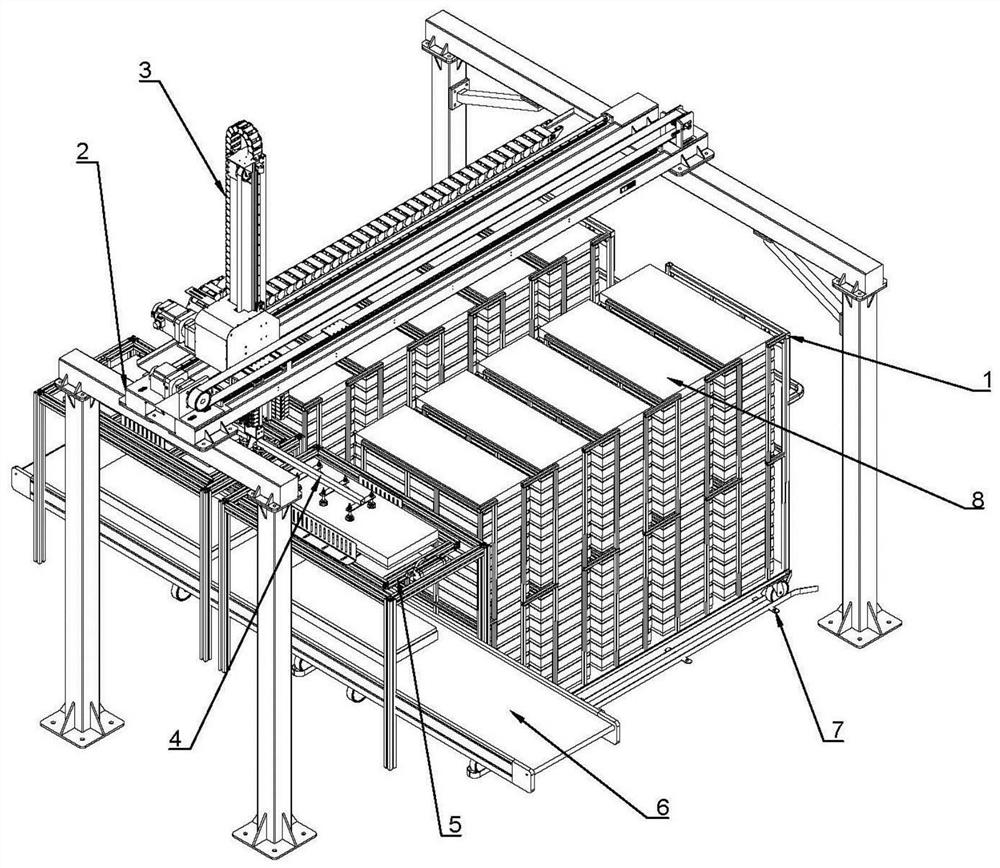

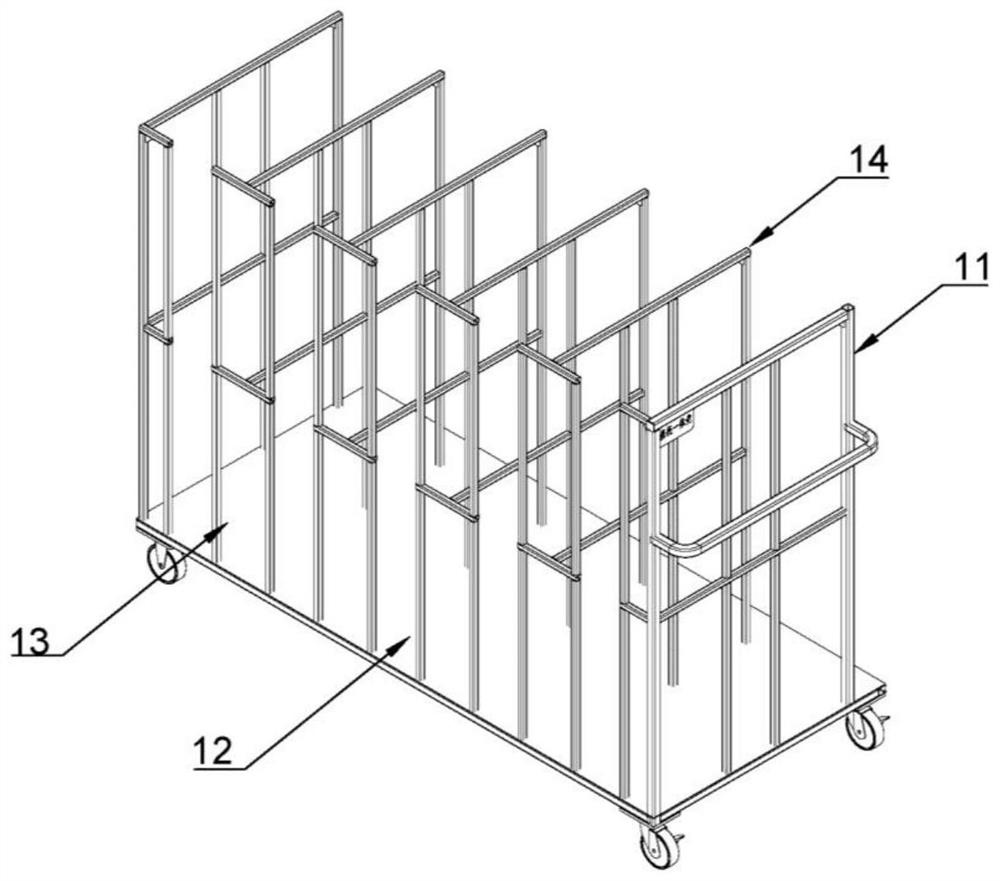

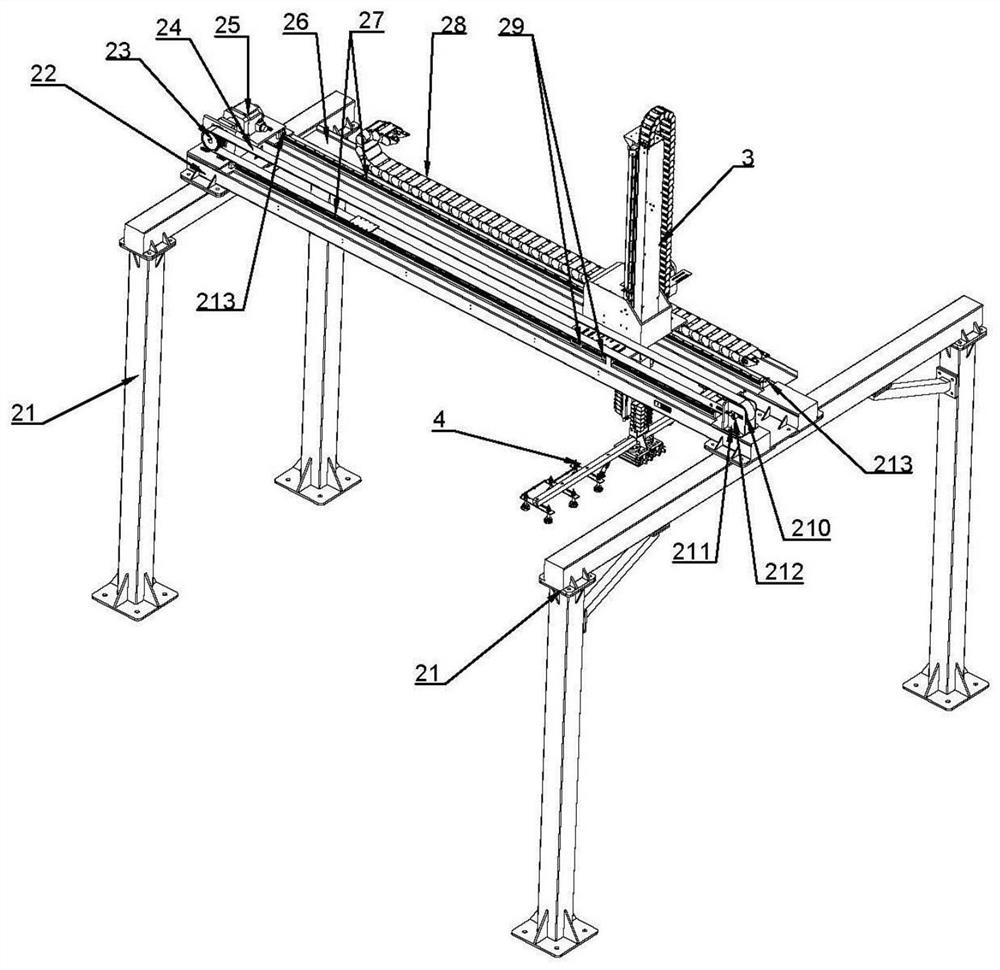

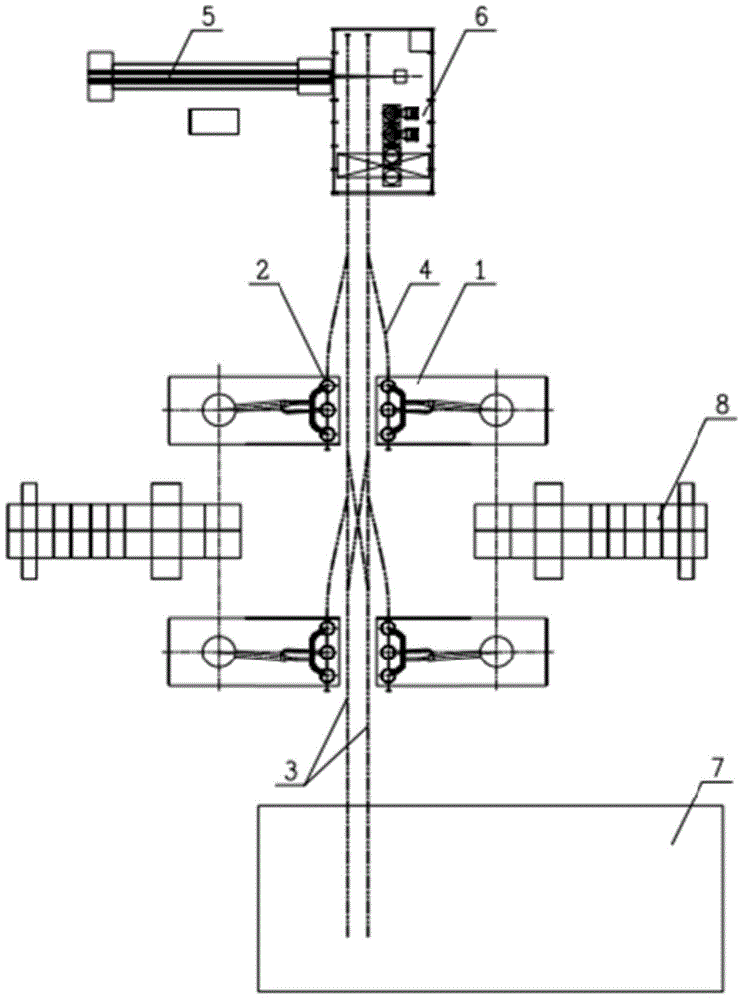

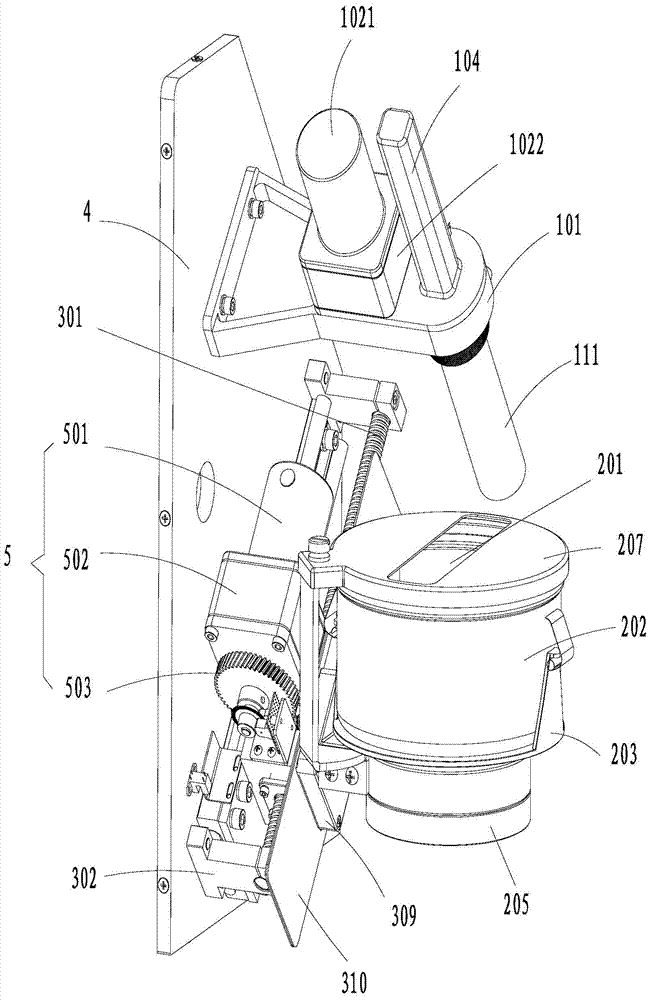

Automatic bottom support assembly line feeding system

ActiveCN112061765AGuaranteed neatnessImprove feeding efficiencyConveyor partsControl engineeringAgricultural engineering

The invention provides an automatic bottom support assembly line feeding system. The automatic bottom support assembly line feeding system comprises a storage and transportation vehicle, a supportingmechanism and a feeding mechanism. The storage and transportation vehicle is used for loading and transporting a bottom support assembly, and a goods outlet is formed in the top of the storage and transportation vehicle; the supporting mechanism is used for bearing the feeding mechanism, and a space capable of containing the storage and transportation vehicle is formed below the supporting mechanism; the feeding mechanism is used for taking out the bottom support assembly from the goods outlet and conveying the bottom support assembly to a belt line; the feeding mechanism comprises a telescopic mechanism and a clamp; the telescopic mechanism is connected with the clamp and drives the clamp to move in the vertical direction, and the telescopic mechanism is arranged on the supporting mechanism and can move on the supporting mechanism in the horizontal direction; and the clamp is used for clamping the bottom support assembly. Compared with the prior art, the provided automatic bottom support assembly line feeding system can achieve automatic belt line feeding of the air conditioner bottom support assembly, so that the number of operators is reduced, and the purposes of reducing the labor cost and improving the production efficiency are achieved.

Owner:GREE ELECTRIC APPLIANCES ZHENGZHOU +1

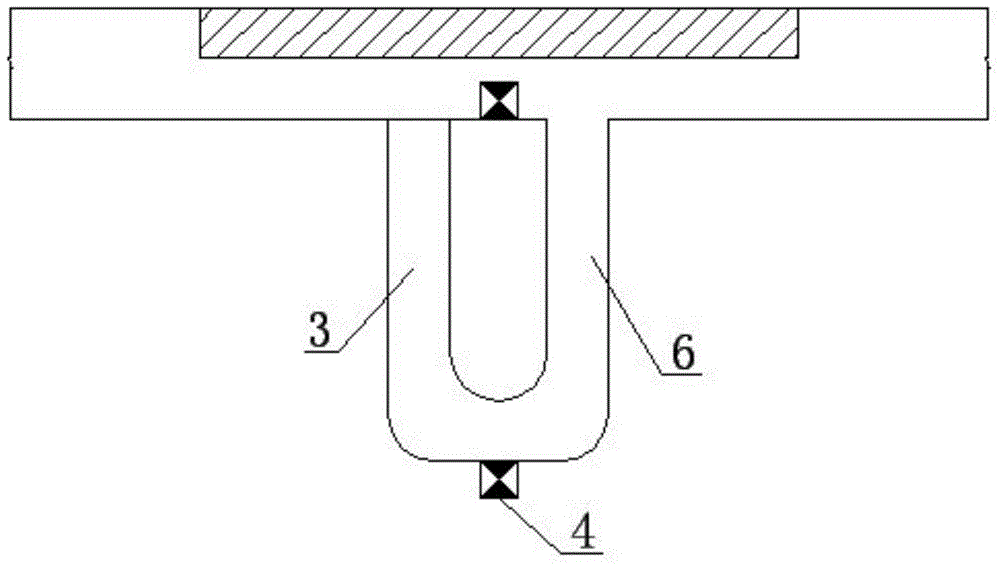

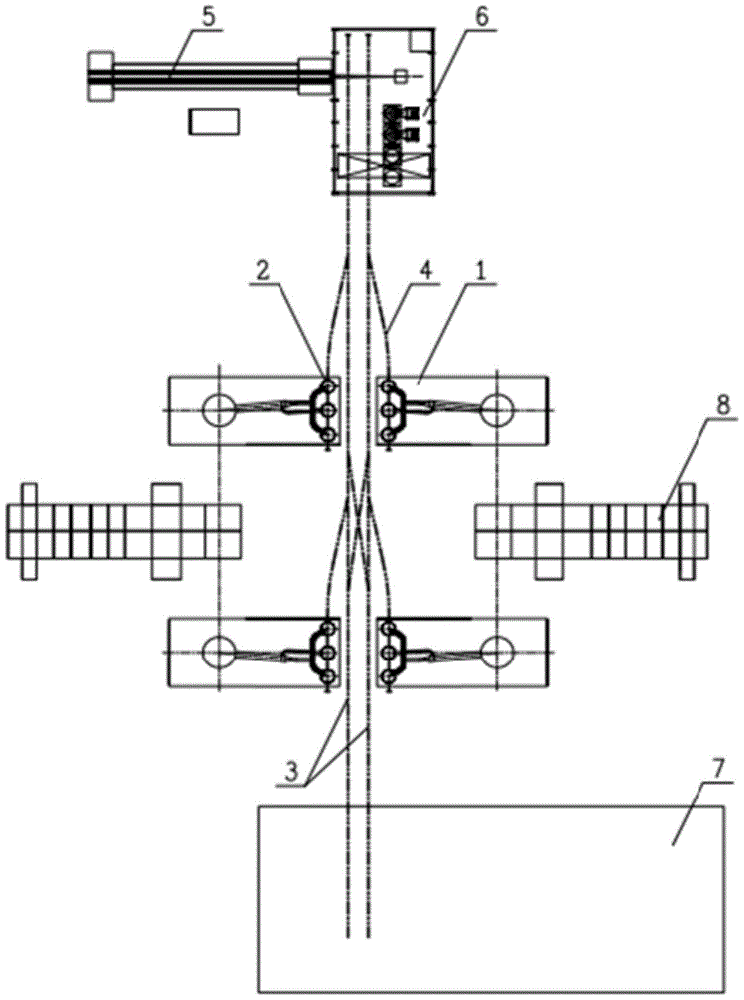

Molten iron transport system

ActiveCN105170965ACompact layoutSmall footprintMelt-holding vesselsRailway tracksIron transportMaterials science

The invention discloses a molten iron transport system. The molten iron transport system comprises casting houses (1) of ironmaking blast furnaces and a steel-making workshop (7), parallel track lines (3) are arranged between the casting houses (1) of the ironmaking blast furnaces and the steel-making workshops (7), the casting houses (1) of a plurality of ironmaking blast furnaces are symmetrically and compactly arranged at two sides of the parallel track lines (3), each casting houses (1) of each ironmaking blast furnace is connected to adjacent track line (3) via a molten iron pot storing line (4) of each casting houses, and a molten iron pot (2) of each casting houses (1) of each ironmaking blast furnace can be transported to the track lines (3) along each molten iron pot storing line (4). The steel-making workshop (7) is arranged at one end of the parallel track lines (3), the molten iron pots (2) can be transported to the steel-making workshop (7) along the track lines (3). The molten iron transport system is compact in arrangement, less in land occupation without a transition across workshop and a crane, so the investment can be saved.

Owner:BERIS ENG & RES CORP

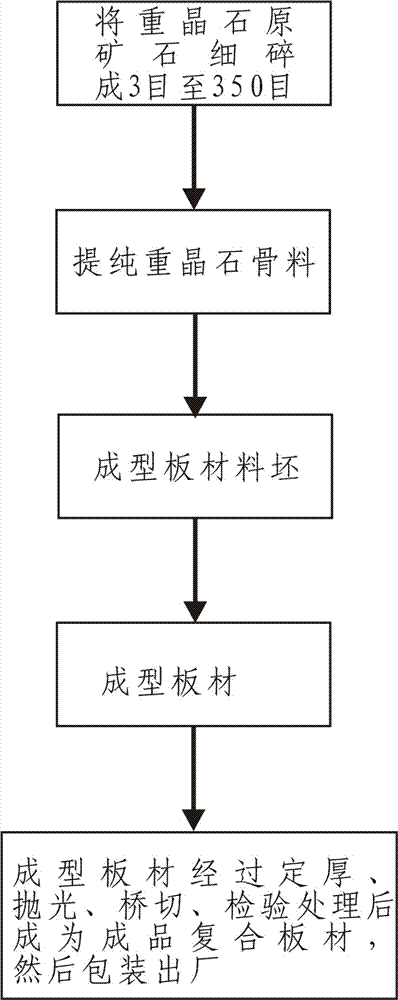

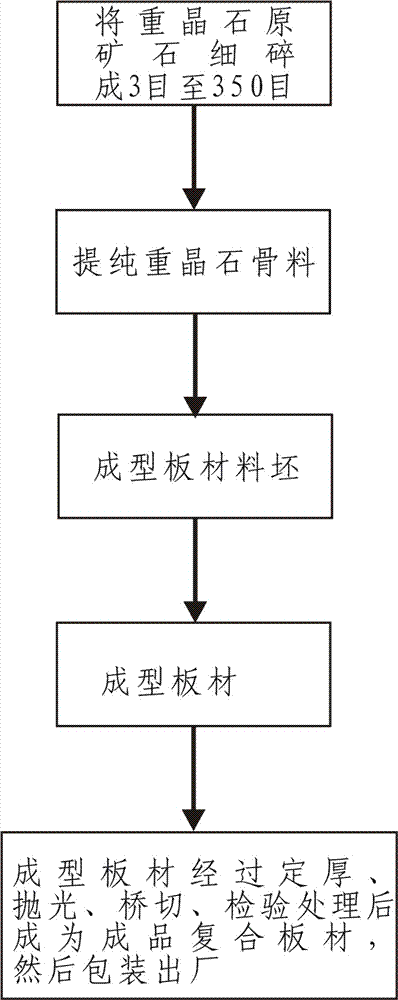

Novel high-performance hydrofluoric acid-resistance artificial functional composite plate and preparation method thereof

The invention provides a novel high-performance hydrofluoric acid-resistance artificial functional composite plate and a preparation method thereof. The plate is mainly made of barite aggregate, resin and a serial of modified agents. According to the preparation method, the finished plate can be formed after a serial of processes of barite packing graduation, special resin and the serial of modified agents adding, mixing and stirring, organic combination reaction, plate blank forming, high-temperature and high-pressure reaction, high-frequency vibration, cure reaction (80-120 DEG C), thickness determining, polishing, bridge cutting, detection and the like. The composite plate has special anti-corrosion performance, excellent mechanical performance and durability, and is superior in product conveying, installation, maintenance and the like.

Owner:SICHUAN QINGCHUAN HONGYUAN STONE IND

Air purifier for removing harmful gas and dust in long tunnel

InactiveCN102505953AReduce ventilation timeReduce use costDust removalDispersed particle separationElectric heatingCentrifugal fan

The invention relates to an air purifier for removing harmful gas and dust in a long tunnel, which aims to solve difficulty of ventilation in construction of the long tunnel. By the aid of a centrifugal fan, harmful gas CO, CO2, NO, NO2, sulfide and dust in the long tunnels are delivered into a degradation tank through an induced draft hood and a connecting pipe. Residual CO and NO after degradation are delivered into an adsorption box through a connecting pipe, steam in residual gas is filtered by porous fiber separation membrane, residual CO and a small quantity of NO are adsorbed by a low-temperature variable-pressure adsorption tower after the processes of degradation and membrane filtering, the variable-pressure adsorption tower adsorbing CO and NO is delivered out of the tunnel, and then CO and NO are desorbed after the adsorption tower is heated to the temperature ranging from 80 DEG C to 135 DEG C by electric heating tapes in the adsorption tower. The air purifier for removing harmful gas and dust in the long tunnel has the advantages that harmful gas delivery distance is short, ventilation time is short, ventilation efficiency is high, service cost is low and the like, pollution caused by harmful gas of a tunneling face to the integral tunnel can be avoided effectively, and the air purifier is applicable to removing harmful gas and dust of the tunneling face of the long tunnel.

Owner:谢飞鸿

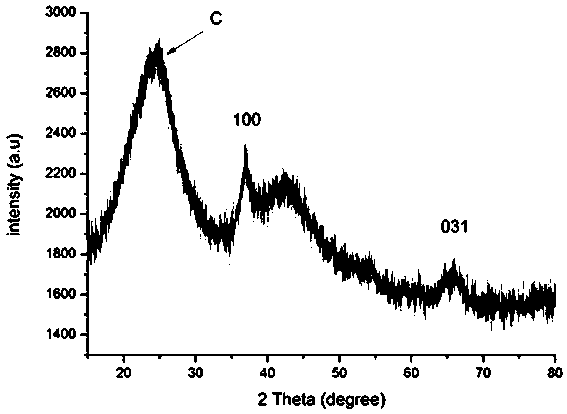

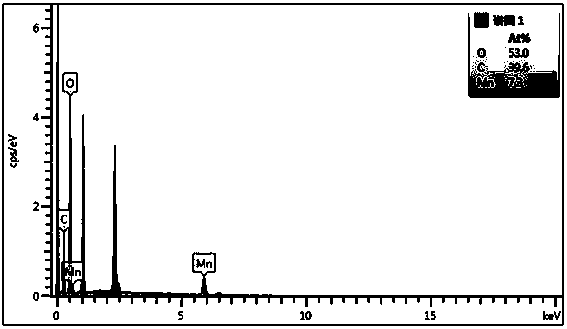

Graphene-loaded hollow manganese dioxide composite material and preparation method thereof

ActiveCN111653435ASimple processHigh specific capacitanceHybrid capacitor electrodesGrapheneOxide compositeManganese oxide

The invention relates to a graphene-loaded hollow manganese dioxide composite material and a preparation method thereof. The preparation method comprises the following steps: adding graphite oxide into water, and performing ultrasonic dispersion to obtain graphene oxide colloid; respectively mixing a manganese salt, L-lysine and sodium borohydride with water to obtain a manganese salt solution, anL-lysine solution and a sodium borohydride solution; mixing the graphene oxide colloid with the manganese salt solution, the L-lysine solution and the sodium borohydride solution in sequence, puttingthe obtained mixture into a hydrothermal kettle, reacting, and dispersing the oxide composite material generated by the reaction in water to obtain a turbid liquid, mixing the turbid liquid with a potassium permanganate solution, washing to obtain a graphene-loaded manganese dioxide composite material, re-dispersing the graphene-loaded manganese dioxide composite material, mixing the re-dispersedgraphene-loaded manganese dioxide composite material with hydrochloric acid, filtering, and washing to obtain the graphene-loaded hollow manganese dioxide composite material. The preparation method is simple in process, and the prepared graphene-loaded hollow manganese dioxide composite material is high in specific capacitance, long in cycle life and excellent in conductivity.

Owner:WUHAN UNIV OF SCI & TECH

Method for clearing harmful gas and dust in long tunnel

InactiveCN102505952AQuality improvementReduce ventilation timeDust removalDispersed particle separationFiltrationEngineering

The invention relates to a method for clearing harmful gas and dust in a long tunnel, aiming at solving a problem of difficulty in ventilation of the whole tunnel during a construction period of the long tunnel. The method for clearing harmful gas and dust in the long tunnel orderly comprises the following steps of: carrying and transporting a ventilator by a movable carrier, and transmitting harmful gases of CO, CO2, NO, NO2, sulfide and dust to a degradation pool by a fan; degrading the harmful gases of CO2, NO, NO2, sulfide and dust through reaction of alkali compounds in the degradation pool, and filtering steam by a porous fiber separation membrane; absorbing CO and a little NO through a low-temperature pressure swing absorption tower after degradation and membrane filtration; carrying the pressure swing absorption tower which absorbs CO and NO out of the funnel, and heating to 80-135 DEG C by an electric heating strip in the absorption tower so as to remove CO and NO. The method has the advantages of short conveyance distance of the harmful gases, short ventilation time, high ventilation efficiency, low using cost and the like, can effectively clear pollution of the harmful gases in the whole funnel, and is suitable for clearing the harmful gases and dust in a driving face of the long funnel.

Owner:谢飞鸿

Compact hot metal transport system

ActiveCN103343632BSmall footprintReduce investmentBlast furnace detailsIndustrial buildingsSteelmakingIron transport

Owner:BERIS ENG & RES CORP

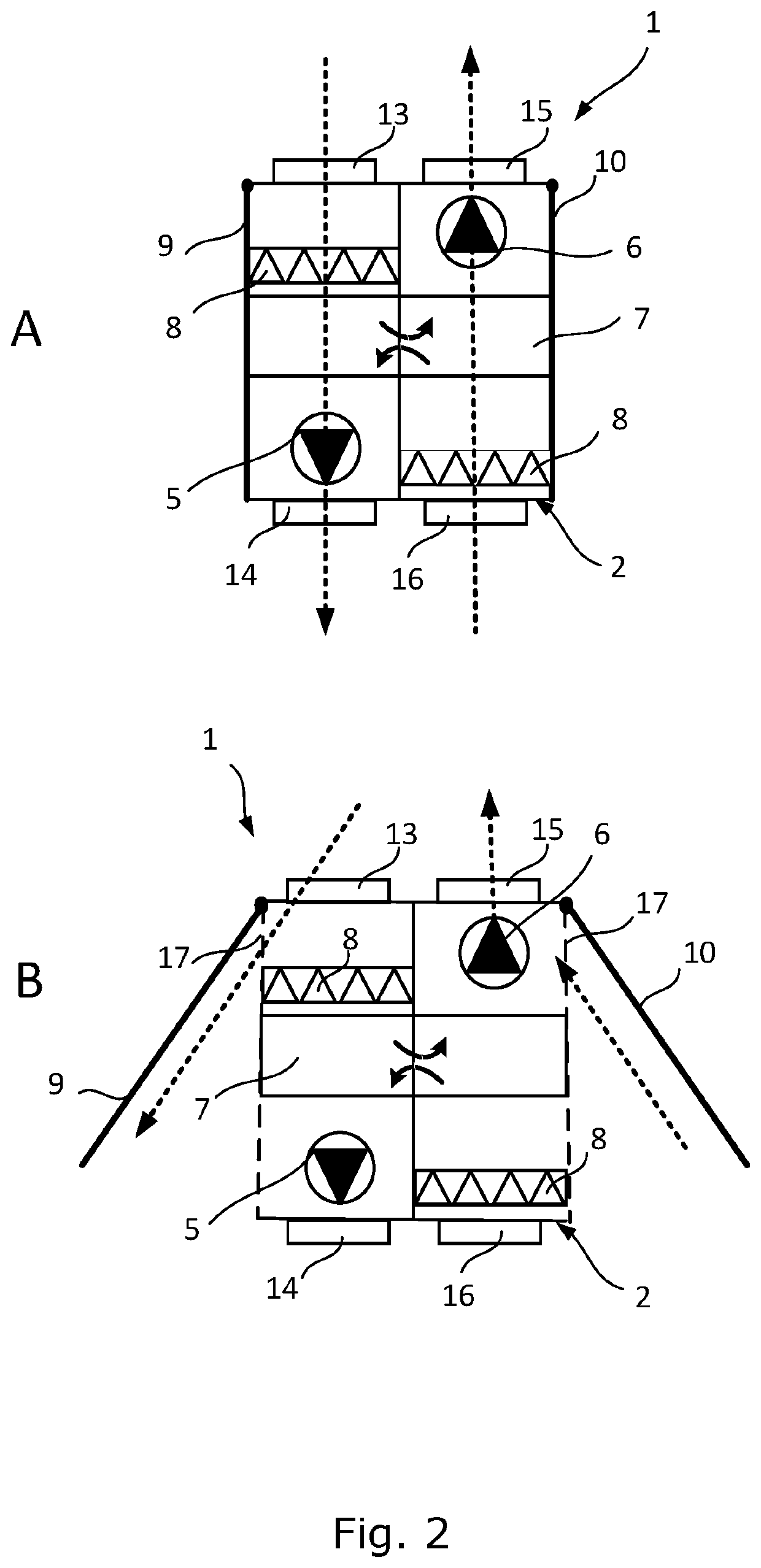

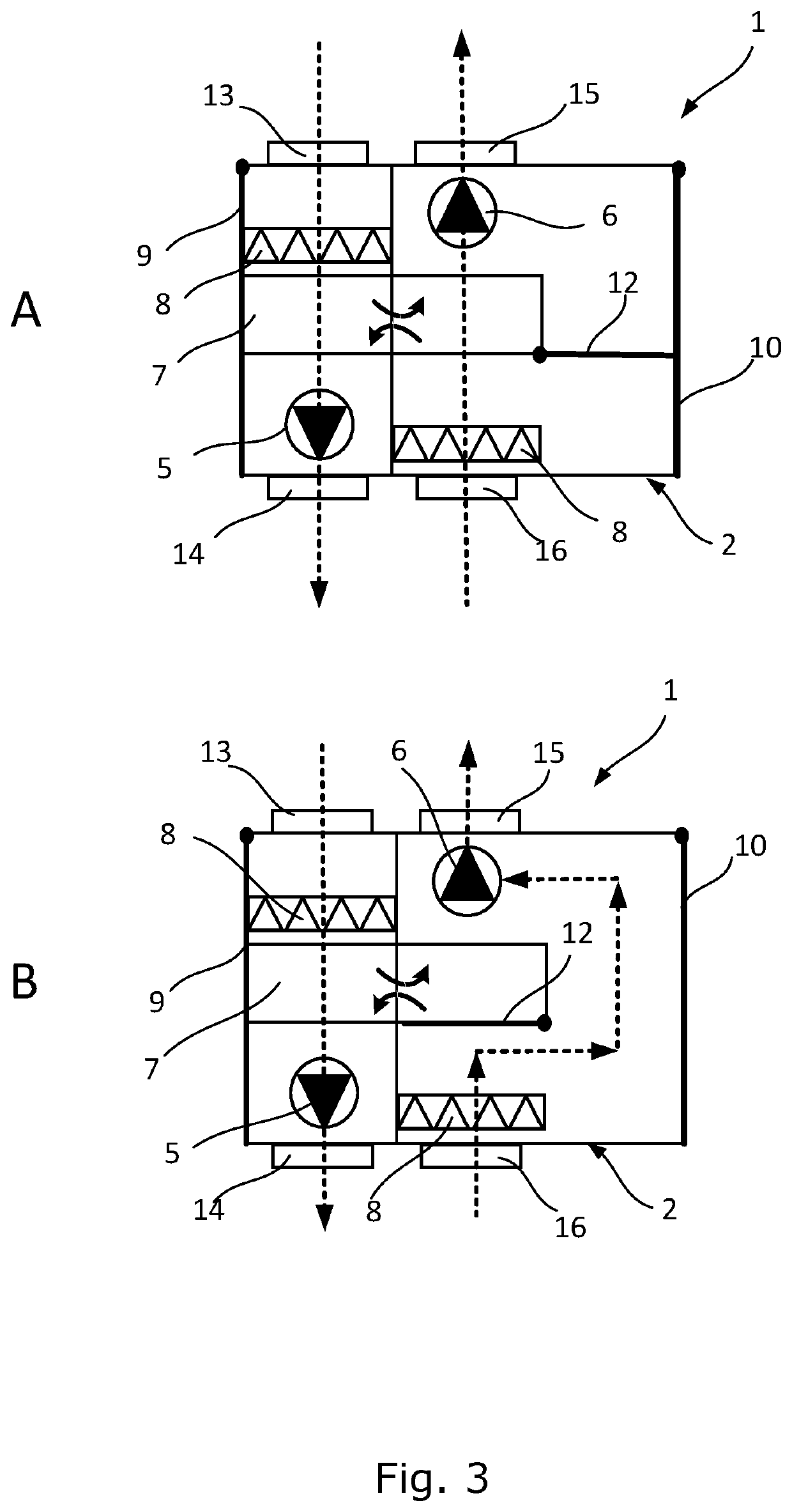

Hybrid ventilation system

ActiveUS20200256572A1Increase in sizeMinimum electric power consumptionEnergy recovery in ventilation and heatingMechanical apparatusAir filterControl system

The present invention relates to a decentralized hybrid ventilation. The ventilation system comprises a housing having an inlet channel and an outlet channel. A first fan is arranged in the inlet channel for providing an airflow into the room and a second fan is arranged in the outlet channel for providing an airflow out of the room. A heat exchanger and filters are arranged in said channels for exchanging heat between and for filtrating air flowing into the room and air flowing out of the room. Furthermore, the ventilation system comprises a first and a second service door each providing, when open, an opening between the room and one of said channels to diverge the airflow from primarily flowing through the air filters and / or heat exchanger. The ventilation system also comprises a control system configured for switching between different modes of operations.

Owner:AIRMASTER

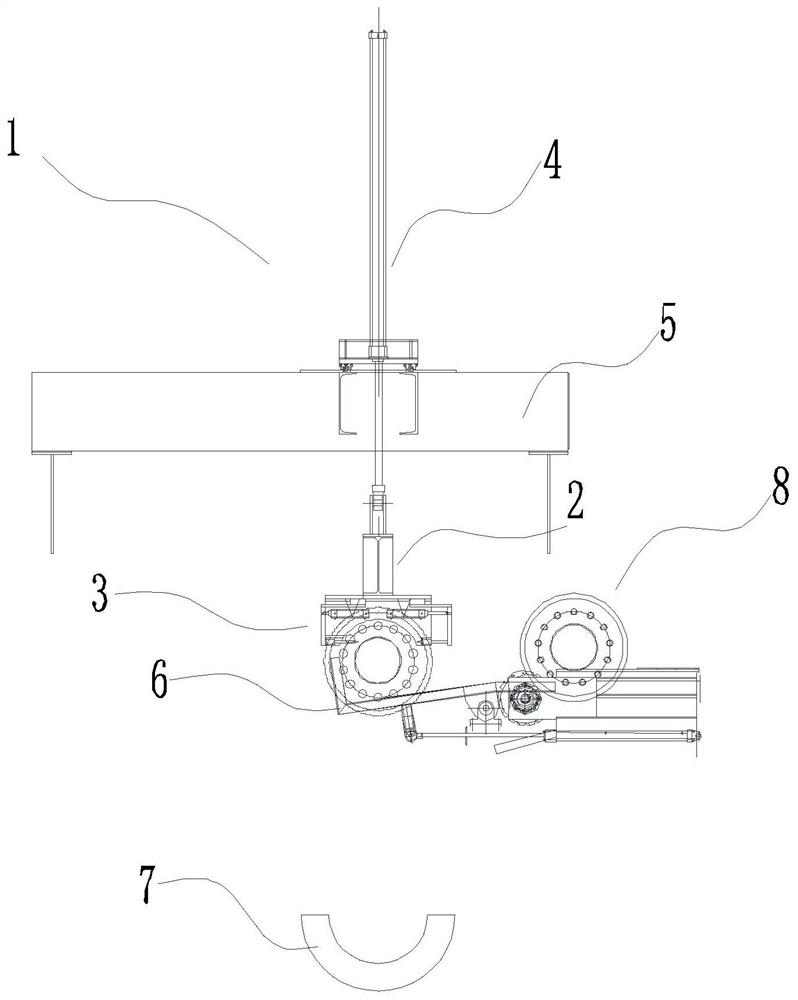

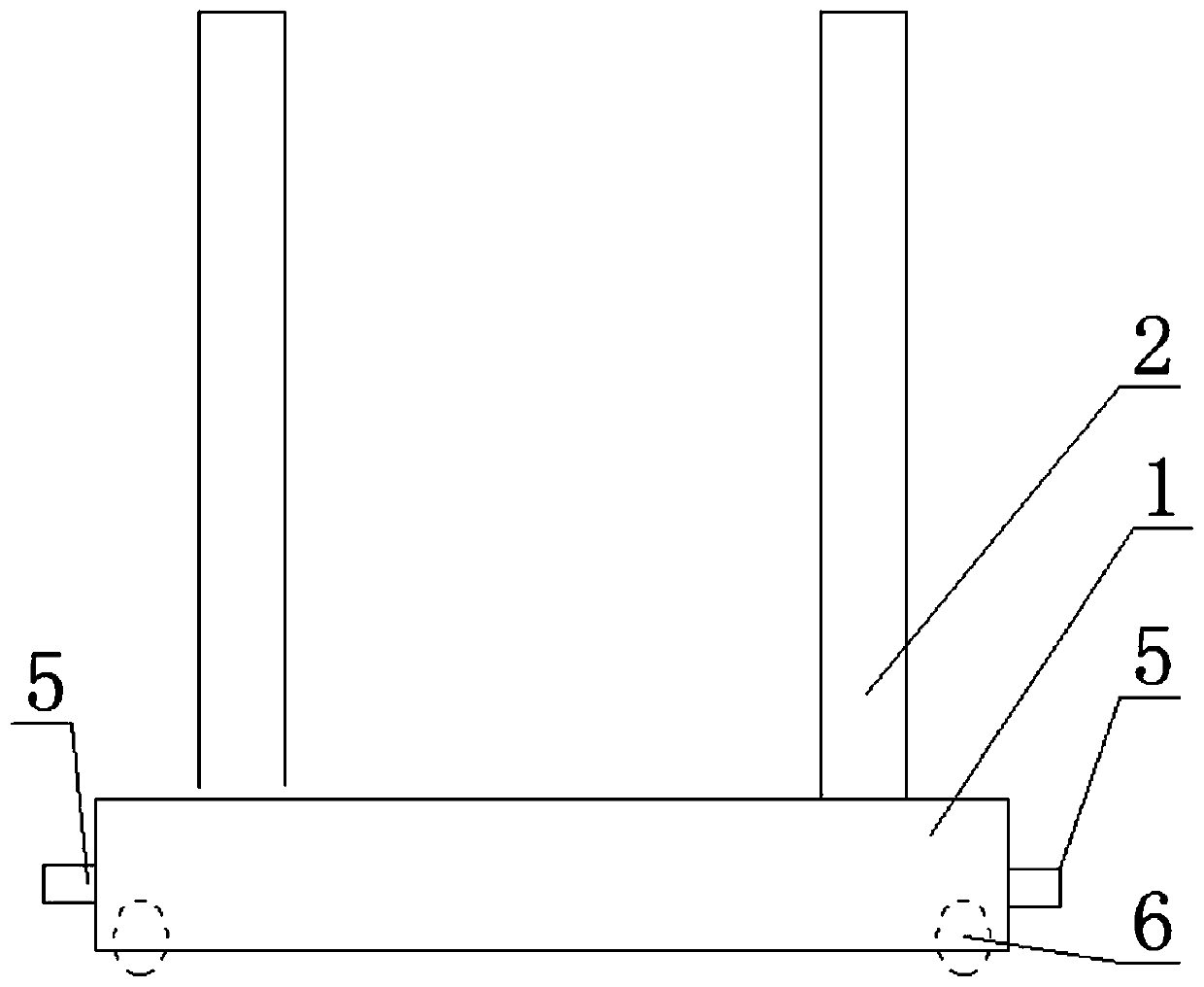

Reinforcement cage hoisting mechanism and reinforcement cage conveying line

PendingCN112875485AShort transport distanceImprove efficiencyBuilding material handlingLoad-engaging elementsRebar

Owner:周兆弟

Three-dimensional porous carbon-manganese oxide core shell structure material as well as preparation method and application thereof

ActiveCN110706940AImprove work efficiencyShort transport distanceMaterial nanotechnologyHybrid capacitor electrodesCapacitanceNano structuring

The invention discloses a three-dimensional porous carbon-manganese oxide core shell structure material and a preparation method thereof. The three-dimensional honeycomb porous carbon prepared by taking bark as a raw material is used as a skeleton, and a MnO2 nano structure grows on the surface of the skeleton to prepare the C-coated MnO2 with a core shell structure. The three-dimensional porous carbon-manganese oxide core shell structure material enables overall conductivity and electrochemical activity of the MnO2 material to be improved with the help of the high conductivity and a large specific surface area of the carbon skeleton, and gives a full part in the synergistic effect of the core shell structure, so that the three-dimensional porous carbon-manganese oxide core shell structurematerial has the advantages of high conductivity, large specific capacitance and good cycling stability, and can be used as a supercapacitor electrode material.

Owner:FUJIAN UNIV OF TECH

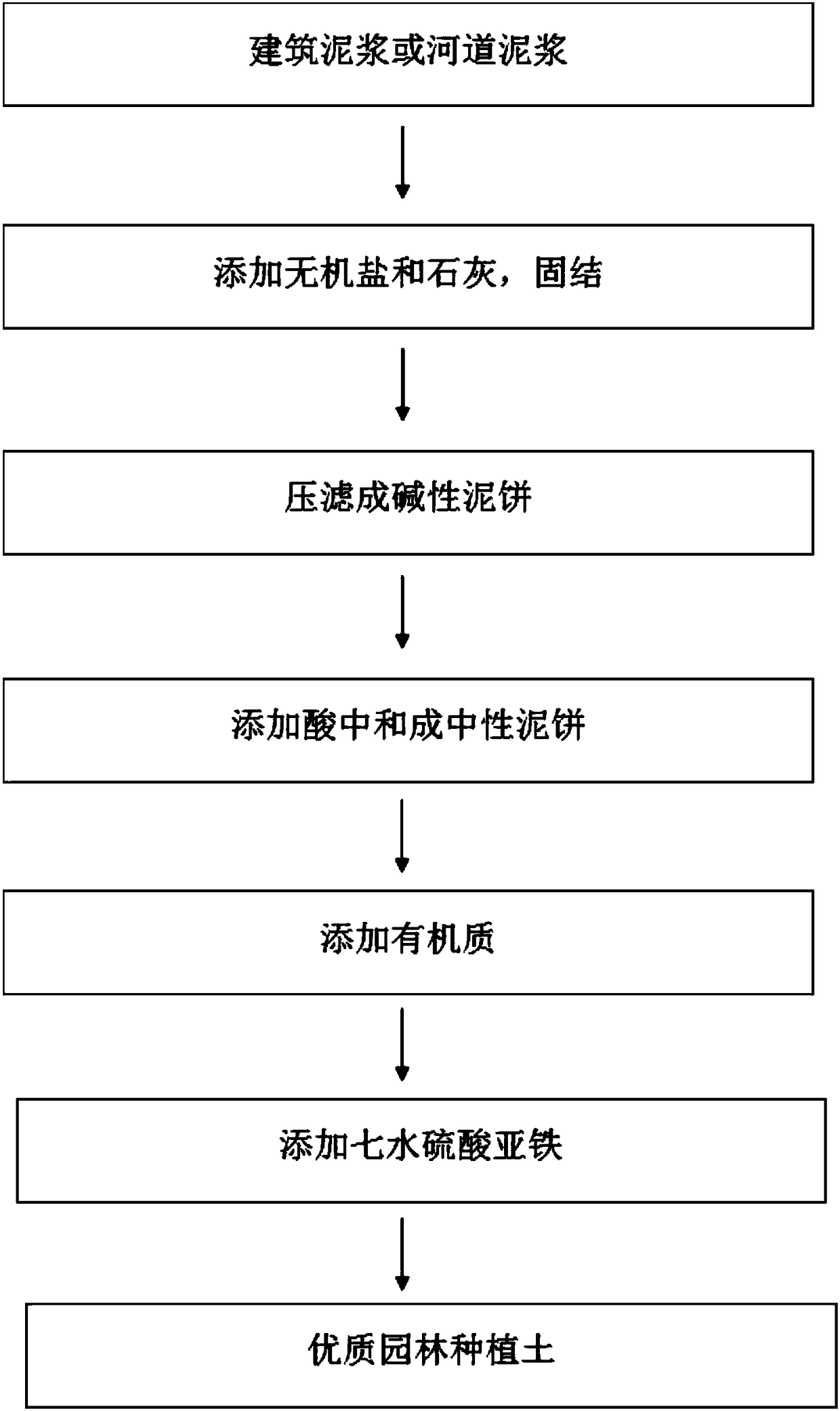

Production method of garden planting soil

InactiveCN108299066ASolve ecological problemsAdapt to growthCalcareous fertilisersGrowth substratesPlant soilSoil loss

The invention provides a production method of garden planting soil, construction mud and riverway mud can be effectively recycled, the wastes are turned into treasure, not only are the ecological problems produced by accumulation of the construction mud and riverway mud solved, but also significant economic benefits can be produced. Oxalic acid, acetic acid, citric acid, nitric acid, sulfuric acidor hydrochloric acid is added to a high alkaline solidified mud cake for acid neutralization, and the mud cake is stabilized in a neutral state and adapts to the growth of garden plants; by additionof an organic matter, ferrous sulfate heptahydrate and the like in the neutral mud cake, the nutrition required for the garden plant growth is met, and high-quality garden planting soil is prepared; the quality of the planting soil is better than that of planting soil actually adopted by 95% or more of garden projects; the social need is large, the transportation distance is short, the cost is extremely low, enterprise and social benefits are high, and the problem of water and soil loss caused by excavation of mountain slopes and the problem of agricultural cultivated land destroyed by excavation of farmland topsoil can be avoided.

Owner:ROAD ENVIRONMENT TECH

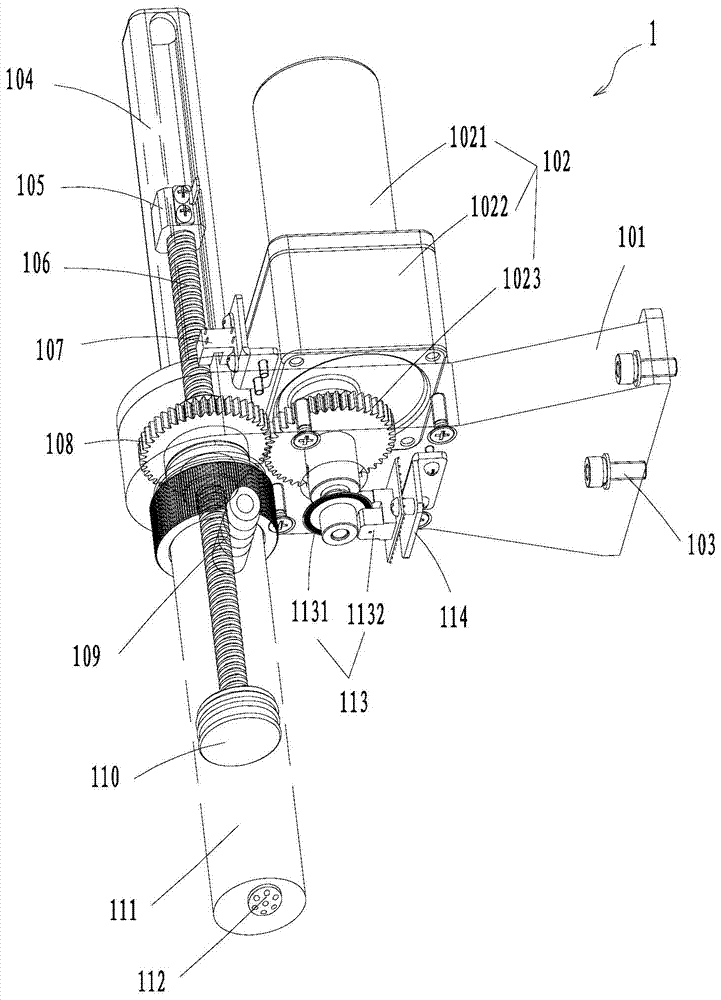

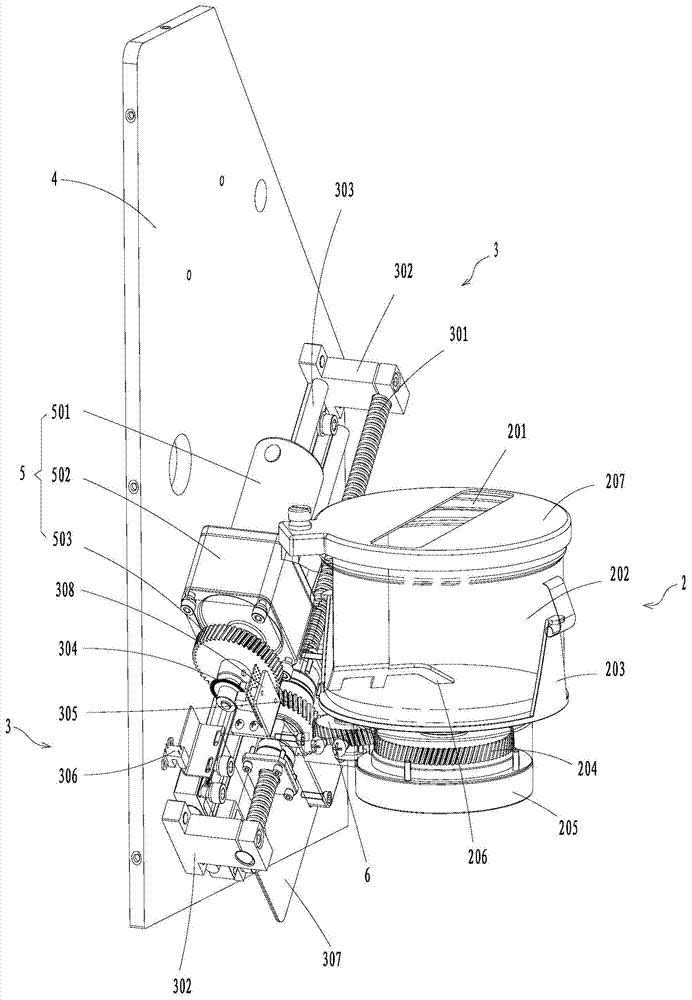

Mixed material casting apparatus for cooking

ActiveCN104840105AShort transport distanceGuaranteed cooking effectCooking vesselsFood shapingEngineeringMixed materials

The invention provides a mixed material casting apparatus for cooking. The mixed material casting apparatus for cooking comprises an accommodating box accommodating mixed material and a material absorbing and pushing mechanism casting the mixed material absorbed from the accommodating box into a pot, and further comprises a conveying mechanism, wherein the material absorbing and pushing mechanism is arranged on a pushing work position over the pot; the accommodating box is arranged right under the pushing work station or beyond; an absorbing port is formed in the top of the accommodating box; the conveying mechanism drives the accommodating box to move relative to the material absorbing and pushing mechanism, so when the accommodating box approaches the material absorbing and pushing mechanism, the mixed material can be absorbed from the absorbing port of the accommodating box by the material absorbing and pushing mechanism; and when the accommodating box gets away from the material absorbing and pushing mechanism, the mixed material is cast into the pot by the material absorbing and pushing mechanism. The accommodating box and the material absorbing and pushing mechanism are separated from each other and material is fetched via cooperative movements of the same; blocking between the accommodating box and the material absorbing and pushing mechanism is prevented; the accommodating box is far way from a heat source before casting; the pushing mechanism can quickly move in and out; short material conveying distance is achieved and even mixing can be realized; and mixed material cooking effect can be guaranteed.

Owner:PANSUM TECH

High-performance hydrofluoric acid-resistance artificial functional composite plate and preparation method thereof

The invention provides a novel high-performance hydrofluoric acid-resistance artificial functional composite plate and a preparation method thereof. The plate is mainly made of barite aggregate, resin and a serial of modified agents. According to the preparation method, the finished plate can be formed after a serial of processes of barite packing graduation, special resin and the serial of modified agents adding, mixing and stirring, organic combination reaction, plate blank forming, high-temperature and high-pressure reaction, high-frequency vibration, cure reaction (80-120 DEG C), thickness determining, polishing, bridge cutting, detection and the like. The composite plate has special anti-corrosion performance, excellent mechanical performance and durability, and is superior in product conveying, installation, maintenance and the like.

Owner:SICHUAN QINGCHUAN HONGYUAN STONE IND

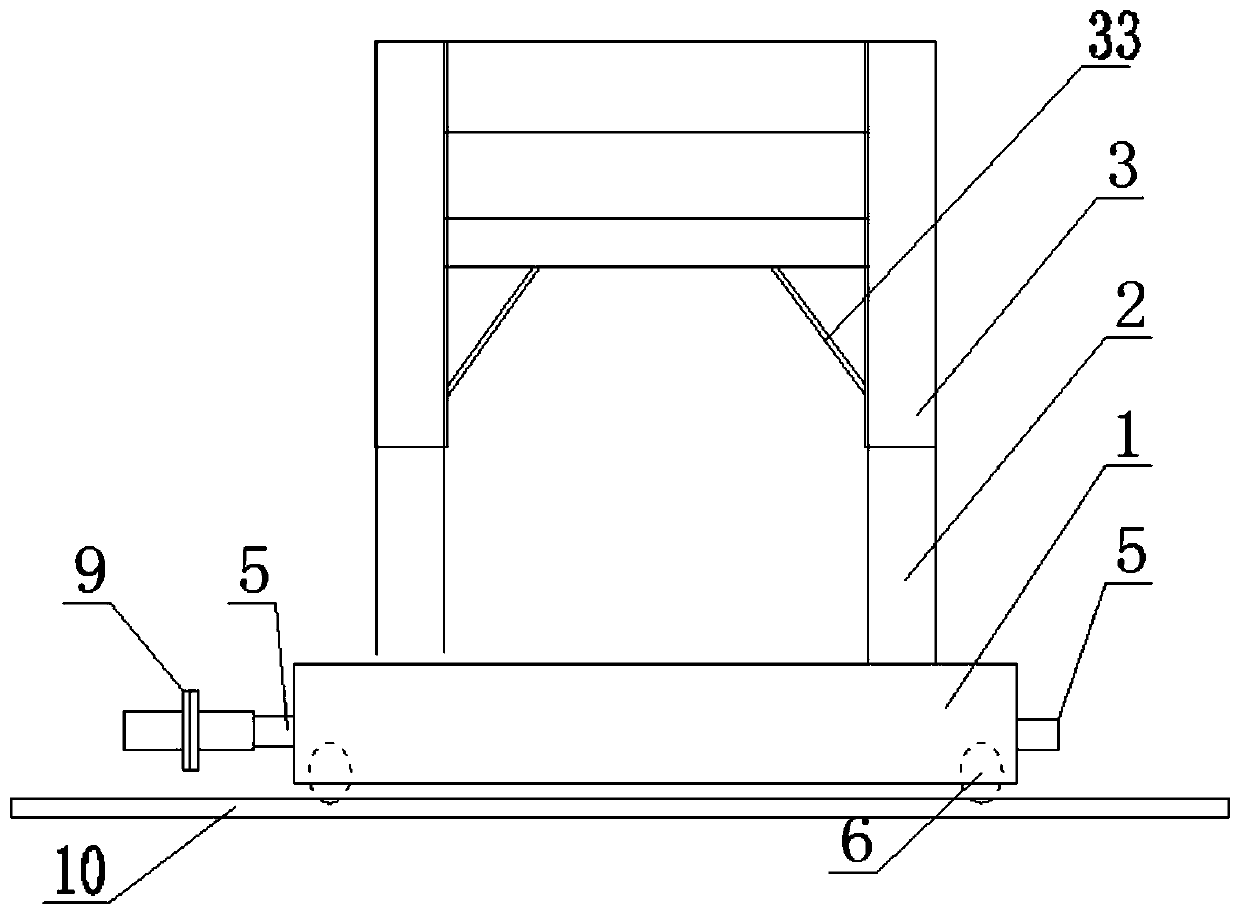

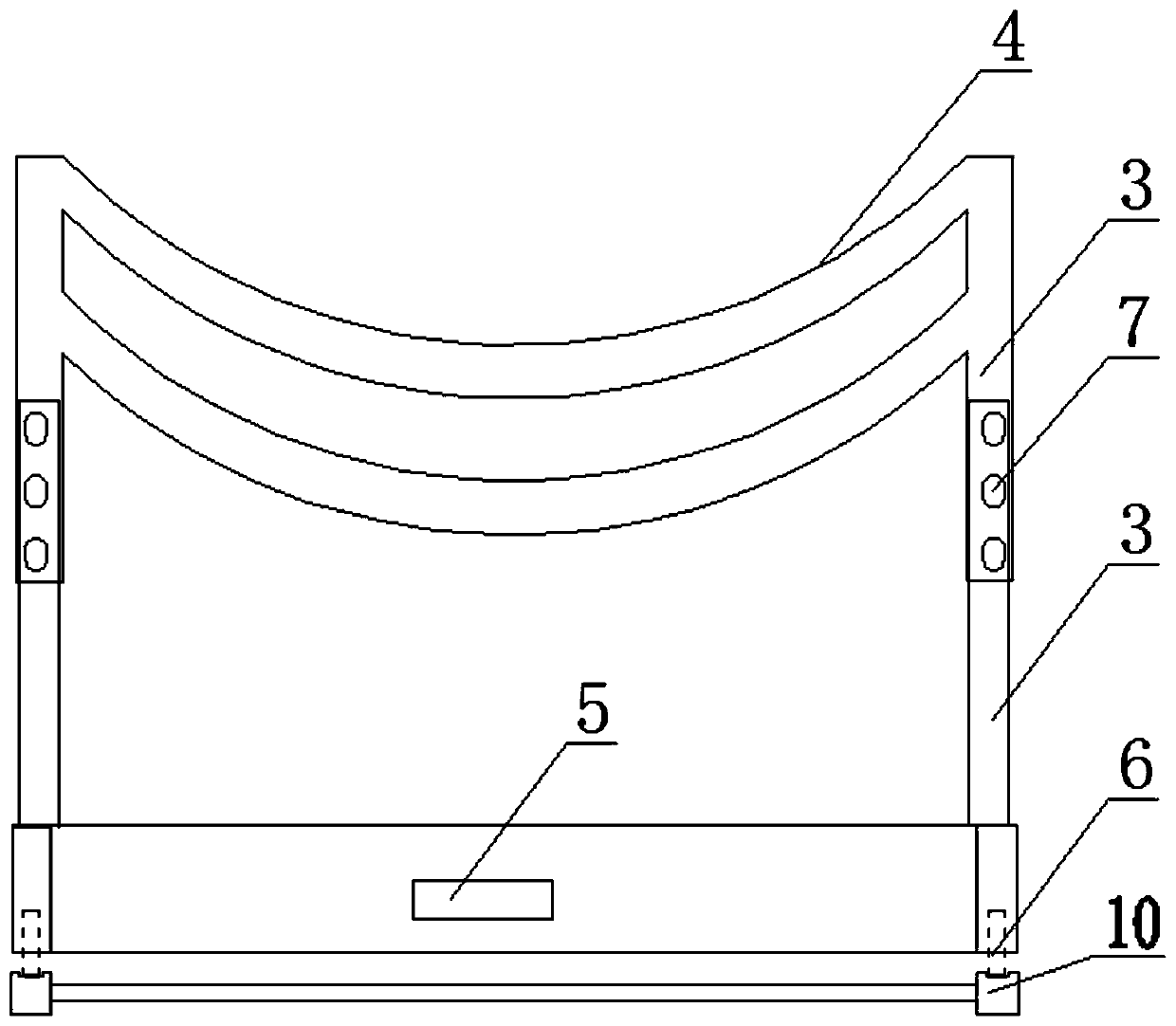

Device and construction method for manufacturing and mounting glass fiber reinforced plastic group tank on site on basis of corrosion prevention

PendingCN110282577AFree from destructionShort transport distanceLifting framesCarriagesGlass fiberEngineering

The invention provides a device and construction method for manufacturing and mounting a glass fiber reinforced plastic group tank on site on the basis of corrosion prevention. The device comprises a rail module, a walking device, a lifting support and an arc-shaped supporting part. The rail module is erected on an anticorrosive layer, and a rail communicates with a glass fiber reinforced plastic tank rolling area and a glass fiber reinforced plastic mounting area. The walking device is driven by a winch to move on rails. The lifting support is erected on the walking device, and locating holes are formed in the lifting support and the walking device and are connected through a pin shaft. A jack is arranged on the walking device and used for adjusting the height of the lifting support. The arc-shaped supporting part is erected on the lifting support for bearing a glass fiber reinforced plastic tank. According to the device and construction method, manufacturing, transporting and mounting of the glass fiber reinforced plastic tank are integrated and streamlined on the basis of corrosion prevention, the equipment transportation cost is reduced, the manufacturing and mounting efficiency is improved, and the anticorrosive layer on the foundation is not damaged in the whole manufacturing and mounting process.

Owner:MCC TIANGONG GROUP

Distribution of a flowing medium

InactiveUS7311803B2Shorten the lengthShort transport distanceLiquid surface applicatorsMachine wet endEngineeringHomogeneous distribution

Owner:VALMET TECH INC

Collocation method for fusing intelligent plane warehouse and overhead warehouse in aluminum plate strip production equipment

ActiveCN101947547BScientific and orderly configurationReduce the use of areaMetal rolling arrangementsStorage garageHot rolled

The invention discloses a collocation method for fusing an intelligent plane warehouse and an overhead warehouse in aluminum plate strip production equipment. The intelligent plane warehouse is arranged between a hot rolling workshop and a cold rolling workshop; the overhead warehouse is arranged among an annealing furnace, each finishing unit and a tray conveying mechanism; a track for running of a plurality of coil cars is mutually vertical to the tray conveying mechanism; and a track for a plurality of discharge cars in the overhead warehouse extends beside the annealing furnace or the each finishing unit. Hot-rolled coils on a hot mill discharge mechanism are hoisted to the corresponding positions for storage or cooling through an intelligent crane in the intelligent plane warehouse, and cold-rolled coils are stored at the corresponding positions through a stacker or cooled in the overhead warehouse. The aluminum plate strip production equipment collocated with the intelligent plane warehouse and the overhead warehouse is totally adjoined, needs no transport equipment such as the crane, a forklift or an automatic vehicle and the like, has the effect on shortest transport distance, realizes good circulation of low-carbon production of aluminum plate strips, and has the characteristics of lowest product storage quantity and shortest production period.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

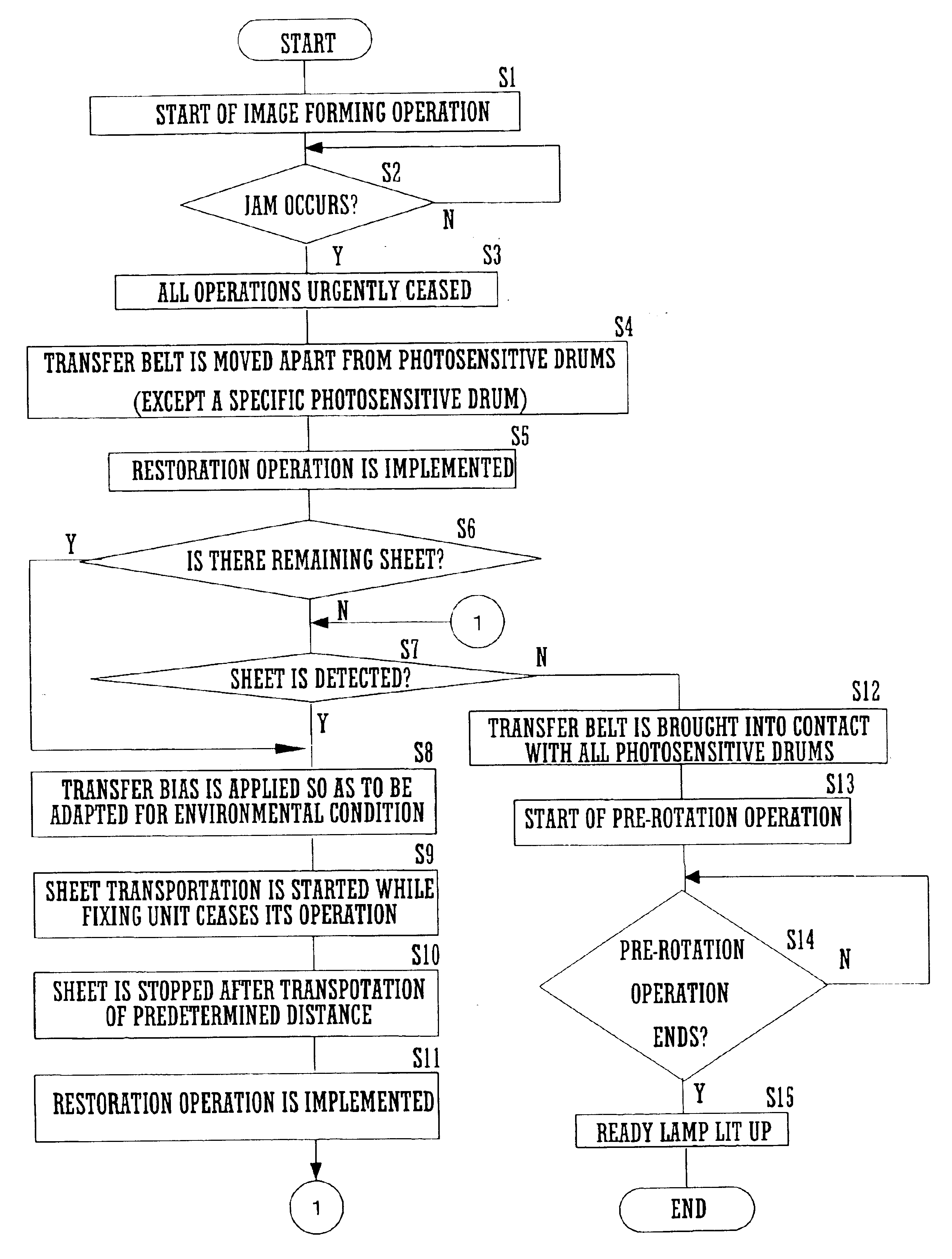

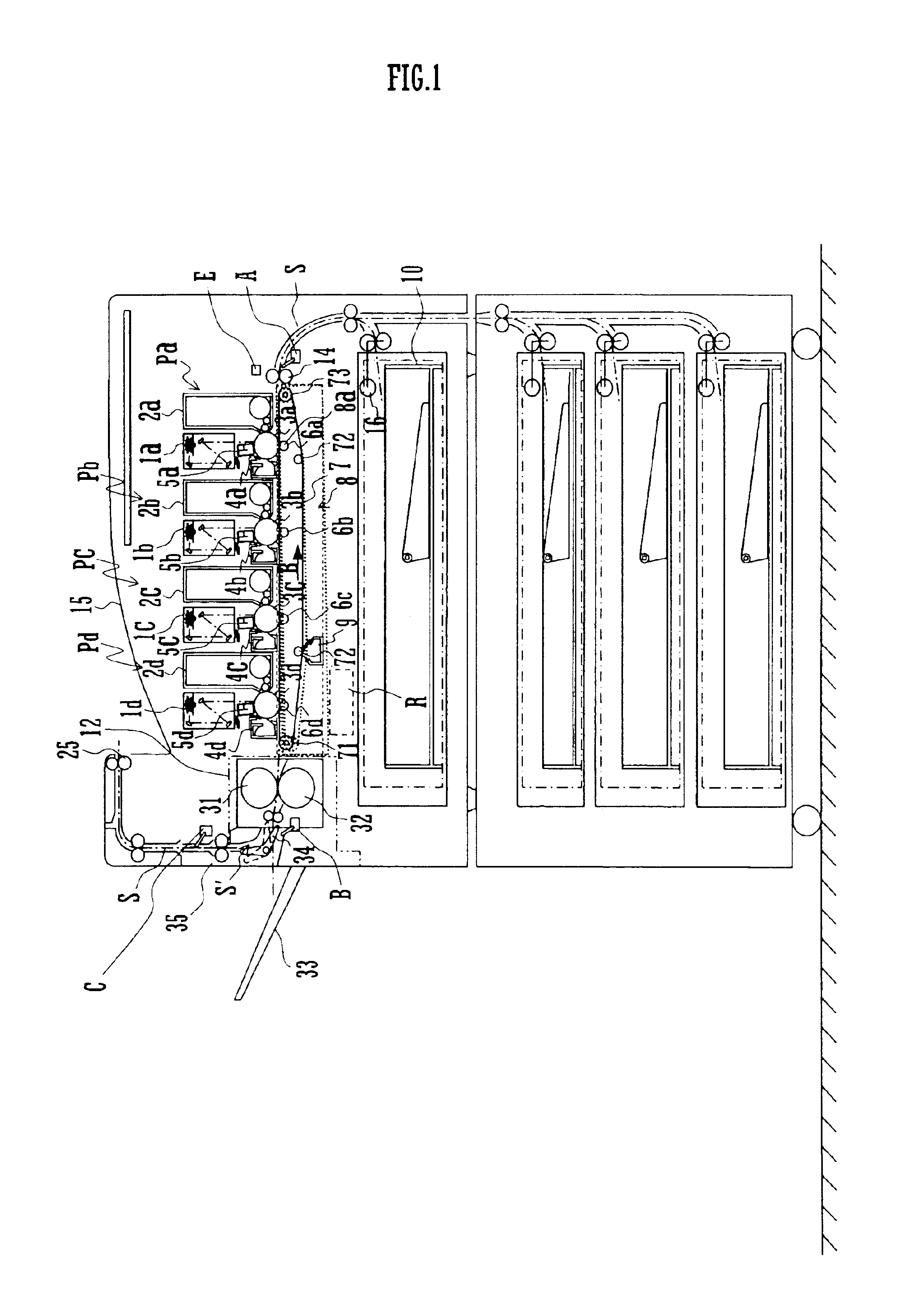

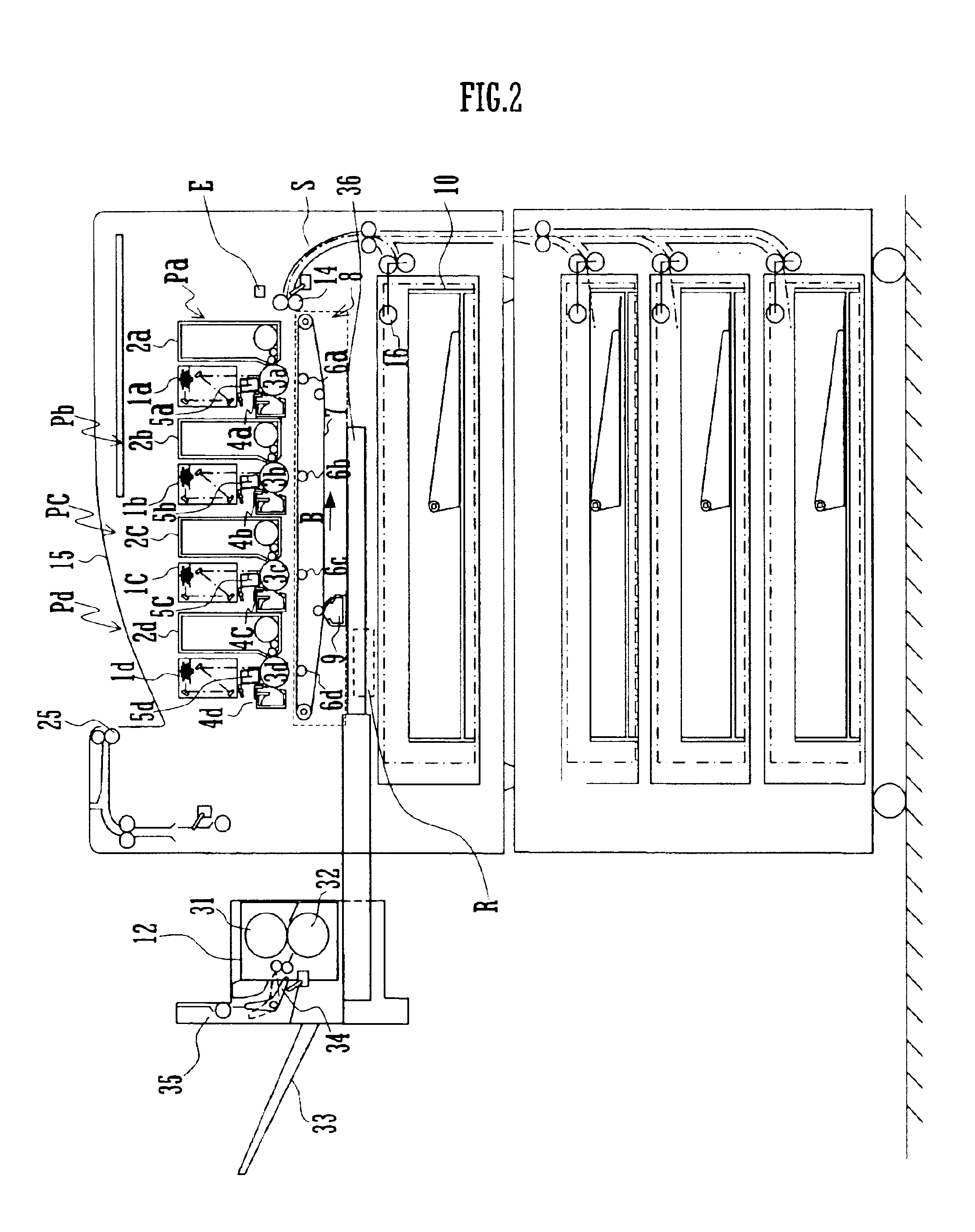

Image forming apparatus

ActiveUS6957022B2Easy to operateForce is smallElectrographic process apparatusImage formationEngineering

A plurality of photosensitive drums are disposed in a sheet transport direction so as to be in contact with a transfer belt and a transfer voltage for transferring toner images on the photosensitive drums onto a sheet transported by the transfer belt is applied thereto. A sensor for sensing a temperature or humidity in the working atmosphere of the image forming apparatus is provided; when a jam occurs, sheet transportation is ceased at a first stage to thereby enable the sheet in the jam to be removed; at a second stage subsequent thereto, transportation of the sheet is restarted; and the transfer voltage applied onto the transfer belt is controlled based on a measurement result of the sensor.

Owner:SHARP KK

Arrangement for processing dust

InactiveUS7987929B2Great suctionTransport distance of the rock materialCombination devicesConstructionsEngineeringSolid matter

Owner:SANDVIK MINING & CONSTR OY

A molten iron transportation system

ActiveCN105170965BCompact layoutSmall footprintMelt-holding vesselsRailway tracksIron transportMaterials science

The invention discloses a molten iron transport system. The molten iron transport system comprises casting houses (1) of ironmaking blast furnaces and a steel-making workshop (7), parallel track lines (3) are arranged between the casting houses (1) of the ironmaking blast furnaces and the steel-making workshops (7), the casting houses (1) of a plurality of ironmaking blast furnaces are symmetrically and compactly arranged at two sides of the parallel track lines (3), each casting houses (1) of each ironmaking blast furnace is connected to adjacent track line (3) via a molten iron pot storing line (4) of each casting houses, and a molten iron pot (2) of each casting houses (1) of each ironmaking blast furnace can be transported to the track lines (3) along each molten iron pot storing line (4). The steel-making workshop (7) is arranged at one end of the parallel track lines (3), the molten iron pots (2) can be transported to the steel-making workshop (7) along the track lines (3). The molten iron transport system is compact in arrangement, less in land occupation without a transition across workshop and a crane, so the investment can be saved.

Owner:BERIS ENG & RES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com